|

Kohler

Company in World War Two

Kohler, WI

1873-Present

This page updated 9-27-2022.

An American Auto

Industry in World War Two Special Edition

I never intended to do a page on the Kohler Company, as the main product

lines with which I am familiar are its lines of plumbing fixtures,

porcelain products, and small engines for lawn mowers and garden

tractors. At least those are the ones with which I am most acquainted. I was therefore totally surprised while touring the

submarine USS Lionfish at Battleship Cove in Fall River, MA in June 2019

to find that all of the torpedo tubes in the boat were manufactured by

Kohler. I would never have expected this. Because of this

unusual World War Two product, I have added this page to my website.

The USS Lionfish at Battleship Cove in Fall

River, MA. Author's photo.

The Kohler Company won the Army-Navy "E"

Award twice during World War Two.

Kohler Company in World War Two: The company had $45,957,000

in major contracts during World War Two. The diversity of the

products can be seen in Tables 1 and 2. Artillery shells, airplane

parts and torpedo launch tubes made up 72.7% of Kohler's major

contracts. It is unknown what type of airplane parts the company

made for the Army Air Forces. However, it was Kohler's second

largest dollar product group.

|

Table 1 - Kohler Company Major World War Two Product

Categories |

|

Product |

Customer |

Amount |

Percentage |

|

Shells |

Army |

$22,127,000 |

48.2% |

|

Airplane Parts |

Army |

$5,858,000 |

12.7% |

|

Torpedo Launch Tubes |

Navy |

$5,441,000 |

11.8% |

|

Generators / Power Plants |

Army |

$4,003,000 |

8.7% |

|

Fuzes |

Army |

$2,016,000 |

4.3% |

|

Generators / Power Plants |

Navy |

$916,000 |

2.0% |

|

Total |

|

40,361,000 |

87.7% |

Table 2 - Kohler Company's Major World War Two Contracts

The information below

comes from the "Alphabetical Listing of Major War Supply

Contracts, June 1940 through September 1945." This was

