|

General Railway Signal Company (GRS) in World War Two

Rochester, NY

1904-1998

This page added 11-9-2022.

In 1904, the General Railway Signal Company (GRS)

was formed by the merger of the Pneumatic Signal Company of Rochester,

NY; Taylor Signal Company of Buffalo, NY; and the Standard Railroad

Signal Company of Arlington, NJ. The company's headquarters and

main production facility was located at 801 West Avenue in Rochester,

NY. At the turn of the 20th Century, railroads were the primary

means of travel within the United States. The Interstate System

and commercial air travel would not replace the railways for travel

within the country until after World War Two. The General Railway

Signal Company was an important contributor to travel safety of the

trains. The company supplied the signal equipment along the tracks

that notified the train engineers that the tracks were safe to use.

For this era, General Railway Signal company was "high tech." Its

signal equipment used the latest electrical technology of lighting,

relays, and batteries to keep the trains running on time and in a safe

manner. This "high tech" image of the company would allow it 38

years later during

World War Two to manufacture some of the most sophisticated equipment to

help win World War Two.

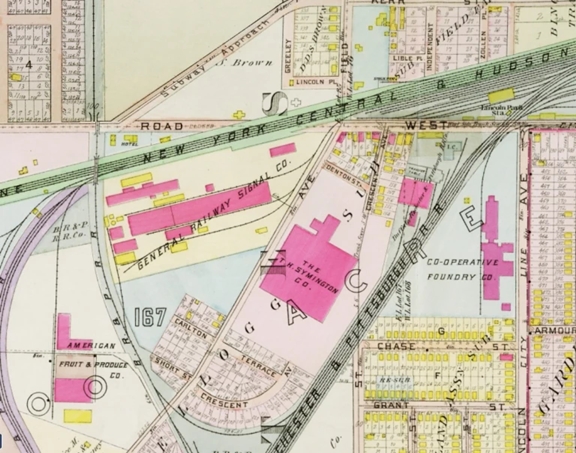

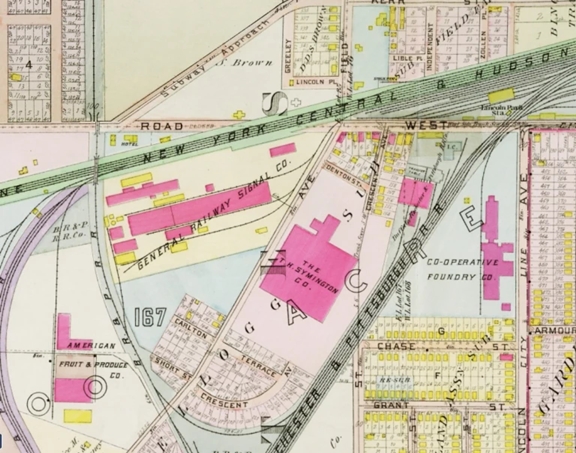

This image from the 1910 City of Rochester

plat map shows the location of the General Railway Signal Company's

factory at 810 West Avenue. The company was at this location until

1993 when operations moved to Brighton, NY, and West Henrietta, NY.

This image shows the plant on a blustery

Christmas Eve Day in 1915. During World War One this plant turned

out artillery shells for the Allied effort. The company would

again make artillery shells when World War Two began.

In 1998, GRS was purchased by Alstom SA, which

discontinued the General Railway Signal Company name on its products.

The original plant and additions are still

in current use by other companies.

General Railway Signal Company World War

Two Products:

