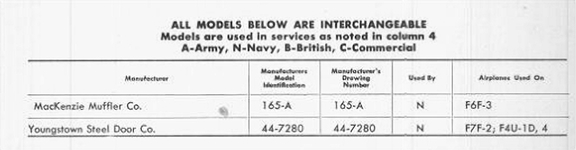

|

Youngstown Steel Door Company During World War Two

Youngstown, OH

1924 - 2016

This page updated 8-15-2024.

Youngstown Steel Door was formed in 1924 to

manufacture for the railroad industry just what the name of the company

implied; steel doors for boxcars. Previously, these had been

made of wood. The company had several innovations for rail car

doors constructed of steel and also made other steel railcar components.

Youngstown Steel Door Company World War Two

Products: Table 1 shows

that the company had $25,084,000 in major contracts during World War

Two. Its first and third contracts were awarded for the

manufacture of $3,786,000 worth of trailers for Army Ordnance.

The manufacture of trailers was 15% of the company's major contracts

during the war. The U.S. Navy Department of Aeronautics was the

company's largest customer. Its nine contracts amounted to $20,966,000 in

disposable drop tanks for several of its fighters and patrol bombers.

Drop tanks gave Navy aircraft the ability to fly longer distances in the

vast expanses of the Pacific Ocean to attack their targets. Using an

estimated cost of $150 per unit, Youngstown Steel Door manufactured

approximately 140,000 drop tanks.