published by the Civilian Production Administration,

Industrial Statistics Division. |

|

Product - Customer |

Contract Amount |

Contract Awarded

|

Completion

Date |

| Fuze Percussion

- Army |

$261,000 |

6-1941 |

6-1942 |

| Shells - Army

|

$1,375,000 |

9-1941 |

3-1944 |

| Ordnance Material

- Army |

$214,000 |

12-1941 |

9-1942 |

| Fuzes - Army |

$257,000 |

1-1942 |

9-1942 |

| Shells - Army

|

$1,029,000 |

1-1942 |

12-1942 |

| Shells - Army

|

$2,761,000 |

1-1942 |

3-1943 |

| Shells - Army

|

$2,975,000 |

2-1942 |

12-1942 |

| Fuzes - Army |

$900,000 |

2-1942 |

1-1943 |

| Generator Sets -

Navy |

$183,000 |

2-1942 |

11-1942 |

| Fuze - Army |

$110,000 |

3-1942 |

7-1942 |

| Fuzes - Army |

$116,000 |

3-1942 |

12-1942 |

| Power Units -

Navy |

$272,000 |

4-1942 |

6-1943 |

| Fuzes - Army |

$372,000 |

4-1942 |

12-1943 |

| Vessel Equipment

- Navy |

$648,000 |

5-1942 |

11-1943 |

| Generators - Army |

$200,000 |

7-1942 |

3-1943 |

| Generators - Navy |

$73,000 |

8-1942 |

3-1943 |

| Generator Sets -

Navy |

$221,000 |

8-1942 |

7-1943 |

| Power Units -

Army |

$1,612,000 |

8-1942 |

11-1943 |

| Cranes - Navy |

$281,000 |

10-1942 |

5-1943 |

| Airplane Parts -

Army |

$5,100,000 |

12-1942 |

3-1944 |

| Airplane Parts -

Army |

$758,000 |

12-1942 |

11-1943 |

| Power Units -

Army |

$613,000 |

2-1943 |

9-1943 |

| Shells 105mm HE -

Army |

$415,000 |

4-1943 |

10-1943 |

| Electric Plants -

Army |

$132,000 |

5-1943 |

6-1944 |

| Electric Plants -

Army |

$51,000 |

5-1943 |

11-1943 |

|

Engine Generator Sets - Navy |

$80,000 |

5-1943 |

3-1944 |

| Power Plants -

Army |

$654,000 |

6-1943 |

5-1944 |

| Electric Plants -

Army |

$368,000 |

7-1943 |

1-1944 |

| Shells 105mm HE -

Army |

$1,598,000 |

7-1943 |

6-1944 |

|

Shells 105mm HE - Army |

$1,436,000 |

9-1943 |

3-1944 |

| Elec Generator

Sets - Army |

$221,000 |

10-1943 |