Table 1 - General Railway Signal

Company's Major World War Two Contracts

The information below

comes from the "Alphabetical Listing of Major War Supply

Contracts, June 1940 through September 1945." This was

published by the Civilian Production Administration,

Industrial Statistics Division. |

|

Product - Customer |

Contract Amount |

Contract Awarded

|

Completion

Date |

| Ammunition

Components - Army Ordnance |

$4,375,000 |

11-1940 |

2-1942 |

| Shells - Army

Ordnance |

$4,738,000 |

8-1941 |

6-1942 |

| Shells - Army

Ordnance |

$4,335,000 |

12-1941 |

2-1942 |

| Shells - Army

Ordnance |

$536,000 |

1-1942 |

11-1942 |

| Shells - Army

Ordnance |

$7,232,000 |

2-1942 |

5-1943 |

| Shells - Army

Ordnance |

$442,000 |

2-1942 |

11-1942 |

| Shells - Army

Ordnance |

$2,365,000 |

3-1942 |

2-1943 |

| Shells - Army

Ordnance |

$867,000 |

4-1942 |

12-1942 |

| Fire Control

Equipment - USAAF |

$83,193,000 |

8-1942 |

4-1944 |

|

Shell Assemblies HE M8 - Army Ordnance |

$4,552,000 |

7-1943 |

12-1943 |

| Shells 75mm

HE - Army Ordnance |

$368,000 |

8-1943 |

10-1943 |

| Signal

Equipment - Treasury |

$4,089,000 |

8-1943 |

2-1944 |

| Shells 105mm

HE - Army Ordnance |

$9,049,000 |

9-1943 |

12-1944 |

| Fire Control

Equipment - USAAF |

$48,688,000 |

1-1944 |

6-1945 |

| Rocket Shells

HE M8A1 - Army Ordnance |

$3,430,000 |

1-1944 |

1-1945 |

| Railroad

Signal Equipment - Treasury |

$96,000 |

6-1944 |

8-1944 |

| Shells 105mm

HE M1- Army Ordnance |

$8,399,000 |

8-1944 |

5-1945 |

| Airplane

Controls - USAAF |

$294,000 |

12-1944 |

4-1945 |

| Shells 105mm

HE M1- Army Ordnance |

$5,192,000 |

12-1944 |

4-1946 |

| Fire Control

Equipment - USAAF |

$35,926,000 |

2-1945 |

2-1946 |

| Total |

$228,166,000 |

|

|

Table 1 shows that the

company's first eight contracts starting in November 1940 through

April 1942 totaled $24,890,000 shells for the U.S. Army. Its

next contract was for a whopping $83,193,000 for fire control

equipment for the United States Army Air Forces. In my

research, I have never seen a company awarded such a large first-time contract for a

new product. Normally, the company gets

a series of smaller contracts as it ramps up production. What

was so important to the winning of World War Two for the United

States Army Air Forces that they would award an $83,193,000 contract

to a company that had only

previously made artillery shells?

The answer is

the B-29 Superfortress four-engine long

range bomber was the most advanced aircraft of World War Two.

One of the main features of the B-29 was that the crew areas were

pressurized. The big advantage to the crew was that the

interior could be climate controlled, and the air crew was not

subject to having to wear heavy clothing and oxygen masks while

being subject to -40 degree Fahrenheit temperatures like the B-17

and B-24 crews did in Europe. In order to do this, the B-29 had

non-manned gun turrets which were operated by remote gun sights.

The General Railway Signal Company was a major, if not the largest supplier, of the B-29 gun sighting stations for all five locations on

the aircraft. Author's photo from the Pima Air & Space Museum

in Tucson, AZ.

