|

Harrison

Radiator Division of General Motors Corporation in World War Two

Lockport, NY

1918-2015

(As Delphi Thermal Systems)

This page updated 6-8-2021.

Harrison Radiator Division, because its

product cooled various fluids heated by the internal combustion engine

and was not seen, it has been overlooked as an important and major

contributor to the winning of World War Two by the US and its allies.

However, heat dissipating equipment in the form of radiators, oil

coolers, intercoolers and other types of heat exchangers produced by

Harrison were prevalent in WWII military equipment to cool engine oil

and coolants for many applications, including combat aircraft. Without the

radiator and oil coolers tank and truck engines would have overheated and stop

running, and military aircraft would not be able to obtain the high

altitudes needed for combat without intercoolers bringing down the

temperature of air being supplied to aircraft engine carburetors.

In 1943 Harrison had 6,003

employees and on April 14th of that year it won the Army-Navy "E" award.

See more on the award at the bottom of the page. Harrison added

four stars to the flag over the next two years.

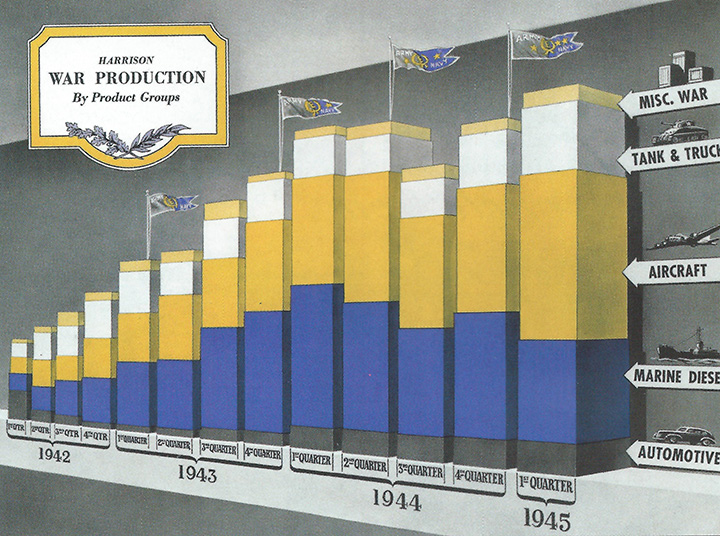

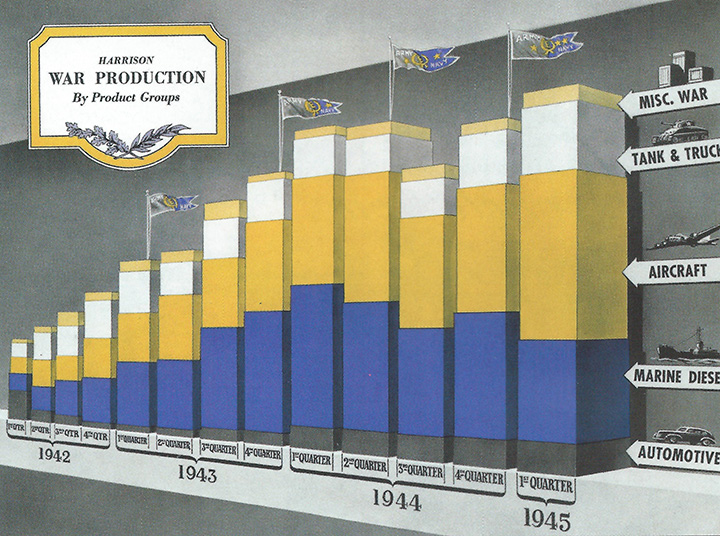

As one can see below,

Harrison Radiator Division supplied a myriad of important cooling

equipment for many types of weapons and equipment during WWII.

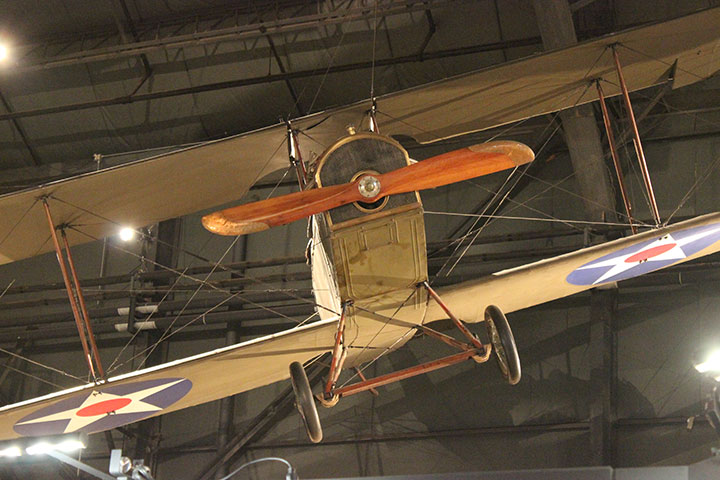

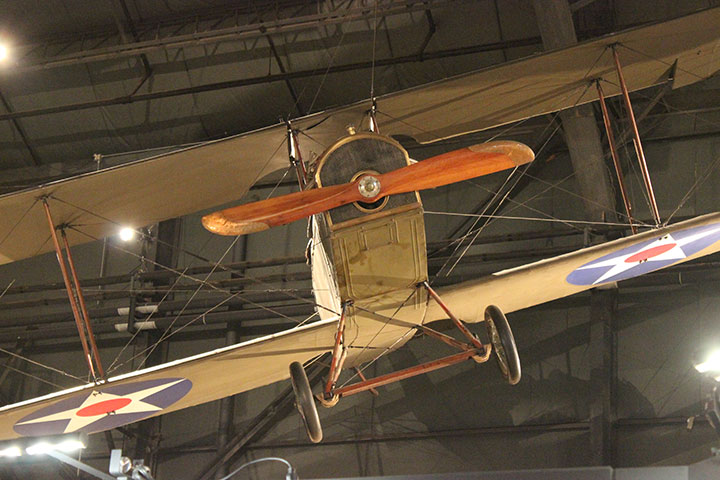

A World War One Curtiss JN-4 "Jenny" on

display at the National Museum of the US Air Force. During this

conflict Harrison supplied radiators for the "Jenny". Author's

photo.

Harrison patented the radiator with the hole

in the center of it to allow the propeller shaft to exit the engine.

Author's photo.

|

Harrison Radiator World War Two Product Groups and Applications |

|

Product Group |

1945 Percentage |

Products |

Applications |

Notes |

| Misc |

3.8 |

Heat

exchangers |

PT

Boats |

PT

boats have been placed here in that they were the only US Navy

combat craft of WWII that were not diesel, as they were powered

by Packard marine engines that used high octane aviation fuel.

See the excepts from the Motor Torpedo Boat Engineers Handbook

below. |

| Tanks

and Trucks |

18.9 |

Radiators, oil coolers |

M4,

M5, M10, 2-1/2 ton 6x6 GMC and 1-1/2 ton 4x4 Chevrolet

trucks |

These

are the known vehicles. There are no doubt many more. |

|

Aircraft |

43.4 |

Oil coolers, diverter

valves, radiators, and supercharger intercoolers |

A-36,

P-39, P-40, P-38, P-47 P-51A, SB2C, B-17, B-24, B-25 |

These

are the known aircraft. There are no doubt many more with

the large percentage size of this product group. |

|

Marine Diesel |

26.4 |

Heat

exchangers, oil and water coolers |

85-foot rescue boats, submarines, destroyer escorts, destroyers and aircraft carriers. |

These

are the known ships. There are no doubt many more with the

large number of ships built of various types. |

|

Automotive |

7.5 |

Radiators |

Automobiles |

All

automobile productions stopped in February of 1942. This

would be a limited amount of service radiators to keep the

existing civilian fleet running. |

The M5 Stuart tank had two Harrison Division

radiators to cool the twin Cadillac V-8 engines that powered the tank.

Author's photo.