12-1943 |

| Elec Generator

Sets - Navy |

$409,000 |

11-1943 |

12-1944 |

| Generator Sets -

Army |

$103,000 |

11-1943 |

4-1944 |

| Power Units M121A

- Army |

$251,000 |

11-1943 |

7-1944 |

| Elec Generator

Sets - Navy |

$160,000 |

12-1943 |

8-1944 |

| Shells 105mm HE -

Army |

$787,000 |

2-1944 |

10-1944 |

| Trpedo Launch

Tubes - Navy |

$5,441,000 |

3-1944 |

8-1945 |

| Airplane Valves -

Navy |

$63,000 |

4-1944 |

12-1944 |

| Shells HE M42A1 -

Army |

$1,368,000 |

4-1944 |

12-1944 |

| Mobile Laundry

Pts - Army |

$139,000 |

6-1944 |

4-1945 |

| Mobile Laundry

Pts - Army |

$431,000 |

6-1944 |

6-1945 |

| Shell Parts 105mm

M1 - Army |

$1,200,000 |

6-1944 |

12-1944 |

| Shells Renovation

105mm - Army |

$60,000 |

6-1944 |

12-1944 |

| Shells 105mm HE

M1 |

$1,947,000 |

6-1944 |

3-1945 |

| Power Unit Parts

1M21A - Army |

$233,000 |

8-1944 |

4-1945 |

| Elec Generator

Parts - Army |

$362,000 |

9-1944 |

9-1945 |

| Engine Bearing

Shells - Navy |

$340,000 |

9-1944 |

1-1945 |

| Packing Services

- Army |

$405,000 |

11-1944 |

11-45 |

| Rotating Bands -

Army |

$886,000 |

11-1944 |

5-1945 |

| Shell Parts 105mm

M1 - Army |

$3,959,000 |

11-1944 |

6-1945 |

| Shell Parts 105mm

- Army |

$1,277,000 |

1-1945 |

2-1946 |

| Elec Generator

Parts - Army |

$166,000 |

1-1945 |

7-1945 |

| Mobile Laundry

Parts - Army |

$300,000 |

1-1945 |

7-1945 |

| Eng Generator

Sets - Army |

$193,000 |

3-1945 |

6-1945 |

| Elec Generator

Sets - Army |

$218,000 |

4-1945 |

9-1945 |

| Mobile Laundry

Parts - Army |

$53,000 |

5-1945 |

2-1946 |

| Total |

$45,957,000 |

|

|

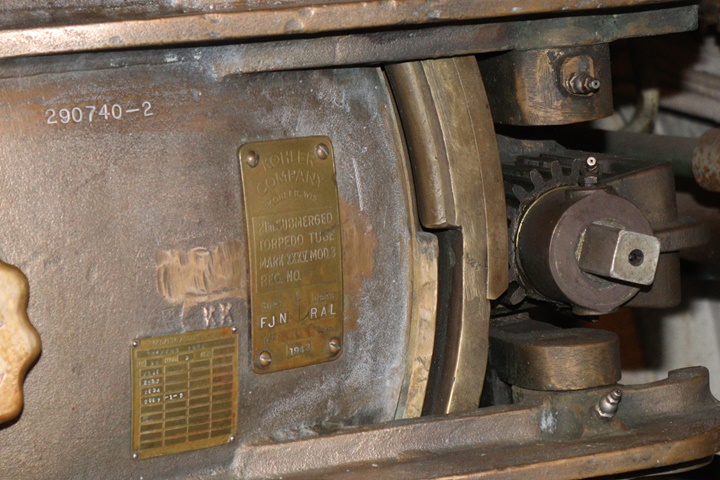

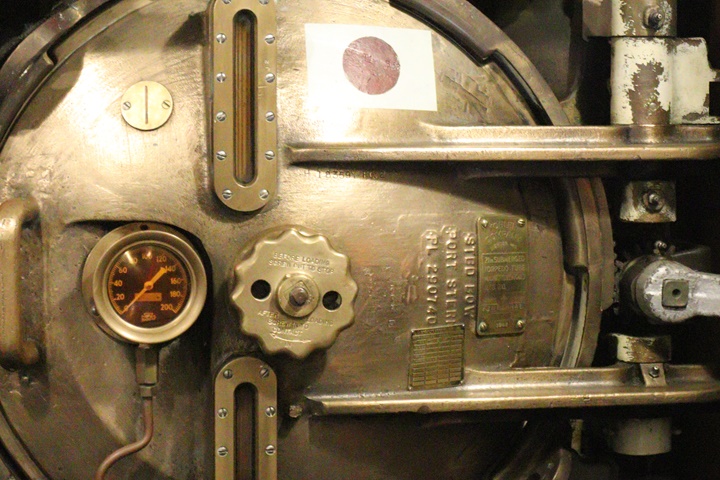

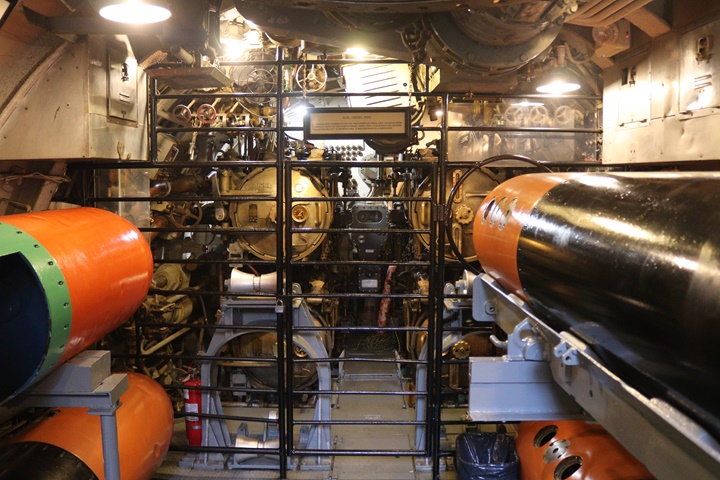

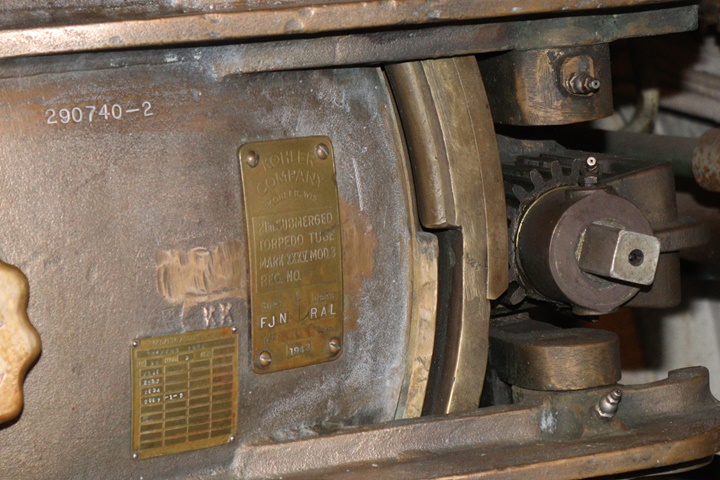

Torpedo Launch Tubes: The company

was awarded a contract by the U.S. Navy for $5,441,000 in March 1944 to

produce torpedo tubes for submarines.