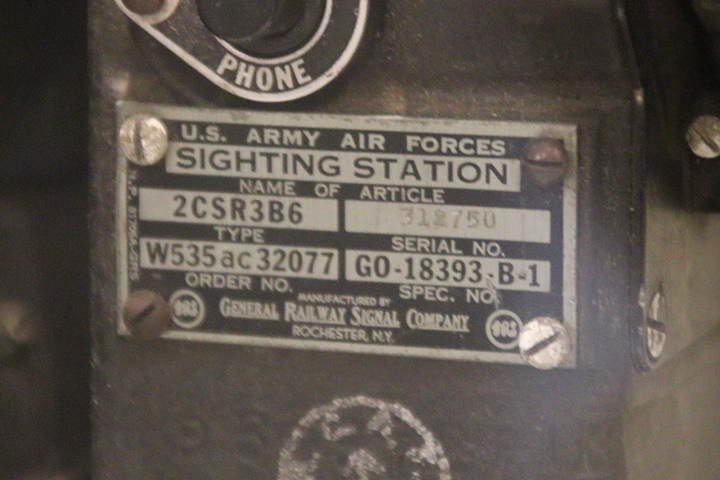

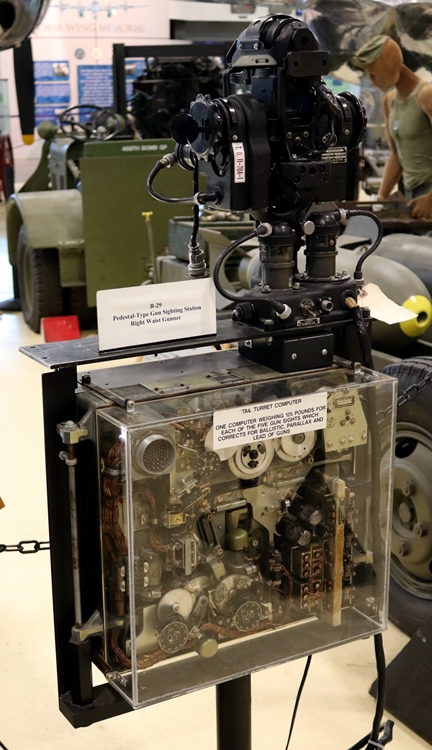

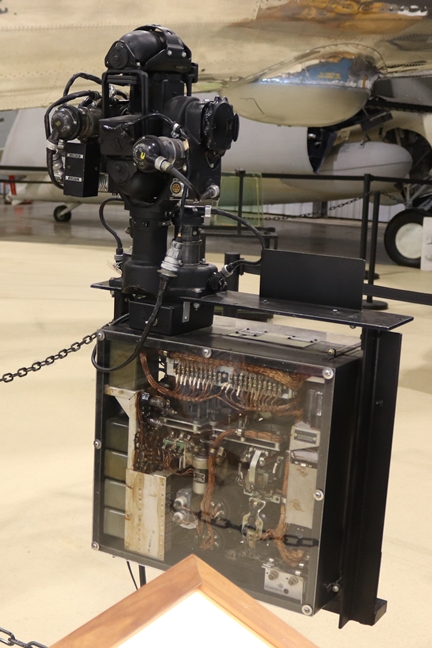

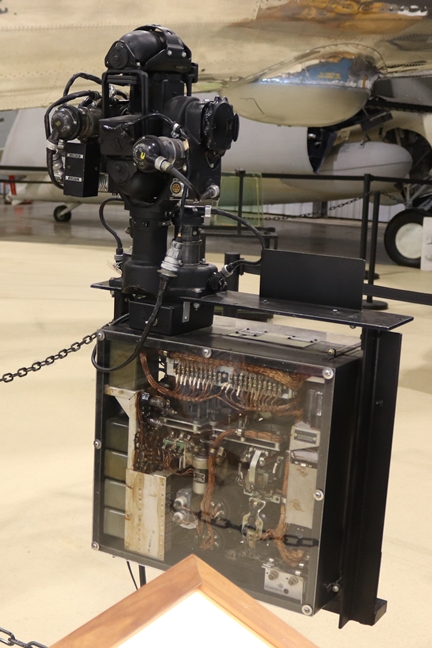

This B-29 General Railway Signal Company

B-29 tail gun sighting station is on display at the Indiana Military

Museum in Vincennes, IN. It is virtually identical to the

other four sighting stations on the B-29. Author's photo.

The B-29 project was the most

expensive American project of World War Two. It was even more

expensive than the Manhattan Project that produced the atomic bomb.

It was also a rushed project where all the new technology had to be

tested and then produced in four plants dedicated to B-29

production. Therefore, in August 1942, GRS was given an

$83,193,000 contract to produce this highly technical product.

|

Table 2 - General Railway Signal

Company's Major World War Two Product Categories |

|

Product |

Amount |

Percentage |

|

Fire Control Equipment

- USAAF |

$167,807,000 |

74% |

|

Artillery Shells and Rockets |

$55,880,000 |

24% |

|

Railroad Signal Equipment -

Treasury |

$4,185,000 |

1.9% |

| Airplane

Controls - USAAF |

$294,000 |

.1% |

|

Total |

$228,166,000 |

100% |

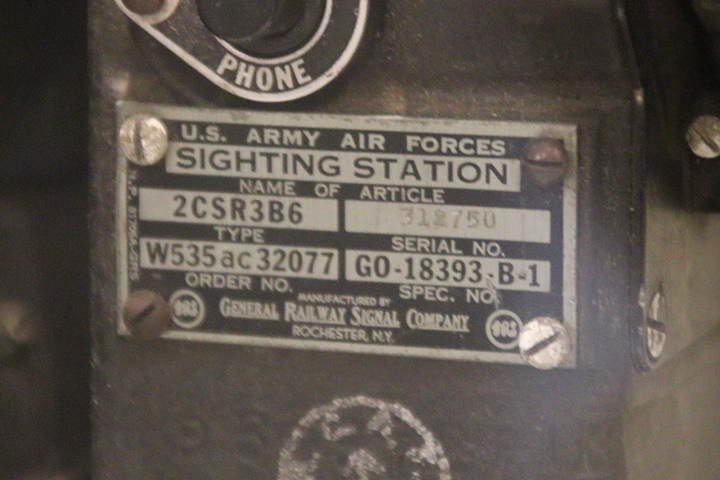

This data plate shows this this sighting

station is serial number

312750. It should be noted that the company did not build this

number of units. As noted below, the Singer Manufacturing Company

produced 20,794 computers for the B-29s remote gun control system.