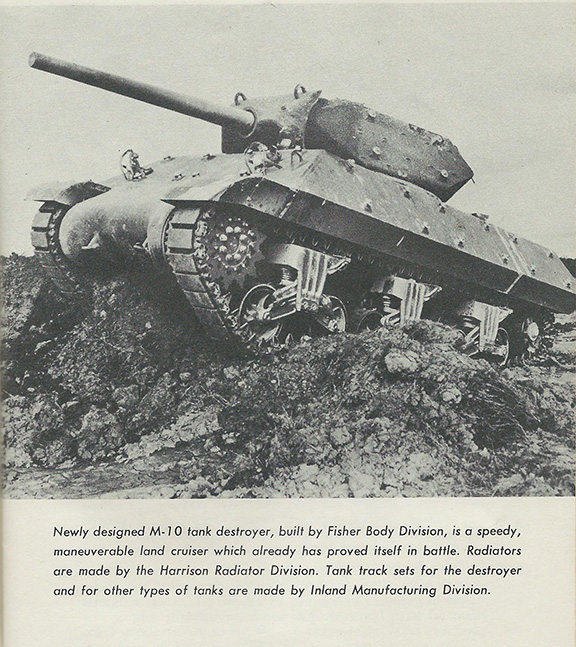

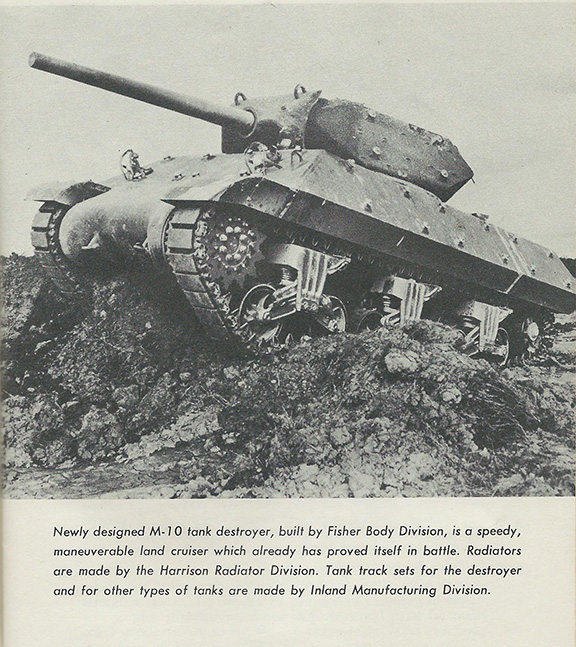

This photo is from the 1942 GM Annual Report

and indicates Harrison supplied the radiators for the M10.

This M10C Achilles is the British Lend-Lease

version of the M10 Wolverine tank destroyer built by the Fisher Body

Tank Arsenal in Grand Blanc, MI, and was photographed at the Bastogne

Historical Center in Belgium in May of 2008. The 6,706 M10s that were built

were powered by twin diesel engines that were built by the Detroit Diesel

Division of GM, which would have been cooled by two Harrison built

radiators. Author's Photo.

This M4A2(76)HVSS Sherman tank is located at

the Beatty Street Drill Hall in Vancouver, BC, and was one of 7,508 M4A2s

built by the Fisher Body Grand Blanc, MI Tank Arsenal during WWII. The

M4A2(76)HVSS was powered by two Detroit Diesel 6-71 engines which used

Harrison oil coolers and radiators. Photo courtesy of David Jackson, Jr.

Harrison provided two radiators and four oil

coolers for the 2,135 M26 Pershing tanks built by Fisher Body and

Chrysler at end of the war. Author's photo from Fort Jackson, SC

added 9-22-2015.

Harrison radiators cooled the engines for

GMC built 2-1/2 ton 6x6 trucks. Author's Photo.

This former Navy 1-1/2 ton 4x4 dump truck was one of many types produced

by Chevrolet during WWII and equipped with Harrison Radiators.

Photo courtesy of Rob Ellert.

In April of 1943 Harrison employees were

notified that the M7 Motor Gun Carriage was equipped with Harrison

radiators. 4,315 were built during the conflict. Author's

photo from the Patton Museum added 12-1-2015.

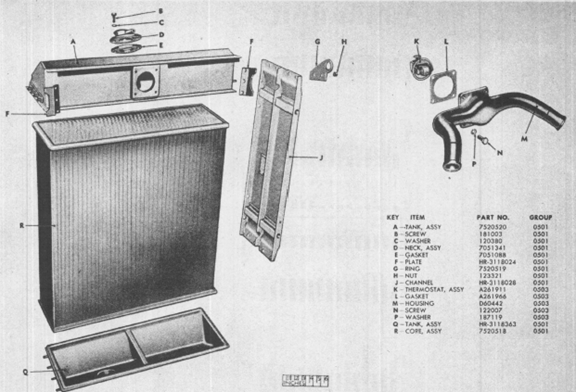

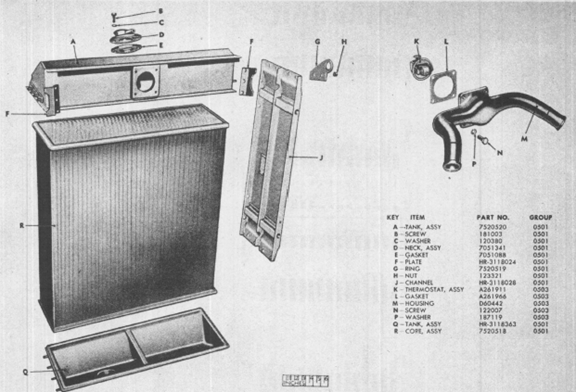

Harrison supplied radiators and oil

coolers for 4,731 M24 Chaffee light tanks during World War Two.

The radiator tank was Harrison part number 3118363 and the oil cooler

8508471. Author's

photo from the former Ropkey Armor Museum added 12-1-2015.

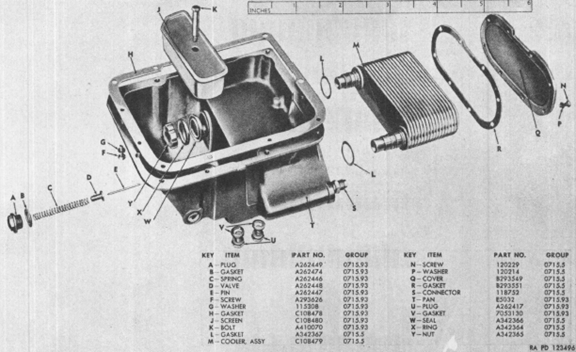

This drawing from the M24 Ordnance Supply

Catalog shows the tank assembly as HR-3008363. Image added

6-8-2021.

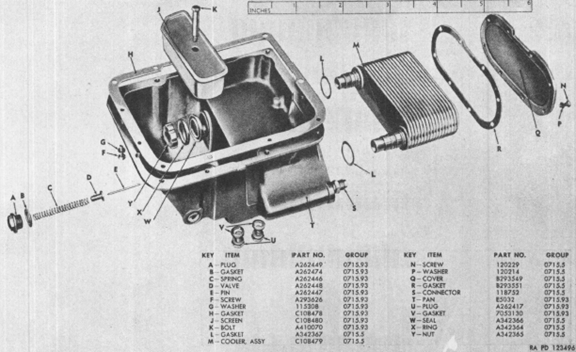

This drawing the transmission oil cooler

assembly located in the transmission pan as Ordnance part number C108479

Image added 6-8-2021.

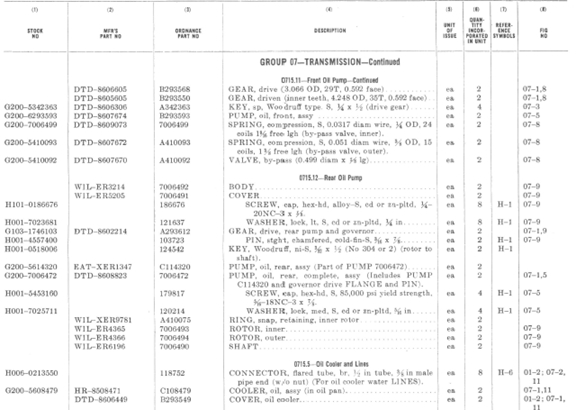

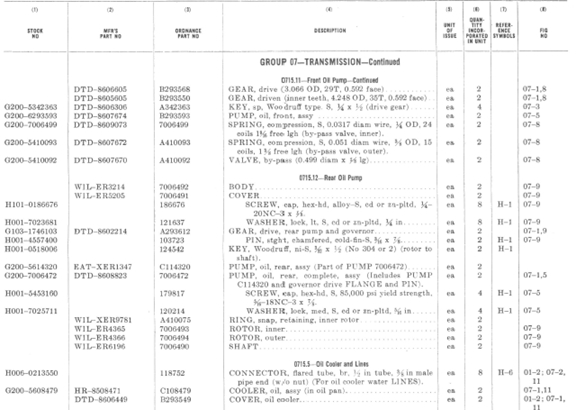

This page of the M26 Ordnance Supply Catalog

cross references the Ordnance part number C108479 to Harrison Radiator

part number 8508471. Image added 6-8-2021.