Table 1 - Youngstown Steel Door

Company's

Major World War Two Contracts

The information below

comes from the "Alphabetical Listing of Major War Supply

Contracts, June 1940 through September 1945." This was

published by the Civilian Production Administration, Industrial

Statistics Division. Table added 2-5-2023. |

|

Product - Customer |

Contract Amount |

Contract Awarded

Date |

Completion

Date |

| Trailers - Army

Ordnance |

$3,200,000 |

4-1943 |

3-1944 |

| Droppable Fuel

Tanks - Navy Department of Aeronautics |

$1,706,000 |

8-1943 |

5-1945 |

| Ammunition

Trailers - Army Ordnance |

$586,000 |

10-1943 |

4-1944 |

|

Droppable Fuel Tanks - Navy Department of Aeronautics

|

$765,000 |

1-1944 |

12-1944 |

| Dropbl Fuel Tanks

- Navy Department of Aeronautics |

$5,723,000 |

2-1944 |

11-1945 |

| Fuel Tank

Machinery - Navy Department of Aeronautics |

$107,000 |

2-1944 |

12-1944 |

| Dropbl Fuel Tanks

- Navy Department of Aeronautics |

$923,000 |

8-1944 |

7-1945 |

| Fuel Tank

Assemblies - Navy Department of Aeronautics |

$147,000 |

8-1944 |

11-1944 |

| Dropbl Fuel Tanks

- Navy Department of Aeronautics |

$822,000 |

9-1944 |

7-1945 |

| Dropbl Fuel Tanks

- Navy Department of Aeronautics |

$4,755,000 |

2-1945 |

10-1945 |

| Dropbl Fuel Tanks

- Navy Department of Aeronautics |

$4,356,000 |

4-1945 |

1-1946 |

| Dropbl Fuel Tanks

- Navy Department of Aeronautics |

$229,000 |

4-1945 |

7-1945 |

| Drop Tanks - Navy

Department of Aeronautics |

$1,540,000 |

5-1945 |

3-1946 |

| Fuel Tank Parts -

Navy Department of Aeronautics |

$87,000 |

6-1945 |

7-1945 |

| Steel

Pipes - Army Corps of Engineers |

$138,000 |

7-1945 |

12-1945 |

| Total |

$25,084,000 |

|

|

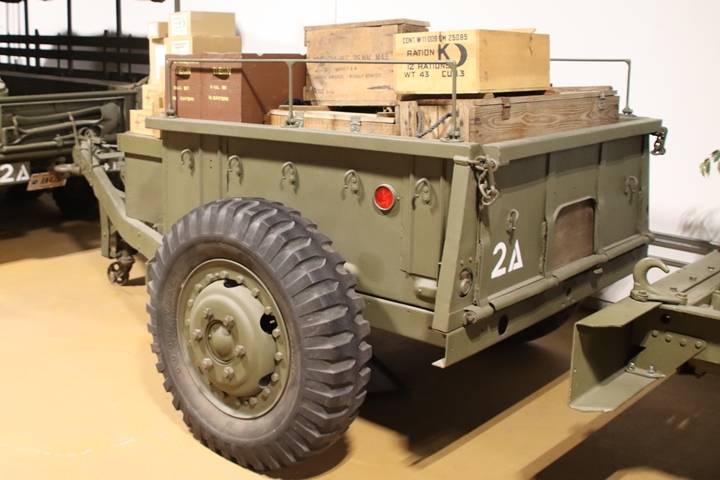

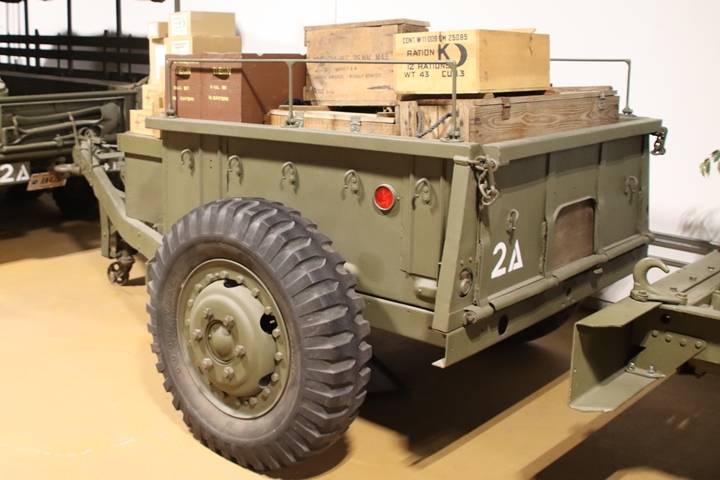

M10 Ammunition Trailer:

This M10 ammunition trailer, produced by

Youngstown Steel Door, is part of the collection of the Wheels of Liberation

in Gettysburg, PA. Author's photo.

This trailer does not have the data plate

that was normally attached to vehicles and trailers. Instead, it

has this brass tag. Author's photo.

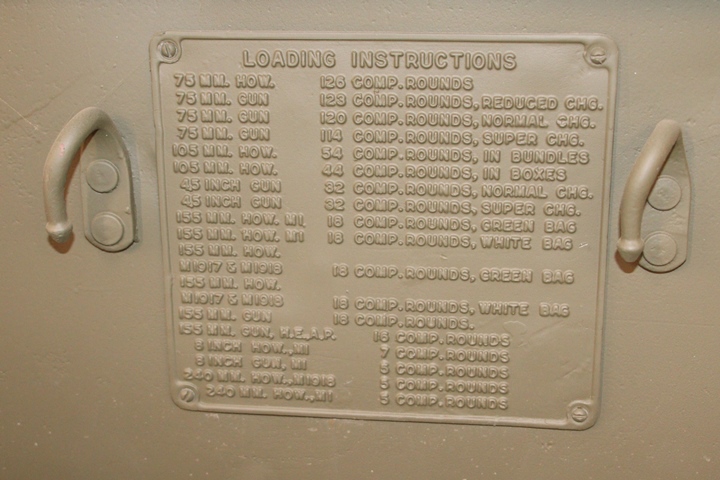

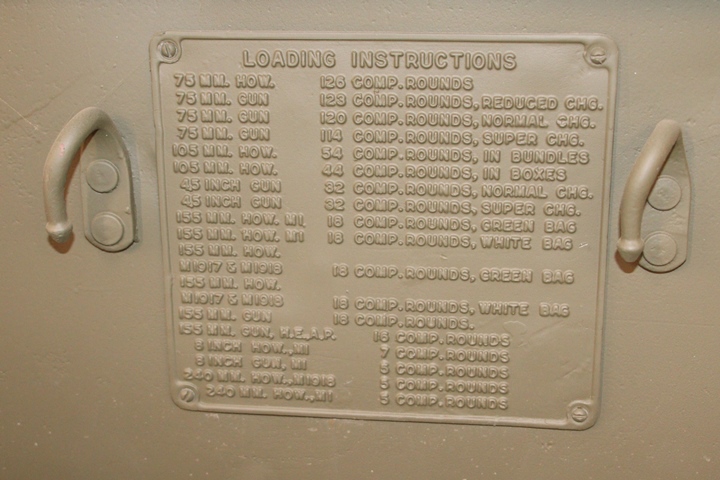

The loading instructions indicate the

amounts of different types of ammunition that can be loaded into the

trailer. Author's photo.

The metal box on the front of the trailer

was for the storage of fuzes for the ammunition stored in the main

section of the trailer. Author's photo.

Author's photo.

This Youngstown Steel Door Company-built M10

ammunition trailer is on display at the Indiana Military Museum in

Vincennes, IN. Author's photo added 8-15-2024.

This M10 trailer was built in 1944.

Author's photo added 8-15-2024.

Author's photo added 8-15-2024.

Author's photo added 8-15-2024.

