|

Pontiac

Motor Division in World War Two

Pontiac, MI

1893-2010

Rest in Peace!

This page updated 8-1-2020.

The Pontiac Motor Division emerged from the

original Pontiac Buggy Company, founded in 1893 by Edward

Murphy. In 1907 it became the Oakland Motor Car Company, which was

acquired by General Motors in 1909. In 1926 Oakland introduced its

Pontiac line of automobiles. They became so popular that the Oakland was discontinued. A new Pontiac Plant was built in 1927.

It was

within this plant that the Division produced the war products described

below.

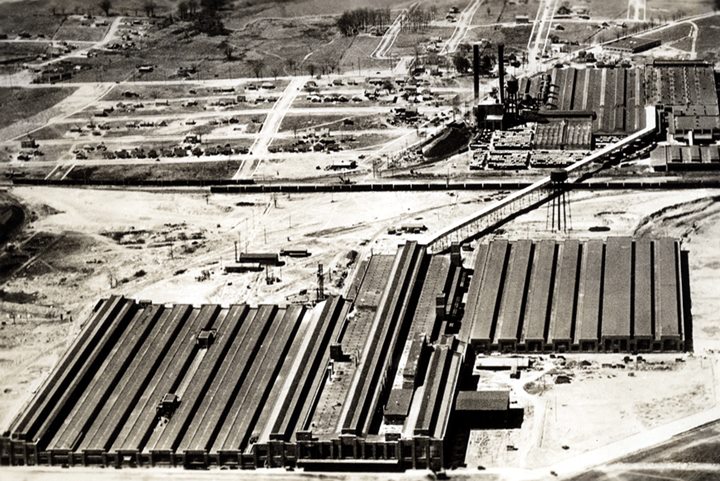

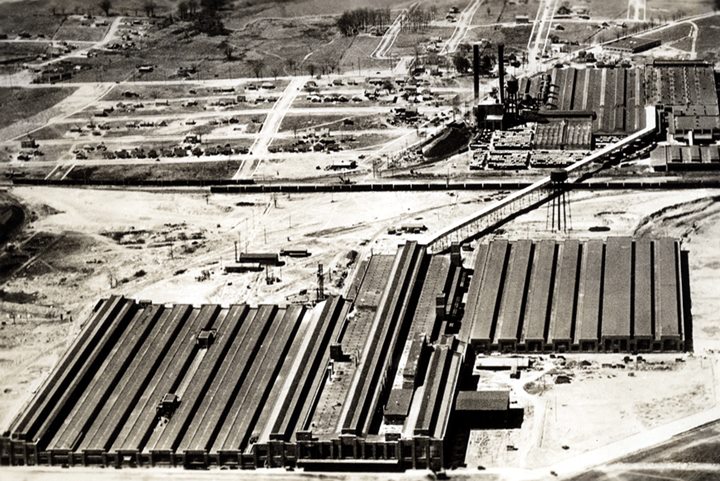

The new Pontiac Plant in 1927. The

Fisher Body Plant is across the railroad tracks. The overhead

conveyor transported the finished bodies from the Fisher Body plant to

Pontiac final assembly plant. This was long before GM combined the

managements of the body and final assembly plants into one.

Today's automobile plants have both functions under one roof.

Photo added 12-25-2016.

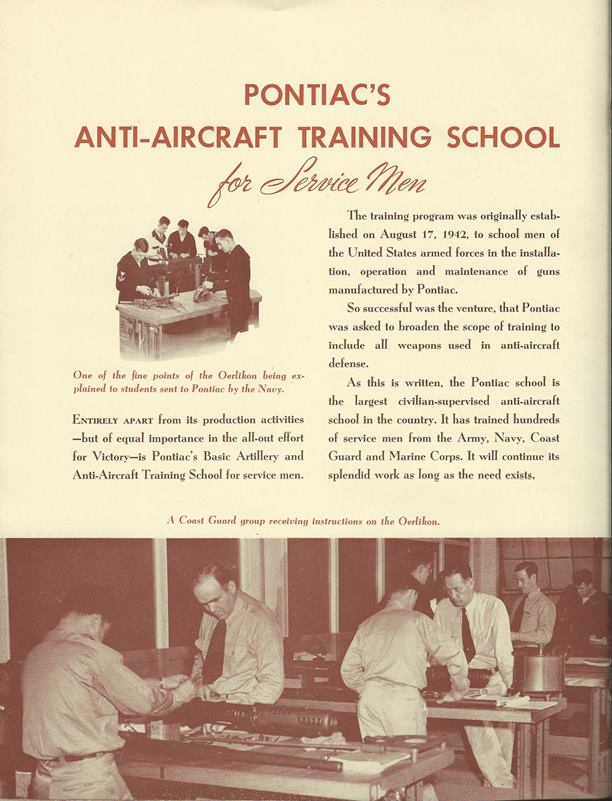

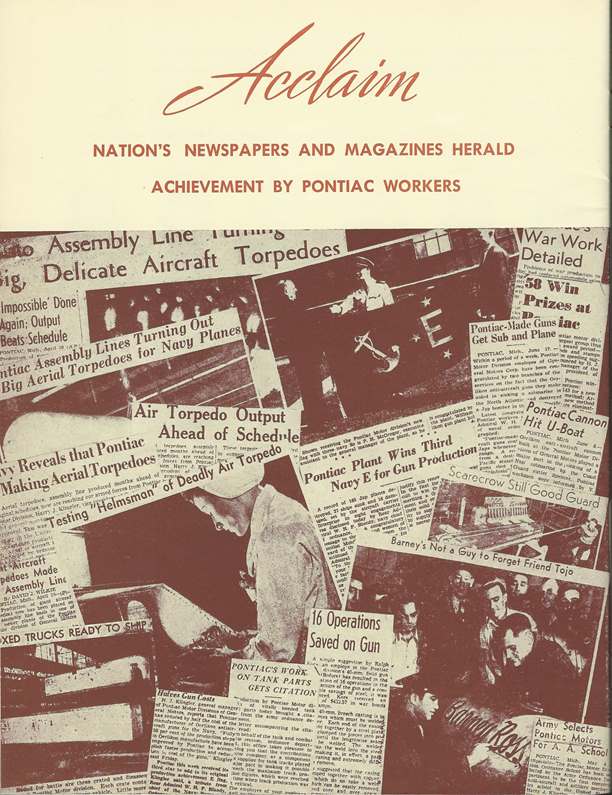

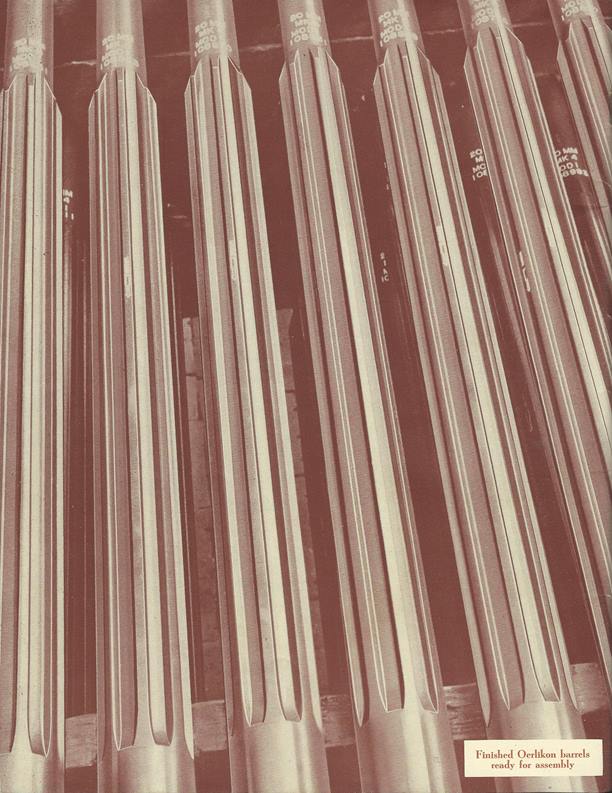

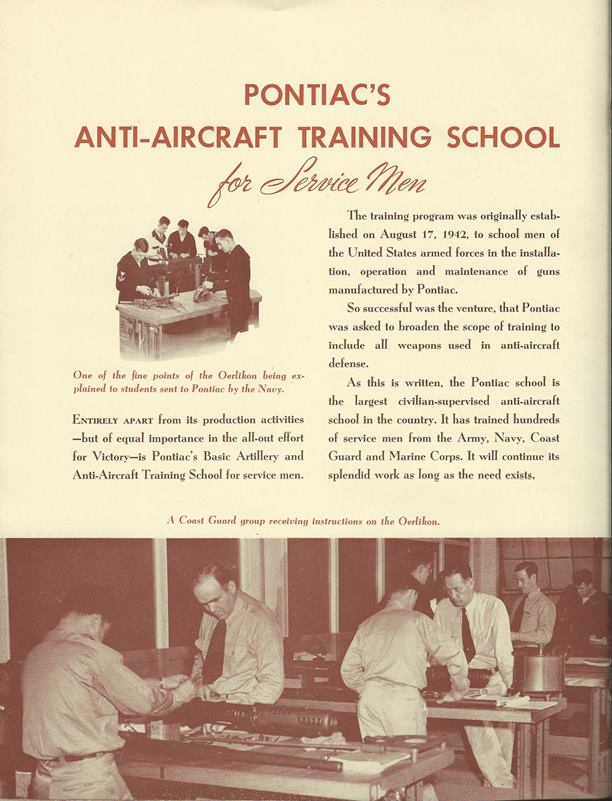

Pontiac's Plant #4 was the first auto

manufacturer to win the Navy "E" award on January 20,1942. Pontiac received

this award for delivering 20mm Oerlikon anti-aircraft guns to the Navy ahead of

schedule. Pontiac Plant #4 did not convert its Navy "E" award when

it became a combined Army-Navy "E" Award, as it could have

done.

This Navy "E" award was not noted by the War Department's Army-Navy "E"

award public relations release dated

December 5, 1945. There is no mention of Pontiac being one of the

original war plants to receive the Navy "E" award, nor that is

was one of those that did not convert.

As of November 1943 Plant #4 had added four stars. It would add a fifth

for a total of six awards..

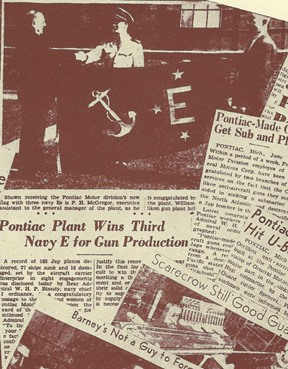

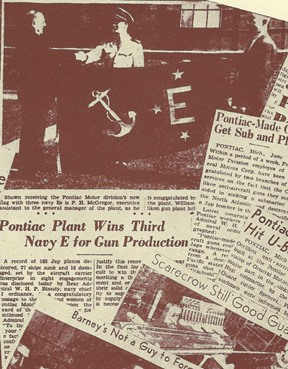

This clip from the November 1943 "Pontiac at

War" booklet shows the Pontiac Oerlikon Plant

receiving the Navy "E" award for the third time. It is

also noted on the "E" for Excellence page of "Pontiac at War" had received

four stars for the Navy "E" flag.

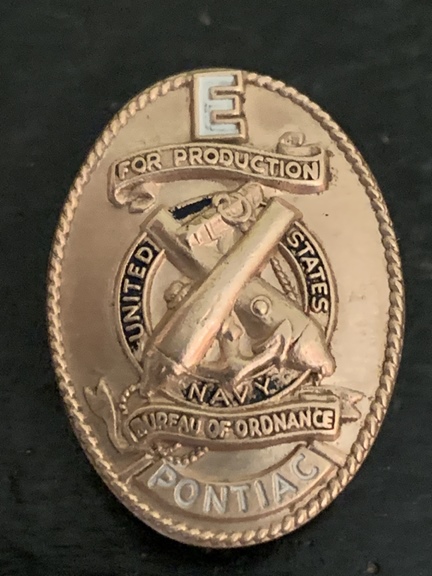

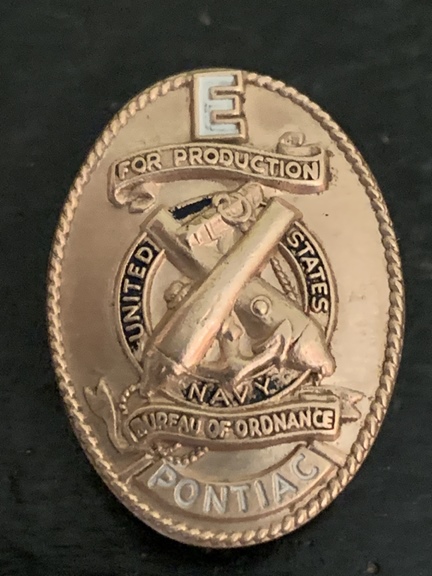

Here is the pin the Navy gave all of the

employees of the 20mm gun plant. Photo courtesy of the Todd L.

Carlson collection added 8-1-2020.

This ring commemorates Pontiac's winning of

the Navy "E" Award and is made from 20mm Oerlikon barrel stock.

Photo courtesy of the Todd L. Carlson collection added 5-26-2020.

The internal grooving of a 20mm barrel can

be seen here. Photo courtesy of the Todd L. Carlson collection

added 5-26-2020.

Photo courtesy of the Todd L. Carlson

collection added 8-1-2020.

The Navy

"E" Award ring was just one of several Pontiac had made. Photo

courtesy of the Todd L. Carlson collection added 5-26-2020.

Pontiac's Plant #11 won the Army-Navy

"E" Award one time for the manufacture of the Mark XIII aerial torpedo.

Pontiac's Plant #14 won the Army-Navy "E" Award one time.

Pontiac Motor Division of GM

World War Two Production Statistics: (47,026) 20mm Oerlikon

anti-aircraft cannon, (39,275) single 20mm Oelikon mounts, (5,760) twin 20mm Oerlikon mounts,

(4,526) Mark XIII aerial torpedoes, 155mm artillery shells, tank axles for the M-5 Stuart

and M24 Chaffee tanks built by

Cadillac, parts for Detroit Diesel to include fly-wheel housings,

connecting rods and cylinder liners, truck engine castings for GMC to

include six cylinder blocks for all GMC 270 engines, some but not all engine heads for GMC 270 engine, oil pump housings, bearing caps. Pontiac produced 4,900

40mm Bofors anti-aircraft gun mechanisms and 17,892 40mm Bofors gun tubes through

March 1944.

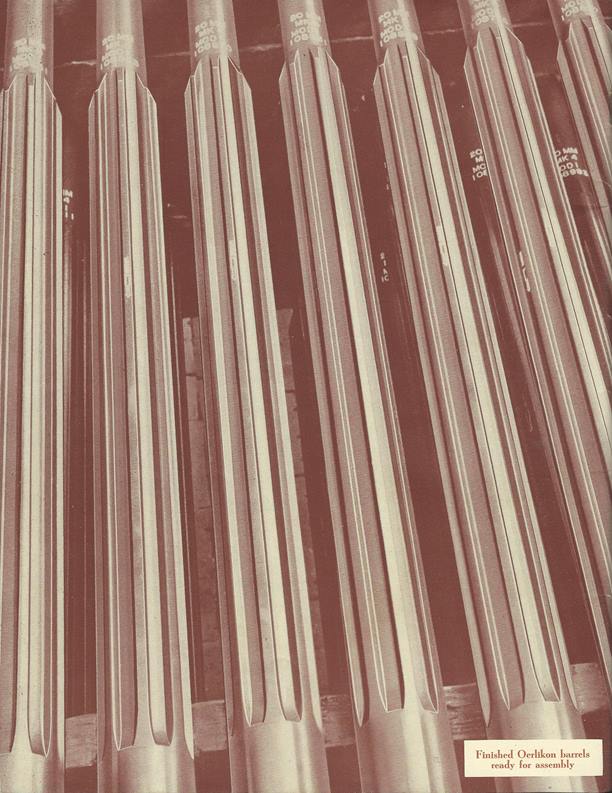

Pontiac 20mm Oerlikon anti-aircraft cannon:

There are two different documented dates for the beginning of the

Pontiac 20mm

program. "Pontiac at War," shown below, gives March 6,

1941. The "U.S. Navy Bureau of

Ordnance in WWII" by Buford Rowland gives a contract signing date of

April 3, 1941. In any event, eight months before Pearl Harbor,

Pontiac started work on the production of the 20mm Oerlikon cannon for

the United States Navy. The original contract was for 2,000 weapons for

the British under Lend-Lease. The contract was then modified for

another 4,000 weapons. It is unknown whether the 4,000 units were

for the British or the U.S. Navy. The initial production rate was

for 200-400 weapons per month. By the time of Pearl Harbor,

Pontiac had delivered 115 weapons. Each weapon included both the gun and

the mount as shown in the first set of photos below.