This M4A2(76) photographed at the Milford

Proving Grounds was one of 2,854 built by the Fisher Body Tank

Arsenal in Grand Blanc, MI. Previously 4,614 with a 75mm main gun

had been built by Fisher. These came with two Harrison radiators,

two oil coolers and one transmission cooler. The M4A2 was powered

by twin Detroit Diesel engines and many of the M4A2 tanks were supplied

to the Russians under Lend-Lease. Those going to Russia came

equipped with Harrison by-pass valves on the oil coolers to assist the

oil warming up on engine starts in the cold winters. Photo added

12-1-2015.

The P-51D Mustang, along with the B and C

models, were powered by the Packard built V-1650 Rolls-Royce Merlin

engine, which to many made the Merlin powered Mustangs the best piston

powered fighter aircraft ever built. In any event, the engine built up a lot of

heat that needed to be dissipated through its radiator, which was

supplied by the Harrison Radiator Division of General Motors.

Author's photo.

Even today, 70 years later with newer

technology and materials available, the Harrison radiator built during

World War Two is still considered to be the best unit to cool the

Mustang.

The following is from an online "white paper"

from the 51 Factory that rebuilds Merlin engines in San Mateo, CA.

"Radiator: The original Harrison

radiator is an excellent design and very efficient but is somewhat

susceptible to plugged tubes as they are relatively thin and narrow.

Keeping the coolant clean and free of contaminates is critical.

The replacement truck core type radiators

are less efficient, having fewer tubes with a larger cross section;

however, they are less likely to become plugged with corrosion

particles, silicates, and contaminates.

The best system is an original Harrison

radiator in excellent condition having 95% or more the tubes open

and maintaining clean coolant". (Bolded added for emphasis by DDJ)

Today Mustangs are worth several million

dollars and an engine rebuild starts at $100,000, so making sure the

engine is properly cooled is important for correct operation of the aircraft.

Here is the complete "white paper" from 51 Factory.

http://www.51-factory.com/cooling_system_maintenance.pdf

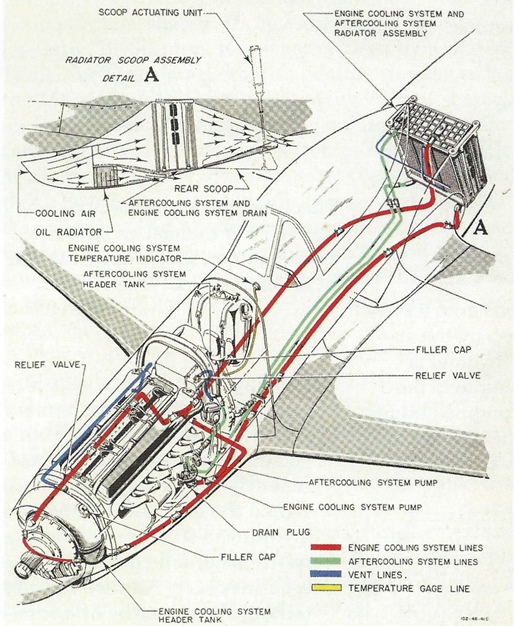

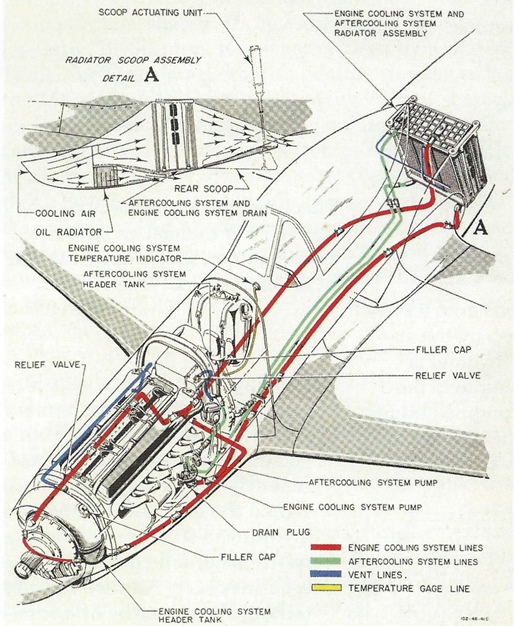

This diagram illustrates P-51 cooling system

and the location of the Harrison radiator in the air scoop.

Illustration added 10-6-2015.

The Lockheed P-38, powered by twin Allison V-1710 engines, was

instrumental in helping the US win back the Southwest Pacific in

1943-1944. Depending on the model, P-38s had Harrison radiators,

oil coolers and intercoolers. This particular model is a P-38J.

Author's Photo.

P-38 radiators were located in the twin booms for all models. Author's Photo.

This is how a Harrison radiator would have been mounted in boom of the P-38. Author's Photo.

Previous to the P-38J and L models, the intercooler was long tubing

located along the inside leading edges of the outer wings, which used

conduction between the two metal surfaces to cool the air going into the

carburetor. The J and L models had a core type intercooler moved

to the center intake below the engine while the two outside intakes are

for oil coolers. Author's Photo.

The oil coolers were always mounted below the engine in all models of

the P-38. Author's

Photo.

Here a World War Two worker at Harrison

Radiator assembles the cooling tubes for an oil cooler. Once

assembled, the tubes all have to be soldered together.

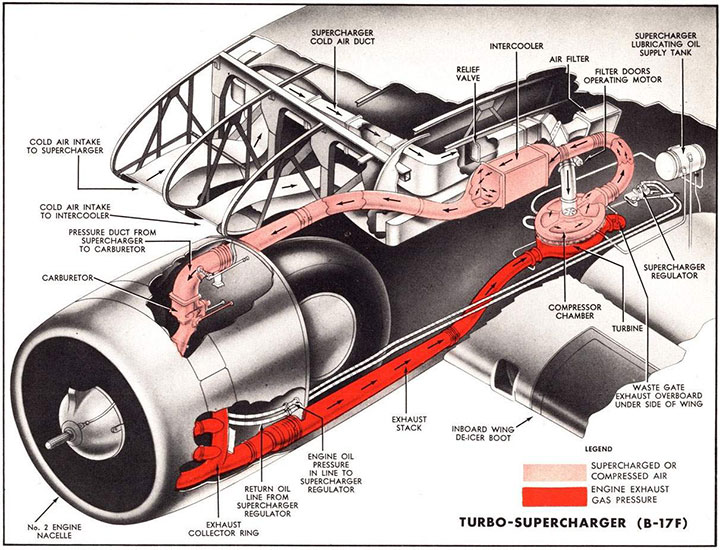

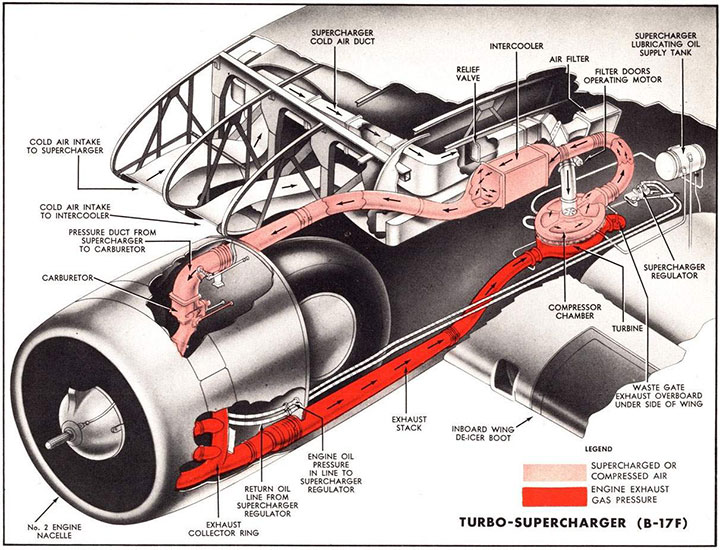

The Republic P-47 Thunderbolt used Harrison intercoolers to cool intake

air from the supercharger. Author's Photo.

The shape of the P-47's fuselage was

determined by size of its Harrison intercooler and General Electric

super turbocharger system. This example of off a this system is on

display at the National Museum of WWII Aviation in Colorado Springs, CO.

Author's photo added 10-9-2017.

Author's photo added 10-9-2017.

The museum has taken one of the exhaust

outlets off to show the what the Harrison Radiator intercooler looks

like. Author's photo added 10-9-2017.

This photo gives a better view of the

intercooler. This is an excellent display as it the turbo system

was so important to the success of the P-47, and yet because it is

internal to the aircraft, is never seen. Author's photo added 10-9-2017.

This show how the exhaust and intercooler

hot air exited the aircraft. Author's photo added 10-9-2017.

Located on the bottom of the engine is an

example of a Harrison oil cooler for the P-47. Author's photo

added 10-9-2017.

The North American A-36, the dive bomber version of the Allison powered

P-51A, used Harrison Division built radiators, as did the Allison

P-51A's. Author's Photo.

The radiator was located behind the air scoop on the bottom of the A-36.

Author's Photo.