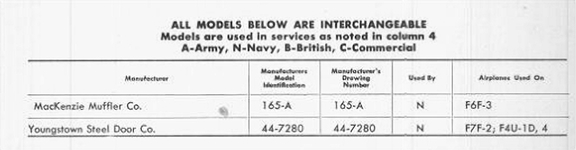

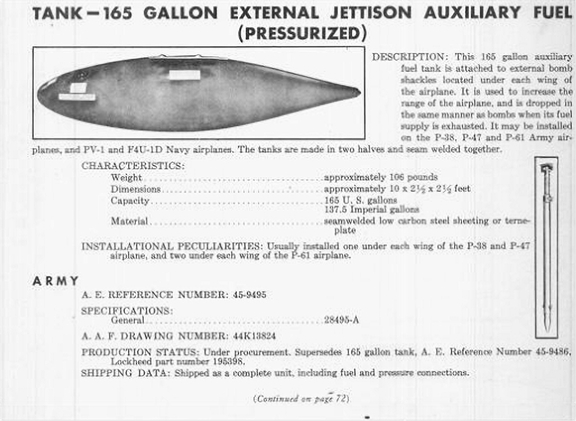

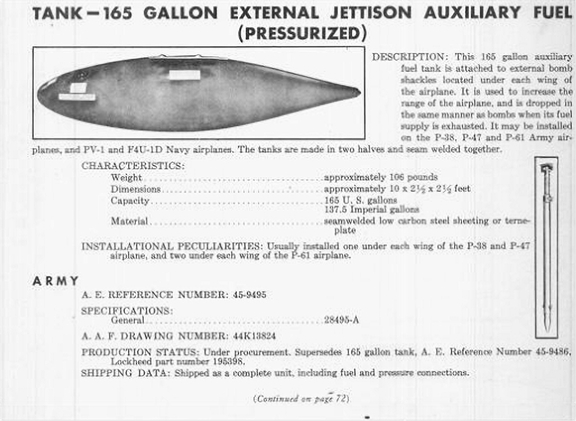

U.S. Navy Drop Tanks: Youngstown Steel Door Company's main

products that helped to win World War Two were drop tanks for U.S. Navy

aircraft.

This 165 gallon drop tank is on display at

the National Museum of WWII Aviation in Colorado Springs, CO. The

information below indicates that Youngstown produced these as its part

number 44-7280.

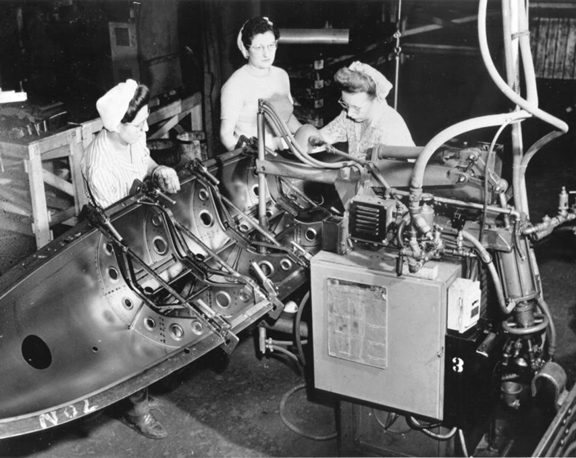

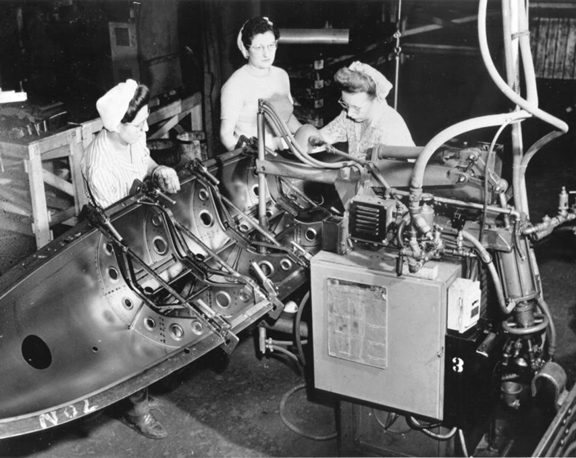

This factory photo shows the internal

bracing that was required to stiffen the exterior half-shells of a drop

tank. Not only did these braces provide strength, but they

prevented the aviation fuel from sloshing back and forth during flight.

The women are operating a spot welder that welded the interior braces to

the half-shells. Aviation fuel weighs six lbs. per gallon.

Each 165 gallon tank added 990 lbs. of take-off weight. The

bracing was needed to keep the exterior half-shells as light as possible

without crumpling due to the 990 lbs. of fuel. Photo courtesy of

the Ohio Memory Collection.