There were four manufacturers of the 20mm

Oerlikon during World War Two. Besides Pontiac, there was the

Hudson Motor Car Company that produced the weapons in the U.S. Navy

Ordnance plant in Center Line, MI and American Oerlikon Gazda

Corporation. The U.S. Navy replaced Hudson with Westinghouse at

Center Line in 1943. In December 1941 contracts with each of the

companies were modified for an increase in the production of the weapon.

Each company was given a monthly production rate. While there are

no known production numbers available for the individual companies of

the 20mm cannon and its mount, totals are available, and an estimate of

each manufacturer can be made. This is done in the table below.

Between June 1941 and December 1945, a total of

146,956 20mm Oerlikon guns were produced. This also comes from the "U.S.

Navy Bureau of Ordnance in WWII" by Buford Rowland. It is

known that Hudson built

33,201 guns. From the table below it can be seen that

Pontiac produced an estimated 47,026 20mm Oerlikon cannons.

|

Production of 20mm Oerlikon Cannon in World War Two |

|

Company |

Contracted Monthly Production Rate - 20mm Oerlikon Cannon |

%

of the Total Production Contracted |

Estimated or Known Number of 20mm Oerlikons built |

Comments |

|

American Oerlikon Gazda Corporation |

500 |

27 |

39,678 - Estimated |

|

|

Pontiac |

600 |

32 |

47,026 - Estimated |

Pontiac delivered 115 weapons

previous to Pearl Harbor. |

|

Centerline Naval Ordnance Plant -Hudson |

750 |

41 |

Confirmed

33,201 out of estimated 60,252 |

Hudson did not deliver any weapons until after Pearl Harbor.

Production started 7-7-41 and ended 10-43. |

|

Centerline Naval Ordnance Plant -Westinghouse |

750 |

41 |

27,051 - Estimated |

Westinghouse took over production at Center Line in 10-43. |

|

Total |

|

100 |

146,956 |

|

The same thought process can be used to

estimate the number of single weapon mounts that Pontiac and others

built during the war. There were a 122,735 mounts built by the

same four companies.

|

Production of 20mm Oerlikon Single Mounts in World War Two |

|

Company |

Contracted Monthly Production Rate - 20mm Oerlikon Mounts |

%

of the Total Production Contracted |

Estimated or Known Number of 20mm Mounts built |

Comments |

|

American Oerlikon Gazda Corporation |

500 |

27 |

33,139 - Estimated |

|

|

Pontiac |

600 |

32 |

39,275 - Estimated |

Pontiac delivered 115 weapons

previous to Pearl Harbor. Pontiac also built 5,760 twin

20mm Oerlikon mounts under a separate contract starting January

1945. |

|

Centerline Naval Ordnance Plant -Hudson |

750 |

41 |

Confirmed

33,201 out of estimated 50,321 |

Hudson did not deliver any weapons until after Pearl Harbor.

Production started 7-7-41 and ended 10-43. |

|

Centerline Naval Ordnance Plant -Westinghouse |

750 |

41 |

27,051 - Estimated |

Westinghouse took over production at Center Line in 10-43. |

|

Total |

|

100 |

122,735 |

|

Pontiac's first war contract was building

20mm Oerlikon anti-aircraft cannons for the US Navy. This

particular weapon, along with the stand and gun sight, were all built by

Pontiac. This weapon is serial number 223843. Author's photo

from the 2016 Virginian Museum of Military Vehicles Open House.

Author's photo.

Author's photo.

Data plates on the Mark 10 20mm gun stand.

The serial number on the middle plate is 267182. This matches the serial

number on the bottom plate. Author's photo.

The serial number on the Mark 4 gun breach

is 223843. Author's photo.

The brass Mark 4 gun sight assembly was also

manufactured by Pontiac. Author's photo.

It has a weight of 12 pounds. Author's

photo.

The Destroyer Escort DE 766 USS Slater in

Albany, NY. Author's photo added 12-17-2019.

The USS Slater has four Pontiac-built dual

20mm Oerlikon gun mounts on it. These two are on the starboard

side of the ship. Author's photo added 4-10-2020.

These two are on the port side of the ship.

These are four of 5,760 dual mounts built by Pontiac. Author's

photo added 4-10-2020.

This is of the Pontiac-built 20mm Oerlikon anti-aircraft gun dual mounts

on the starboard side of the USS

Slater. The weapon closest to the camera was also

built by Pontiac. Author's photo added 11-14-2017.

The serial number is 4919x. Author's photo added 11-14-2017.

This is the USS Massachusetts at Fall River,

MA. The Oerlikon 20mm cannon in the foreground was built by

Pontiac. Author's photo added 12-17-2019.

Author's photo added 12-17-2019.

This is Serial Number 43469. Author's

photo added 12-17-2019.

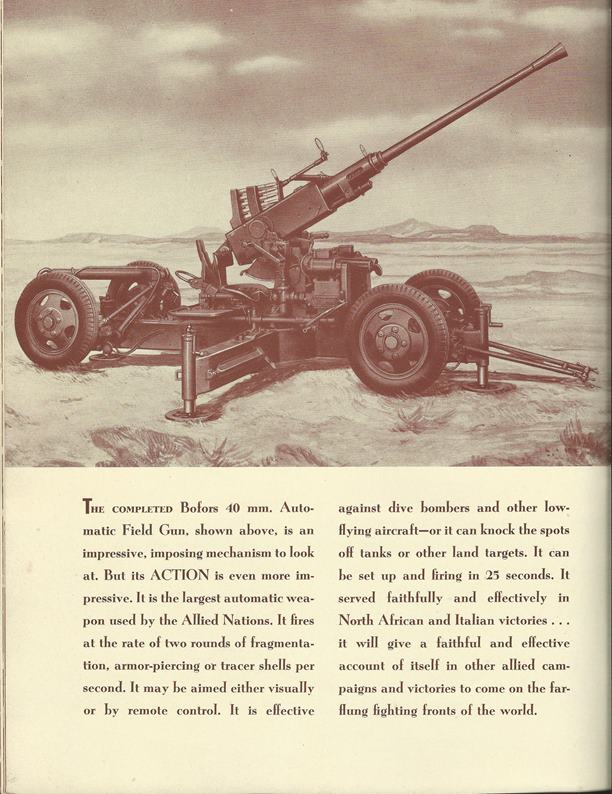

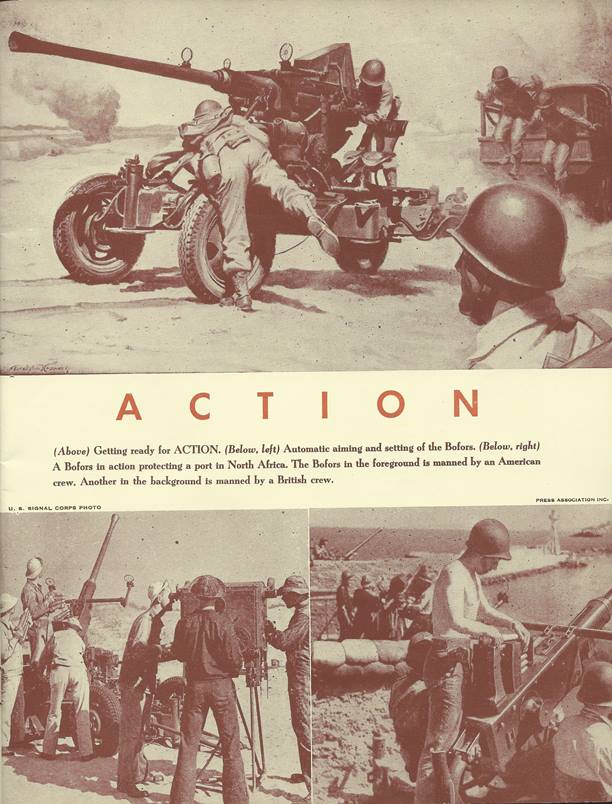

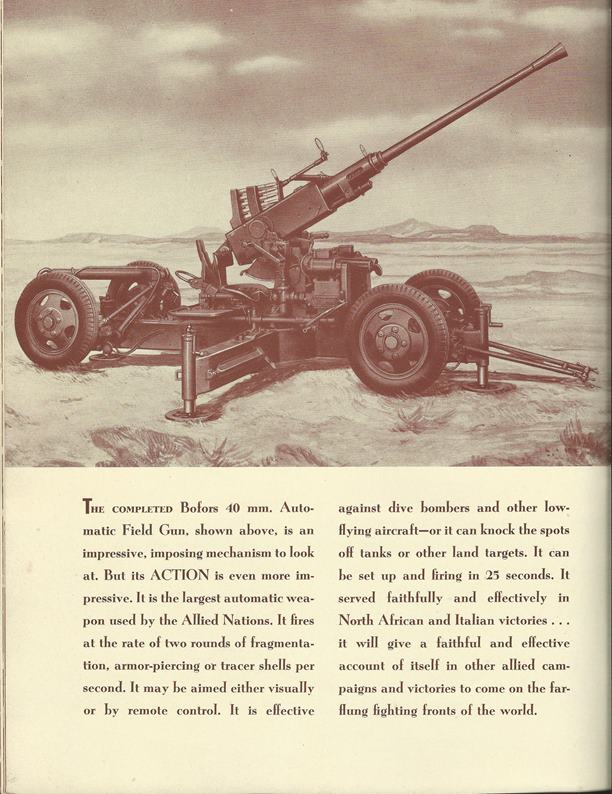

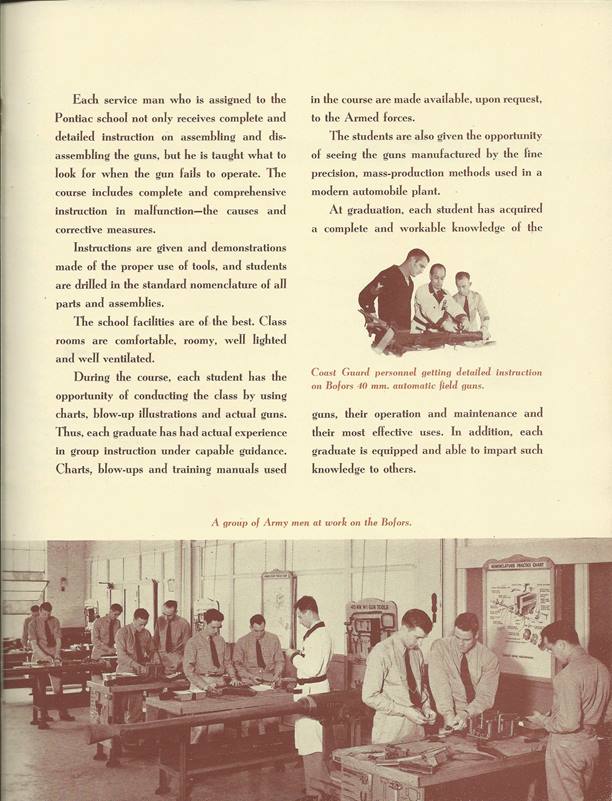

Pontiac 40mm Bofors Anti-Aircraft Cannon:

Pontiac began work on the 40mm Bofors anti-aircraft gun mechanisms and

gun tubes in January 1942.

Pontiac cleared 217,000 square feet of the sheet metal plant space to

manufacture the weapon. The Bofors could fire 130

rounds per minute, and the two pound projectiles had a range of 5,420

yards.

The information for the two tables below

comes from " The History of the Americanization of the Bofors 40mm

Automatic Antiaircraft Gun" written by the Historical Section of the

Ordnance Department in May 1944.

Pontiac produced 16.5% of the gun mechanisms

and 20.8% of the gun tubes for the US Army 40mm Bofors like the one

shown above. Note that the information came from an article

written in May 1944. Over a year of war still remained,

and the need for gun tubes continued.

|

Production

of 40mm Gun Mechanisms for the US Army as of March 1944 |

|

Company |

Date |

Quantity |

Percentage |

Comments |

|

Chrysler |

3-31-1944 |

24,802 |

83.5% |

|

|

Pontiac |

After

12-1943 |

4,900 |

16.5% |

This was the scheduled amount that was completed some time

in 1944. |

|

Total |

|

29,702 |

|

|

|

Production

of 40mm Gun Tubes for the US Army as of March 1944 |

|

Company |

Date |

Quantity |

Percentage |

|

Chrysler |

3-31-1944 |

51,684 |

60.2% |

|

Pontiac |

3-31-1944 |

17,892 |

20.8% |

|

Otis Fensom |

3-31-1944 |

16,258 |

18.9% |

|

War Supplies |

10-42 |

40 |

0.1% |

|

Total |

|

85,874 |

|

Pontiac sent complete 40mm guns

consisting of the mechanisms and tubes to Firestone, Koppers and J.I.