The Curtiss built SB2C also had its engine oil cooled by Harrison

coolers. Author's Photo.

The famous and distinctive looking Curtiss P-40 Warhawk. When the

US first entered WWII in December of 1941, the P-40 was the front line

fighter for the US Army Air Force. It defended the country and

took the battle to the enemy until more modern fighters such as the

P-38, P-47 and P-51 could be produced in quantity and enter the fight.

In the meantime, the P-40 held the line, for which it gets very

little credit today. The P-40 took the fight to the enemy with the

help of Harrison radiators and oil coolers that were located in the big

and distinctive air scoop under the engine. Author's Photo.

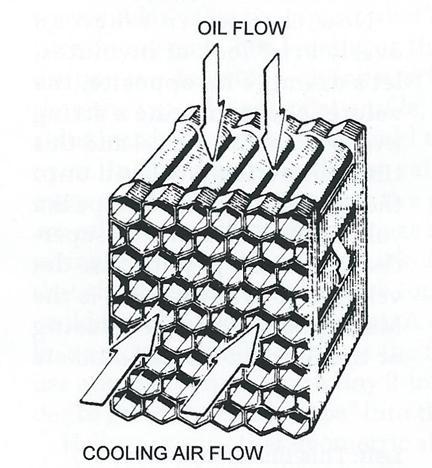

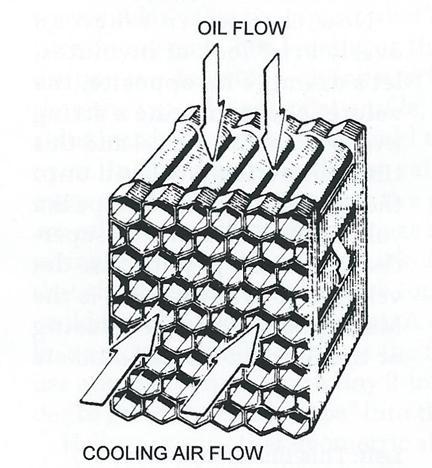

The P-40 used a Harrison honeycomb oil

cooler that looked like this. Illustration added 10-6-2015.

The P-39, also powered by an Allison V-1710 engine like the P-38 and

P-40, was cooled by Harrison built radiators. The radiator was

located directly under the engine which is located behind the pilot. Author's Photo.

The Bell P-39 was built in the Buffalo and

Niagara Falls, NY area, not far from the Harrison plant in Lockport, NY,

where the radiators were built. Today the Niagara

Aerospace Museum, located at the Niagara Falls airport is part of what

was the Bell Wheatland plant during WWII, has on display a P-39 found

several years ago in a lake in Russia.

For more on this historic find and aircraft,

the video below explains the significance of the aircraft. Note

towards the end at 3 minutes and 54 seconds the narrator mentions the

original Harrison radiator was still in the aircraft and the Harrison ID

tag is shown.

http://link.brightcove.com/services/player/bcpid34757272001?bclid=0&bctid=87804472001

The famous B-17 Flying Fortress. In 1939 Harrison Radiator

Division engineers designed an intercooler to cool the hot air being

supplied to the carburetors from the GE superchargers. Harrison

supplied many intercoolers for the B-17 throughout the war.

Author's Photo.

This drawing shows the location of the intercooler in a B-17 engine

nacelle.

The Consolidated B-24 Liberator, like the B-17, had one intercooler per

engine that were supplied by Harrison. Author's Photo.

The B-29's huge R-3350 engines required two GE superchargers and

intercoolers each. Author's Photo.

In August of 1945 Harrison notified its

employees it was the supplier of elliptical oil coolers for the new

Grumman F7F Tigercat twin engine fighter. Author's photo added

9-22-2015.

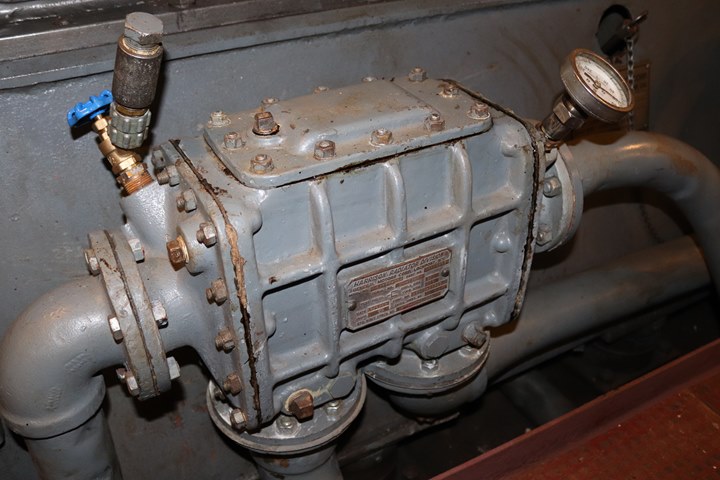

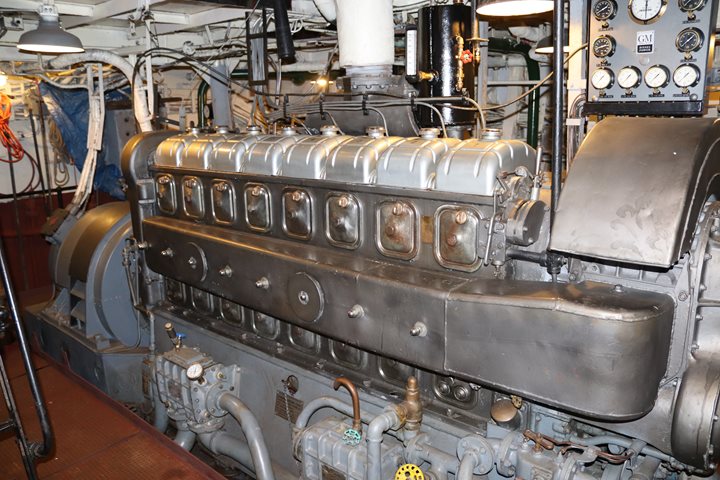

The USS Slater DE-766 on display along the

Hudson River water front in Albany, NY has at least two Harrison

Radiator heat exchangers in the engine rooms. Author's photo added

8-23-2017.

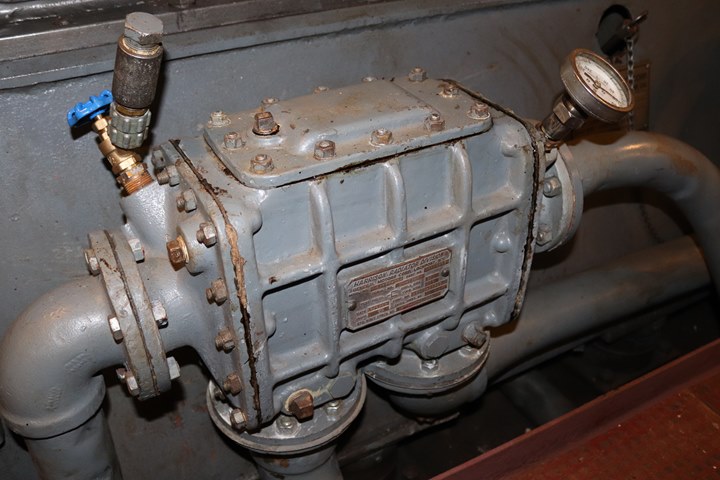

There are two Harrison Radiator engine heat

exchangers on the GM Cleveland Diesel 8-268A service generator engine.

They can be seen along the floor line in the photo. One is for

engine coolant and the other is for engine oil. Both use saltwater

as the coolant. Author's photo added 8-23-2017.

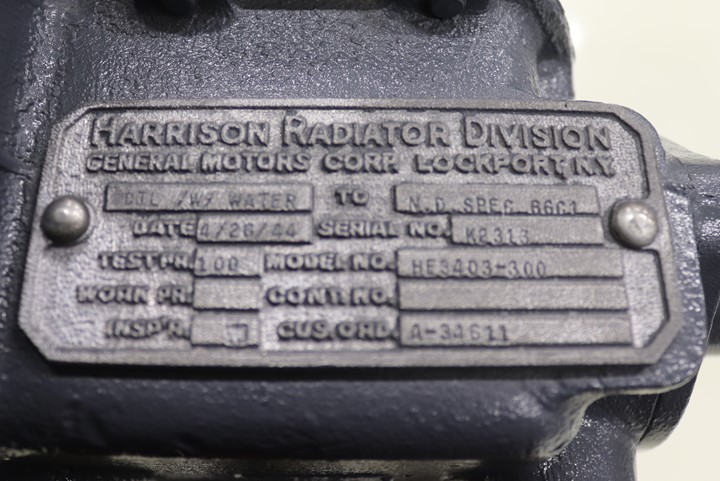

This Harrison Radiator exchanger is Model

Number HE2120-354 and Part Number 8501957. The Serial Number is

00-7360. This is a replacement unit built on 12-5-1952. With

salt water running through it, it only makes sense that naval heat

exchangers would have to be replaced on a regular basis. Author's

photo added 8-23-2017.