Therefore, GRS most likely produced about the same amount of sighting

stations. Author's photo.

Author's photo.

Author's photo.

Author's photo.

Author's photo.

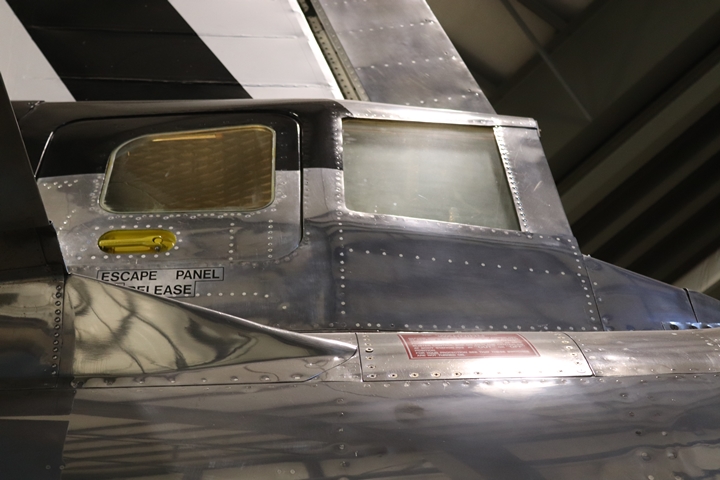

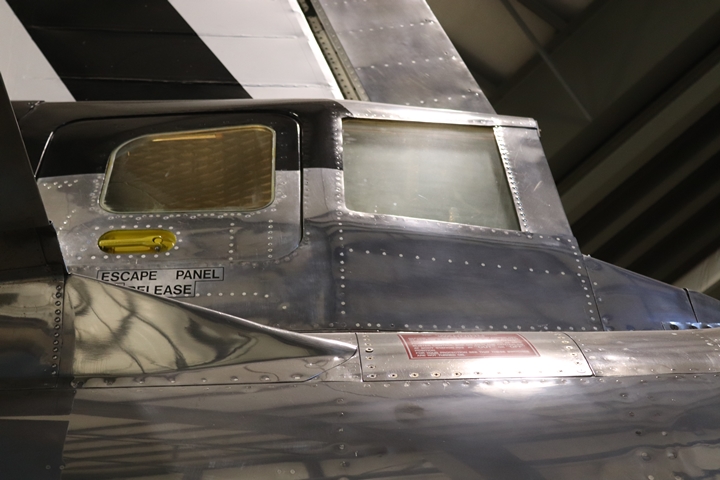

This is the tail gun position on the

B-29. Author's photo.

This is the interior view of the B-29's tail

gun position.

The New England Air Museum in Windsor Locks,

CT built a special display hangar to

display its B-29 named "Jack's Hack." Author's photo.

