|

Haynes

Automotive Company

Haynes Stellite Company During World War Two

Kokomo, IN

1912-Current

This page added 12-23-2023.

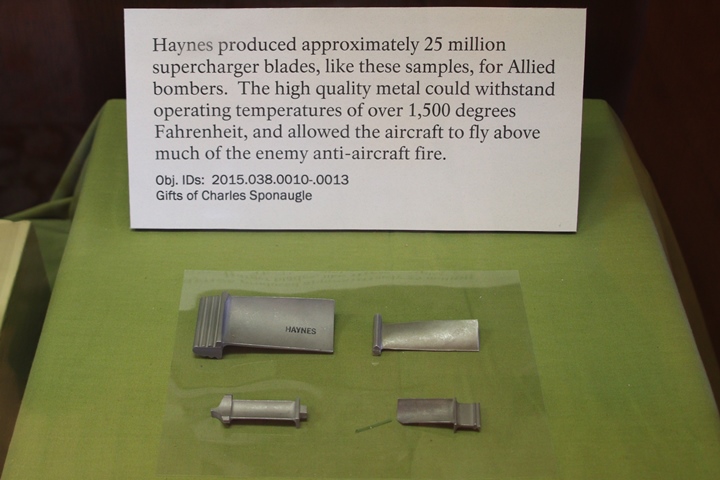

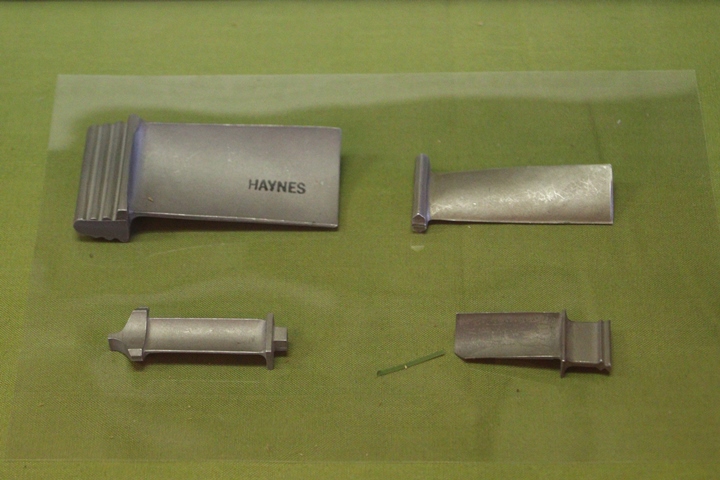

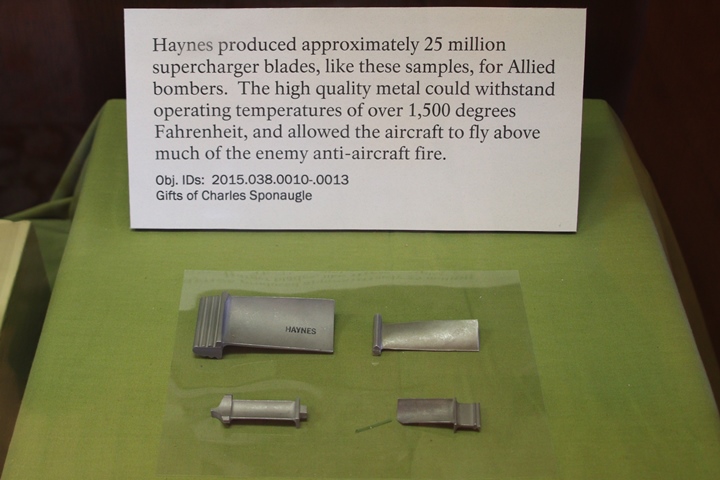

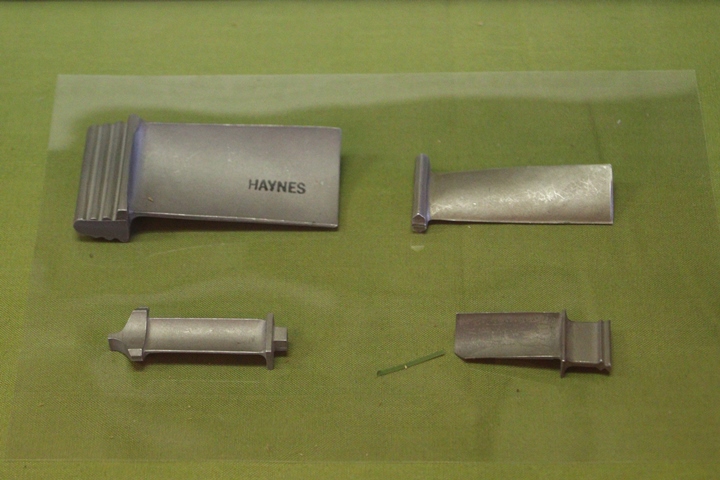

This display of four turbo supercharger blades, or buckets, was a total

surprise to me when I visited the Howard County Historical Museum in

February 2023. Until I saw this display, I was unaware of the

existence of the Haynes Stellite Company in Kokomo, IN, and the

company's importance in the production of the turbo supercharger blades.

In spite of their

small size, Haynes Stellite turbo supercharger buckets were a very

important product in helping to win World War Two.

But first we will take a deeper look at Elwood Haynes, who invented Stellite,

and his relationship with Kokomo, IN.

Elwood Haynes is to Kokomo, IN what R.E. Olds is

to Lansing, MI, and Henry Ford is to Detroit, MI. All three

started automobile companies in each of their respective cities.

Today, each of those cities still have auto companies as the result of these automotive pioneers. R.E. Olds was responsible

for Oldsmobile and the Reo Auto Car Company in Lansing. While both

Oldsmobile and Reo have gone out of business, Lansing has two relatively

new General Motors assembly plants in the area. These plants are

the result of R.E. Olds bringing Oldsmobile to Lansing. Both of

the new assembly plants were built while other cities were losing their

GM plants.

The Ford Motor Car Company still has a huge

presence in the Detroit area. Henry Ford's legacy still lives on

in southeast Michigan and is responsible for many jobs in the area.

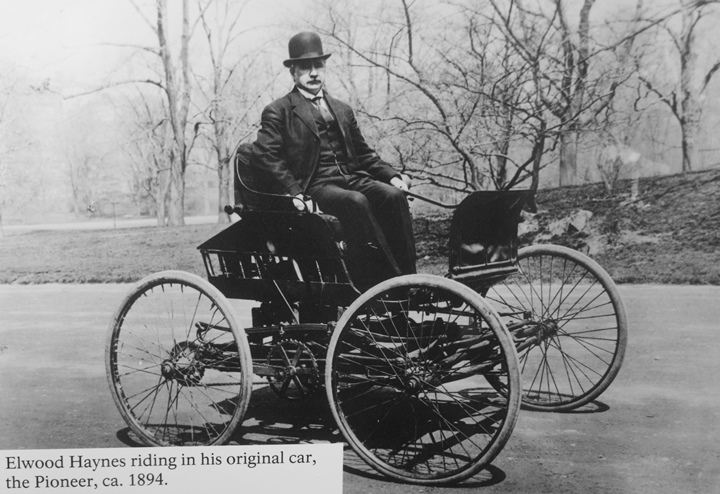

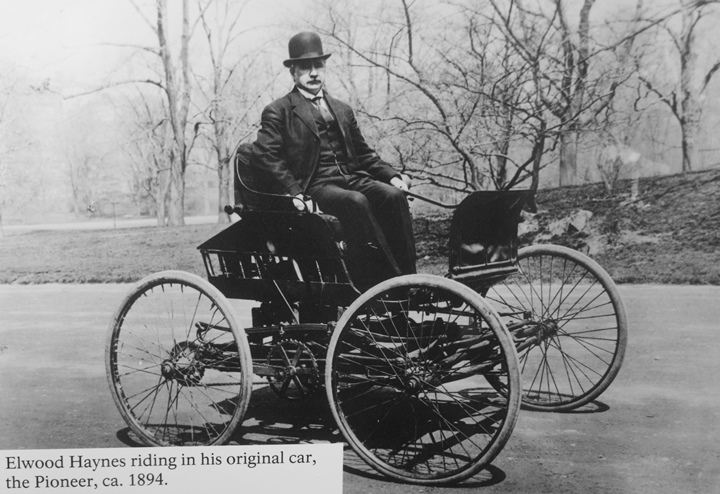

Elwood Haynes was the second person in the

United States to design and drive an automobile. He did this in

Kokomo, IN in 1894. In 1895, Elwood Haynes and Elmer Apperson

began the Haynes-Apperson Company with the goal of producing fifty

vehicles in 1895. This was the first company in the United States

to begin production of automobiles. In 1901, Mr. Apperson left the

company to begin a new automobile company with his brother in Kokomo,

the Apperson Brothers Automobile Company. Mr. Haynes continued on

with the original company and in 1903 renamed his company the Haynes Automotive Company.