Case for installation on the carriage.

|

Production

of 40mm Gun Carriages for the US Army as of March 1944 (M1,

M2, M2A1) |

|

Company |

Date |

Quantity |

Percentage |

|

Firestone |

3-31-1944 |

20,021 |

84.5% |

|

Koppers |

4-1944 |

2,270 |

9.6% |

|

J.I. Case |

12-1943 |

1,414 |

5.9% |

|

Total |

|

23,705 |

|

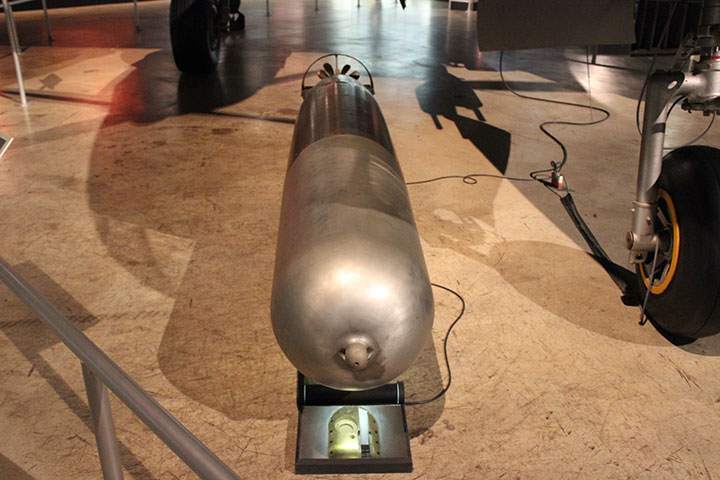

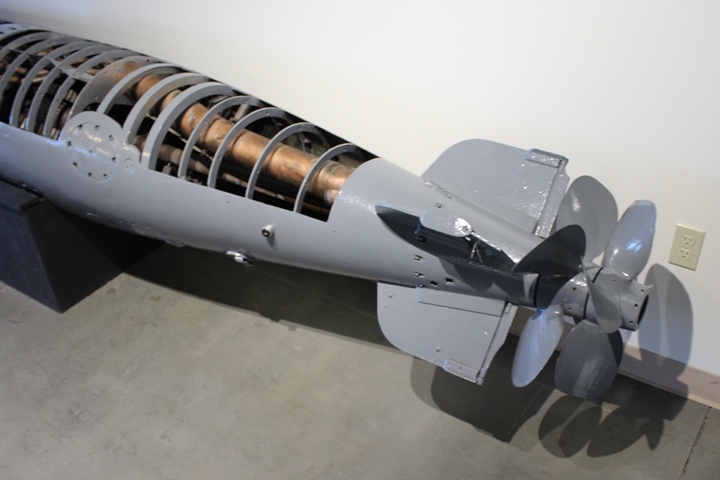

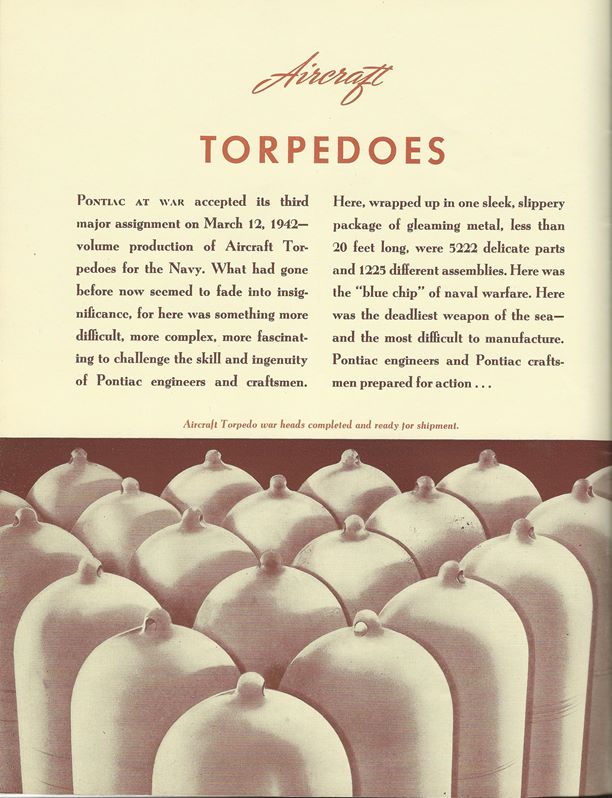

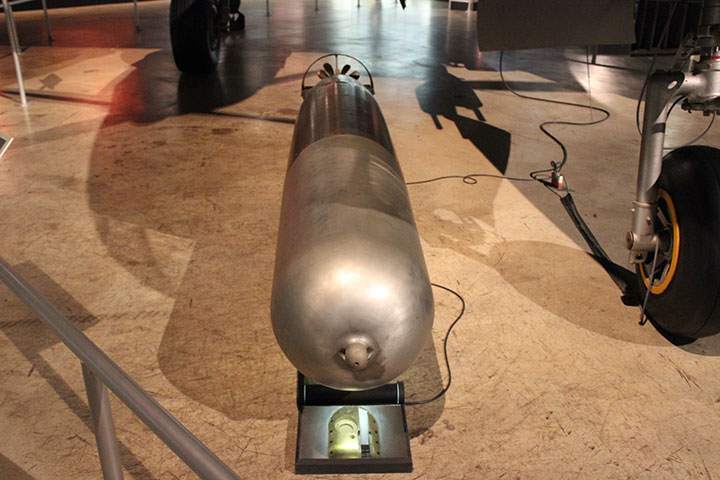

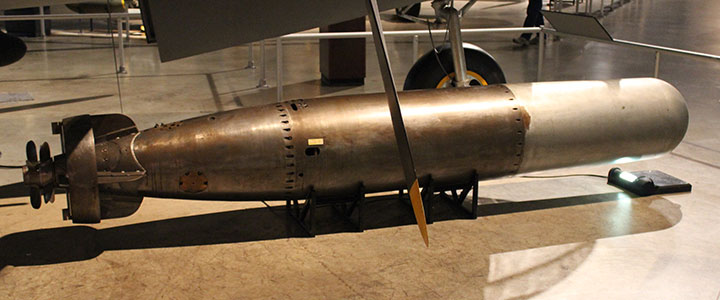

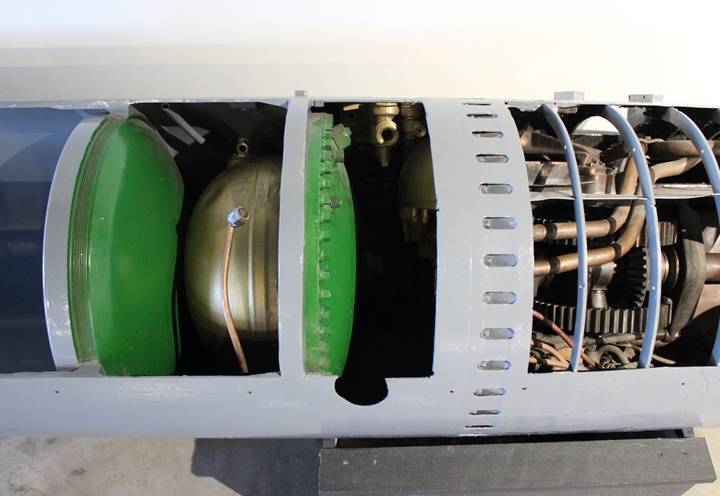

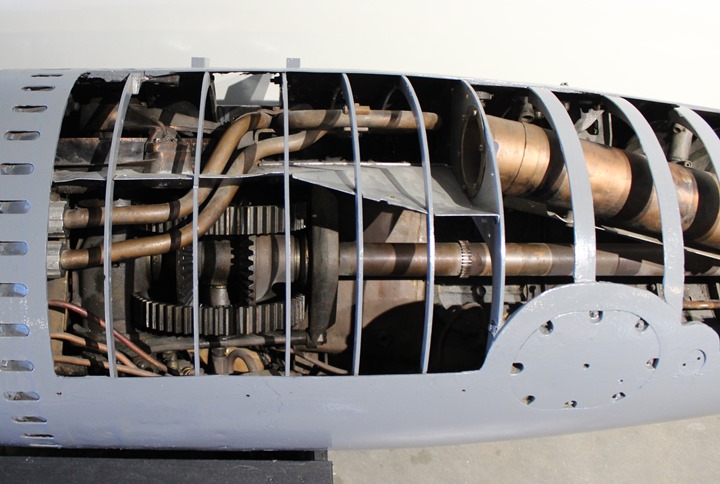

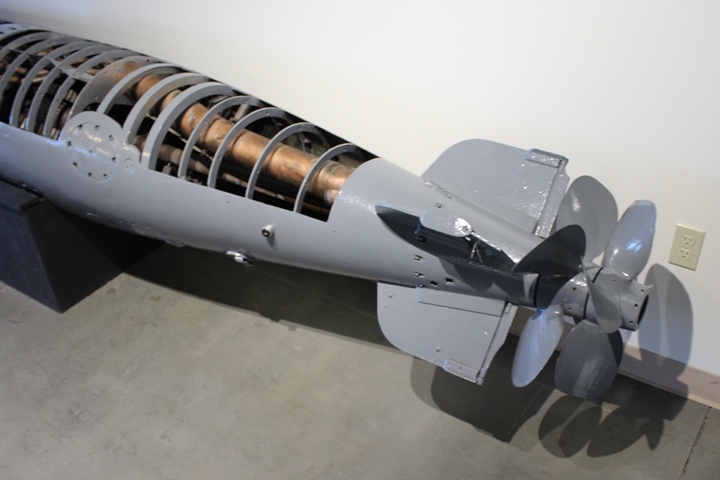

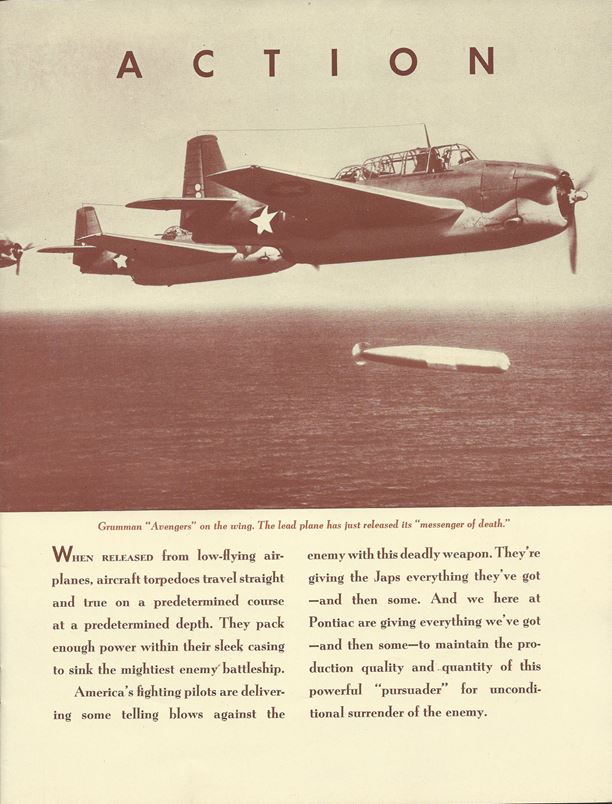

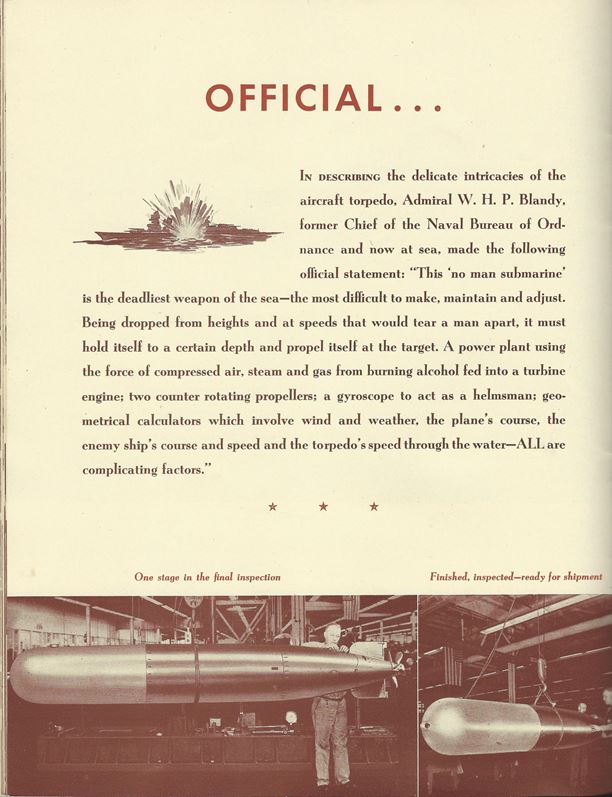

Pontiac Mark XIII Aircraft Torpedo:

Pontiac built (4,526) Mark XIII aerial torpedoes during World

War Two. This was 26% of the Mark XIIIs built.

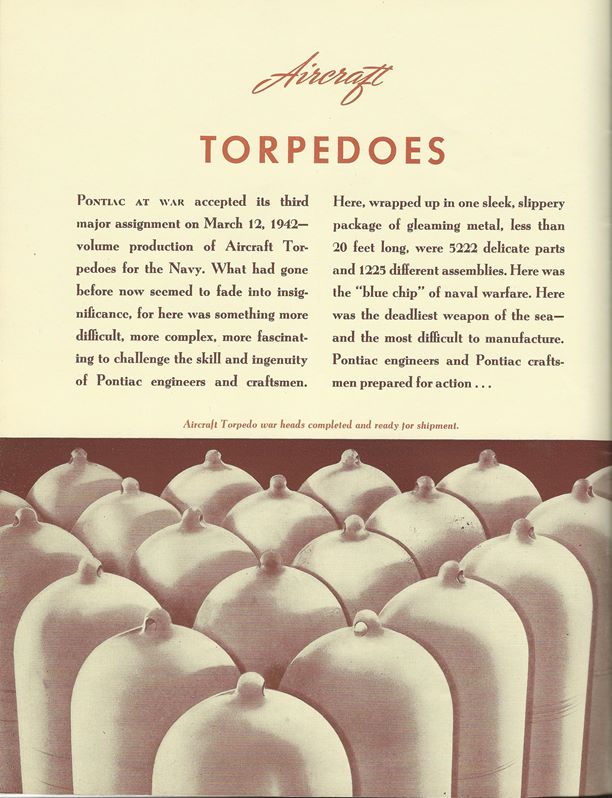

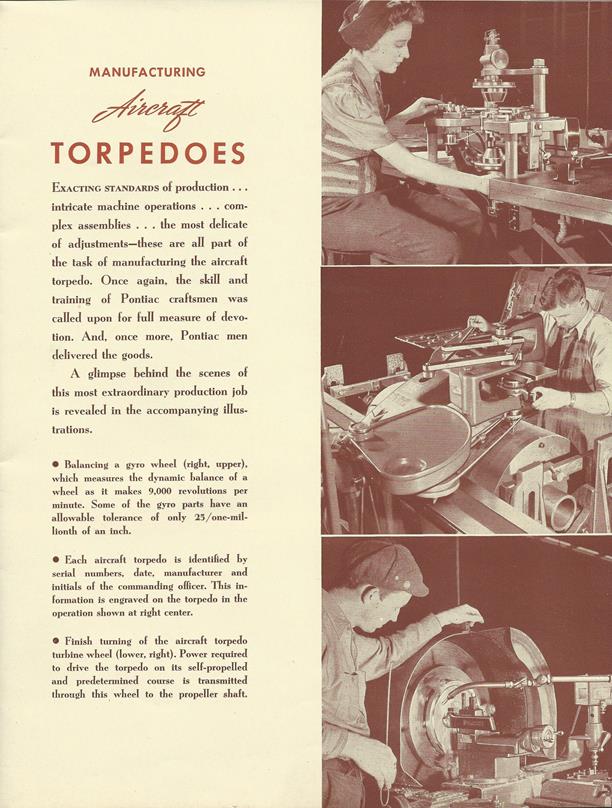

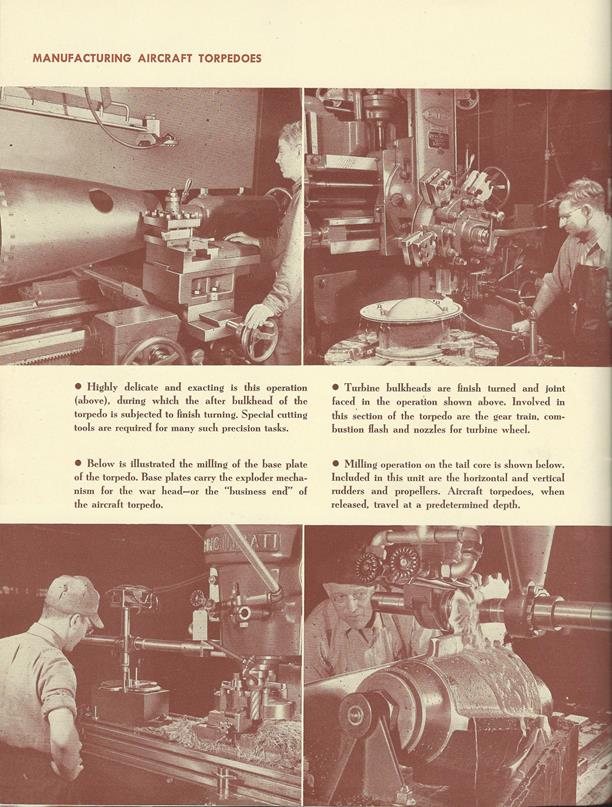

On March 12, 1942 Pontiac began work on the

Mark XIII aircraft torpedo. The thirteen-foot long weapon

consisted of 1,225 assemblies of 5,222 individual parts. The gyro, which guided the

weapon to its target, turned at 9,000 rpms. It had a diameter of

22.5 inches and weighed 2,216 pounds, of which 600 pounds was the Torpex

explosive. The internal steam turbine propelled the Mark XIII at 33 knots

for a maximum range of 6,300 yards. The Naval Torpedo Section, Amertorp

Corporation, and International Harvester also produced the Mark XIII during World

War Two. The four companies built 17,000 torpedoes. 1,500 were used in combat. Author's photo from the Liberty

Aviation Museum in Port Clinton, OH.