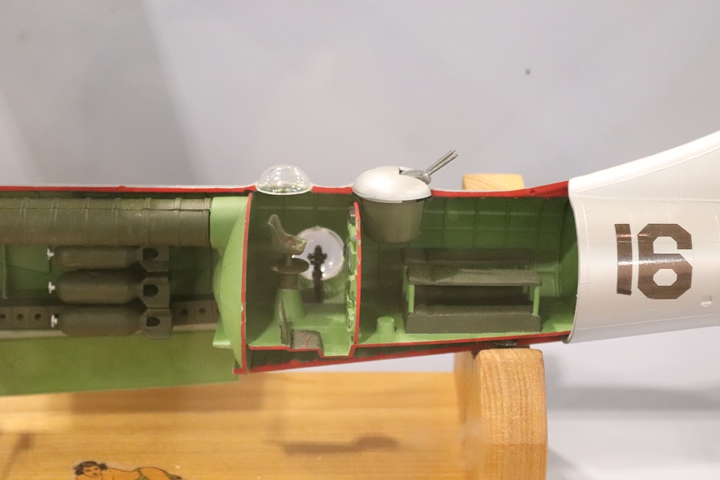

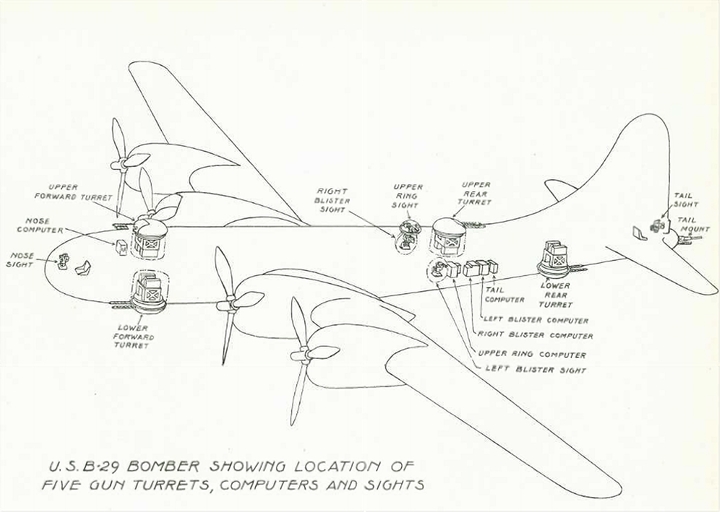

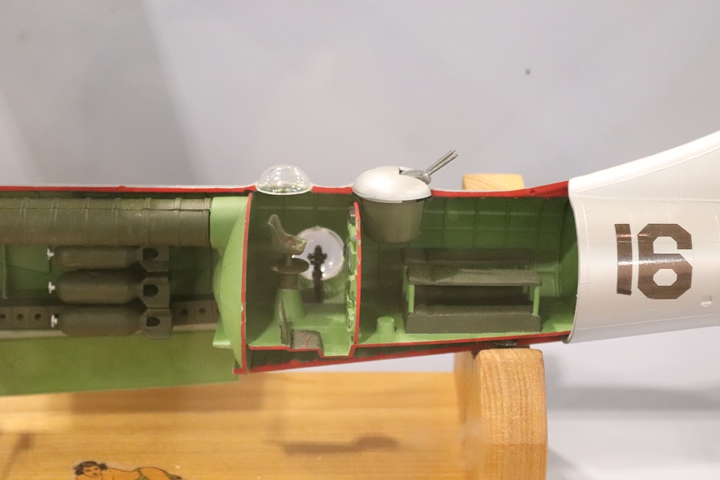

This cut-away model of a B-29 at the New

England Air Museum will be used to explain the defensive gun control

system on the aircraft. Author's photo.

This image shows the front of the aircraft.

The forward dorsal and ventral front turrets can be seen. They are

self-enclosed units with no place for a gunner in the turret. The

bombardier that sat at the front of the aircraft had primary control of

these two turrets. This allowed him to aim both turrets in the

forward position to fire on a Japanese fighter making a head-on attack.

When the aircraft was not being attacked from the front, he could turn

over control of the dorsal turret to the gunner in the top dorsal

sighing position in the rear of the aircraft. Control of the lower

ventral turret could be turned to the port side waist sighting station

gunners. Author's photo.

This B-29 front fuselage is on display at

Fantasy of Flight in Polk City, FL. The stairs to the nose section

allows visitors to view the inside of the cockpit area and the

bombardier's sight station. Author's photo.

The sighting station is in the foreground.

Some of the parts are missing, such as the GE selsyn generators.

This unit could have been built by either GE or GRS. The data

plate was not visible for identification. However, GRS did build

sight stations for this location. Author's photo.

This photo of "Jack's Hack" shows the

forward dorsal and ventral remote controlled turrets. Author's

photo.

This section of the cut-away shows the rear

gunner's positions. The gunner was located at the top of the

fuselage sat in what was known as the "barber's chair." He was the

overall coordinator of the gunners and was the primary gunner for the

rear dorsal turret. If the aircraft was being attacked from above,

he could use both the dorsal turrets if the bombardier did not have

frontal attacks. The gunners in the side blisters had primary

control over the rear ventral turret which is not in this view. In

an attack from below, they could also control the front lower ventral

turret if the bombardier was not using that turret. The side

blister gunners could also take control from the tail gunner of his

turret if he was not under attack. Author's photo.

This view shows the rear ventral and tail

turrets. The tail gunner had a primary control of the tail guns,

but could turn control of the tail turret to the side blister gunners.

Author's photo.

