|

Matthews Company in World War Two This page added 4-25-2022. In 1890, Scott J. Matthews started his own boat building company in the very small town of Bascom, OH which is a small land-locked town in northwest Ohio. According to the historical record, Scott J. Matthews built a 70 foot yacht at this location and then sailed it with his family on a 9,000 mile journey. Nothing is mentioned about how he moved it 31 miles from Bascom, OH to Lake Erie. After the successful trip with the 70 foot yacht, businessmen in Port Clinton provided Mr. Matthews with free land to build a factory. In 1906 Mr. Matthews moved to Port Clinton as the Matthews Company. During World War One the company built subchasers and during World War Two it built a variety of small boats including the LCP and LVCP landing craft. In 1974 the company went bankrupt In March 1997 much of the former Matthews plant was destroyed by an arson fire.

Matthews Company World War Two Products: The U.S. Navy purchased $7,827,000 in major war contracts from the company during World War Two. Matthews produced both the LCP and LVCP landing craft along with launches and small boats.

Estimated Number of boats and landing craft built by Matthews Company: One of the challenges of reporting on the Matthews Company is a determination of how many landing craft and other small boats the company built during World War Two. One source in the historical record showed that the company built 555 LCVPs and had 69 cancelled at the end of the war. Another source gave 496. Neither had any primary sources listed to substantiate the numbers given. Many historical sources note a number of LCVPs built by a boat company, not realizing there were other types of landing craft built during World War Two. Not all landing craft were LCVPs as most persons believe. Table 2 shows the production of different types of small landing craft in World War Two. This can be used as a guide for attempting to determine what types of the unspecified landing craft in Table 1 were.

Table 2 gives the projected production after July 1945. However, production for the small landing craft most likely were all cancelled after August 15, 1945. However, the figures normally given in most references include the projected last six months of production. Contracts NObs 1954, NObs 2008, and NObs 2046 specifically identify the landing type awarded on the contract. Shipbuildinghistory.com indicates that Matthews built the LCP, LCP(R) and LCVP. The Navy contract Obs 826 for Landing Craft was awarded a year before the LCVP and the LCP(R) went into production, so contract Obs 826 must have been for some other type of landing craft. This contract is most likely for the LCP which was in production in 1941. The Navy contracts Obs 1036 and Obs 1247 are more problematic as the LCP, LCP(R), and LCVP were all in production in 1943 and 1944.

Using data from known Chris Craft contracts, I

can estimate the cost of landing craft purchased by the U.S. Navy.

While there will be some variation between manufacturers related to the

number of landing craft built, the Navy knew the cost of building them

and the cost of the boats should be similar. Chris Craft had LCVP contract NObs 827 for $9,996,000 which divided by the 1,700 units in the contract yields $5,880. This value was applied to Matthews contracts NObs 2008 and NObs 2046 as they were identified as LCVPs. Chris Craft had LCP(R) contract NObs 1881 for $736,000 which divided by the 150 units in the contract yields $4,906. This value was applied to Matthews contracts NObs 2008 and NObs 2046 as they were identified as LCVPs. For Matthews contract NObs 1036 and NObs 1247, I calculated the estimated number of landing craft for the LCP, LCP(R), and LCVP types. This is because it is not clear which types they are. In looking at the Chris Craft contracts, there was no chronological pattern as to what landing craft type was ordered.

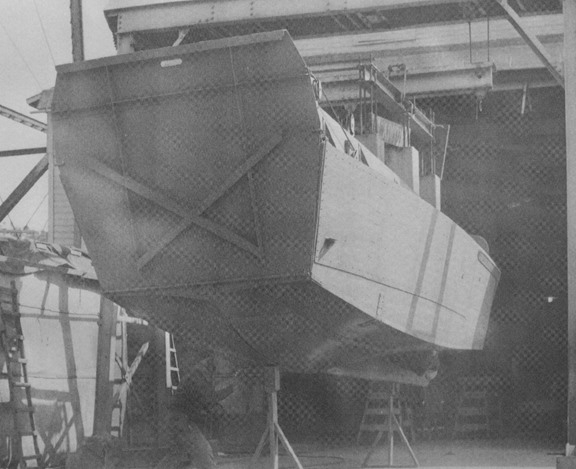

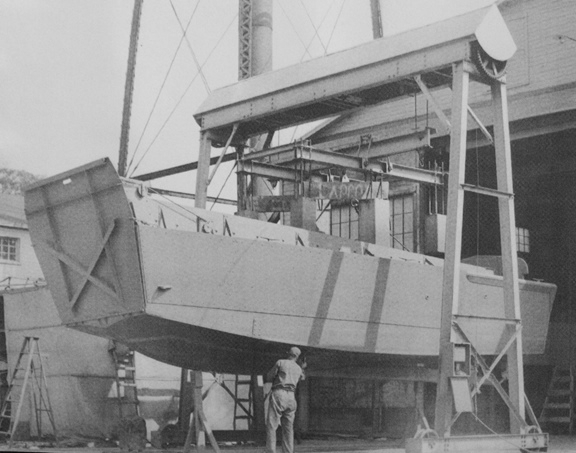

From this exercise, it appears Matthews Company built at least an estimated 434 LCPs. It also built at least an estimated 205 LCVPs. Until I find more information, this is all that can be determined. It would appear that NObs 1036 or NObs 1247 could be LCP, LCP(R), or LCVP contracts to match the numbers given by other sources. However, according to Shipbuildinghistory.com, one or both of NObs 1036 or NObs 1247 is an LCP(R) contract. However, until more information is obtained, I will not guess as to which type they are. The following three photos show two different LCVPs that the company built during World War Two. Note that the one in the first photo, which is being tested on Lake Erie, has a different ramp than the one in the following two photos. It has a large opening at the top of the ramp. Both boats have a ribbing that runs along the top from the stern to the armor plating. All three photos and the subchaser photos are from a very nice display at the Maritime Museum of Sandusky, OH. Unfortunately, the display did not give any production numbers.