The company continued until 1925 when it went out of business.

However, Elwood Haynes' legacy and his

long term impact on Kokomo, IN does not end with the closing of his

automobile company. It opened a new chapter in 1930 with the

arrival of the Chrysler transmission plant that occupied the former

Haynes Automobile Company factory on Home Avenue. Chrysler and the

various companies that have purchased the brand name have not only stayed in

Kokomo, but built new factories in the area. Currently, a joint

effort between Stellantis and Samsung SDI is building an electric vehicle battery plant

that will employ 1,400 workers just north of Kokomo. The demise of the Haynes

Automobile Company in 1925 allowed for a state-of-the-art automotive

electric vehicle battery plant to be built in the Kokomo area 100 years

later.

.

This image of Mr. Haynes is courtesy of the

Howard County Museum, Kokomo, IN.

The "Pioneer" was Elwood Haynes' idea.

However, it was a local mechanic by the name of Elmer Apperson that

owned the Riverside Machine Shop in Kokomo that built the vehicle.

On July 10, 1894, the "Pioneer" took a trip down Pumpkinville

Pike in Kokomo. This is a replica that was on display at the

former Kokomo Automobile Museum. The original was given to the

Smithsonian Museum by Mr. Haynes. Author's photo.

More information on the Haynes Automobile

Company is in the link at the top of this page.

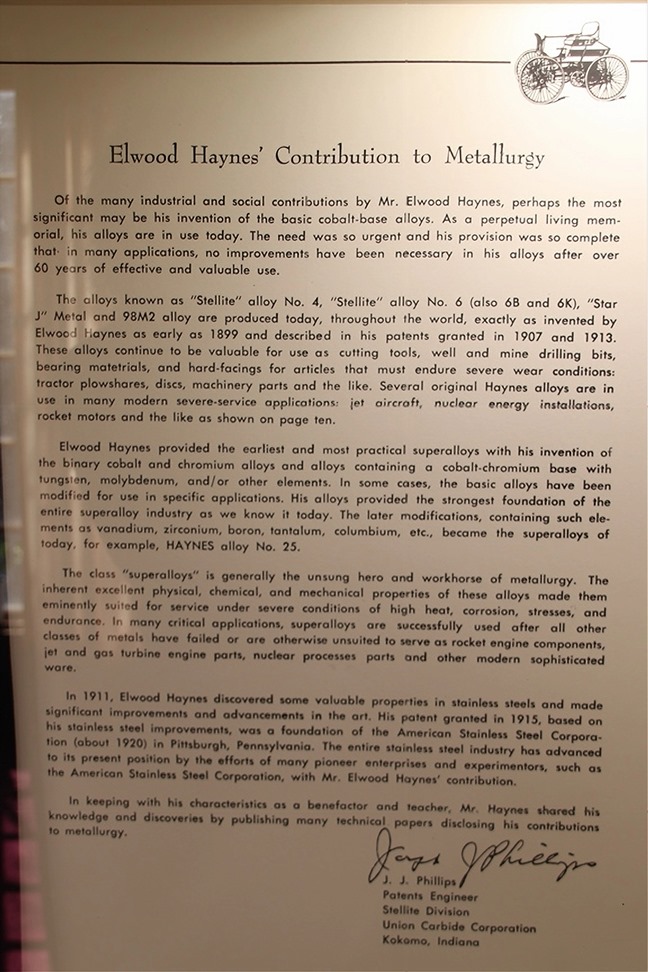

Mr. Haynes

was also very interested in metallurgy. After much experimentation

he

developed several new metals. These led to the creation of the Haynes Stellite Company in Kokomo in 1912. While many companies in Kokomo

have come and gone, Haynes International, the name of the former Haynes

Stellite Company, is still in Kokomo. Unlike many companies

described on this website, it has not moved out of its place of origin

for the cheap labor of the south. It has stayed in Kokomo and

built new plants, a world headquarters, and research center in the city.

Haynes International needs to be recognized for being a good Kokomo

corporate citizen. This is the second of Elwood Haynes' continuing

presence in the area.

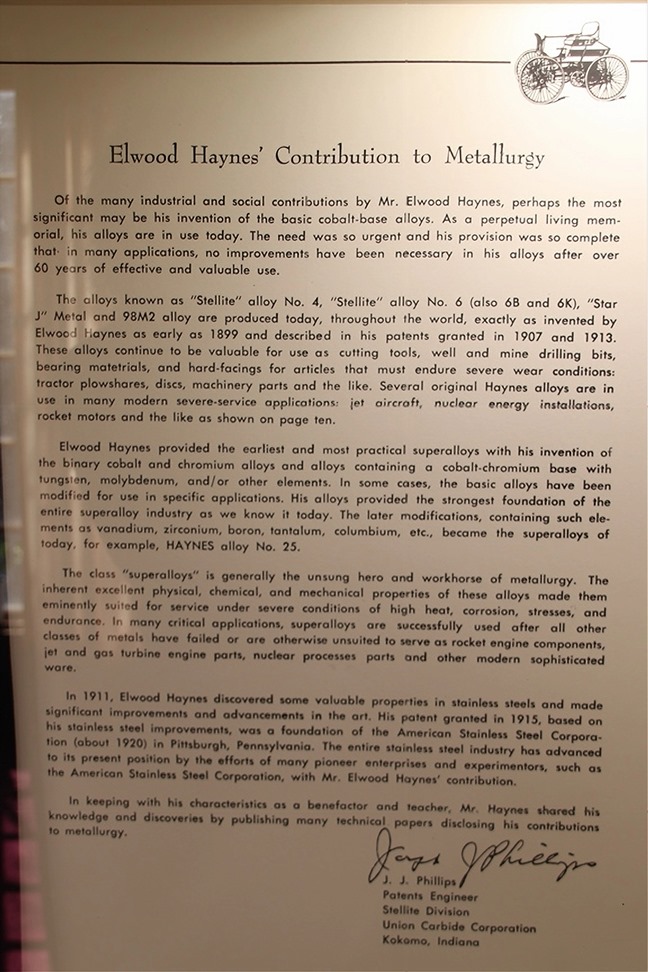

This description of Mr. Haynes' work in

metallurgy is from the Elwood Haynes Museum.

This is the former Elwood Haynes mansion in

Kokomo, IN. Currently, it is a very nice museum that tells the story

of Elwood Haynes. I have found that Kokomo is very cognizant of

its history. This is one of two excellent local history museums in

Kokomo. Author's photo.

Author's photo.

In the northeast corner of the intersection

of South Goyer Road and E Blvd. is a marker commemorating Mr. Haynes'

first automobile ride in the "Pioneer." It is my understanding

that one of these two streets used to be Pumpkinville Pike. Image

courtesy of Google Maps.

Author's photo.

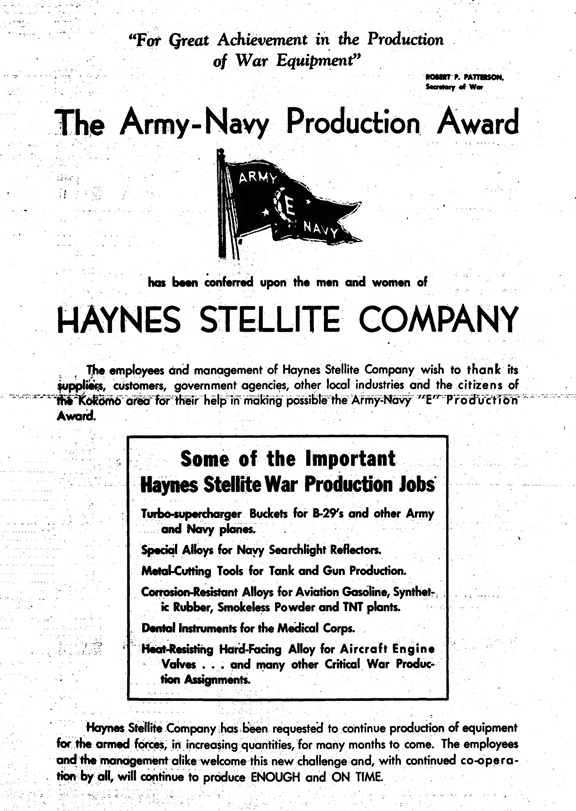

The Haynes Stellite Company won the

Army-Navy "E" award twice during World War Two.

The company won the first award in February 1945.

It won the second award at the end of the war in August 1945

Haynes Stellite Company World War Two

Products: The most well-known product the company made for the

war effort was the 25 million turbo supercharger buckets it produced.

However, further research shows the company's alloys were used in a wide

variety of products for the war effort.