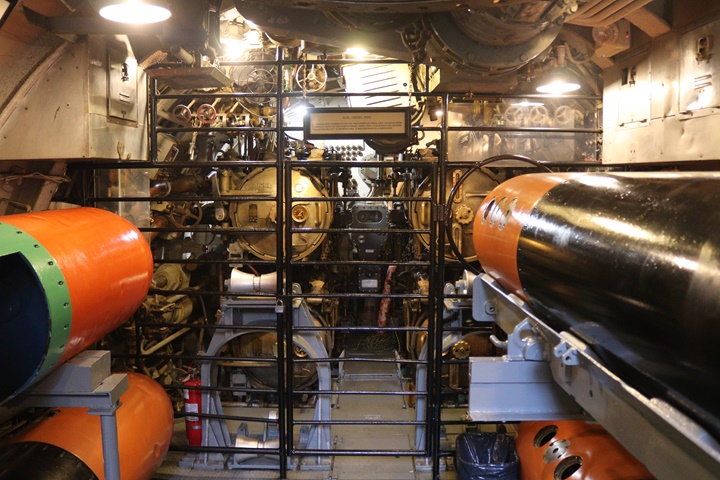

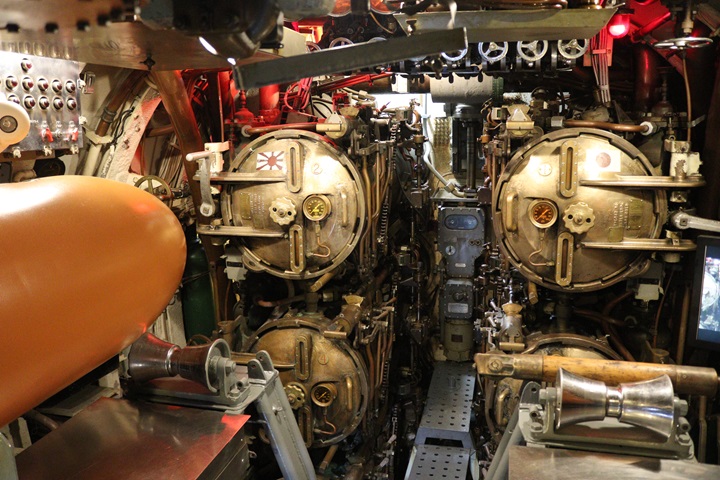

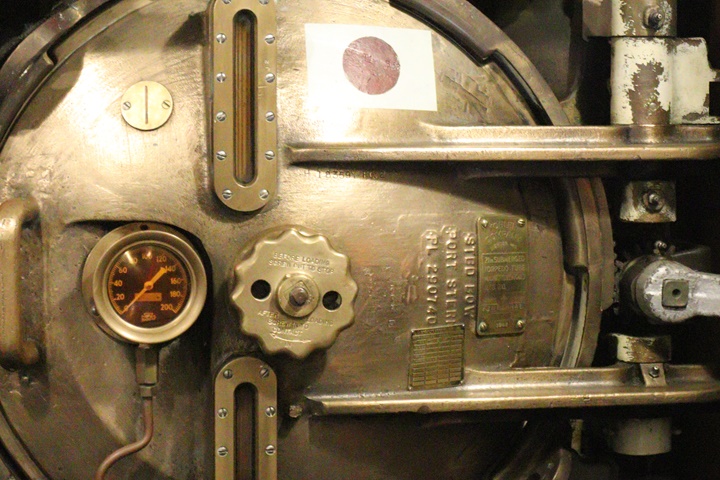

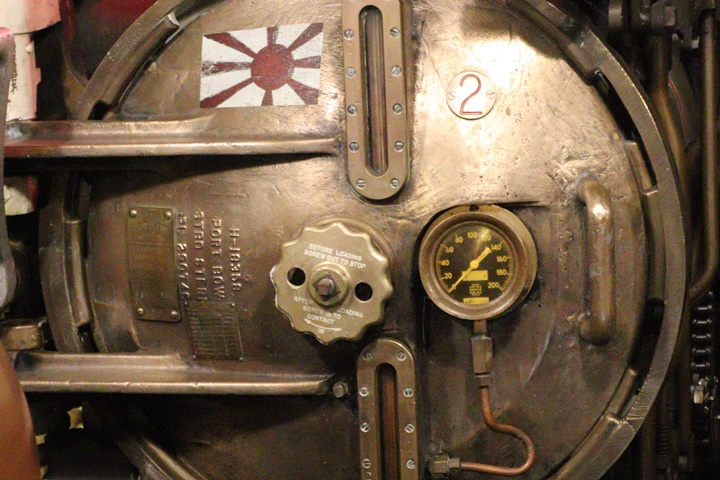

USS Lionfish Stern Torpedo Room:

The self-guided tour of the USS Lionfish

starts at the front of the boat and finishes at the aft torpedo room.

Author's photo.