Author's photo added 8-23-2017.

This is the second Harrison heat exchanger on the back up generator

engine. Author's photo added 8-23-2017.

The data plat on this heat exchanger shows

the core was replaced in 1977 when the Greek navy operated the USS

Slater. Author's photo added 8-23-2017.

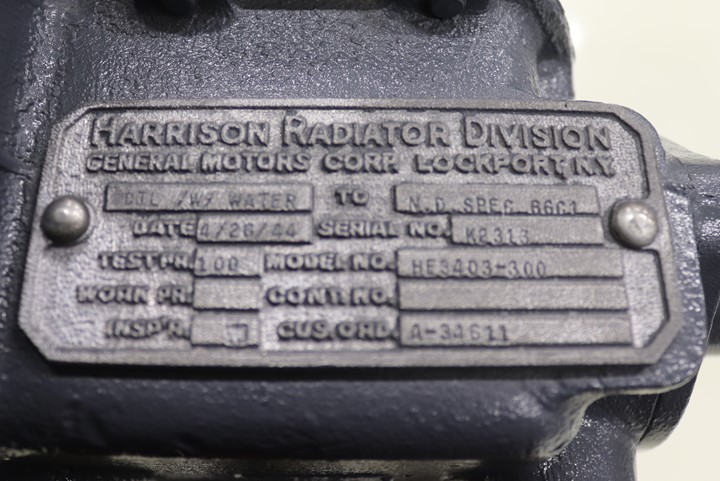

This Cummins Diesel Company engine was used

in a WWII generator set that provided electrical power for small navy

vessels during WWII. The engine with a Harrison Radiator heat

exchanger is on display at the Atterbury-Bakalar Air Museum at the

Columbus, IN airport. Author's photo added 5-3-2018.

Harrison cast the "Cummins Dependable

Diesel" into the heat exchanger casting. Author's photo added

5-3-2018.

This is Model Number HE3403-300 with serial

number K2323. It was built on 4-25-1944. Author's photo

added 5-3-2018.

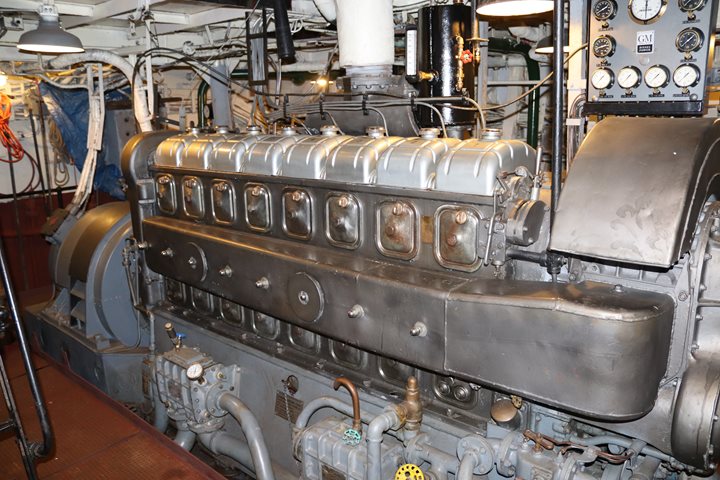

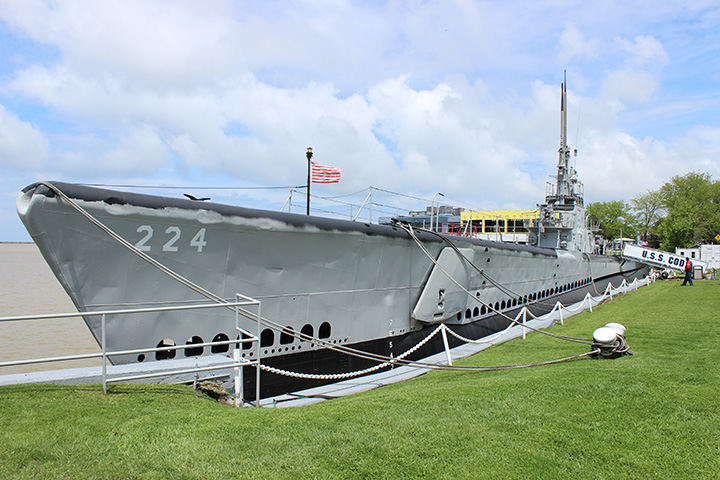

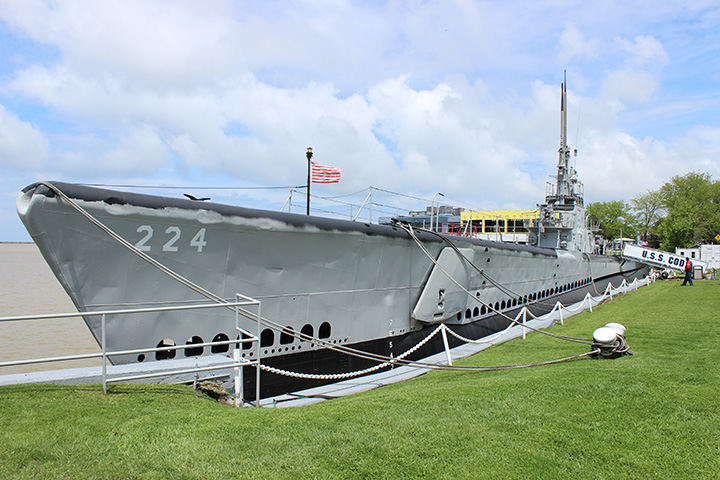

This is the USS Cod, a Gato class submarine from WWII on display at the

downtown Cleveland, OH waterfront. US submarines, along with other

types of US warships, had numerous and various needs for cooling of all

sorts of fluids within the ship. The USS Cod, like many other Gato

class submarines, was equipped with four diesel engines built in

Cleveland by the Cleveland Diesel Division of General Motors. These were

used for charging the batteries and running the generators which in turn

powered the sub's electric motors while on the surface. (This was

different from the German U-Boats. When on the surface their

diesels would not only charge the batteries but also directly drive the

propellers.) The engines

were cooled by fresh water circulated through cooling jackets around the

engines. The hot, fresh water was then run through a heat

exchanger that used outside salt water as the cooling fluid.

Harrison Radiator supplied these type heat exchangers, or coolers as the

navy termed them, for not only submarines but other ships during WWII.

Author's Photo.

This is the USS Yorktown, seen here in Charlestown, SC. Ships of

this size would have numerous and various applications for Harrison

freshwater to saltwater heat exchangers or coolers. Author's

Photo.

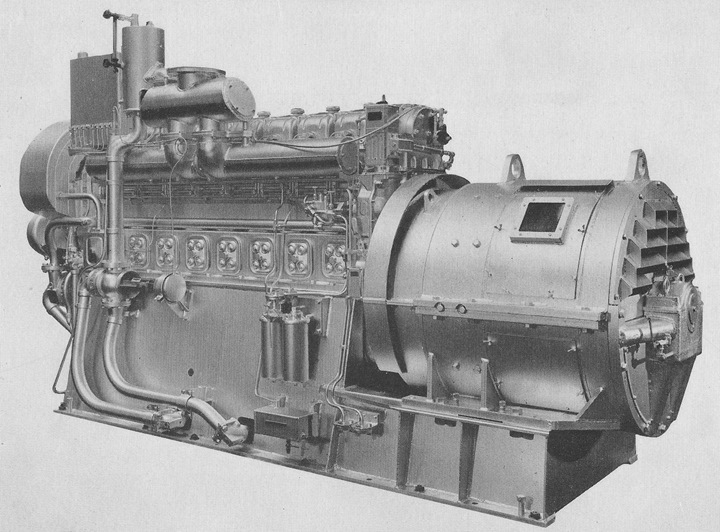

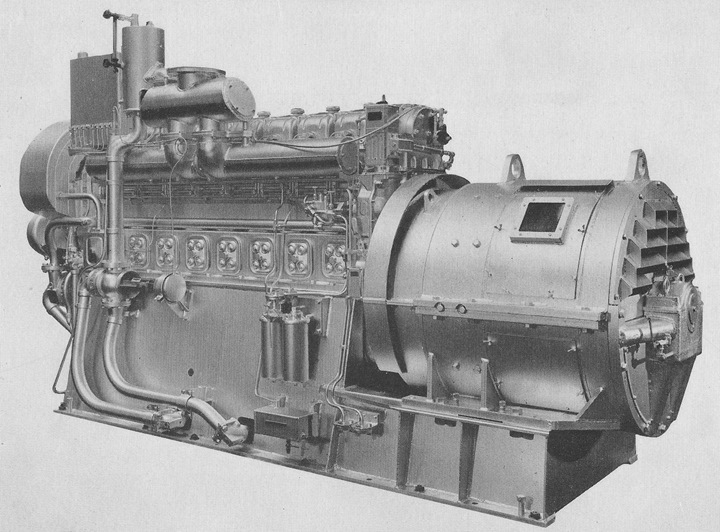

This is a General Motors Cleveland Diesel

8-268 diesel engine driving a Westinghouse 3KVA generator which was used

on many US Navy ships during WWII to supply ship's power. The

units utilized Harrison oil and water coolers. Photo added

12-1-2015.