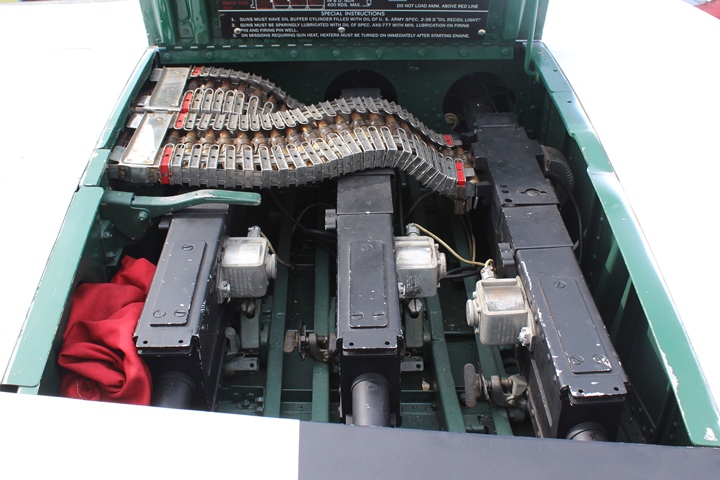

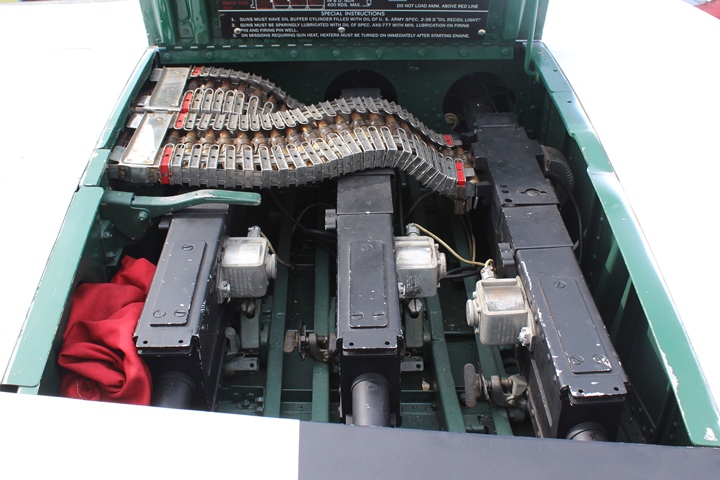

Haynes Stellite Company had $4,512,000

in major contracts during the war. The largest contract was with

army ordnance for $3,797,000 for M2 gun part castings. This was

84% of the company's major contracts. The three other army

ordnance contracts also appear to be M2 gun casting contracts. The

company began making the inner linings for M2 .50 caliber machine guns

for aircraft use. Previous linings were burning out during operation, and

it was not possible to change barrels in flight. Stellite inner

linings from Haynes were the solution. The company also provided

linings for M2 machine guns for both the Korean and Vietnam wars.

The company had four contracts with the Navy

for cutting tools totaling $510,000 or 11% of total contracts.

Table 1 - Haynes Stellite

Company's

Major World War Two Contracts

The information below

comes from the "Alphabetical Listing of Major War Supply

Contracts, June 1940 through September 1945." This was

published by the Civilian Production Administration, Industrial

Statistics Division. |

|

Product - Customer |

Contract Number |

Contract Amount |

Contract Awarded

Date |

Completion

Date |

| Tools - Navy |

NOS-891564 |

$60,000 |

9-1941 |

3-1942 |

| Tools - Navy |

NOS-12554 |

$250,000 |

9-1942 |

10-1943 |

| Cutting Tools -

Navy |

NXS-36618 |

$150,000 |

9-1943 |

9-1944 |

| Metal Castings -

Army Ordnance |

19058-ORD-2824 |

$105,000 |

9-1944 |

2-1945 |

| Steel Cutting

Tools - Navy |

XSX-80125 |

$50,000 |

9-1944 |

9-1945 |

| Gun Part Castings

M2 - Army Ordnance |

33008-ORD-1677 |

$3,797,000 |

12-1944 |

12-1945 |

| Liner Castings-

Army Ordnance |

11070-ORD-3988 |

$100,000 |

7-1945 |

12-1945 |

| Total |

|

$4,512,000 |

|

|

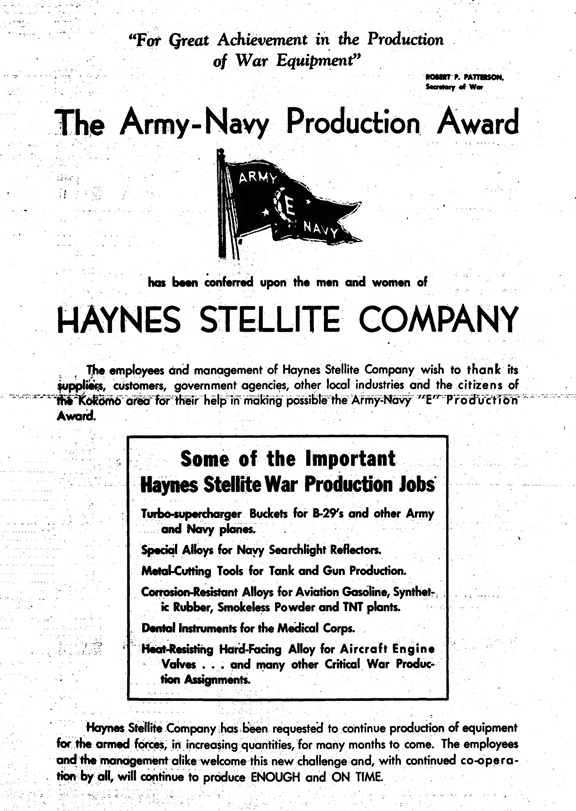

This advertisement was placed in the

February 15, 1945, edition of the Kokomo Tribune announcing the company's

winning of the Army-Navy "E" award. The listing of war production

jobs allows more insight into how the company helped win World War Two.

The first item listed is for turbo

supercharger buckets for Army and Navy Aircraft. This product will

be examined in detail next.

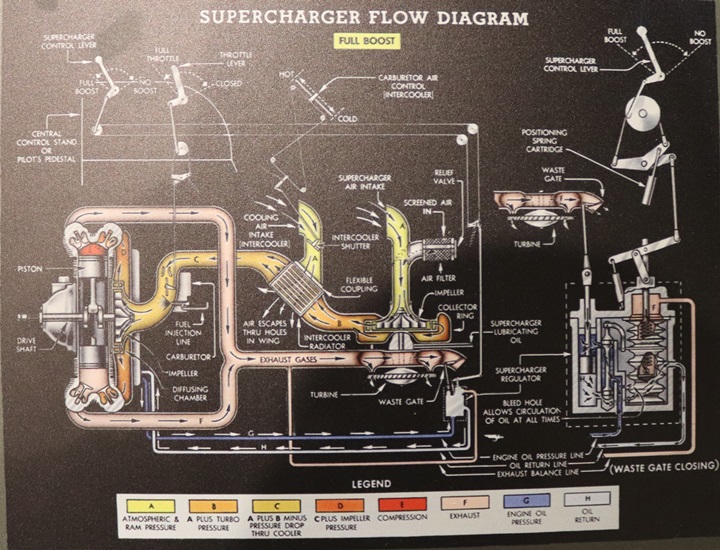

The Haynes Stellite Company and the General Electric Turbo Supercharger:

Word Use: During World War Two, the exhaust driven devices

that delivered increased amounts of air to American aircraft engines

were called turbo superchargers. Current terminology for these

devices is turbo chargers or just plain turbos. This website will

use the World War Two nomenclature for the device.

The term turbo is added to the supercharger to

distinguish it from a supercharger. Superchargers were integral to

the aircraft engine itself and were gear driven by the engine.

Turbo superchargers were not located in the engine but in the exhaust

system. Hot exhaust gas from the engine drove the turbine that

caused the turbo supercharger to spin. The turbines were able to

spin due to the hot exhaust gas hitting the Haynes Stellite buckets, or

blades, in the turbine wheel.

The General Electric turbo supercharger was an

important component in five USAAF aircraft and two U.S. Navy aircraft.

It was used in the USAAF's B-29, as noted in the advertisement above

along with the B-17, B-24, P-38, and P-47. The U.S. Navy

used it in the PB4Y-1.