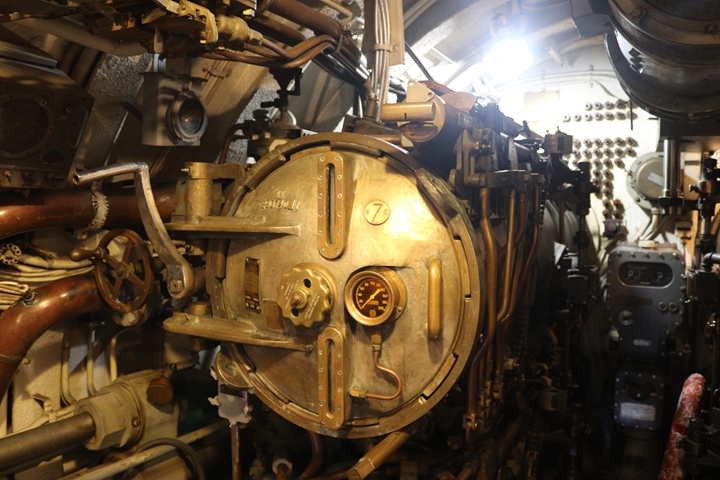

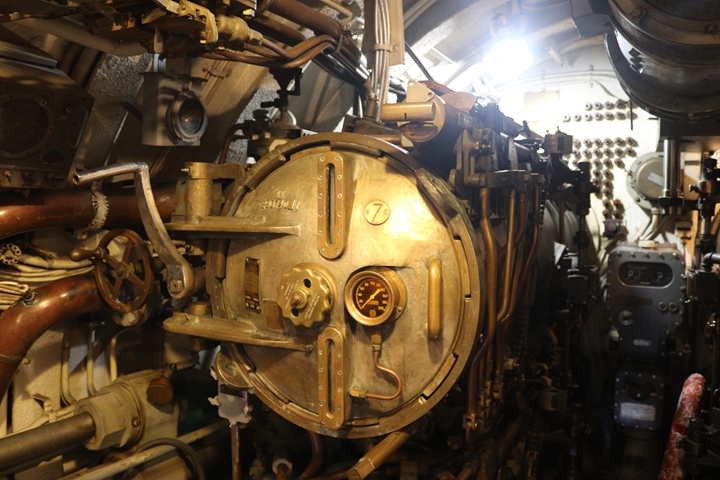

In looking at the torpedo tubes, I noticed

that they had manufacturers tags on them. I have never noticed

this on any of the other submarines I had previously toured.

Author's photo.

I was totally surprised to find that the maker of

porcelain plumbing products had built torpedo tubes to help win World

War Two. How cool is this? Author's photo.

Author's photo.

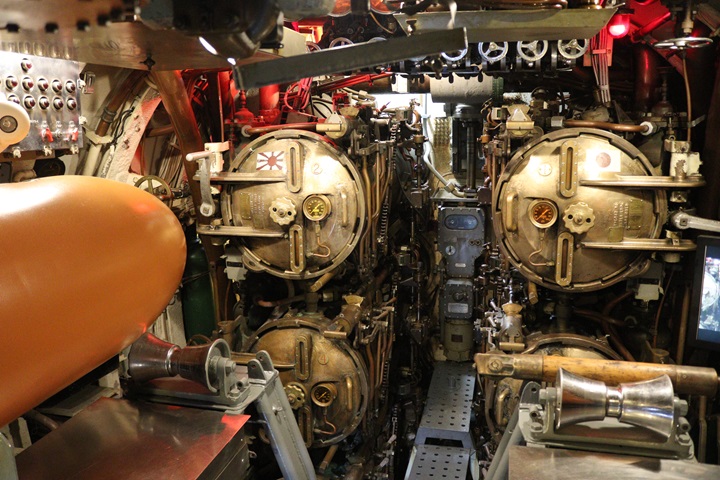

All four aft torpedo tubes were built by

Kohler. Author's photo.

The torpedo tubes are all brass castings

Author's photo.

Author's photo.

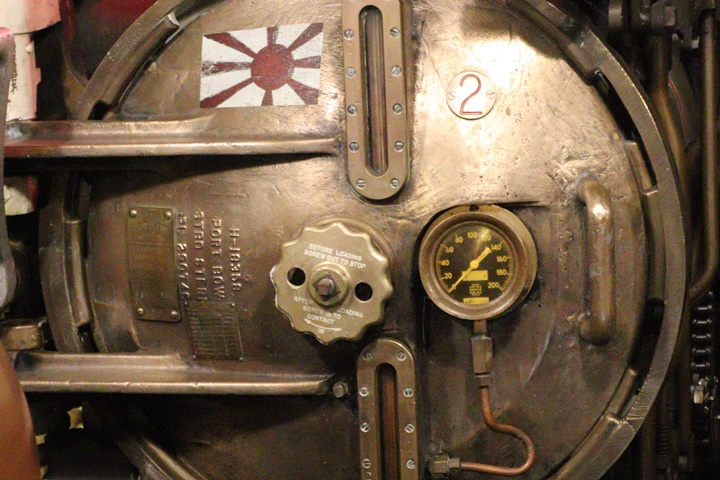

USS Lionfish Bow Torpedo Room:

I finished the tour. Then I went

back to the front of the boat and down into the bow torpedo

room to see what I had missed. I had overlooked the Kohler data plates

on my first pass because there is more distance between where I was able

to view the tubes than at the stern tubes. These were also

Kohler-cast torpedo tubes. The bow has six tubes but only four can

be seen. Author's photo.