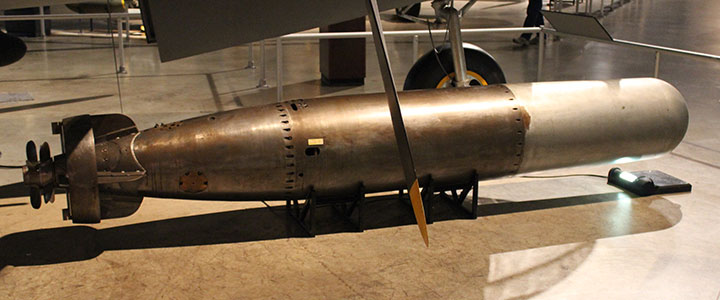

This Mark XIII is on display at the National

Aviation Museum of the US Air Force. Author's photo.

Author's photo.

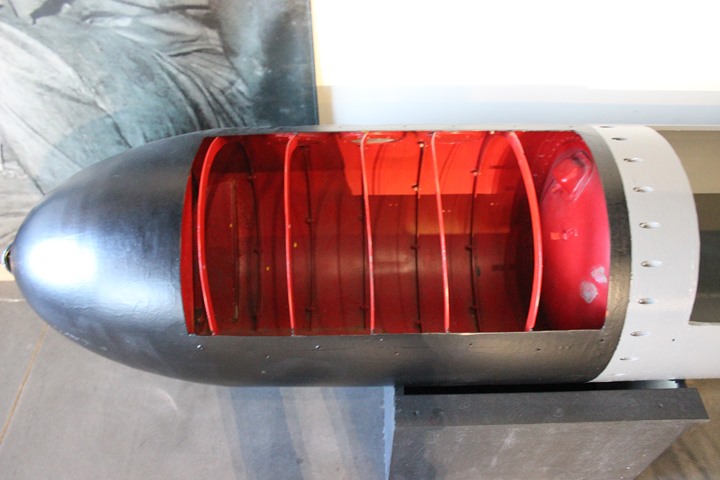

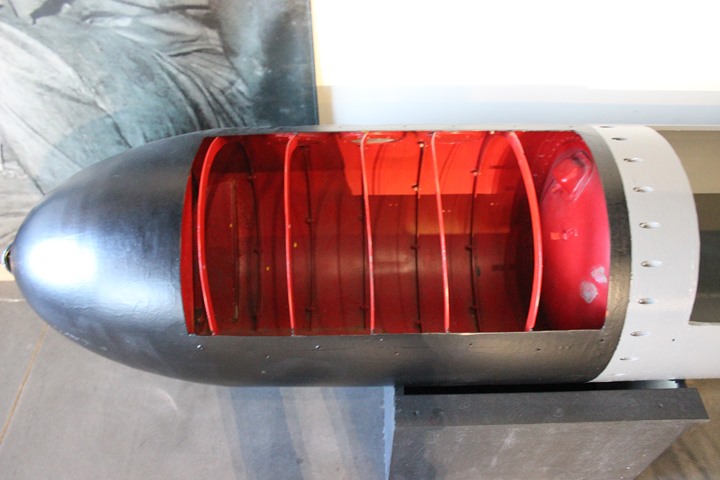

This is the warhead section of the torpedo

that would contain the detonator and 600 pounds of Torpex explosive.

This compound is 1.5 times

more powerful than TNT. Author's photo from the USS Silversides

Museum in Muskegon, MI.

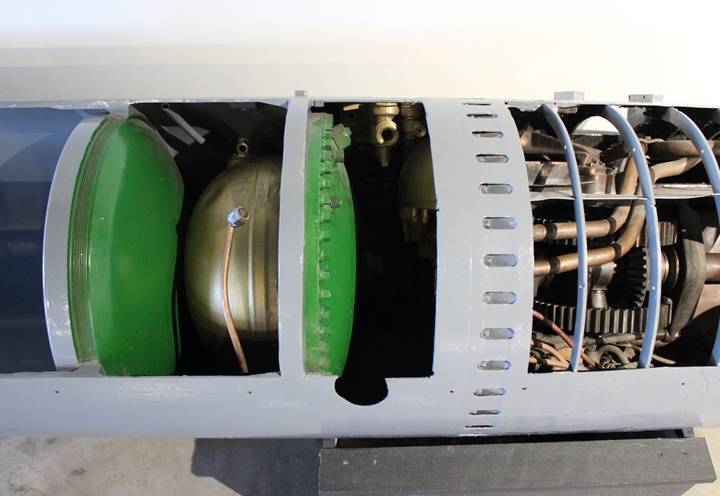

This area would contain the alcohol fuel and

compressed air to power the steam turbine. Author's photo.

Author's photo.

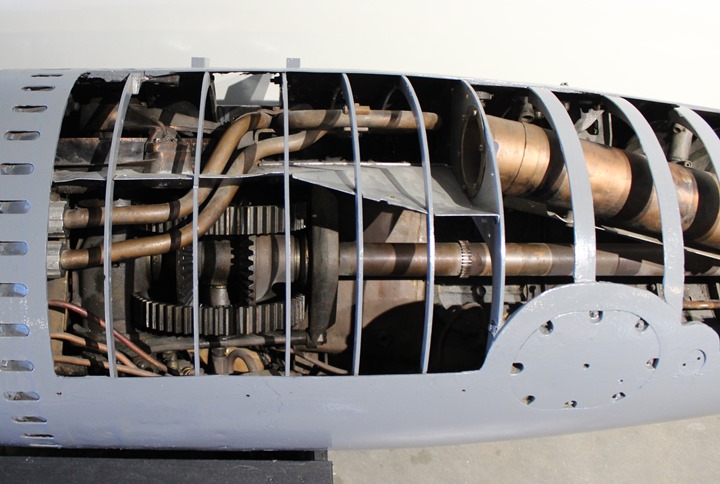

The steam turbine is at the rear of the Mark XIII. Author's photo.

Author's photo.

The primary aircraft that carried the

Pontiac Mark XIII torpedo was the TBM Avenger. It was built by the Eastern

Aircraft Division of GM in Trenton, NJ. Author's photo taken at

the Liberty Aviation Museum.

The Mark 13 was also carried by US PT boats.

One of 21,147 DUKW amphibious trucks built by GMC

and Chevrolet during WWII is next to the PT boat. Pontiac supplied the engine blocks for the

GMC 270 cubic inch engine used in the DUKW. Author's photo

taken at the Liberty Aviation Museum.

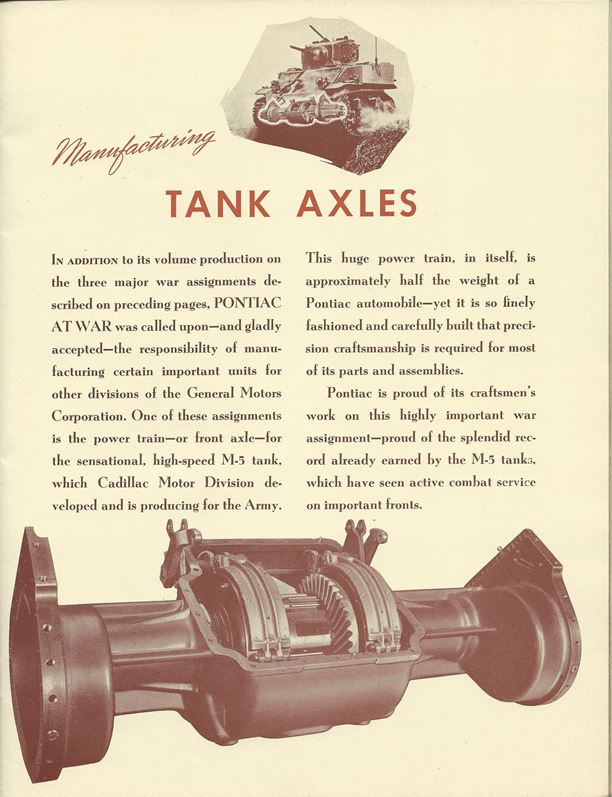

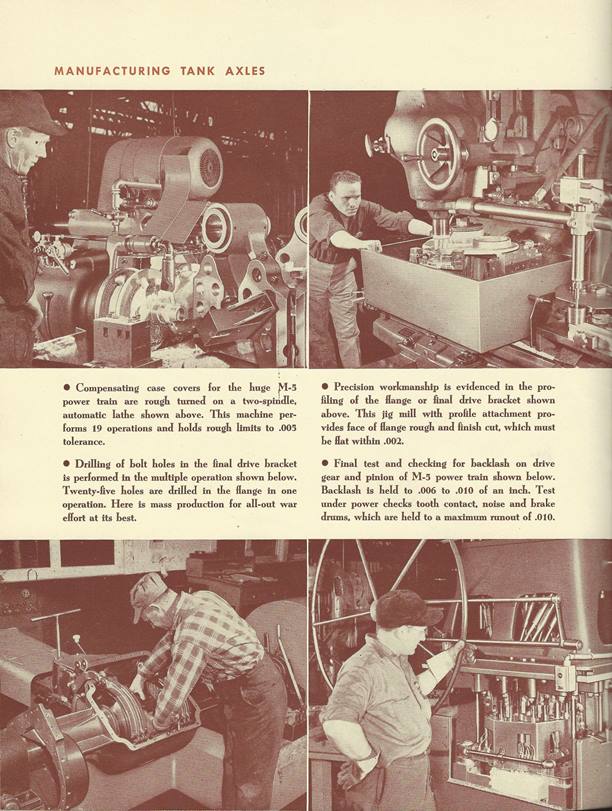

Pontiac built the front differential and axle for the Cadillac-built M5

light tank. Cadillac built 1,824 M5 and 3,530 M5A1 Stewart tanks

in Detroit. Author's photo.

Pontiac also manufactured the front differential and axle for the

Cadillac-built M8 75mm Howitzer Gun

Carriage. Cadillac built 1,778 M8s which had a 75mm howitzer

rather than the 37mm cannon. This M8 is on display at the American

Heritage Museum in Hudson, MA. Author's photo added 4-10-2020.

After Cadillac ceased production of the M3,

it produced the M24 Chaffee light tank. Pontiac supplied

the front drive axles for it. Author's photo taken at the

now closed Ropkey Armor Museum.

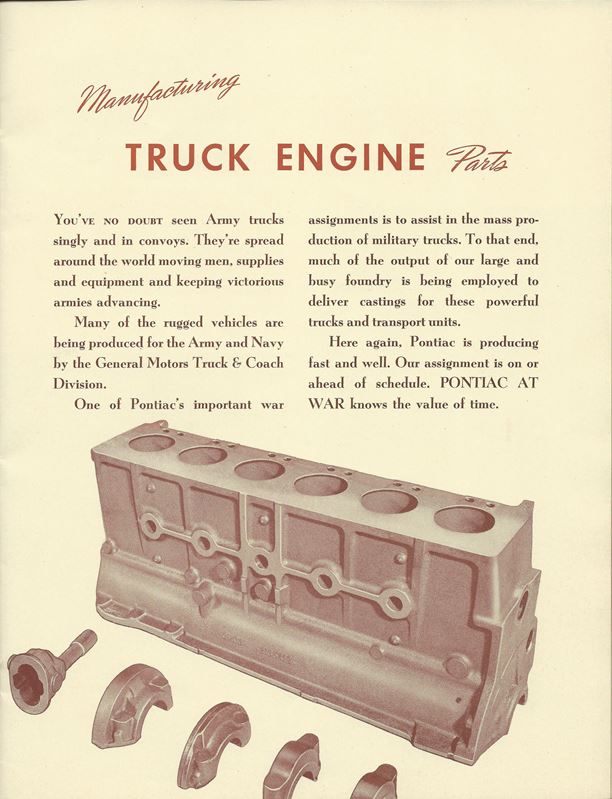

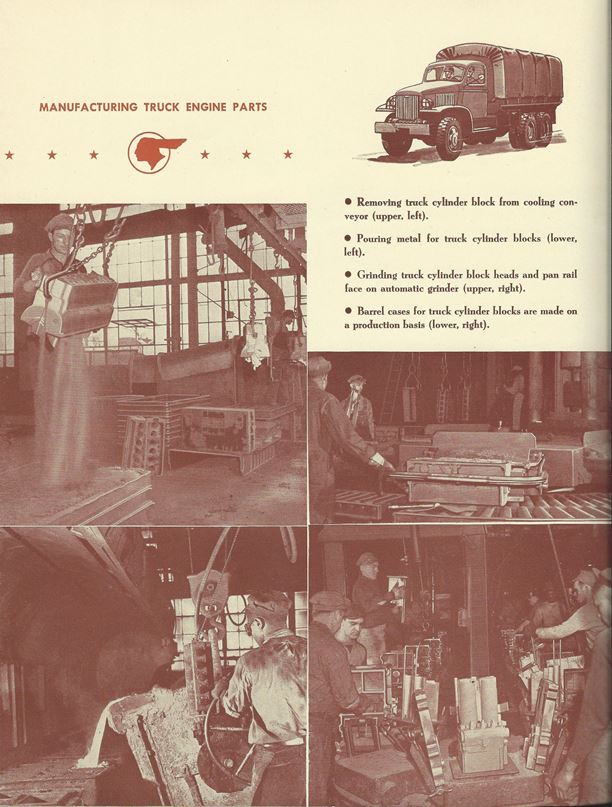

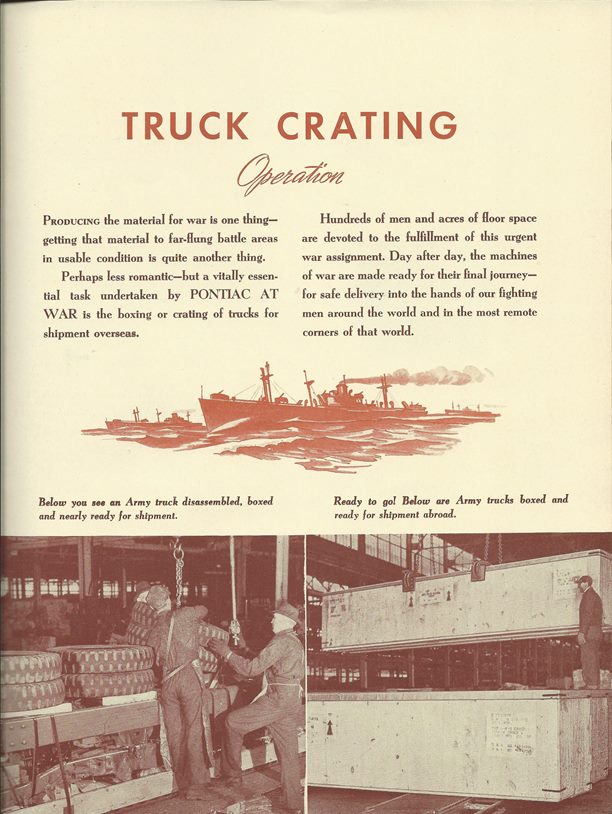

Pontiac cast all of the engine blocks for

528,829 GMC 6x8 and 24,910 6x4 trucks. This was the

270 cubic inch, six-cylinder engine. Pontiac also disassembled and

crated GMC trucks for overseas shipment. This saved valuable

shipping space on transport ships. Author's photo.