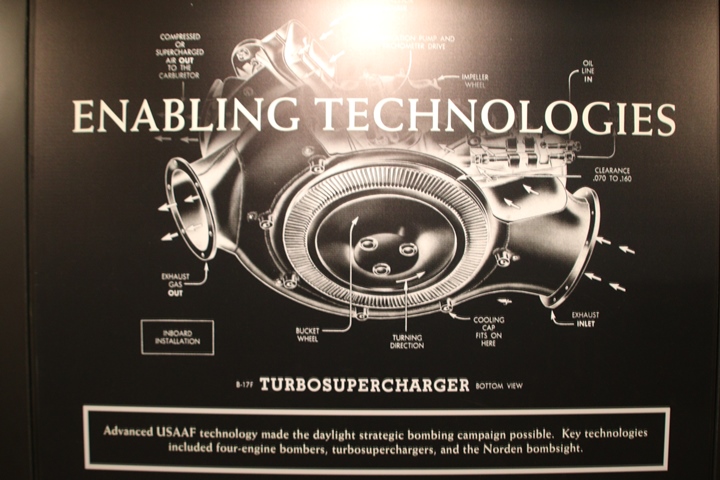

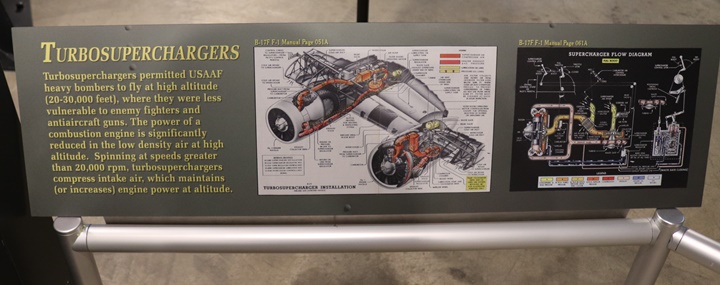

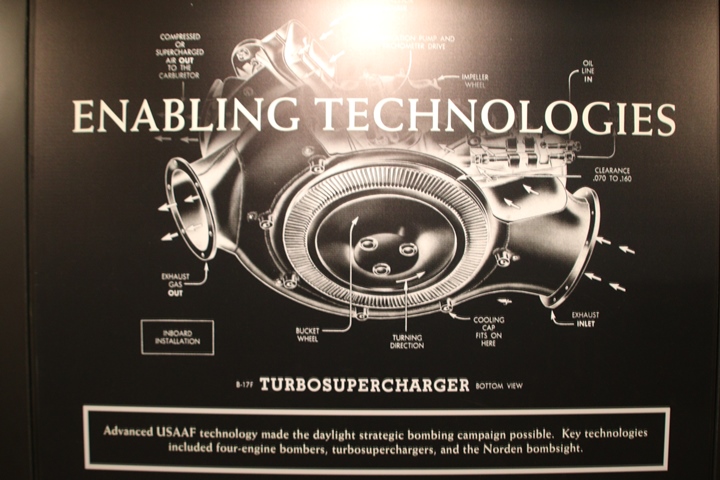

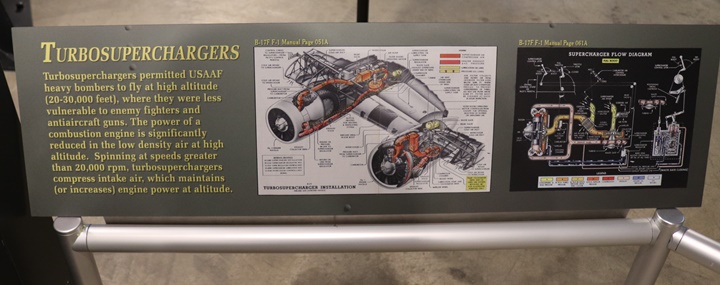

This information board is part of the

displays surrounding the B-17F "Memphis Belle" at the National Museum of

the United States Air Force in Riverside, OH. The information

board notes that the turbo supercharger was a key technology for

daylight strategic bombing along with four-engine bombers and the Norden

bombsight. This places the turbo supercharger in a rather

exclusive club. Author's photo.

The B-17 series aircraft used by the Army

Air Forces during World War Two all came with four GE turbo

superchargers, one for each engine. Author's photo.

The turbo superchargers can be seen here in

the "Memphis Belle." The nearest one is located under the outboard

engine. The exhaust pipe can be seen running along the bottom of

the nacelle to the turbo supercharger. On the inboard engine, the

exhaust pipe is routed beside the landing gear and then through the

nacelle to the turbo supercharger. Author's photo.

This image is a closer view of the B-17's interior engine turbo supercharger

configuration. Not

counting spares, 50,768 turbo superchargers were needed for B-17 production

during World War Two. Author's photo.

The left hand section of the information

board at the "Memphis Belle" gives a concise explanation of why the

turbo supercharger was important and how it worked. Author's photo.

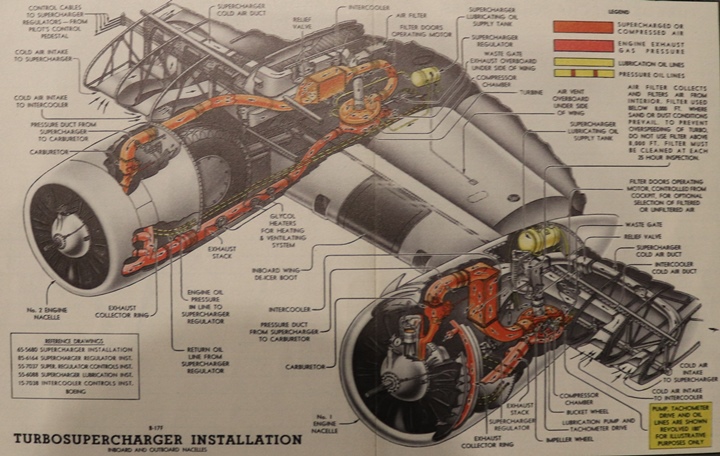

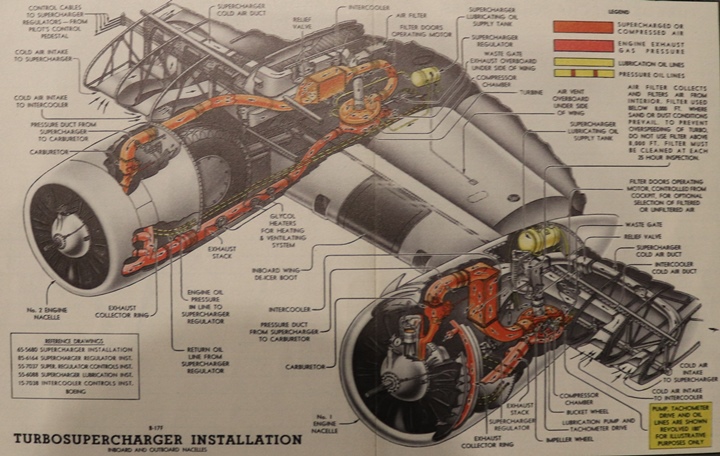

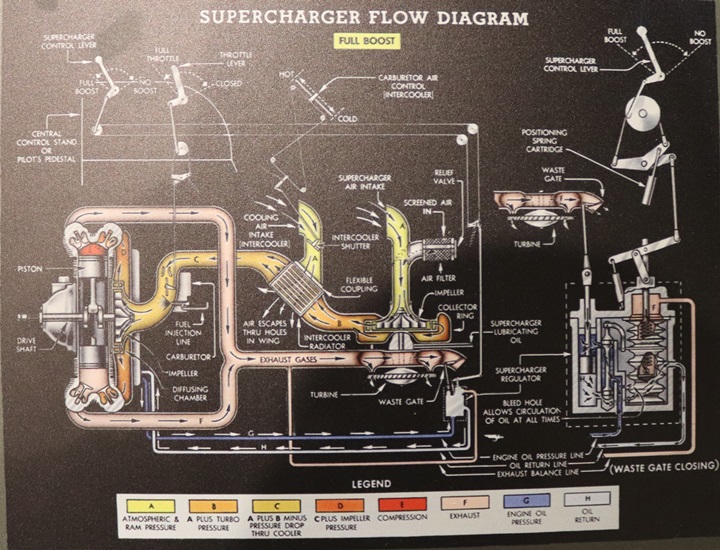

This display shows the routing of the

exhaust gases in red, running from the engine exhaust to the turbo

supercharger along the bottom of the engine nacelle. The

compressed air runs from the top of the turbo supercharger in

orange, which is nearly indistinguishable from the red, to the engine

intakes. Author's photo.

This image shows the side cut-away view of

the system. Author's photo.