The torpedo tubes can be used either in the

bow or the stern. They just go on opposite sides of the boat.

Author's photo.

Author's photo.

It is unknown how many submarines were

outfitted with the Kohler torpedo tubes or how many were built.

Electric Boat Company of Groton, CT cast its own torpedo tubes for the

submarines it manufactured.

Workers at the Kohler plant are working on a

mold with a torpedo tube in it.

Shells: Artillery and tank gun

shells were the largest category of war material the company produced

during World War Two. This category comprised 48.2% of the

Kohler's World War Two output. Many of the contracts were for

unidentified types of shells. However, several contacts

specifically name the shell type.

Kohler had at least six contracts for 105mm

high explosive shells. One application was for use in the

M4A3(105) HVSS Sherman tank. Author's photo added 9-27-2022.

Author's photo added 9-27-2022.

In April 1944 Kohler was awarded a $1,368,000

contract for the production of 76mm M42A1 shells. The company

produced the shell portion only, which was what went down range to the

target. These shells were for use in the Buick M18 Hellcat tank

destroyer. This M18 was on display at the Buick Museum in Flint,

MI in 2015. Author's photo added 9-27-2022.

This image shows M42A1 shell casings in the

ready storage area of the M18. Kohler did not make the shell

casings. Author's photo added 9-27-2022.