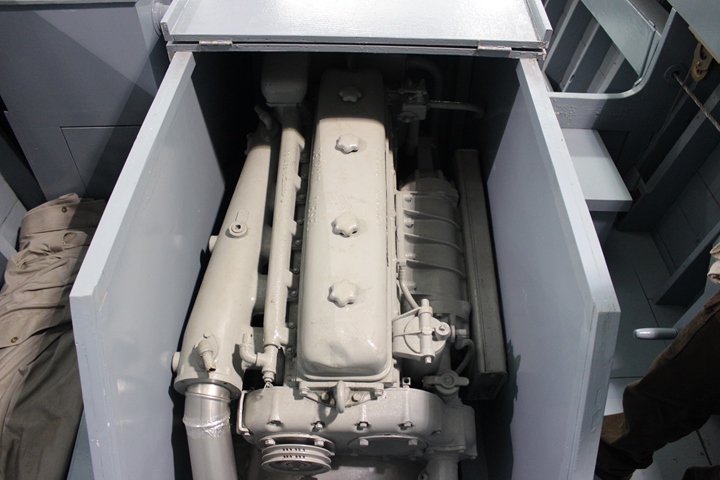

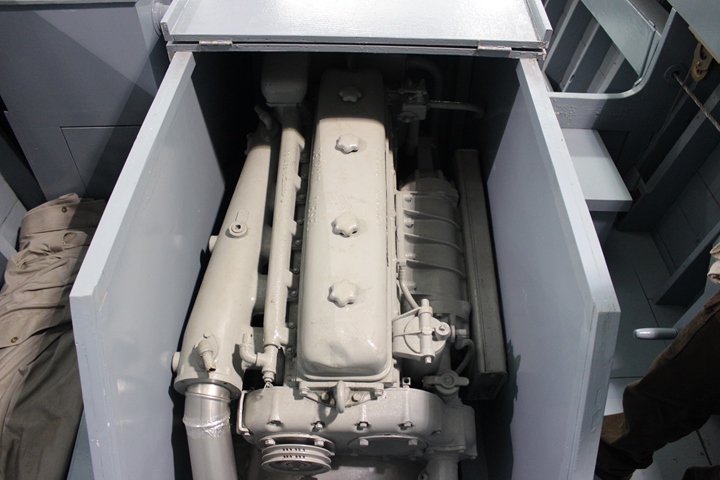

Pontiac supplied the Detroit Diesel Engine

Division of GM with fly-wheel housings, connecting rods, and

cylinder liners for its 6-71 diesel engines. Author's photo.

The Detroit Diesel engine was used in 19,353

LCVPs or Higgins boats. Detroit Diesels were also used in many

other types of landing craft for the US Navy. Author's photo added

4-10-2020.

The Detroit Diesel 6-71 with

Pontiac-manufactured components also powered many LCP(L) landing craft.

Author's photo added 4-10-2020.

Two Detroit Diesel 6046 engines powered

10,968 M4A2 Sherman tanks. Author's photo.