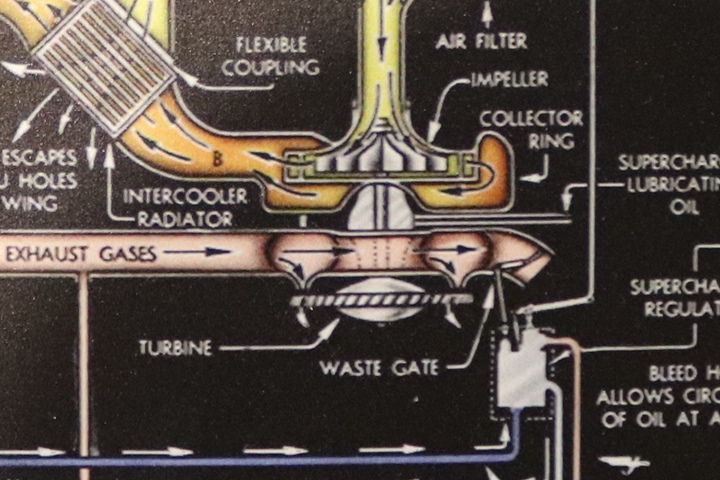

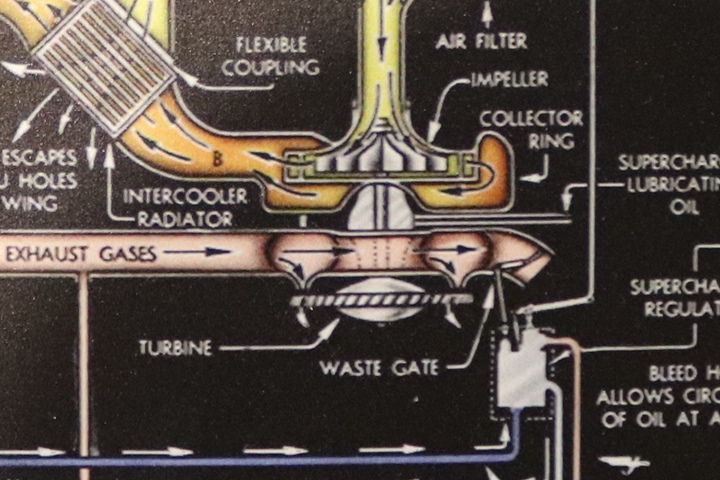

The enlargement of the above image shows the

area of interest for the Haynes Stellite turbine bucket or turbine

blade. Note that the exhaust can flow down the exhaust pipe and

bypass striking the turbine if the waste gate is completely open.

As the waste gate closes while the aircraft climbs in altitude, hot exhaust

air is then directed to the Haynes Stellite turbine buckets, causing

the turbine to spin, which allows the impeller to send compressed air to

the engine. Author's photo.

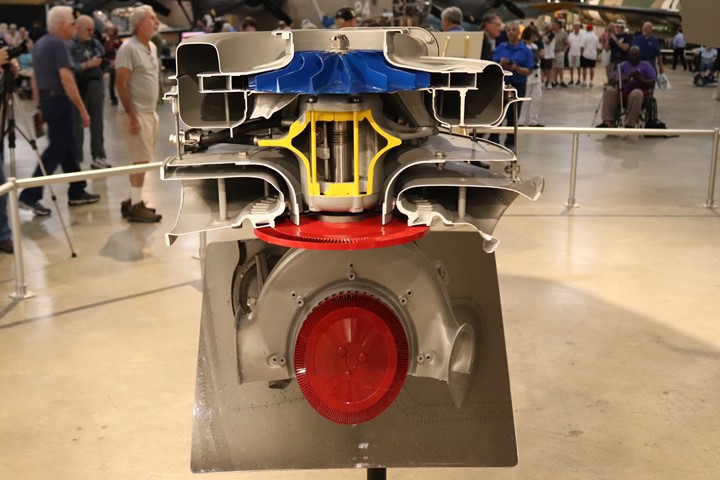

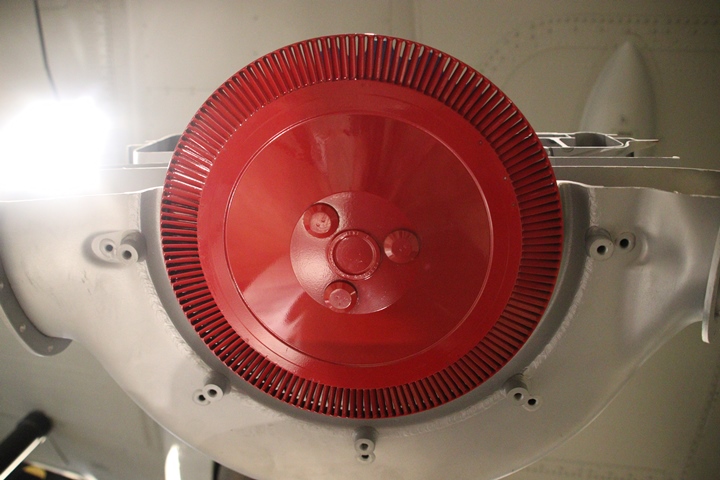

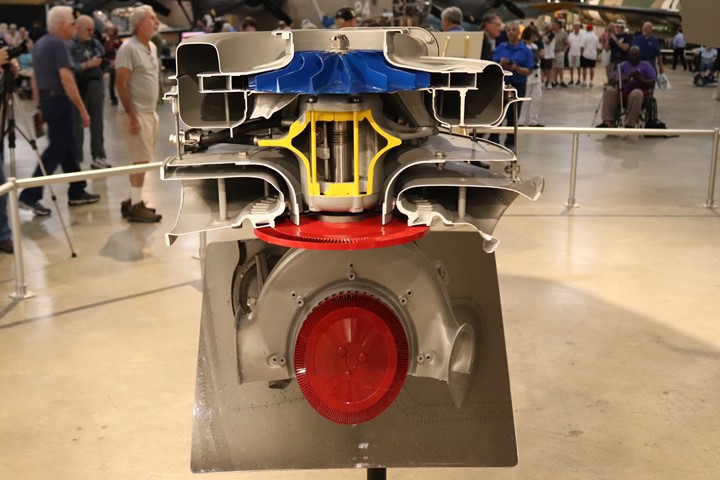

The National Museum of the United States Air

Force has the best display I have found on the GE turbo supercharger.

It has the information boards shown previously, and it also has this

excellent cut-away of an actual turbo supercharger. The museum has

installed a mirror underneath the turbine which helps explain

the function and importance of the Haynes Stellite turbine buckets.

The red paint identifies the hot turbine while blue indentifies the cold

impeller in the unit. Author's photo.