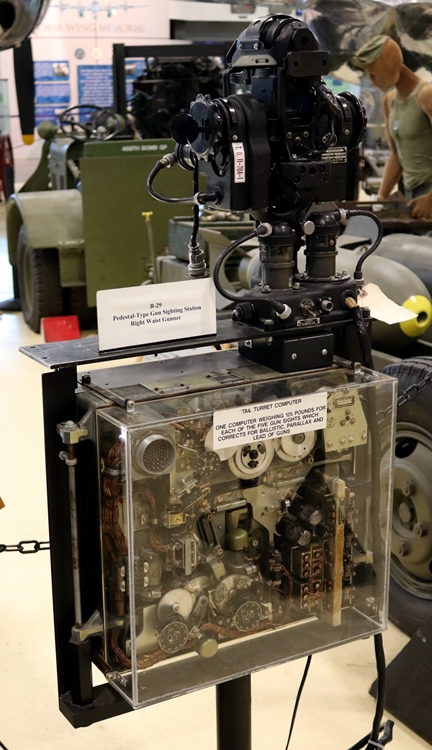

This display is also at the New England Air

Museum. The upper portion is a right waist gunner's sighting

station. This particular example was built by General Electric, but

General Railway Signal Company also built them. Author's photo.

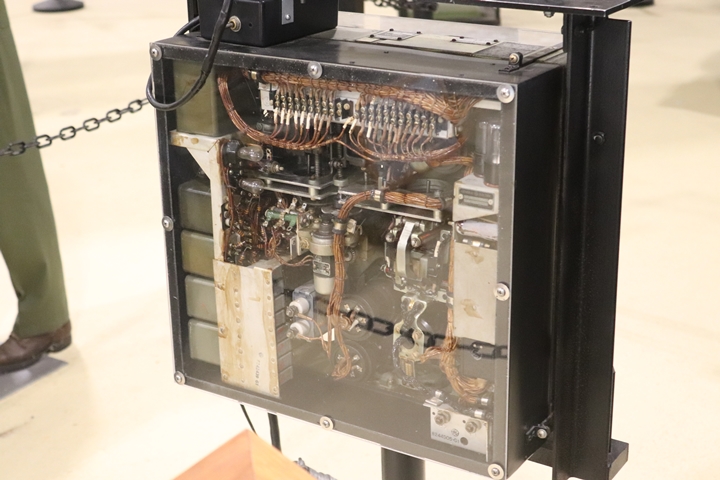

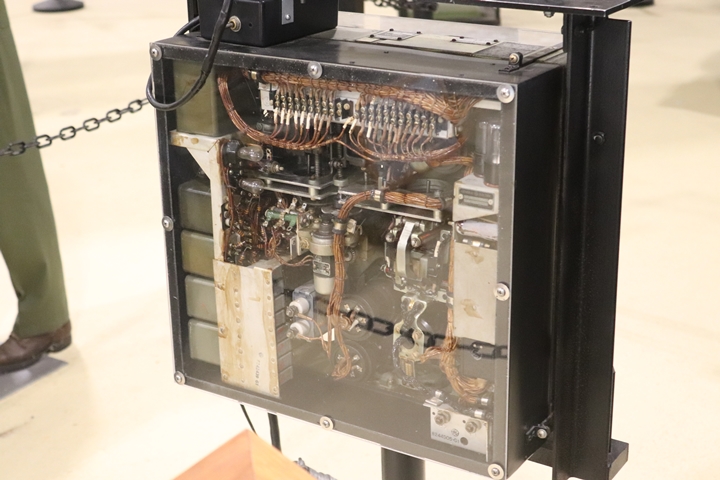

The item on the bottom is the computer for

the tail gun turret. The B-29 was the first aircraft which had a

computer controlled defensive gun system. Author's photo.

The B-29's gun turrets were all computer

controlled and there were a total of five computers on board, one for

each sighting station on the aircraft. General Electric licensed

production of the computers to the Singer Manufacturing Company which

built a total 20,794. Author's photo.

The computer was of the analog electrical

type. Each one was located under the floor near the gun station it

controlled. When in use, the gunner used his General Railway Signal

Company-built sighting station to input the wingspan of the attacking

aircraft and the motion of the enemy aircraft as the gunner tracked it

across the sky. The gunner also framed the target which gave the

computer the distance to the enemy fighter. The navigator was also

responsible for providing needed information that the computer needed to

operate properly. These inputs were indicated air speed, pressure,

outside air temperature, and altitude. The computer also knew the

ballistics of the .50 caliber ammunition that the B-29s used. The

computer took in all these inputs, calculated, a firing solution

and aimed the remote turret or turrets at the proper position to lead

the enemy aircraft.