The Youngstown Steel Door Company was a busy

place during World War Two, providing drop tanks that extended the range

of Navy F6F and Marine F4U fighters. Photo courtesy of the Ohio

Memory Collection.

There were several different designs and

sizes of drop tanks during World War Two. This F6F at the Yanks

Air Museum in Chino, CA has a drop tank attached to the fuselage. Author's photo.

This Grumman F6F with a drop tank is on

display at the New England Air Museum in Windsor Locks, CT. Author's photo.

The F4U Corsair utilized Youngstown Steel

Door Company drop tanks to increase its range as it fought its way up

the Solomon Islands in the southwest Pacific Ocean. Author's photo.

The Lockheed PV-1 and PV-2 both used 165

gallon drop tanks to extend their range on patrol over both the Atlantic

and Pacific Oceans. This PV-2 was on display at a 2013 aviation

event in Topeka, KS. Author's photo.

Author's photo.

Author's photo.

This PV-2 with drop tanks is on

display at the National Museum of Naval Aviation in Pensacola, FL. Author's photo.

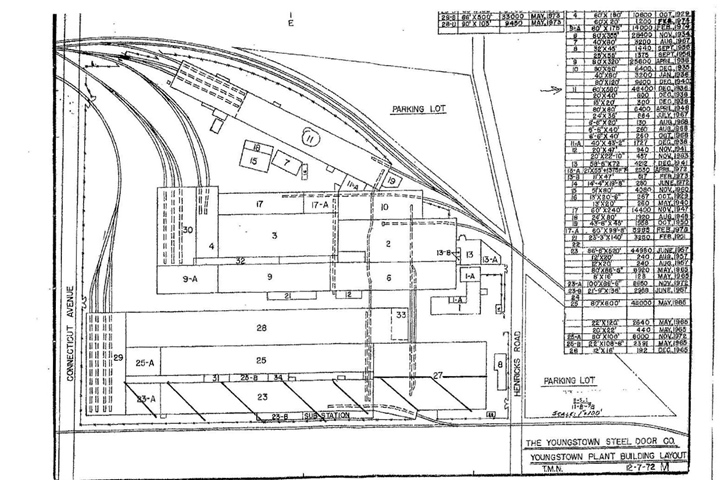

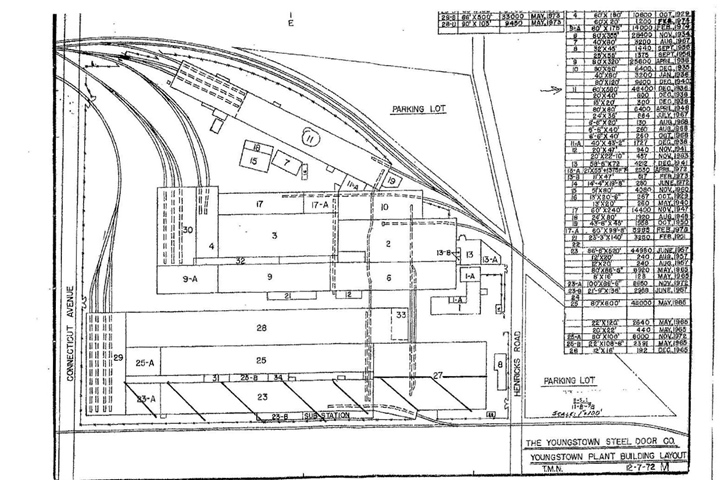

The Youngstown Steel Door Factory:

The factory's address was 3710

Hendricks Road in Youngstown, OH. The factory, as can be seen in

the Google maps satellite photo below, shows that the factory was

located between Hendricks Road to the north and Connecticut Avenue to

the south. The east and west boundaries were railroad tracks.

Image courtesy of Google maps.

This Google Earth image gives an excellent

view of the former Youngstown Steel Door Company plant. Image

added 8-15-2024.

This view is from the northeast corner

looking south down the railroad tracks that run along the east side of

the factory complex. Running west is Hendricks Road. Image

courtesy of Google maps.

This view is looking southeast from the west

side rail tracks and Hendricks Road. Image courtesy of Google

maps.

This view shows the west side of the plant

from Hendricks Road. Image courtesy of Google maps.

This is the southeast corner of the factory

as seen from Connecticut Avenue. Image courtesy of Google maps.

This image shows the southwest corner of the

factory complex from Connecticut Avenue. Image courtesy of Google

maps.

While the Youngstown Steel Door Company went

out of business in 2016, parts of it have been repurposed by several

other companies that have occupied some of the space. Below are

several images of the factory courtesy of Loopnet.com.

There is a lot of space in this high-bay

building.

This view of the same building shows the

high capacity overhead crane in the facility.

It is rare that a plant layout is available

that shows all of the different buildings for a factory complex.

|