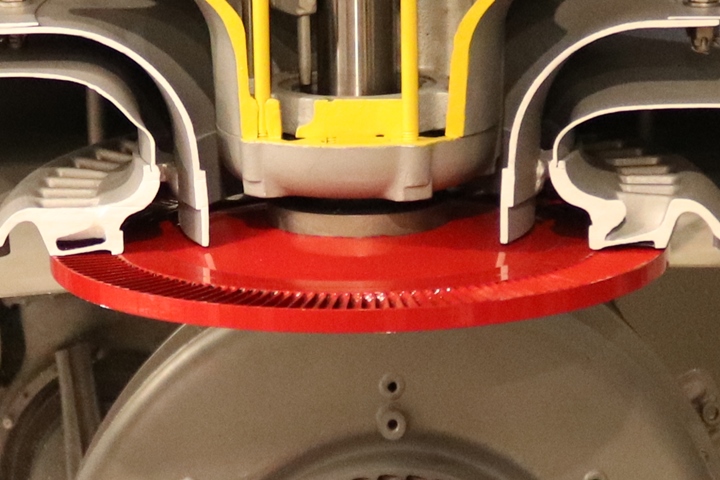

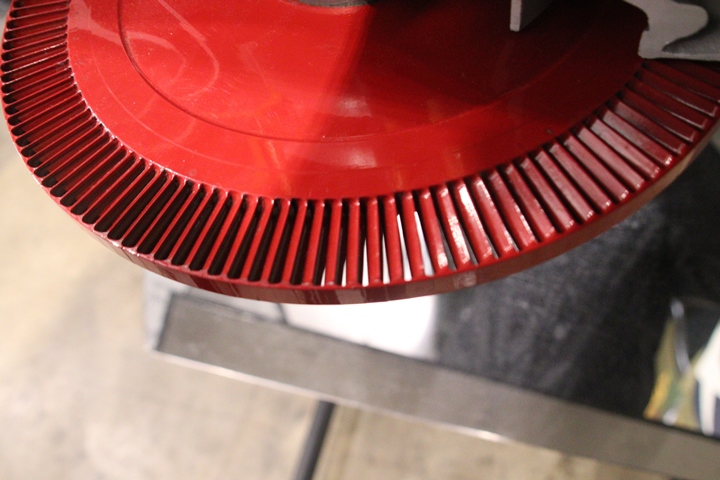

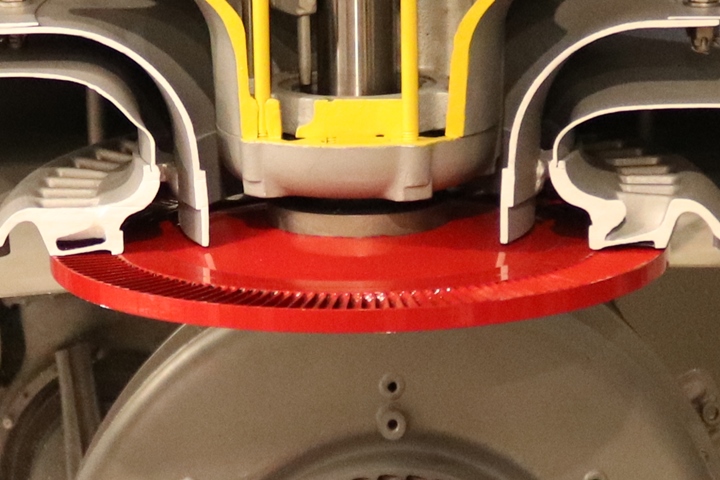

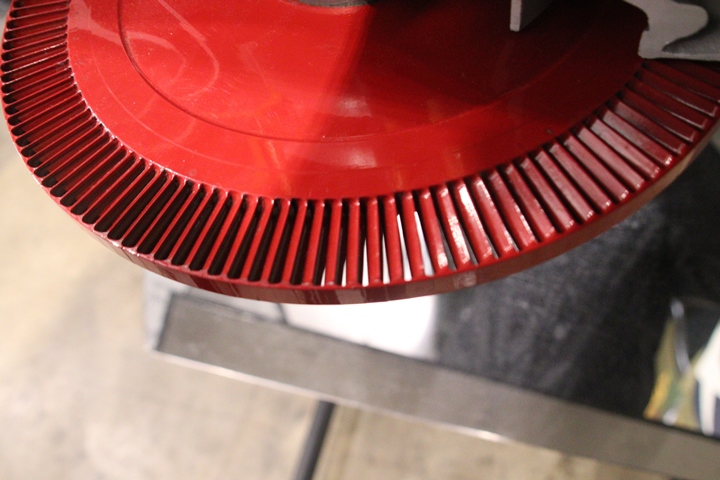

The turbine buckets or blades can be seen on

the outer diameter of the turbine wheel. They are oriented at the

proper angle to cause the turbine wheel to spin at up to 20,000

rpms when the waste gate is completely closed. Author's photo.

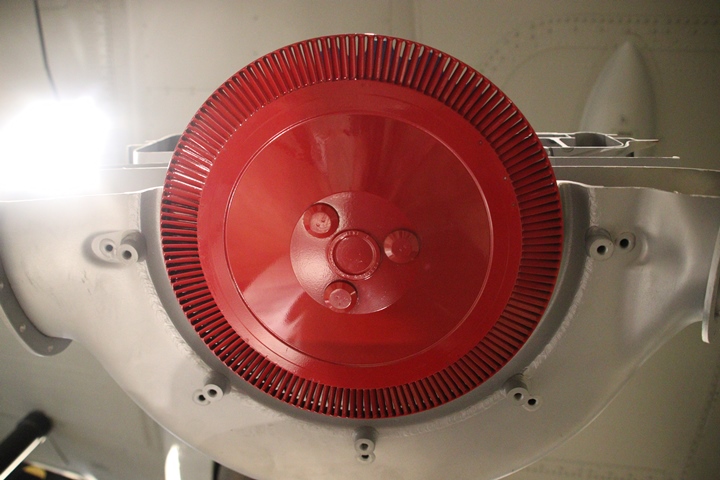

This image shows the entire turbine wheel

and the Haynes Stellite buckets. Author's photo.

The manufacturing of the turbo supercharger

buckets was an intensive and careful process to create a properly

configured bucket. Each bucket had to be the exact size,

configuration, and weight for it to function properly in and operate in the

turbine wheel. Author's photo.

The turbine buckets operated in an extreme

environment with 1,500 degree Fahrenheit temperature exhaust gases

blowing on it from the engine; while on the exterior side, the

temperatures were minus 60 degrees below zero Fahrenheit at 25,000 feet

of altitude. The

Haynes Stellite bucket not only had to operate in the extreme

temperatures but at the 20,000 rpms. Any non-conformity to

specification would cause the bucket to fail and the high speed turbine

wheel to disintegrate. The failure of something as small as the

turbine bucket could cause the loss of an aircraft and its crew as the

aircraft could no longer operate at the high altitudes needed for combat

missions. Author's photo.

For B-17s, B-24s, B-29s, P-38s, and P-47s the failure of a turbine

bucket in the aircraft's engine was similar to the classic poem by Anon

on the loss of a nail in a horse shoe. During the air war in

Europe, bombers flew in tight formation in order for the gunners on

several aircraft to work together in defending against attacking

fighters. If a bomber had to drop out of formation due to any

problem, including a non-functioning turbo supercharger, it then became

easy prey for enemy fighters. If P-47 and P-38 fighters assigned

to protect American bombers had to return home due to a non-functioning

turbo supercharger, there are less than the necessary fighters to

protect the bombers. The number of aircraft lost due not enough

fighters and bombers working in unison could be higher than if all the

aircraft were contributing to the battle.

"For Want of a Nail

by Anon

For want of a nail the shoe was lost.

For want of a shoe the horse was lost.

For want of a horse the rider was lost.

For want of a rider the battle was lost.

For want of a battle the kingdom was lost.

And all for the want of a horseshoe nail."

This is an enlargement of the previous photo

of the Haynes Stellite bucket display at the Howard County Historical

Museum. At peak production during World War Two, the company was

turning out 2,000,000 of these per month. Author's photo.

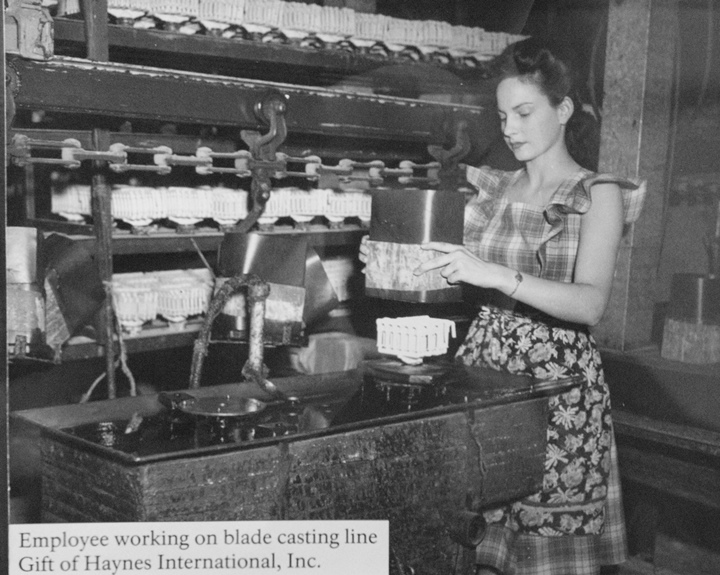

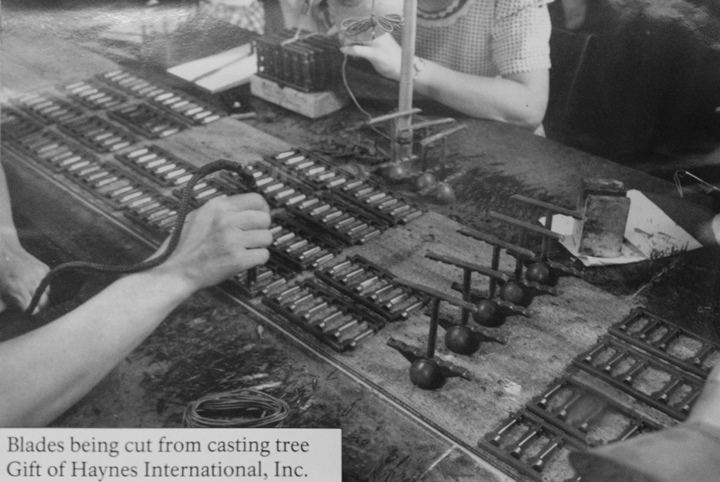

This and the next photo are from the Elwood

Haynes Museum in Kokomo, IN. Not only did the company produce the

bucket for the GE turbo superchargers, but Haynes Stellite metals were

also used in the manufacture of jet engine blades for the early jet engines

that were being built during the war. Author's photo.

Author's photo.

The P-47 was an important American fighter

aircraft that relied on Haynes Stellite turbine blades to operate and

fight at high altitudes. Author's photo from the Evansville

Wartime Museum, Evansville, IN.