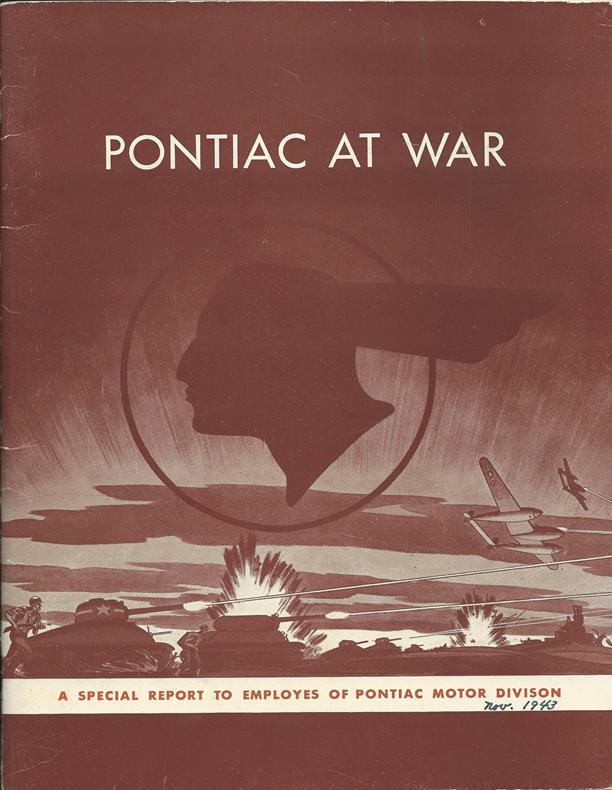

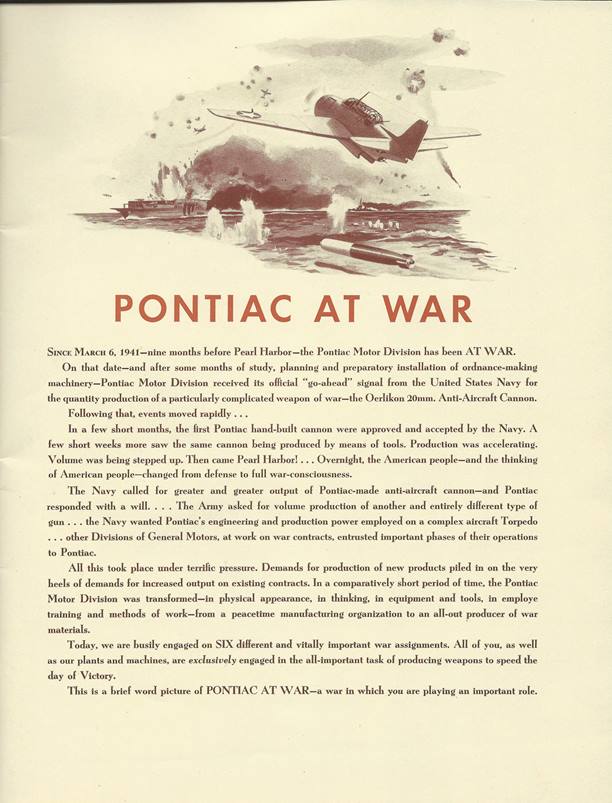

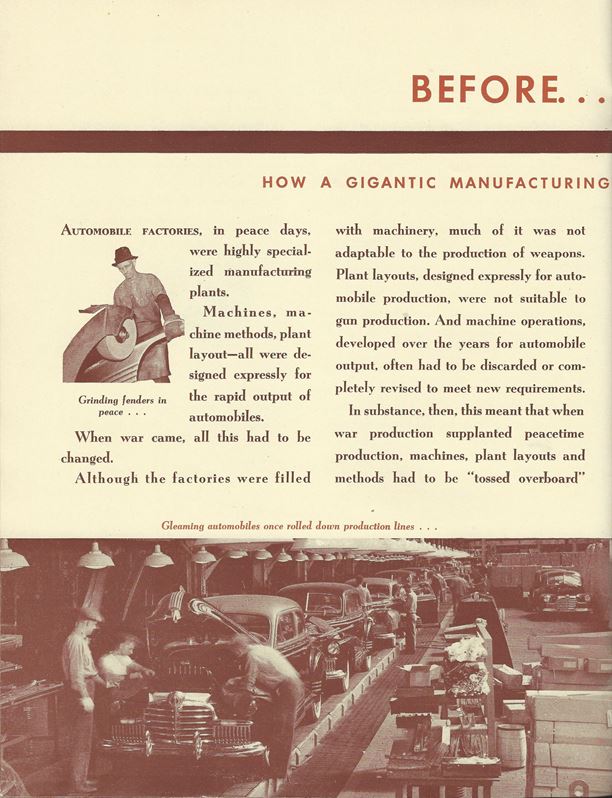

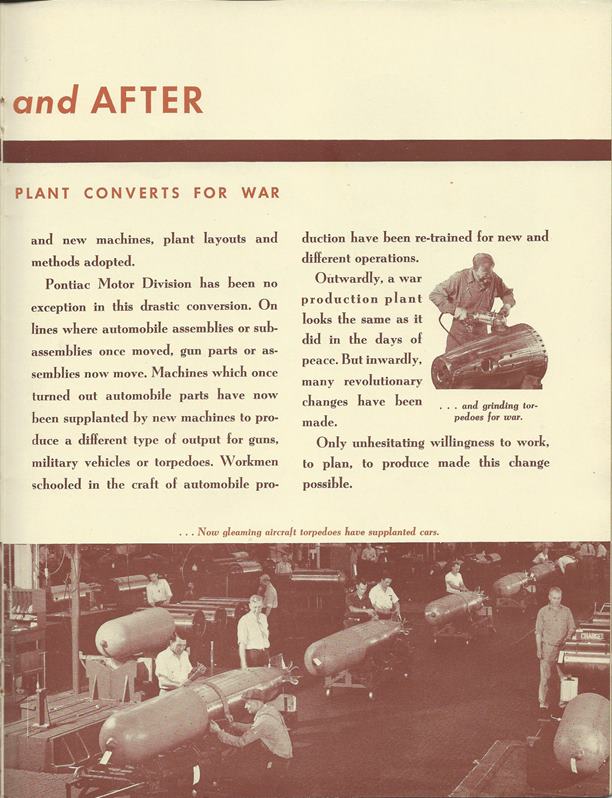

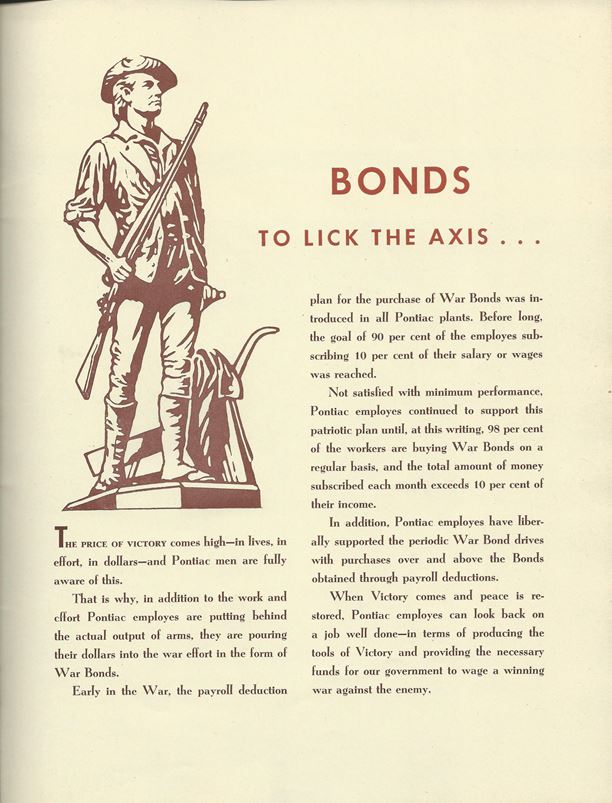

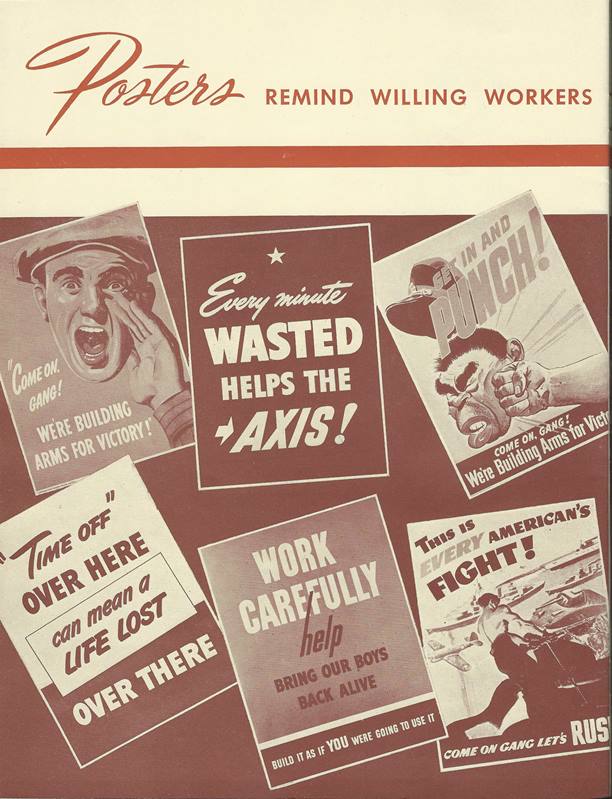

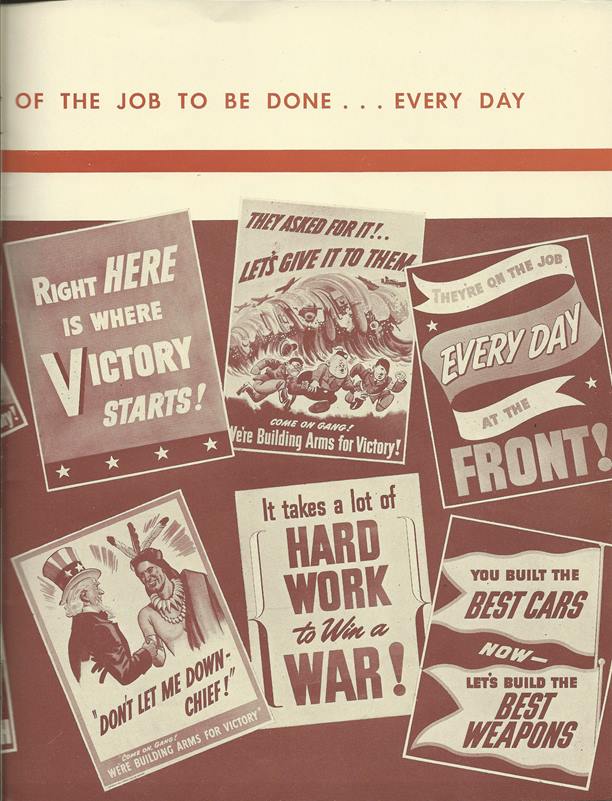

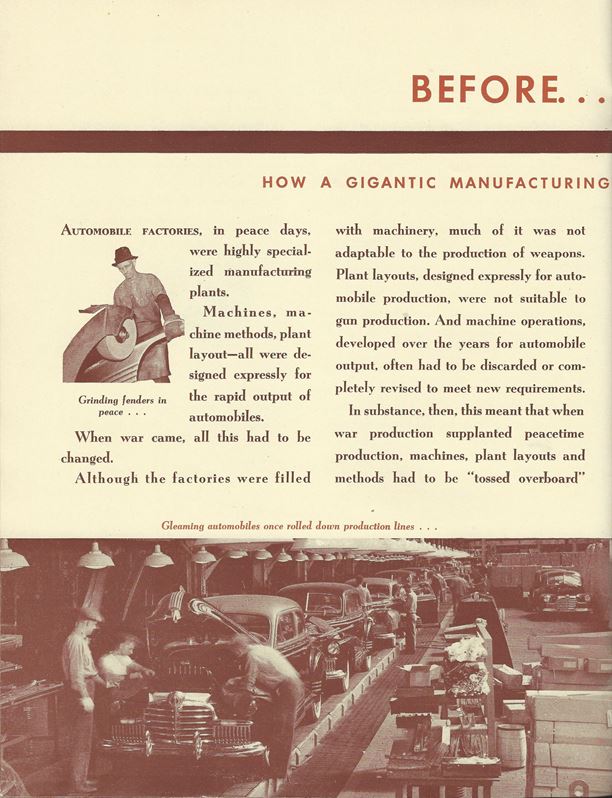

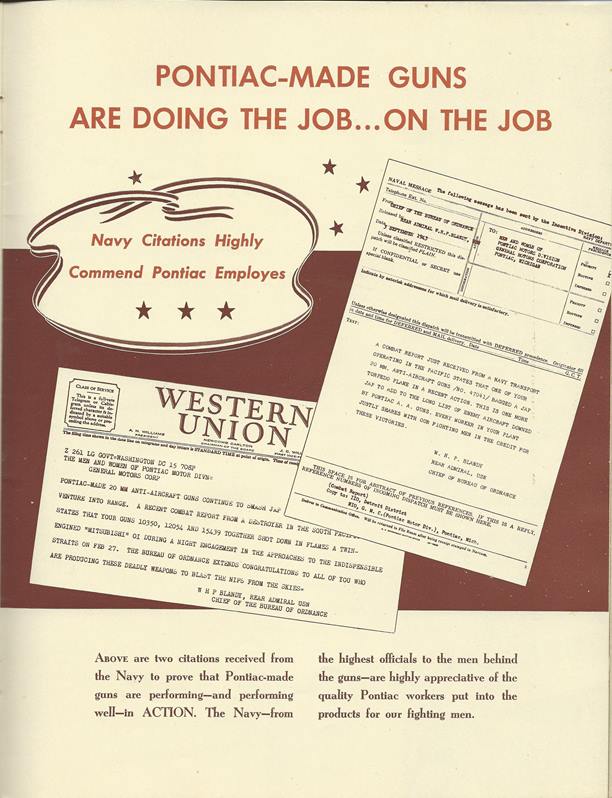

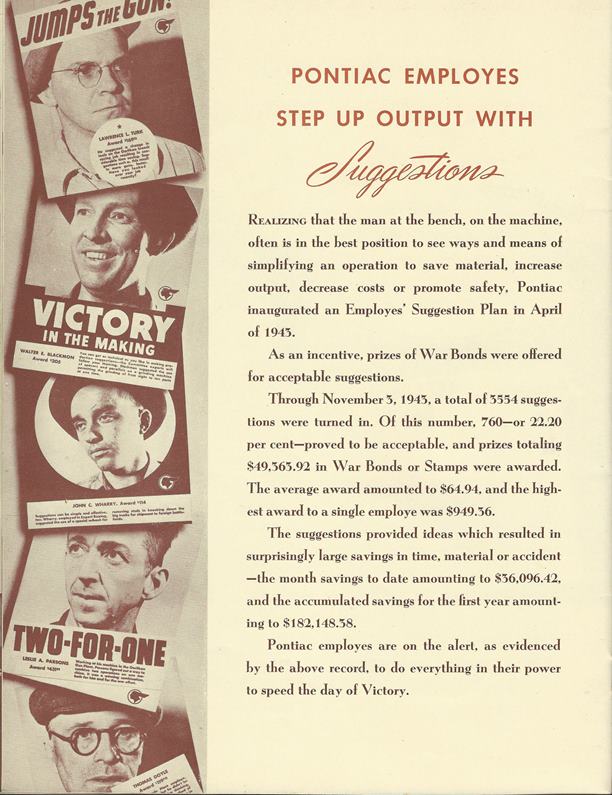

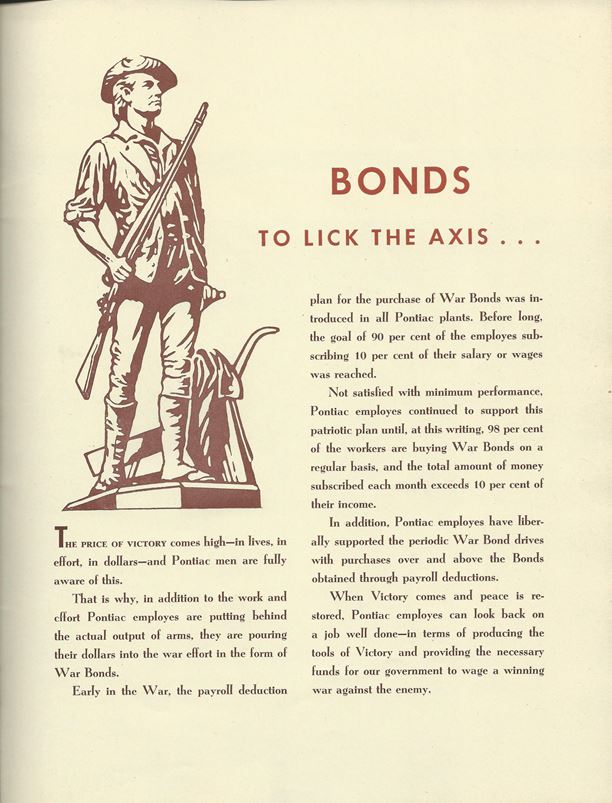

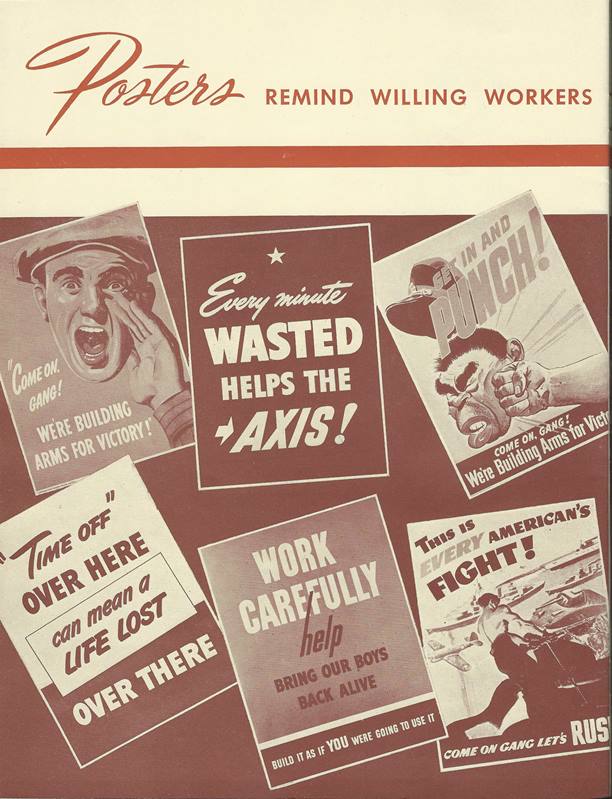

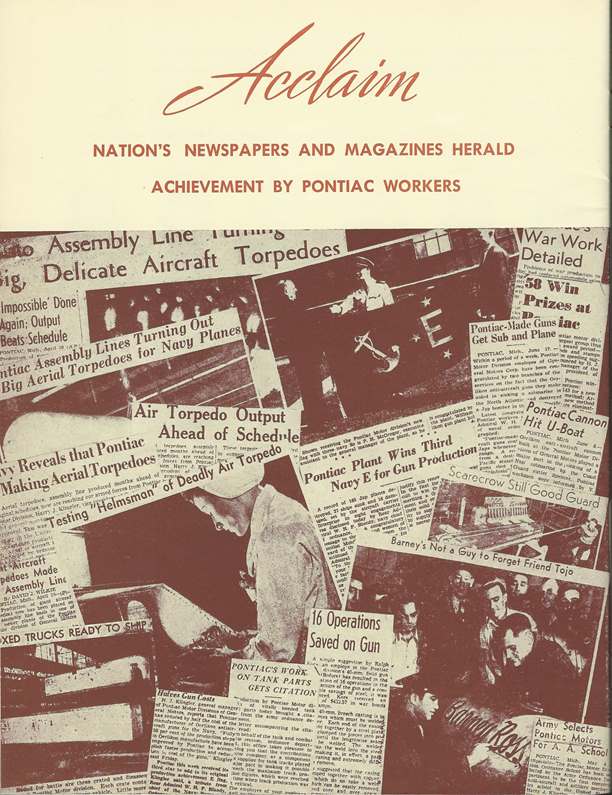

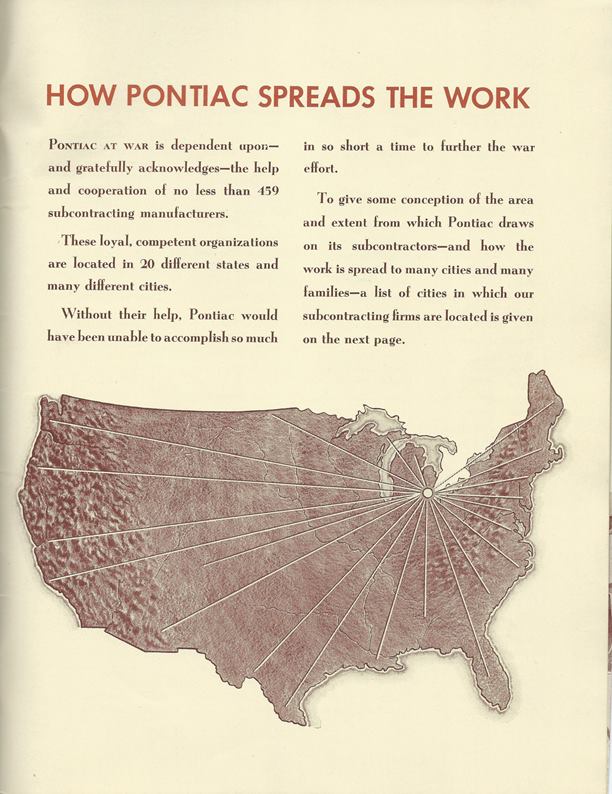

Pontiac at War

A Special Report to Employees of

Pontiac Motor Division

November 1943

This booklet has a wealth of information

about Pontiac's contribution to the war effort, starting in March 1941

through its publication in 1943. The three main war products; the

20mm Oerlikon, the 40mm Bofors, and the Mark XIII aerial torpedo all

have several pages dedicated to them. It includes an excellent

history of Pontiac until the start of World War Two. This rare booklet is a primary source

document, allowing a look back at Pontiac from its inception

through 1943.

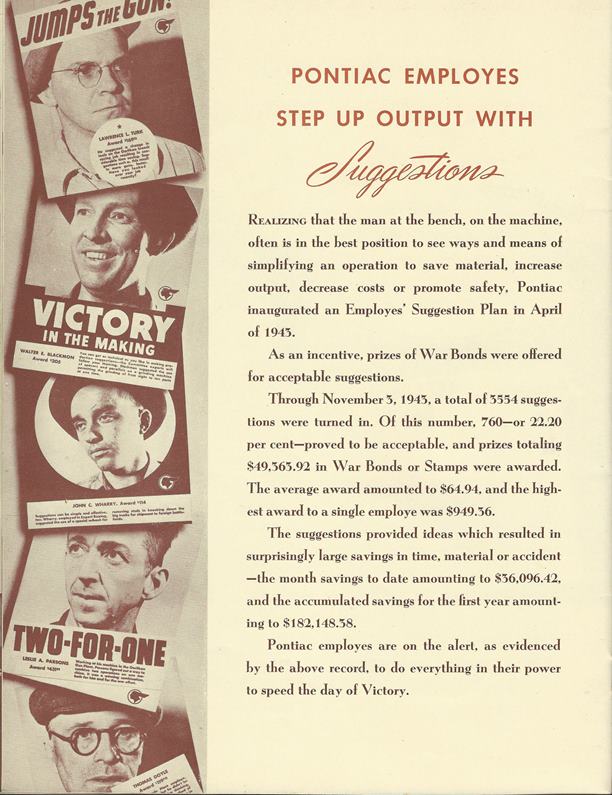

There is no date on the booklet.

However, presumed original owner wrote the date on the cover when he or

she received it. The date November 3, 1943 is documented on the page discussing the suggestion program. The booklet must have been published, then, by the end of

that month.

The history of Pontiac Motor Division

from 1893 until WWII, as written by Pontiac, is included in the next

three pages.