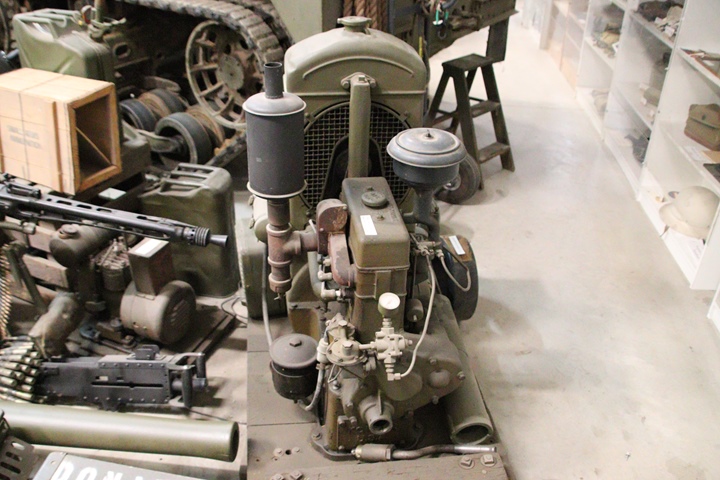

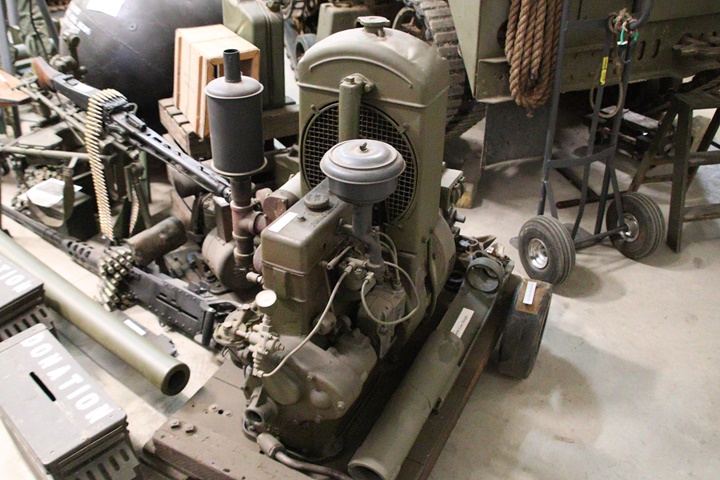

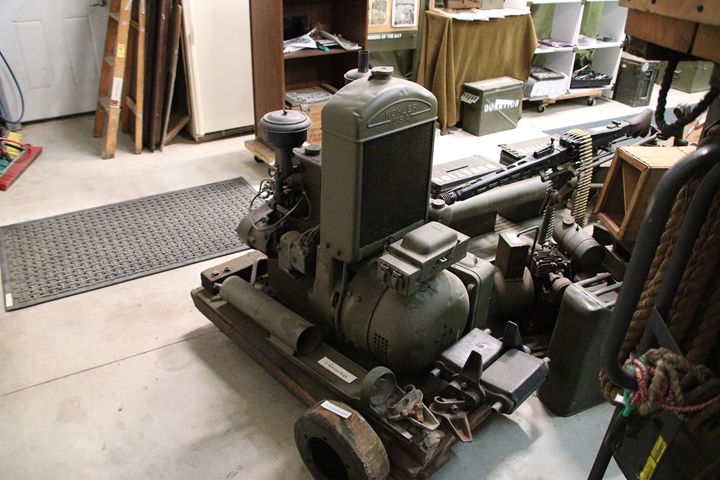

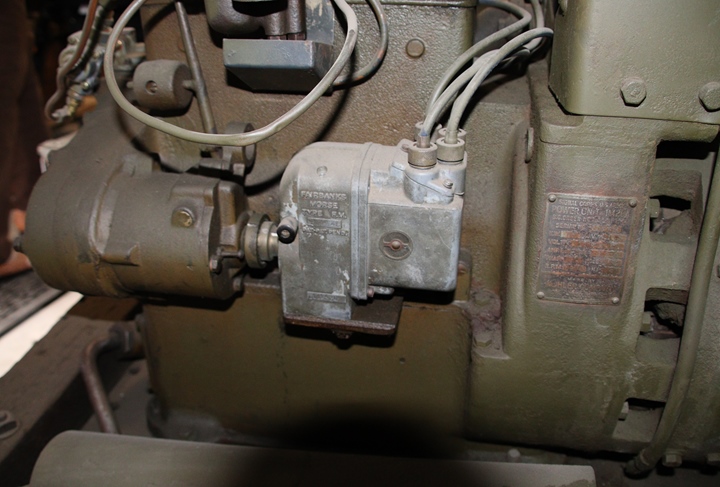

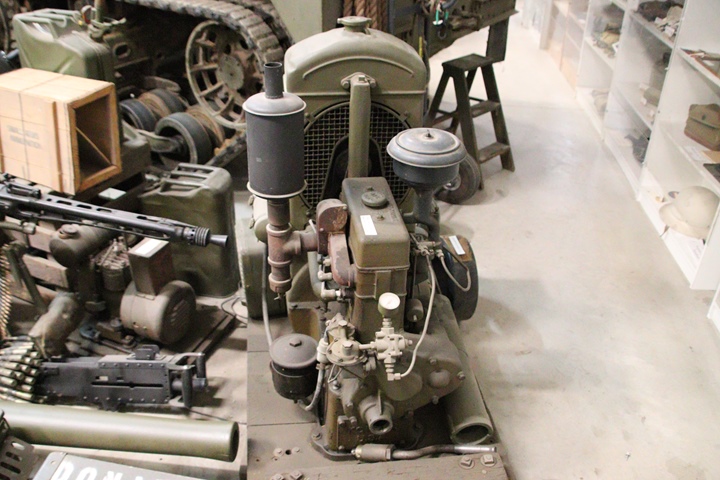

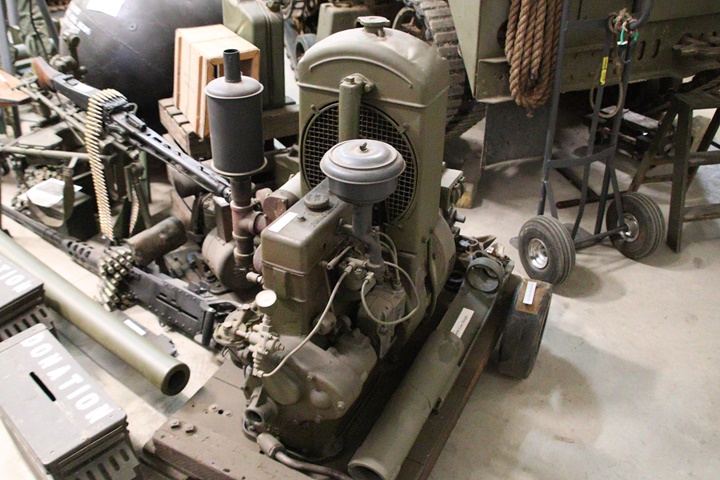

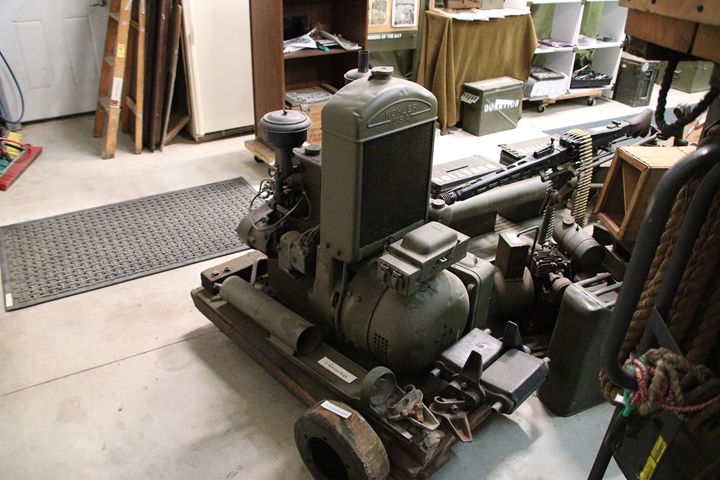

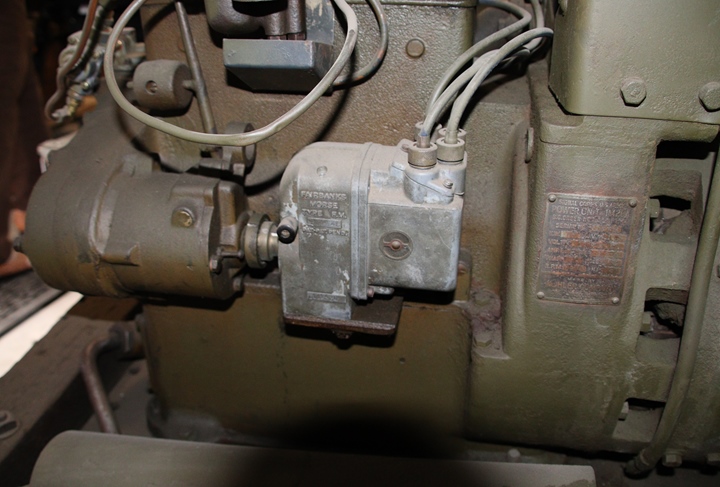

Electric Generators / Power Plants:

This is a Kohler Model 1M21A 115VAC

liquid-cooled power generator on display at the Roberts Armory in

Rochelle, IL. The U.S. Army Signal Corps designation for it was

PU-41/G. Author's photo added 6-2-2021.

Author's photo added 6-2-2021.

Author's photo added 6-2-2021.

Author's photo added 6-2-2021.

Author's photo added 6-2-2021.

The serial number is 87447 and the engine

runs at 1,200 RPM. Author's photo added 6-2-2021.

Plumbing Supplies: During World

War Two hundreds of military bases and installations were built in the

United States. All of the barracks, along with many of the other

buildings on these bases, needed plumbing fixtures, sinks, commodes, and

urinals. Kohler supplied these important products to these bases.

This is the sole survivor of originally

more than 1,000 barrack that were built at Fort Knox, KY during World War Two.

It is now on display the General George Patton Museum of Leadership at

Fort Knox. Author's photo added 9-27-2022.

Kohler Company was one of many companies

that supplied plumbing for the latrines. There was too much

business for any one company to handle. Author's photo added

9-27-2022.

Barracks very similar to this were built at