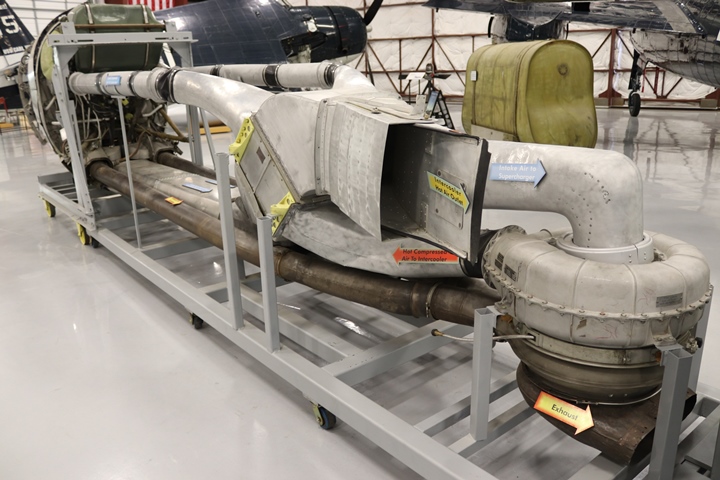

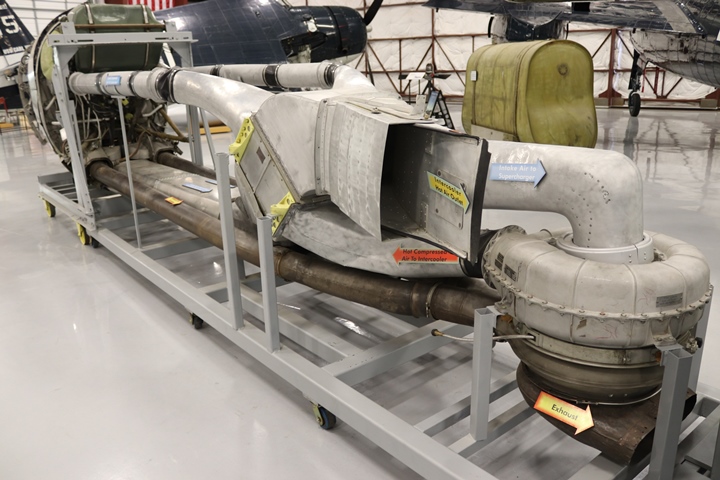

This image shows a complete and complex P-47

turbo supercharger system. The Haynes Stellite turbine buckets may

have been small compared to the rest of the system, but they were a very

important component for proper operation. Author's photo from the

National Museum of World War Two Aircraft in Colorado Springs, CO.

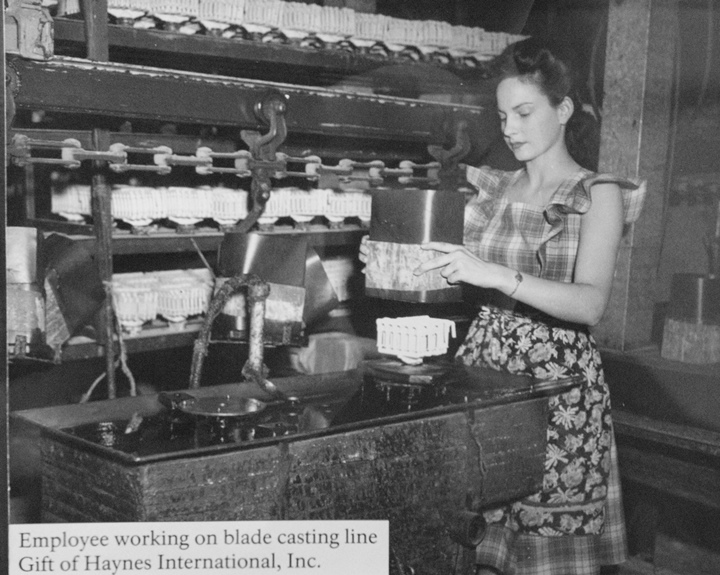

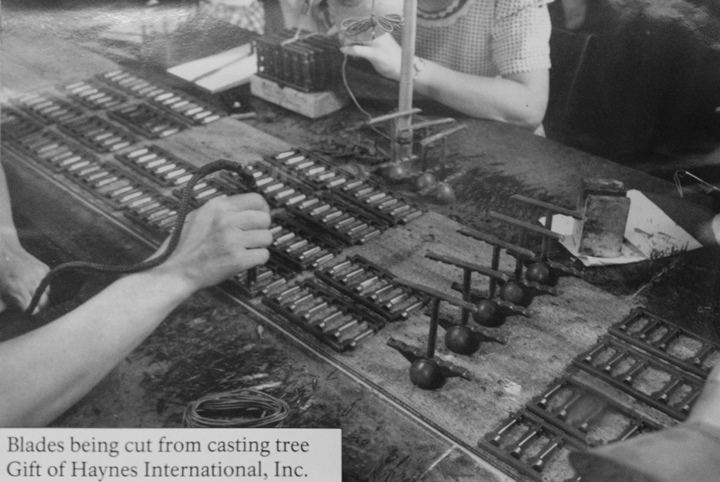

This and the following image are from the

Howard County Historical Museum and show some of the processes involved

in the manufacture of the turbine buckets.

This an example of a GE turbo supercharger that was on display at the

March AFB Museum in Riverside, CA. The red welded sheet metal

component on the top is the cooling cap.

This directed air onto the bucket wheel below it. The small

components on the outside diameter of the bucket wheel are the Haynes Stellite buckets. Hot

exhaust gases at 1,500 deg. Fahrenheit coming from the

aircraft engine entered the intake port and were directed to

the buckets, which spun the bucket wheel, which then spun intake air for

the engine into the bottom section of the compressor, which

compressed the intake air and sent it to the engine's carburetor. This

allowed the aircraft to operate in the rarified air at high altitudes. Author's photo.

The New England Air Museum in Windsor Locks,

CT built a special display hangar to

display its B-29 named "Jack's Hack." Author's photo.

This image shows the location of one of the

two turbo superchargers per engine that were used on the B-29.

Author's photo.

This B-24D is on display at the National

Museum of Air Force. Author's photo.

The B-24 had its turbo superchargers mounted

behind the engine and on the bottom of the nacelle similar to the B-17.

Author's photo.

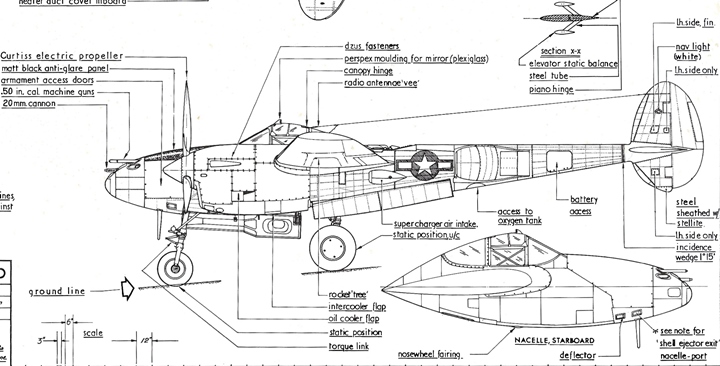

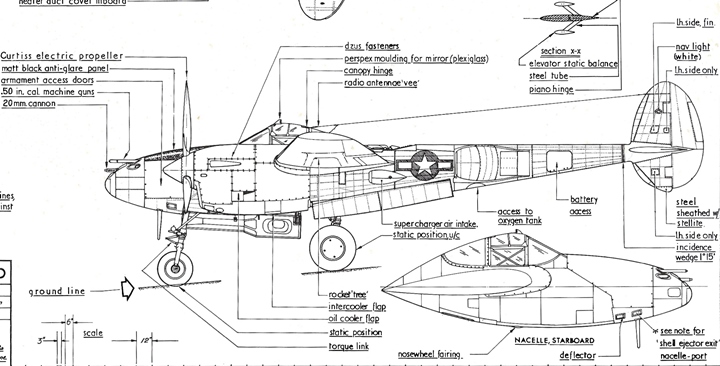

The legendary Lockheed P-38 is most

well-known for the use of the GE turbo supercharger among the USAAF

aircraft that utilized the device. The P-38's twin boom design and

the use of two Allison V-1710 engines made it unique among American

fighter aircraft. This P-38 is part of the flying collection at

the National Museum of World War Two Aircraft in Colorado Springs, CO.

Author's photo.

The P-38's turbo superchargers are located behind the engines on top of

the twin booms. This image shows the left engine turbine section.

The aircraft's canopy can be seen in the background. Author's

photo.

As noted previously, turbine wheels did

disintegrate on occasion for various reasons. With the turbine

wheel on the top of the boom, pieces of the turbine wheel and it buckets

could strike the pilot's cockpit area. The sheet metal guard shown

in this photo was used to deflect the pieces of turbine debris away from

the cockpit. Author's photo.

How cool is this? Not only did

the P-38 have two General Electric B-33 super turbo superchargers with

144 Stellite buckets in

each of the turbines, but the P-38 also utilized Stellite to not damage

the bottom of the rudder if it hit the ground during landing. This image has

information on various components in the Lockheed P-38L. On the

far right of the photo at the bottom of the vertical stabilizer is a

small component. The description reads "steel sheathed w/stellite."

This is an excellent example of the hardness and wear resistance of

Stellite.

This and the next photo show the Stellite

rudder protectors on the P-38. Author's photo.

Author's photo.