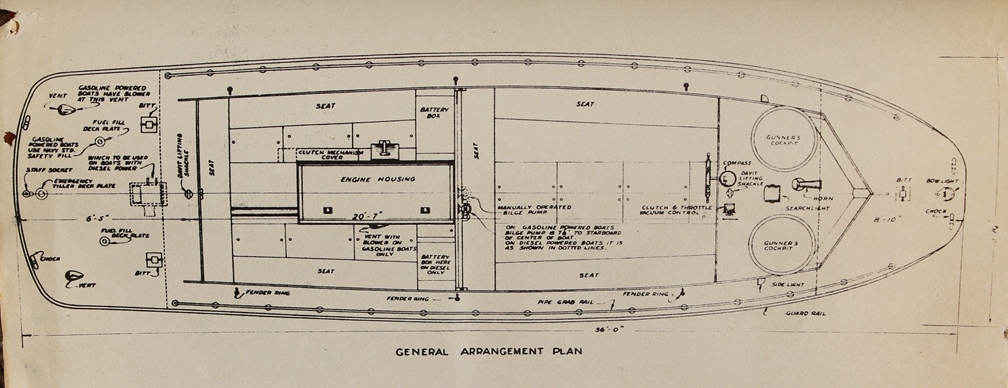

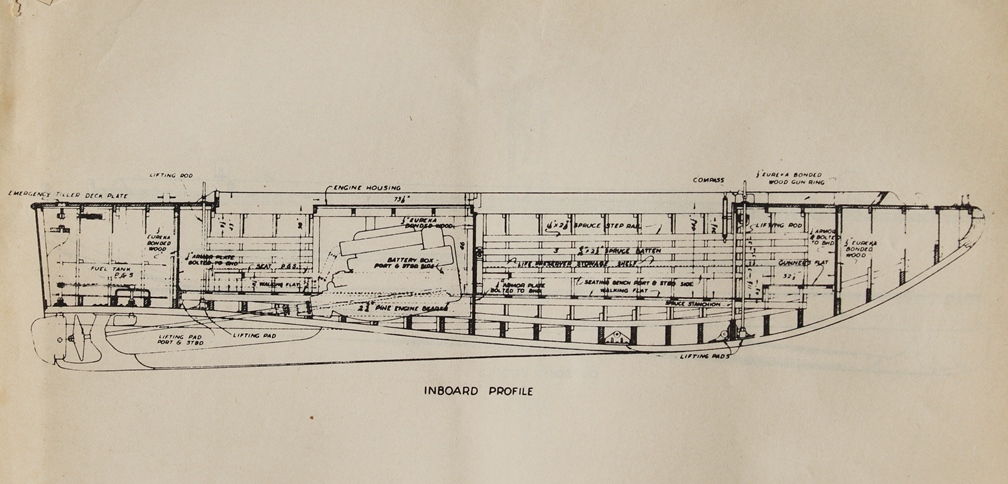

Landing Craft, Personnel, Large (LCP(L)): The LCP and LCP(L) were the same 36 foot landing craft without a ramp.

Landing Craft, Personnel, (Ramp) (LCP(R)): The LCP(R) is an LCP with a three foot wide ramp. Matthews built an undetermined number of these.

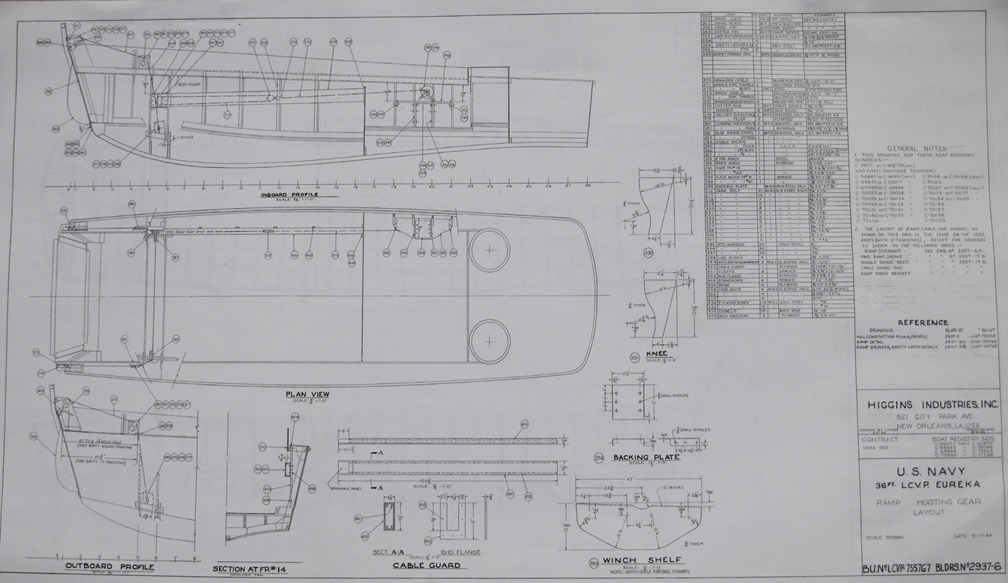

Landing Craft, Vehicle, Personnel (LCVP):

"Yes Virginia, there is a Santa Claus." Like the famous editorial reply by Francis Pharcellus Church to Virginia O'Hallon in the September 21, 1897, New York Sun when asked if there really was a Santa Claus...

"No Virginia, not every LCVP during

World War Two was built

by Higgins Industries."

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||