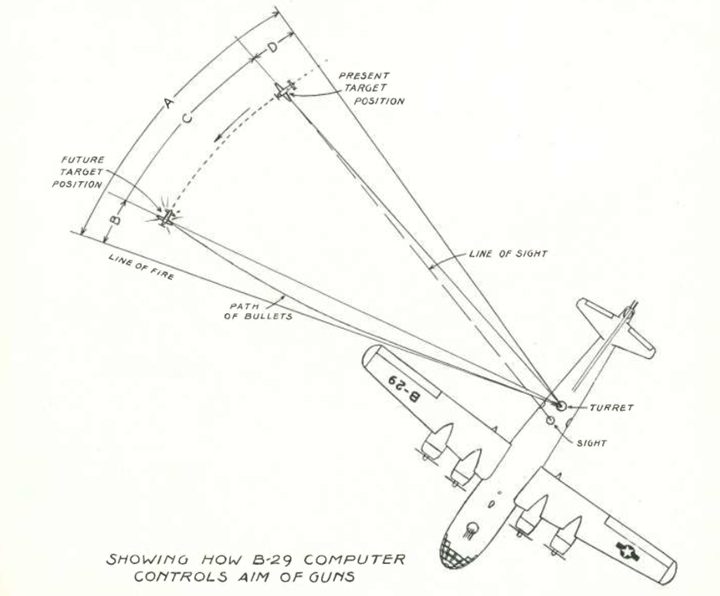

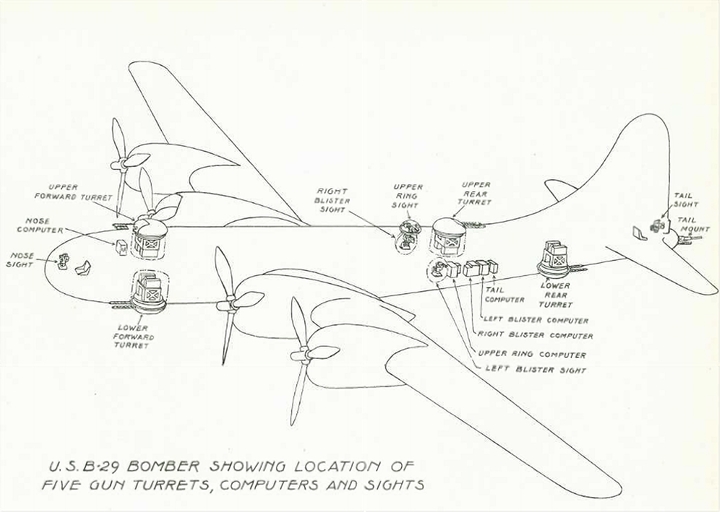

This image shows remote turrets, gun sight

stations, and the location of the computers.

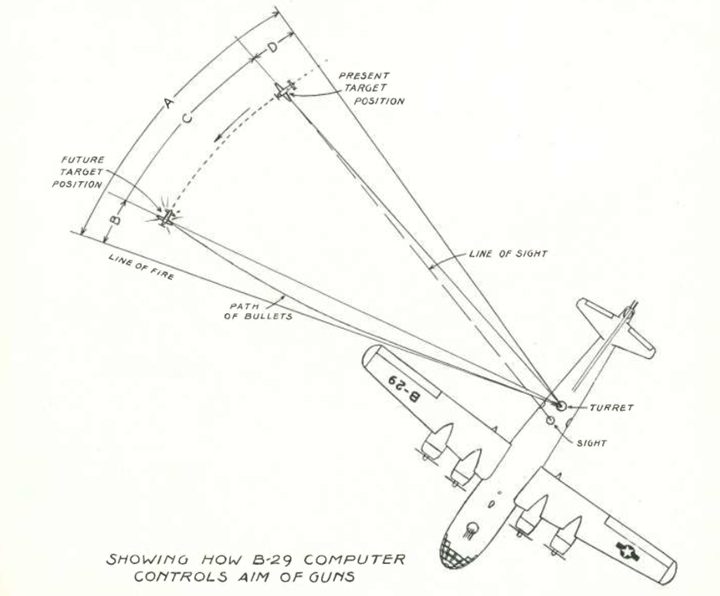

This image shows the final result of the firing

solution. The computer also needs to calculate the parallax

between the gunner's sight and the remote turret location. The

computer uses all of the inputs to determine the proper lead on the

aircraft. This was an extremely sophisticated system for the era.

The General Railway Signal Company-built sighting stations were the

gunner's tool to provide the proper information to the computer to shoot

down enemy aircraft and protect the bomber.

The effective range of the system was 900

yards, which was 50% better than on the manual systems for the B-17 and

B-24. Over the course of 31,000 sorties between August 1944 and

August 1945, B-29 gunners were credited with shooting down 914 Japanese

fighters.