over 1,000 Army and Army Air Forces bases during World War Two.

Author's photo added 9-27-2022.

Barracks like these were still in use at

Fort Custer, MI, Fort Jackson, SC, and Fort Gordon, GA in the 1970s.

I know because I stayed in several of them. The ones at Fort

Jackson and Fort Gordon were painted white. I do not remember

there being two doors to the barracks at these two locations. I

think there was only one. Author's photo added 9-27-2022.

Fort Knox had nice floors. Fort

Jackson and Fort Gordon had linoleum floors. I think Fort Custer

had unfinished floors. The barracks there were rather rough.

Author's photo added 9-27-2022.

The latrines inside the Fort Knox barracks

were basic during World War Two. Author's photo added 9-27-2022.

These were the sinks for the third part of

the three S's in the morning. Author's photo added 9-27-2022.

This was the shower area for the second of

the three S's in the morning. Author's photo added 9-27-2022.

There was not a lot of privacy the

soldiers at Fort Knox when they did the first of the three S's in the

morning. At Fort Jackson, our latrine was set up different from

this. The commodes had stalls, but no doors. Author's photo

added 9-27-2022.

Author's photo added 9-27-2022.

For those who had a father or grandfather at

Fort Knox during World War Two, the last several photos illustrate the

total lack of privacy he had while in the latrine.

When the all-volunteer Army was formed,

barracks like this had to go away. Today, the recruits live in

college style dormitory buildings.

|