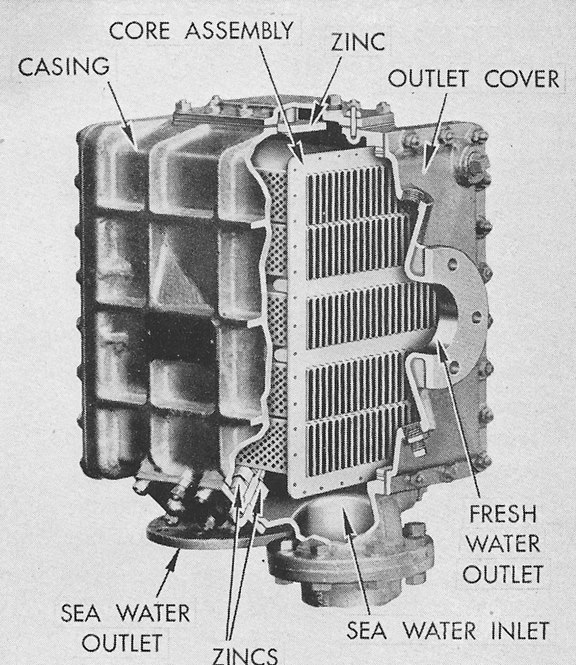

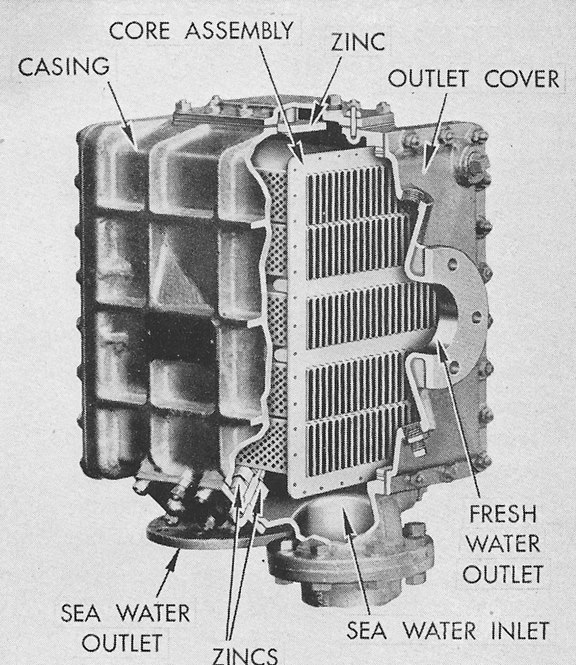

The Harrison water to water cooler.

Photo added 12-1-2015.

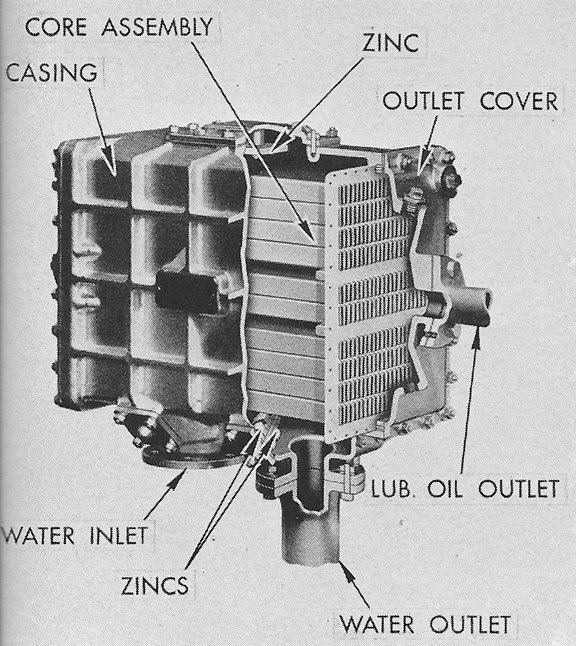

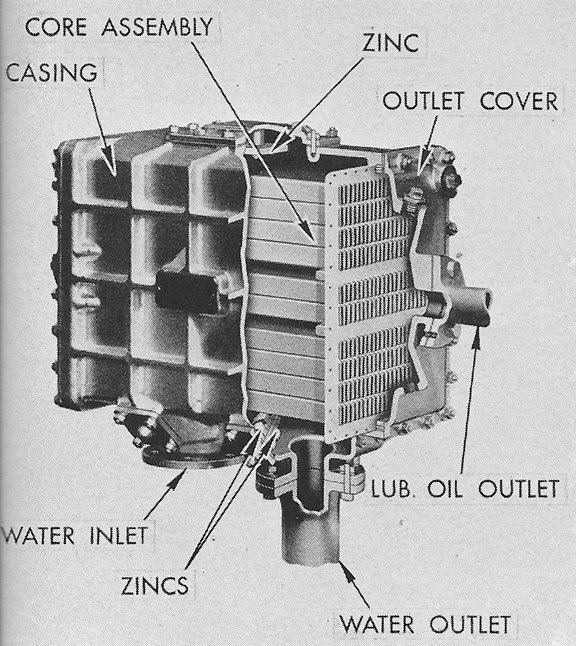

The Harrison oil to water cooler. Photo added 12-1-2015.

The USS Kidd, DD-661, on display at Baton Rogue, LA represents the many

different classes of US destroyers built during World War Two that would

have had many different applications for Harrison built coolers.

Author's Photo.

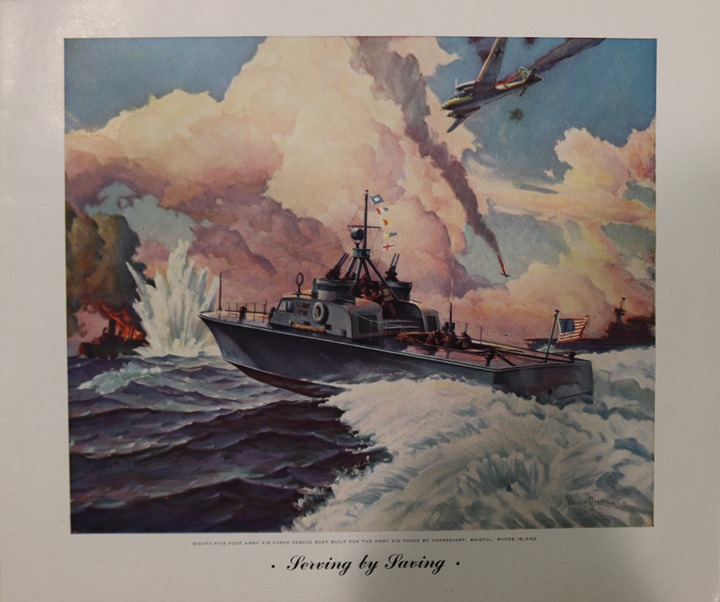

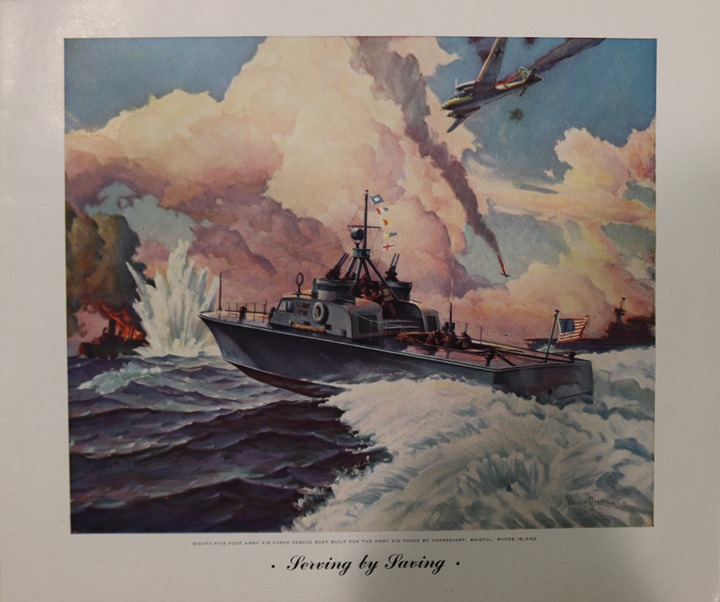

This water color from the Herreshoff

Manufacturing Company shows an 85-foot in a combat rescue situation.