Artillery Shells and Rockets:

Ordnance items were 24% of the company's business during World War Two.

The $55,880,000 worth of two sizes of shells and one type of

rocket shell that GRS built was a significant amount for any company during the war.

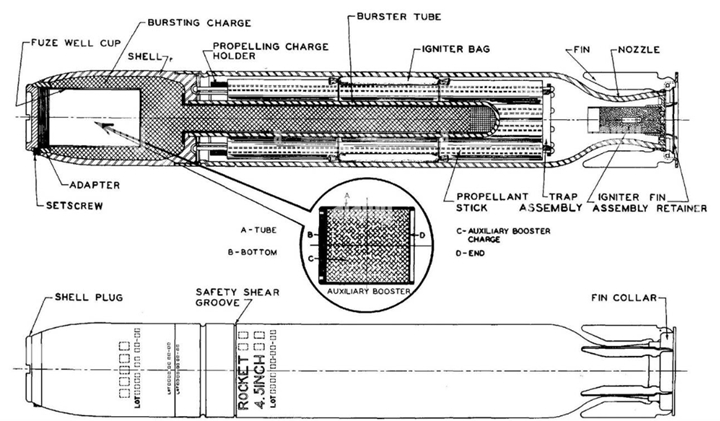

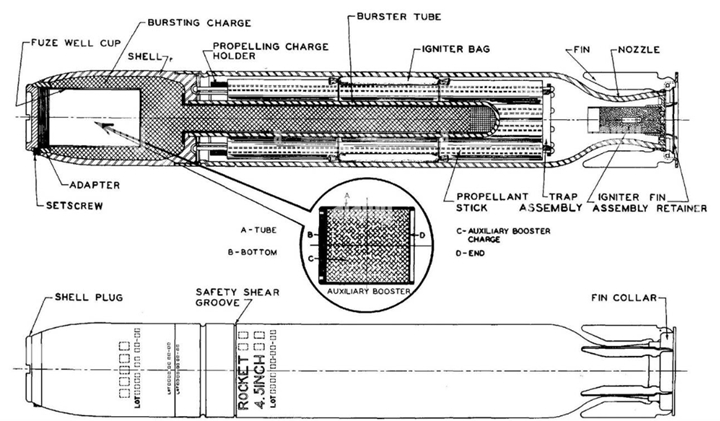

This is an M8 4.5 inch rocket that was used

by both U.S. Army air and ground forces during World War Two.

From the description of the contract stating

the company built "Rocket Shells," it may be that GRS just manufactured

the component labeled as "shell" in the diagram. This was

similar to the artillery shells the company was making. A

munitions plant would have been responsible for assembling all of the

components and hazardous explosives.

The best known use of the 4.5 inch rocket

was launching them from Sherman tanks. This is an actual

combat photo as the Sherman tank crew has added sandbags to the exterior

of the tank for added protection against German anti-tank weapons.

Another launcher was the

T27E1 4.5 inch rocket launcher used by ground troops. This weapon

is on display at the Rock Island Arsenal outside display area.

Author's photo.

Author's photo.

Of interest in the photo are the three

tubes. These make up a 4.5 inch rocket launcher used by the U.S. Army

Air Forces during World War Two. It is on

display at the MAPS Air Museum at the Akron-Canton Airport, OH.

Author's photo.

This image shows the rocket launchers

mounted to a P-47 Thunderbolt fighter.

This is a 75mm high explosive shell similar

to what GRS manufactured. Author's photo from the Museum of the

Soldier in Portland, IN.

The shell would then be assembled into

complete units similar to these by a munitions plant. These are on

display at the National Museum of the United States Army at Fort

Belvoir, VA. Author's photo.

The most common use for the 75MM high

explosive shell was in Sherman tanks when they were used in the

infantry support role. High explosive shells were used to destroy

enemy bunkers and fortifications so that the infantry could advance

beyond them. About 75% of the 75mm shells carried in Sherman tanks

were high explosive types. This Chrysler-built M4A4(75)VVSS is on

display at the Evansville Wartime Museum in Evansville, IN.

Author's photo.

The 105mm howitzer was the most utilized

piece of artillery used by the U.S. Army and U.S. Marine Corps during

World War Two. This 105mm howitzer was on display at the 2021 MVPA

display at Findlay, OH. Author's photo.

General Railway Signal Company was an

important supplier of the high explosive shell for the 105mm howitzer.

Author's photo.

|