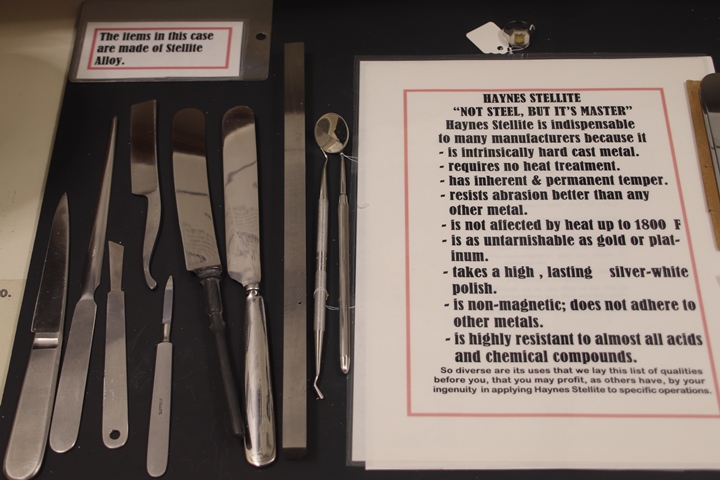

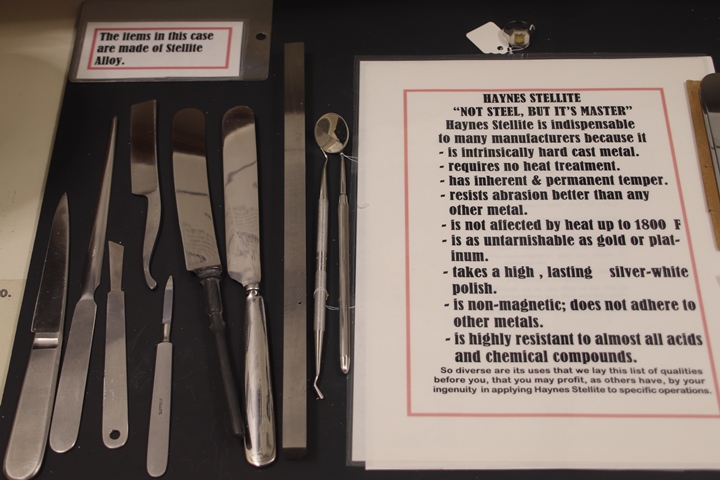

One of the items mentioned in the previous

advertisement was the use of Haynes' alloys for dental instruments for

the U.S. Army Medical Corps. Because the alloys are non-ferrous,

they do not rust. The information sheet with this display at the

Elwood Haynes Museum explains all of the advantages of Haynes products. Author's photo.

This is Fletcher class World War Two

destroyer is the USS Kidd, located in Baton Rouge, LA. Author's photo.

Another product mentioned in the newspaper

advertisement was the use of Haynes alloys as reflectors in U.S.

Navy ship searchlights. The highly reflective alloys used in the reflectors

were shatterproof and were not affected by saltwater corrosion.

Image courtesy of the USS Kidd Veterans Museum.

Not mentioned in the newspaper advertisement

was the company's involvement with the Manhattan Project. This was

due to the top secret nature of the project. Most likely the

Haynes non-corrosive alloys were used in the gaseous diffusion plant in

Oak Ridge, TN. This method of extracting the U-235 from the U-238

involved very corrosive hexafluoride. The company's nickel based

alloys would not have been affected by the hexafluoride.

Author's photo.

This cut-away of a Browning M2 .50 caliber

machine gun was found in the maintenance shop of the National Armor and

Cavalry Museum at Fort Moore, GA. The aircraft version of the M2

.50 caliber machine gun was the standard armament for all American

fighters and bombers during World War Two. Both fighter pilots and

bomber gunners were losing the accuracy of their .50 caliber machine

guns during combat as the barrels wore out. Experimentation revealed that Haynes Alloy No.

21 gave ten times the life of the liner as the previous type. A

special casting method was developed by the company for the manufacture

of the liners.

This cut-away of the end of the barrel shows

the inner liner. After the initial testing that showed that Haynes

No. 21 Alloy was ten times better than the original liner material, more

test examples were made and tested in combat. When it was

confirmed

that the Haynes alloy worked as expected, the company received contract 33008-ORD-1677

for $3,797,000 for a production run of the liners. A special casting

process was developed by the company to produce the liners on a mass

production basis.

The P-51 was the prominent U.S. Army Air

Forces fighter in the later stage of World War Two. It was armed

with six .50 caliber machine guns. Author's photo.

Once mounted in the wings of the aircraft,

the P-51's weapons could not have their barrels changed out until the

aircraft returned from a mission. Stellite No. 21 allowed the

pilots to maintain the accuracy of the weapons for the full load of

ammunition. Author's photo.

The Elwood Haynes Museum has this .50

caliber liner on display. Author's photo.

.50 caliber machine guns were used on B-17s

and B-24s in various locations on the aircraft. However, it was

not feasible for a gunner to attempt a barrel change in flight.

This needed to be performed by an ordnance person between flights while

the aircraft was on the ground. On

B-29s, the turret guns were all remote and not accessible to the crew

during flight. The Haynes Stellite No. 21 used in the liners

helped the bomber crews retain the accuracy of their weapons. Author's photo.

The Haynes Stellite Plants:

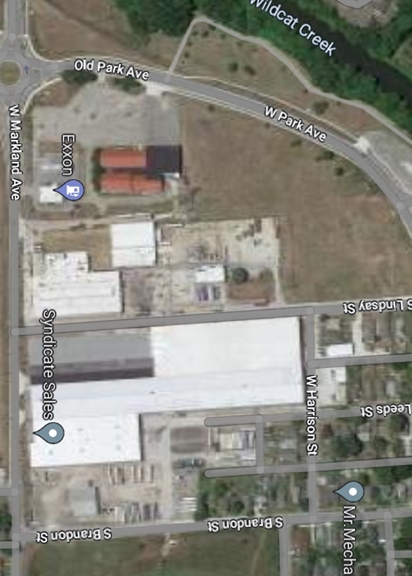

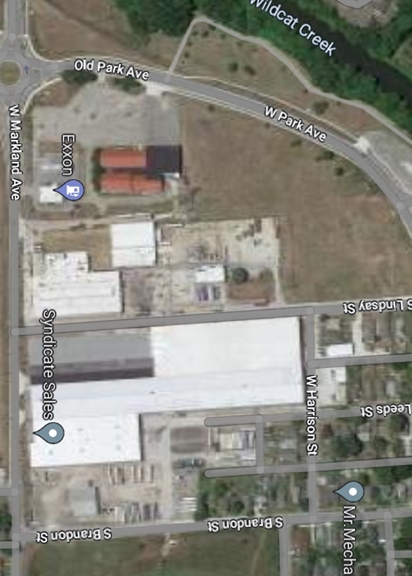

The original location of Haynes Stellite

Company which was also active during World War Two was located at the intersection of South Lindsay

Street and Markland Avenue in Kokomo, IN. The company called this

the Lindsay Street operation.

This shows the early Haynes facility on

Lindsay Street. This photo is from the many displays and photos at

the Elwood Haynes Museum.

This shows the Haynes Stellite facility on

South Lindsay Street at its peak. The date is unknown but most

likely this is what the facility looked like during World War Two.

This image is looking west. Along the left side of the photo is

Markland Avenue. The road that follows the contour of Wildcat

Creek on the right and upper portion of the photo is Park Avenue.

The Haynes Lindsay Street operation has grown into a facility that is

bounded by Markland Avenue to the south and Park Avenue to the north.

The company parking lot can be seen in the lower left hand corner of the

photo. Haynes was not the only industrial facility in the area.

To the south across Markland Avenue was the location of the former

Continental Steel Company. This and the next photo are from large

photographs on display at the Haynes Museum.

This image gives a closer look at the

Lindsay Street operation. Haynes International no longer has a

presence at this location.

This Google Maps satellite view shows what

remains of the former Haynes factory complex.

This Google Map street view is looking

northeast from Markland Avenue.

This Google Map street view is looking south

along South Lindsay Street.

Haynes International Kokomo Area Plants:

As noted above, Haynes International has remained in the Kokomo area and

has both its world headquarters and a large factory complex.

This image of the current Haynes

International factory complex on Kokomo's southwest side is from the

Howard County Historical Museum.

This satellite view also shows the 100 acre complex in southwest

Kokomo on West Defenbaugh Street. The land was purchased for

expansion and new plants in 1945. Image courtesy of Google Maps.

The first building to be built on the new

site was this rolling mill that became operational in 1948. This

image is from the Elwood Haynes Museum.

Currently, the rolling mill is still in use

among the many other factories that have been added since 1948.

Author's photo.

The rolling mill and the windows have been

repainted white. Author's photo.

Haynes International Corporate Center is

located on Park Avenue north of the former South Lindsay Street

facility. Author's photo.

Author's photo.

|