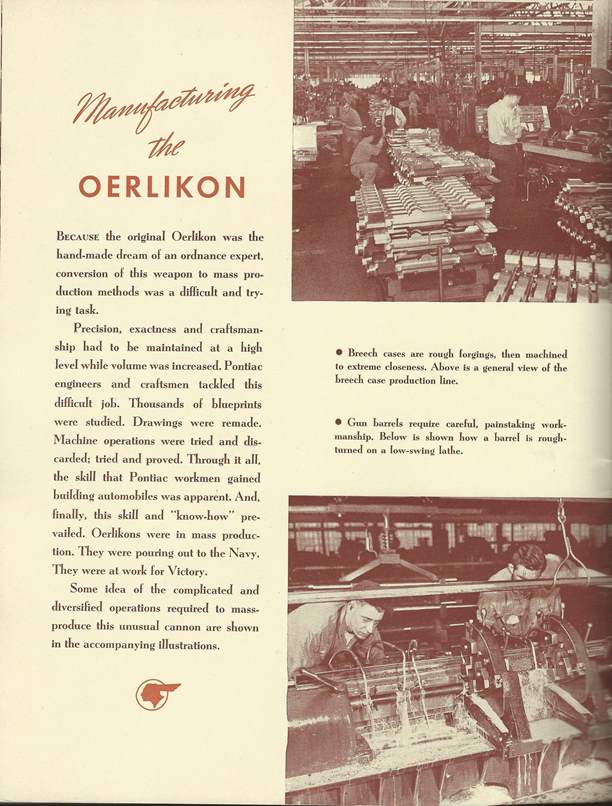

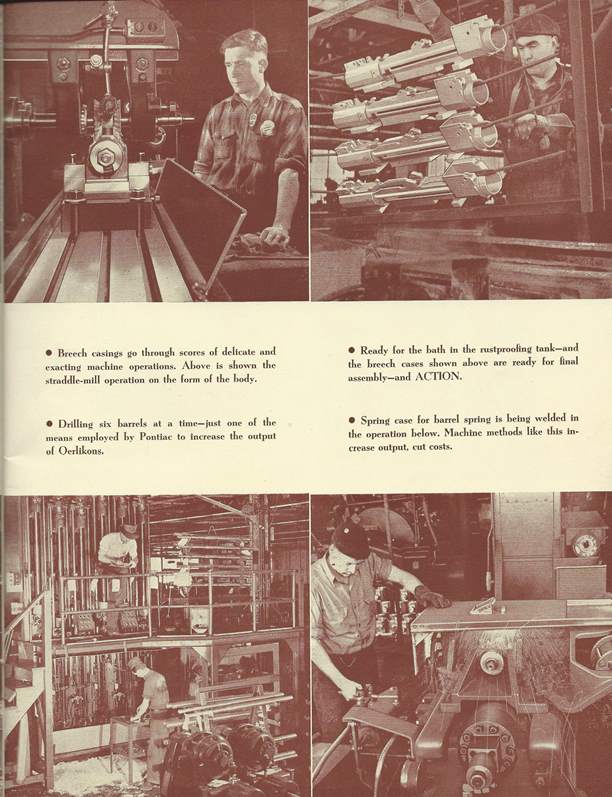

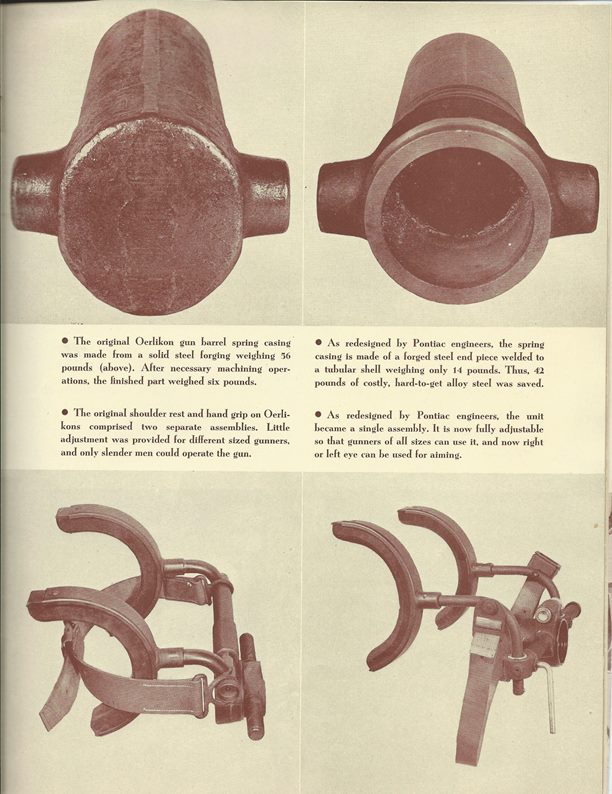

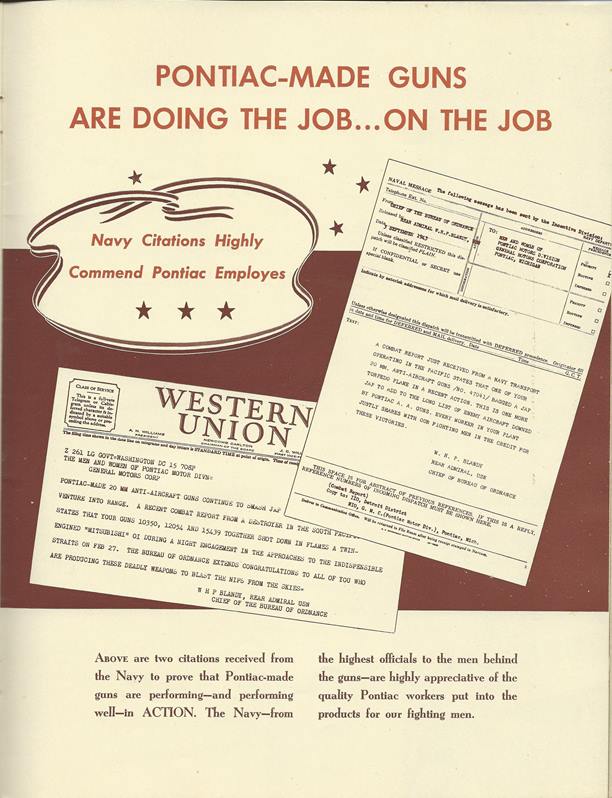

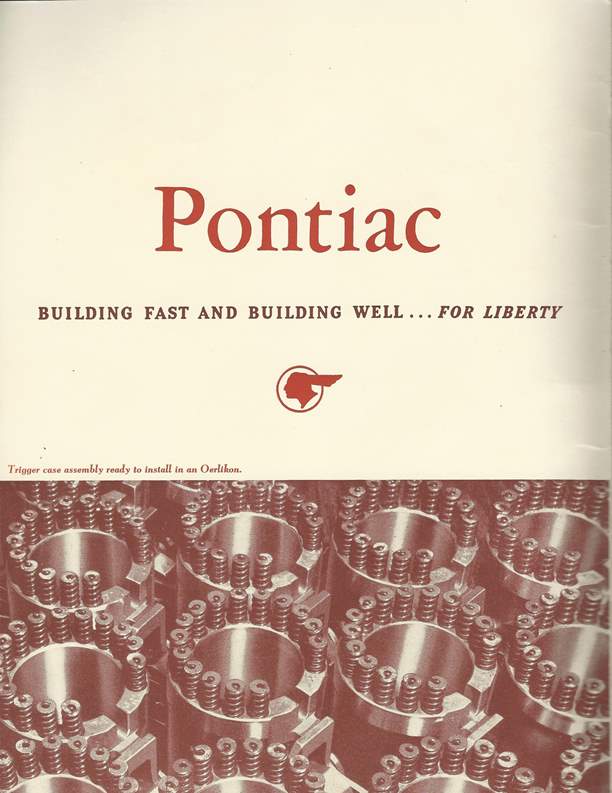

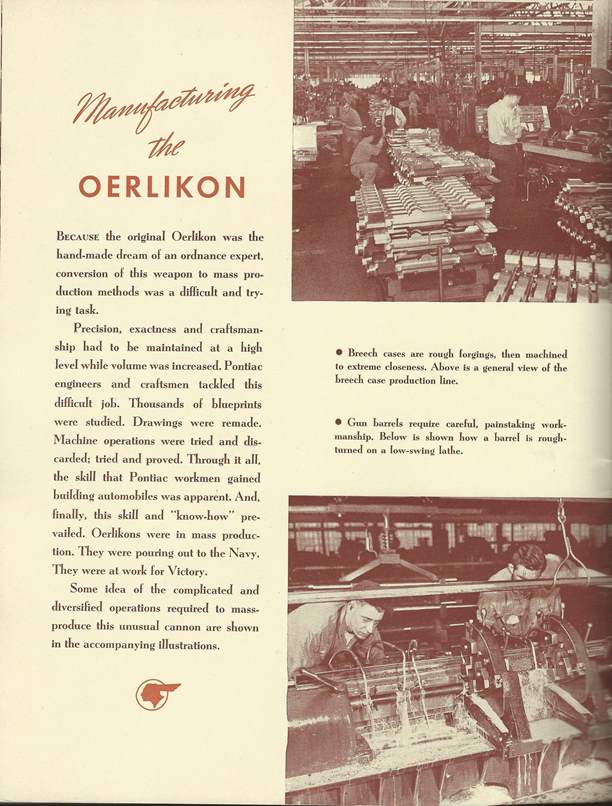

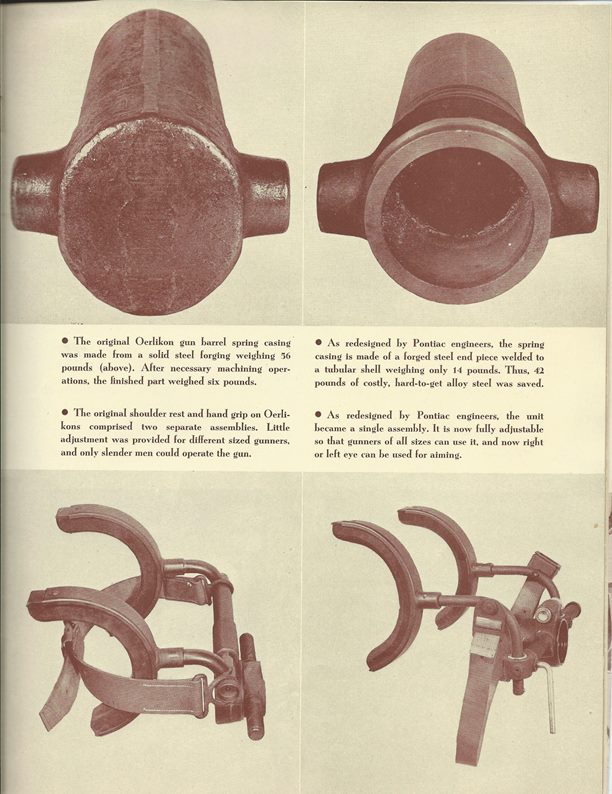

In the next two pages, Pontiac gives more

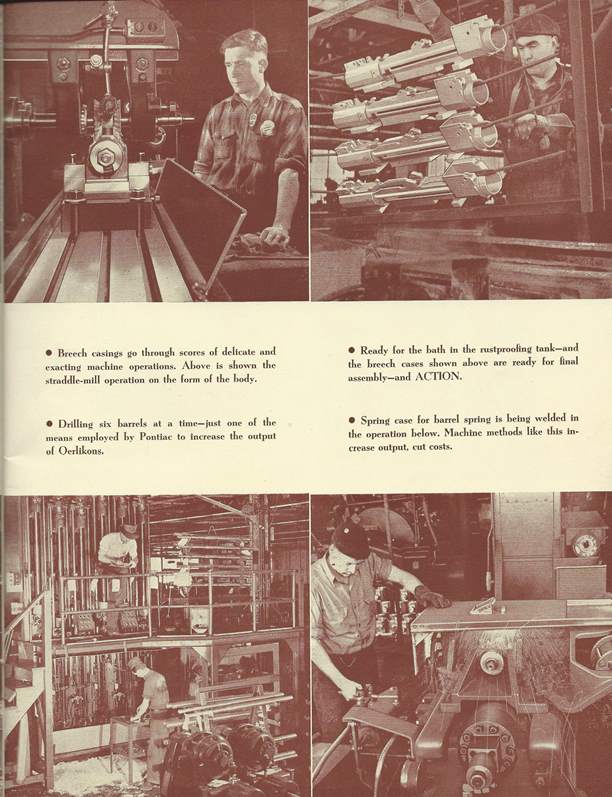

information on its manufacture of the 20mm Oerlikon anti-aircraft cannon

for the US Navy.

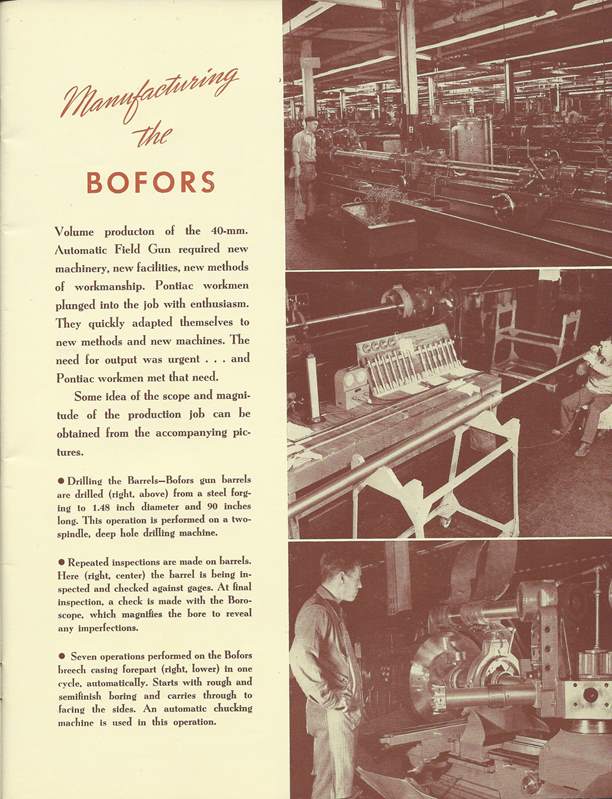

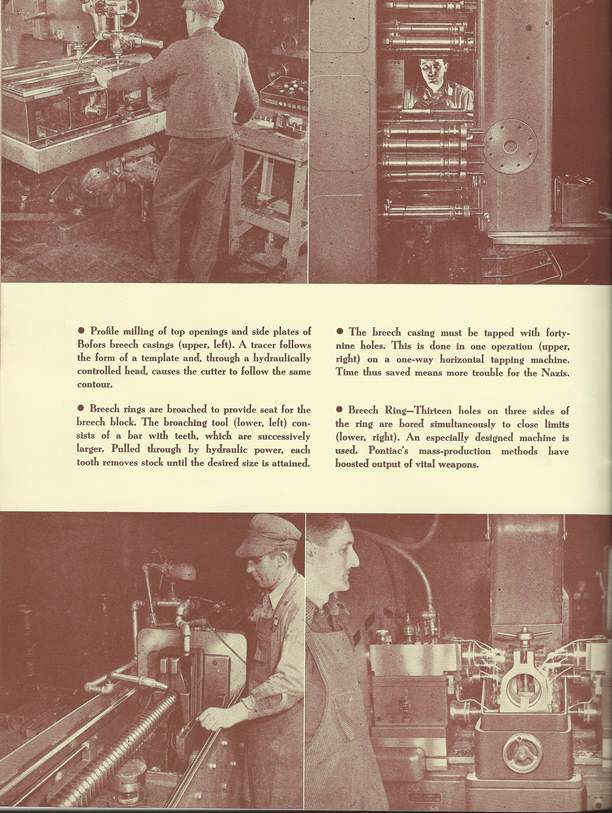

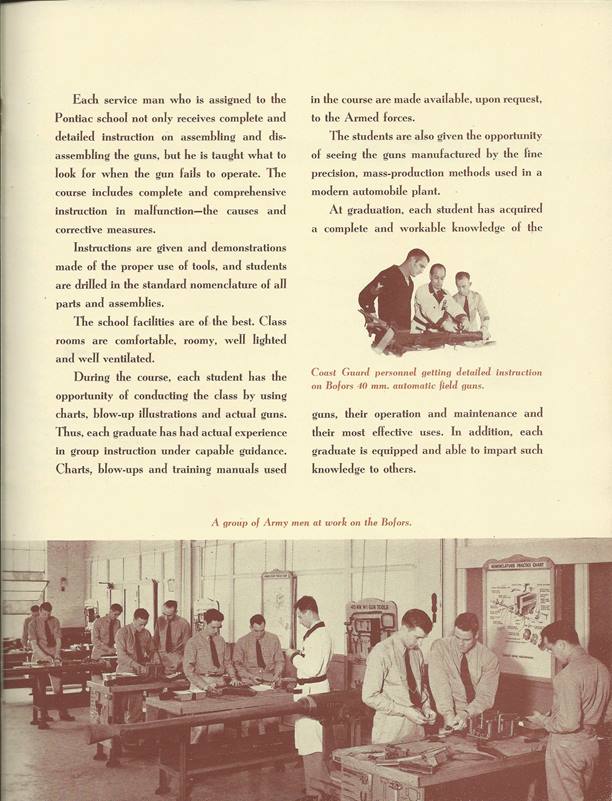

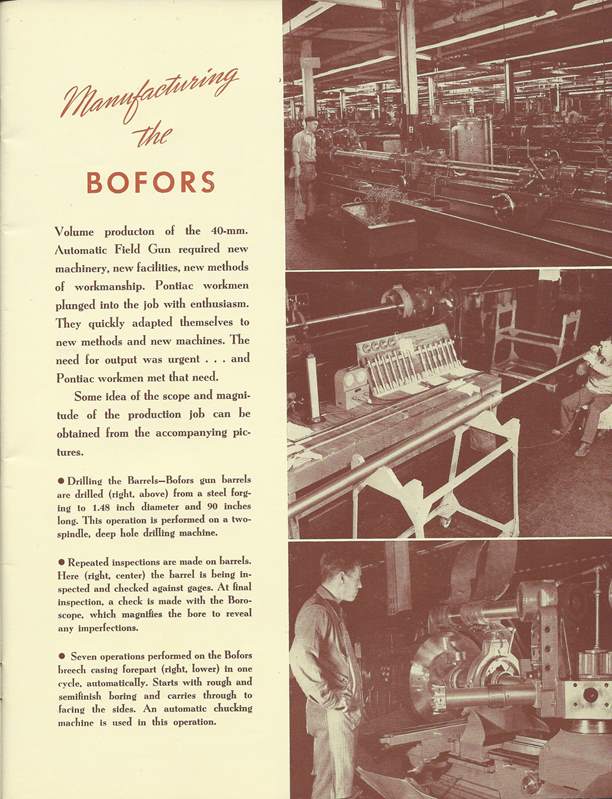

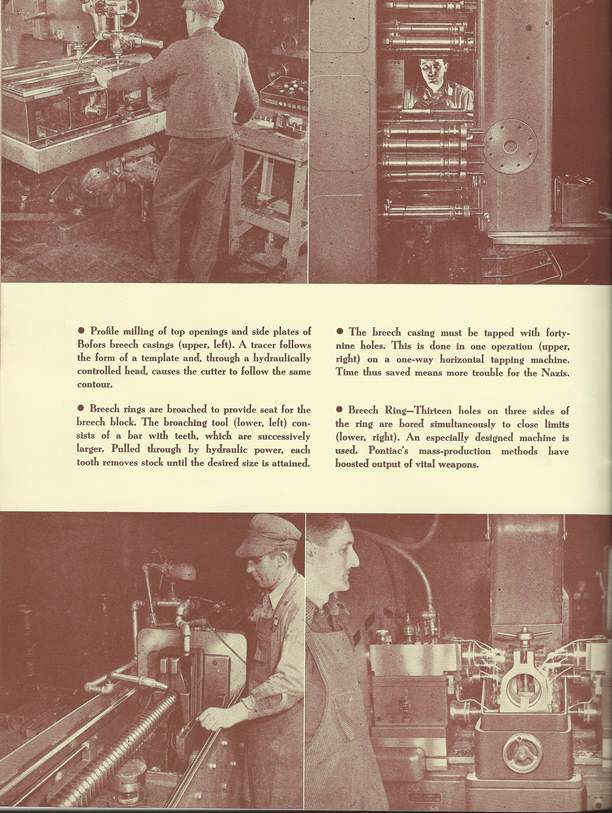

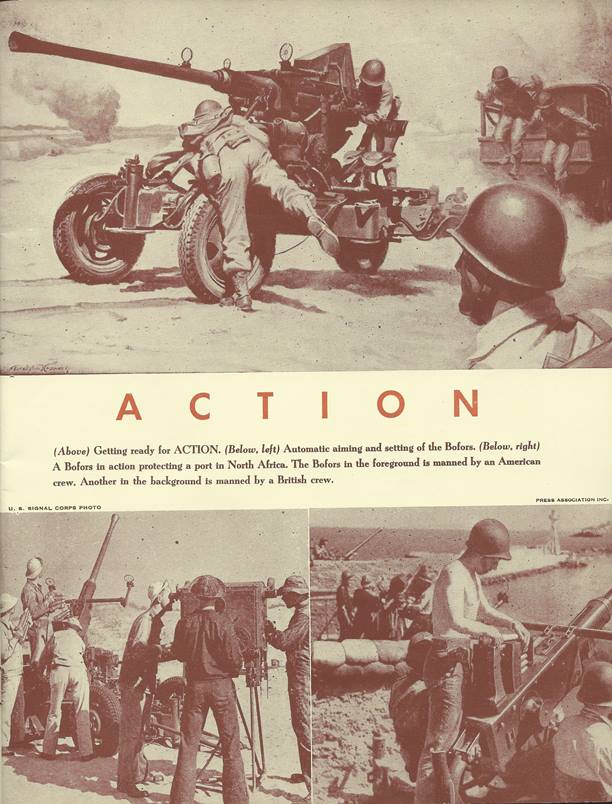

In the next three pages, Pontiac gives

details on its manufacture of the 40mm Bofors anti-aircraft cannon for

the US Army.