The 140 85-foot rescue boats built were equipped with Harrison Radiator

heat exchangers for the two 4M2500 Packard engines that powered each

boat. Water color painting added 1-25-2020.

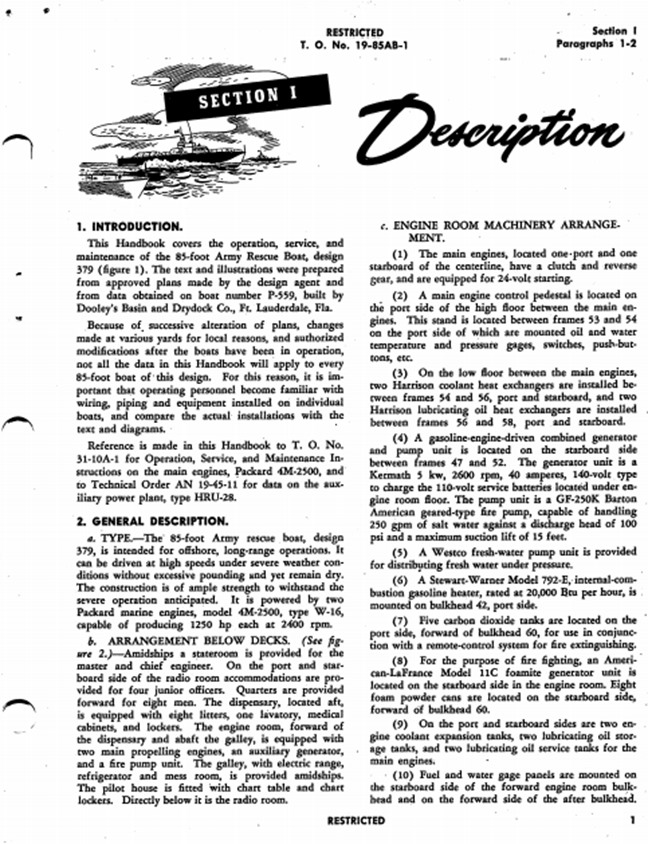

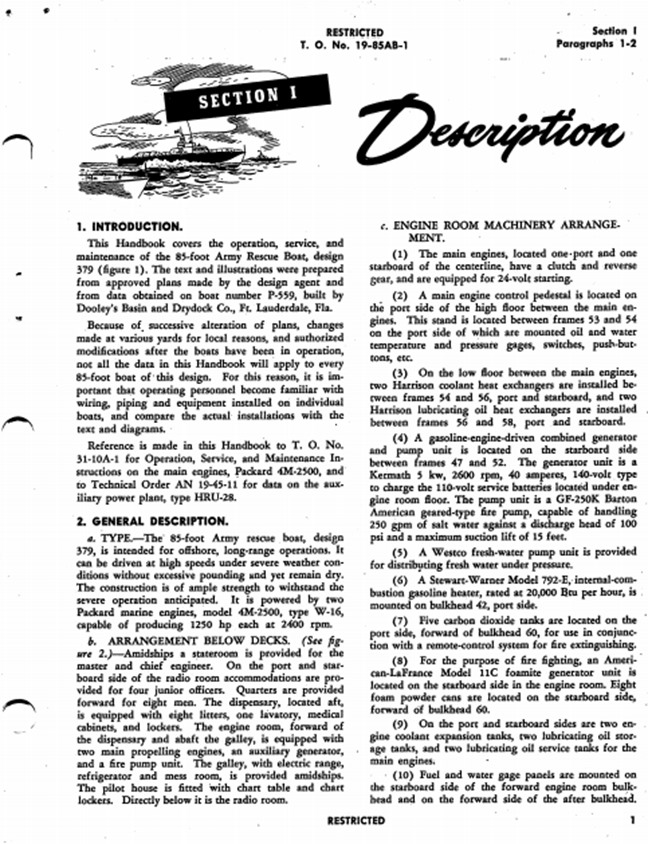

"Engine Room Machinery Arrangement,

Paragraph 3" of the Operator's Manual for the 85-foot Rescue Boat calls

out Harrison heat exchangers. Information added 1-25-2020.

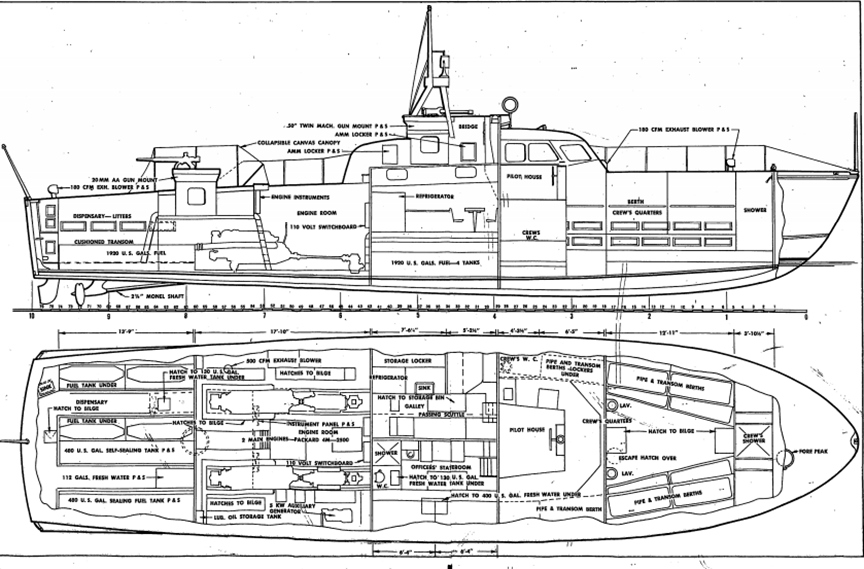

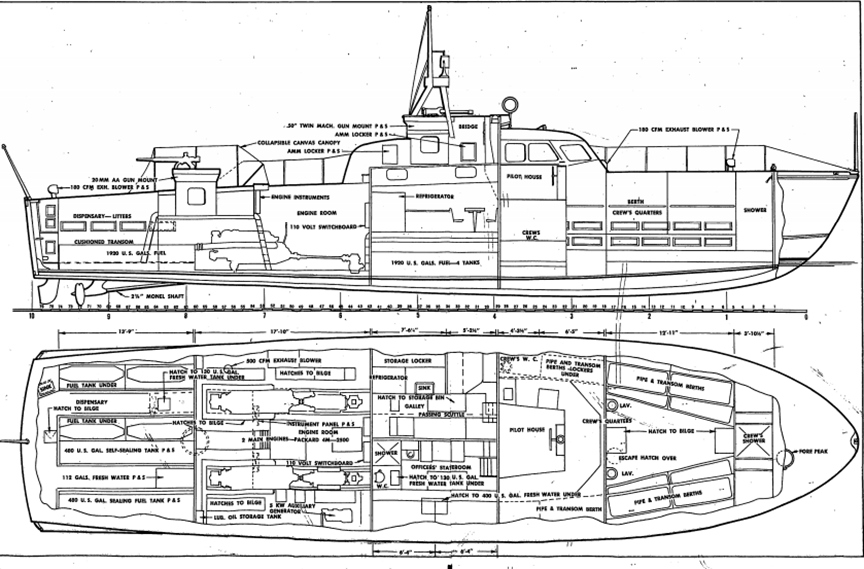

An engineering drawing showing the layout of

an 85-foot rescue boat. Drawing added 1-25-2020.

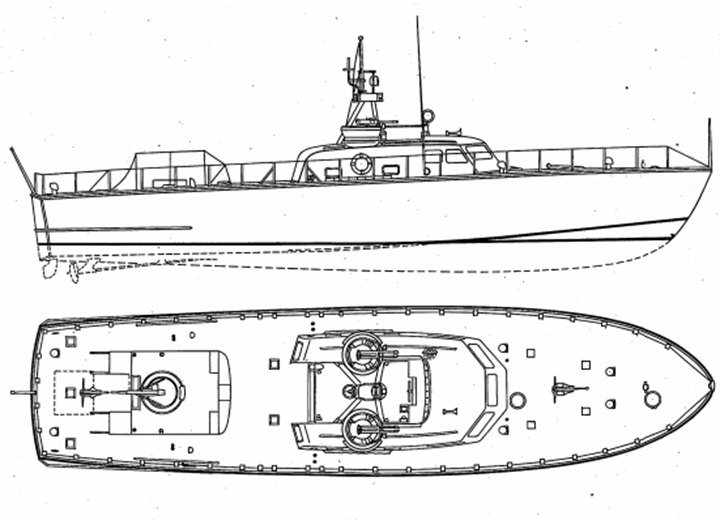

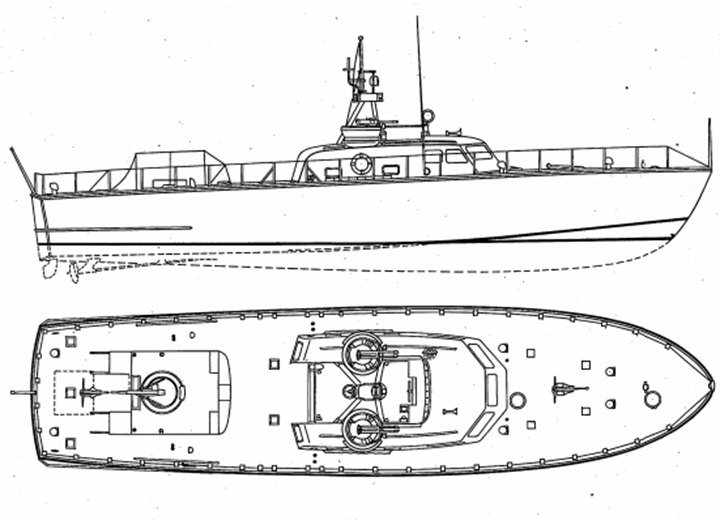

An outline of the 85-foot rescue boat.

Drawing added 1-25-2020.

In the September 1944 edition of the

Harrison Chronicles it was noted that the USS Alabama was completely

equipped with Harrison coolers. Author's photo added 10-2-2015.

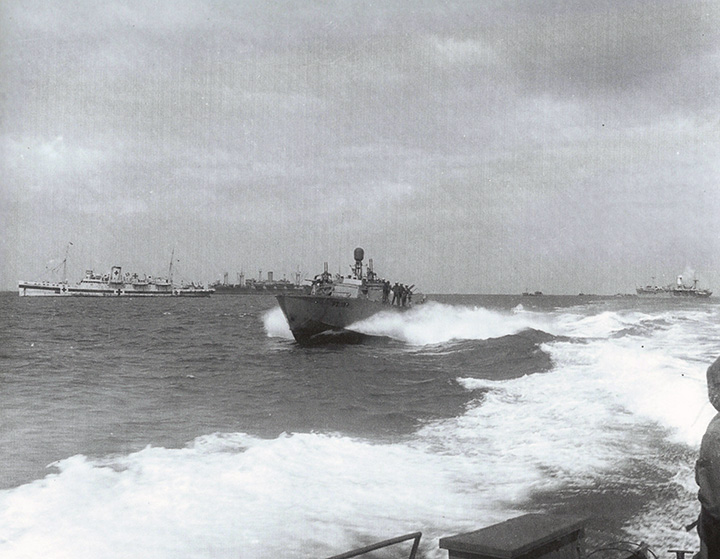

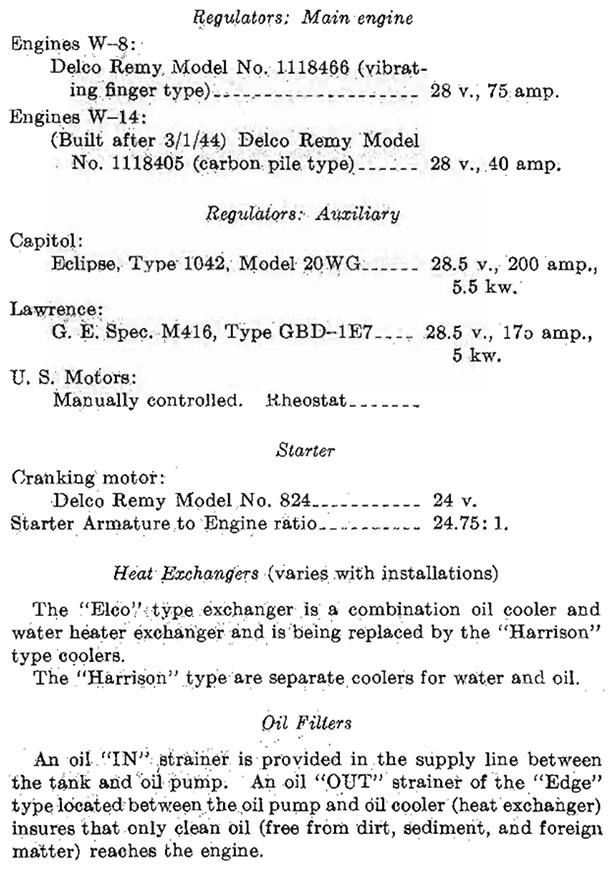

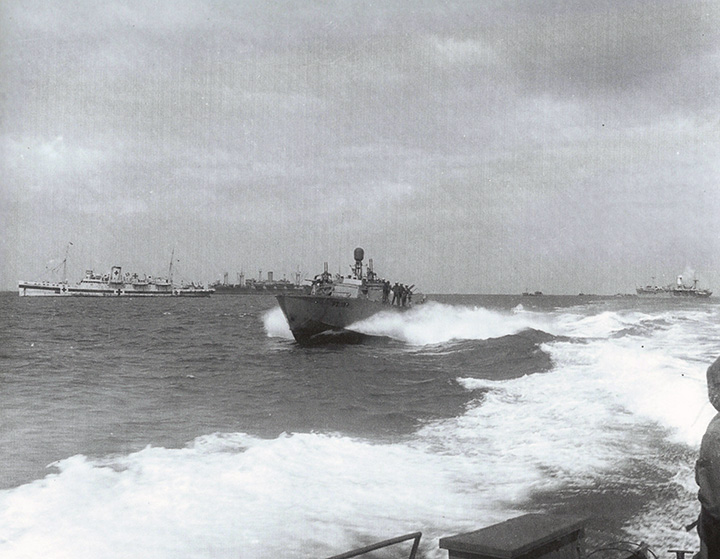

PT-199 passes by several ships in the invasion fleet to carry an admiral

to the beach at Normandy on D-Day, June 6, 1944. Three Packard engines

powered a PT boat, each of which produced 1,500 hp, which produced a

huge amount of heat for the Harrison coolers to dissipate.

In the background are a few of the 6,939 ships

that participated in the Normandy landings, which was the largest fleet

ever assembled. Immediately behind PT-199 is a hospital ship, with

others on the horizon. Many of these ships had Harrison coolers,

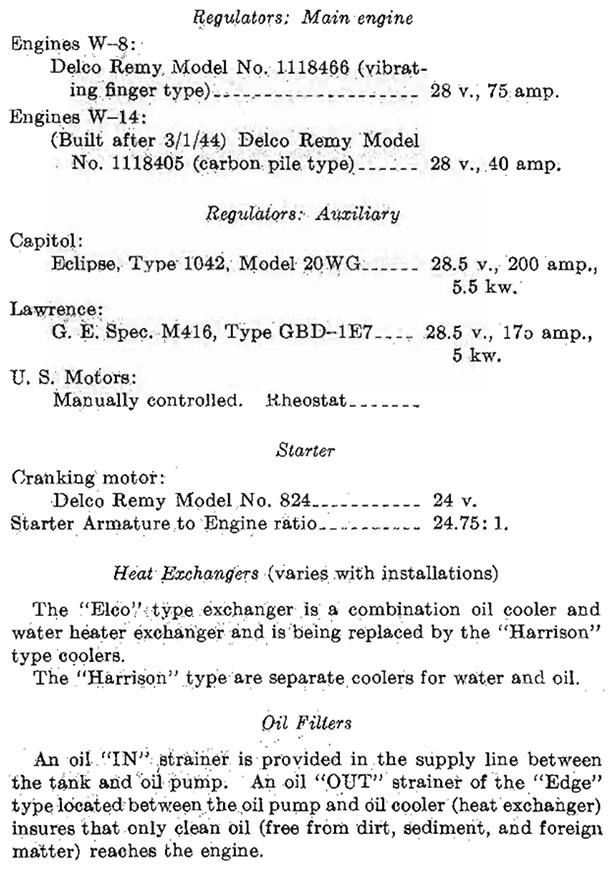

as the Navy called heat exchangers, working to cool various applications

within. Note in the Motor Torpedo Boat Engineers Handbook directly

below that Harrison was specified to replace Elco coolers or heat

exchangers for both oil and water for the Packard 4M-2500 engines.

|