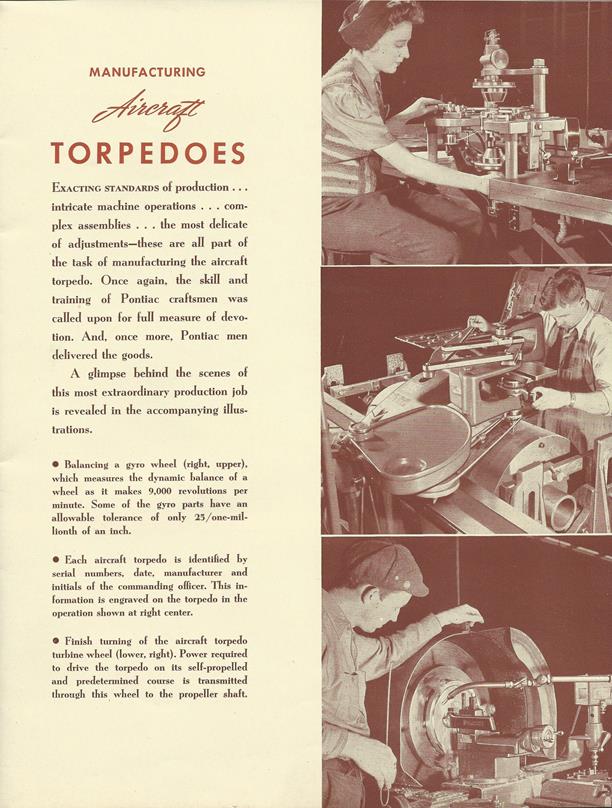

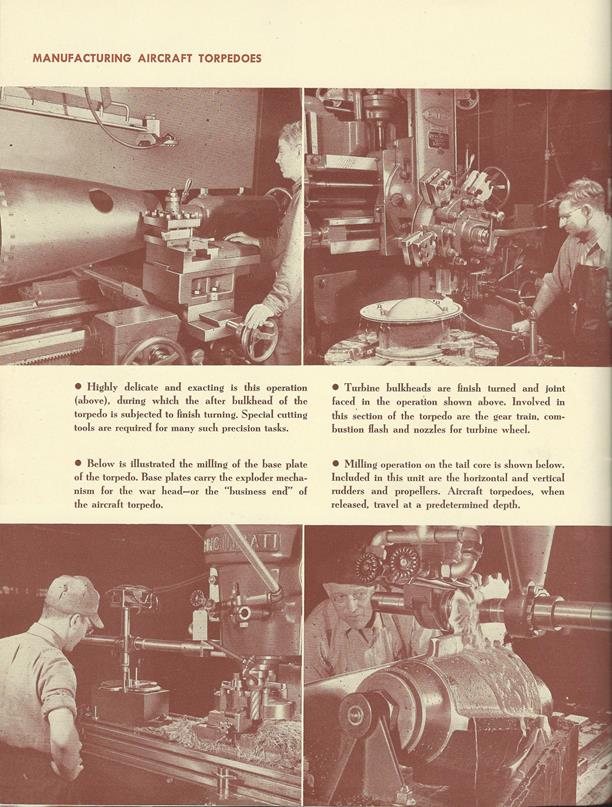

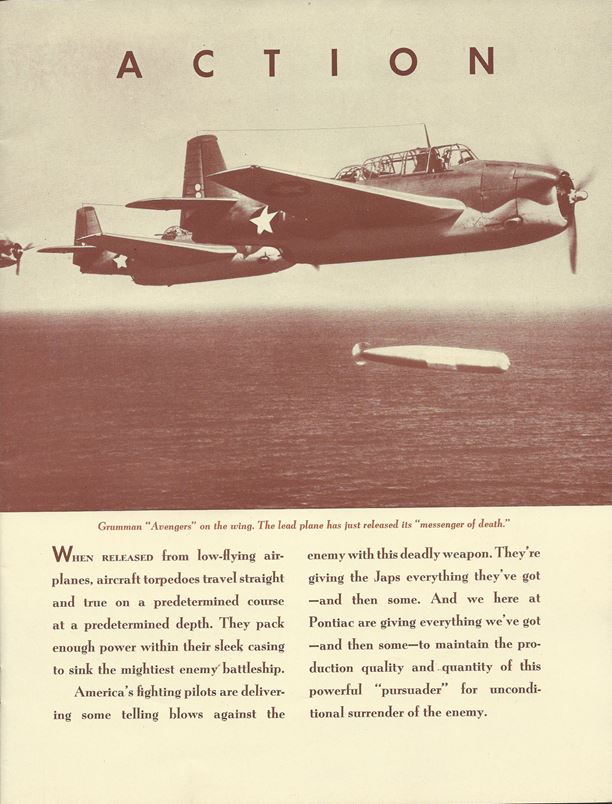

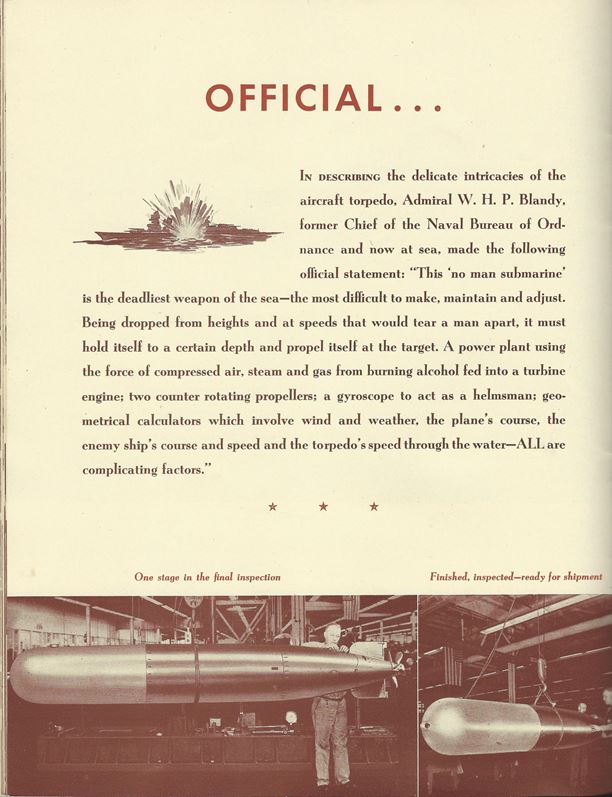

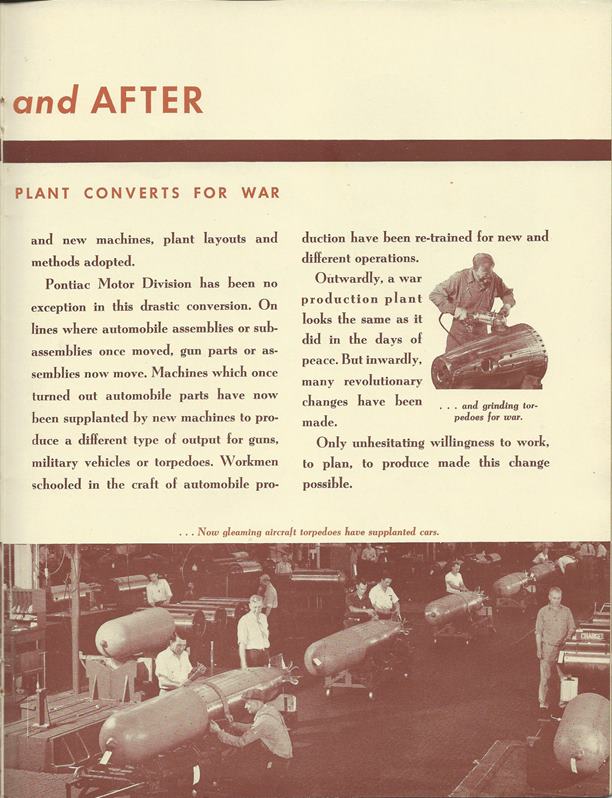

Below are five pages on Pontiac's

manufacture of Mark XIII aerial torpedoes and their use by the US Navy.

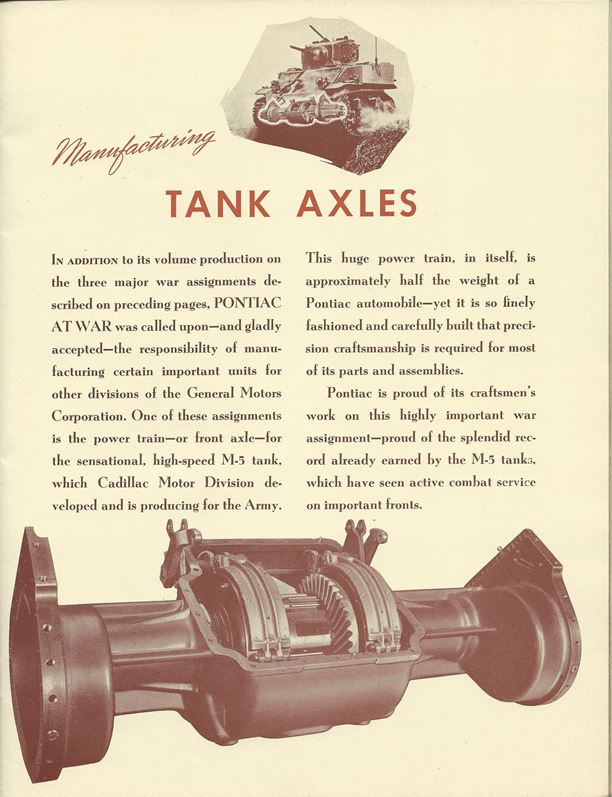

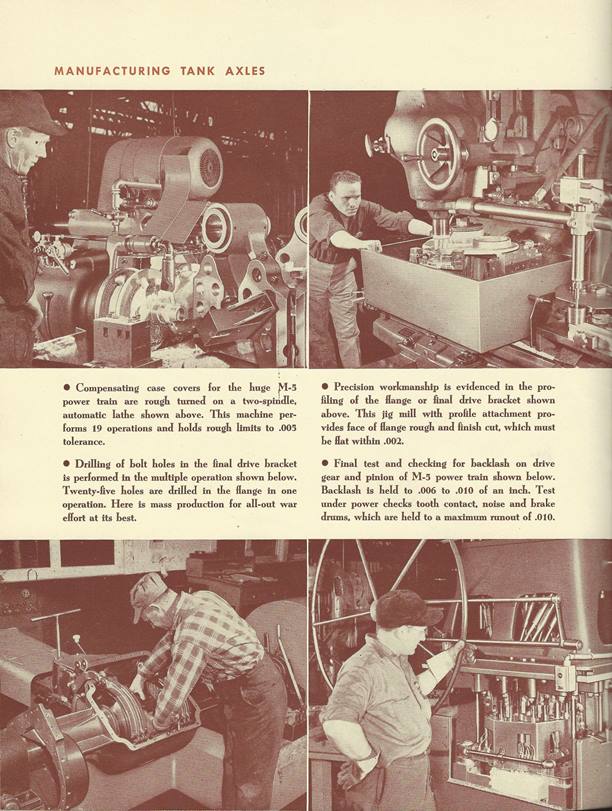

Below is information on Pontiac's

manufacture of tank axles for the M5 Stuart light tank.

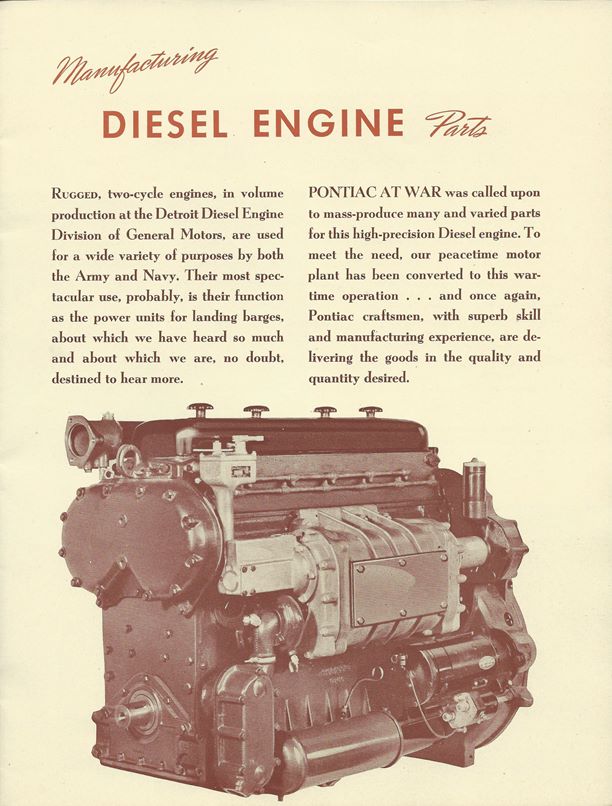

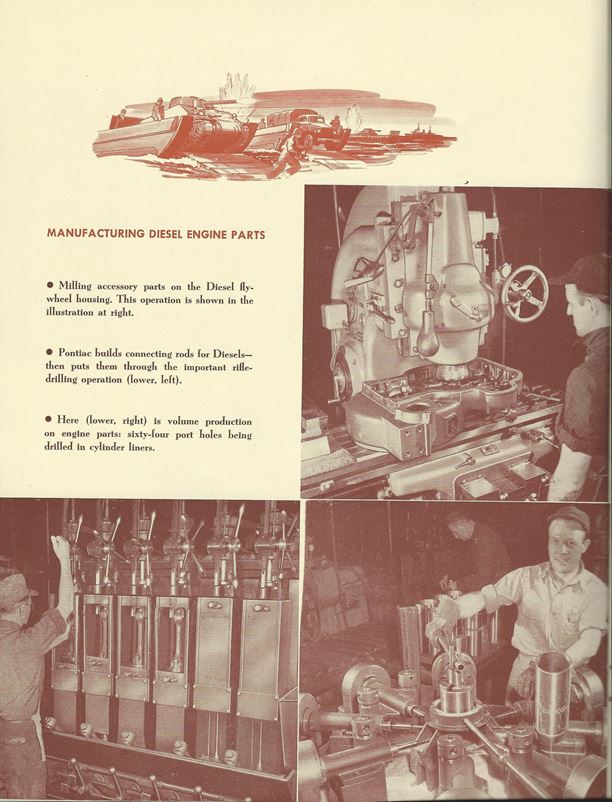

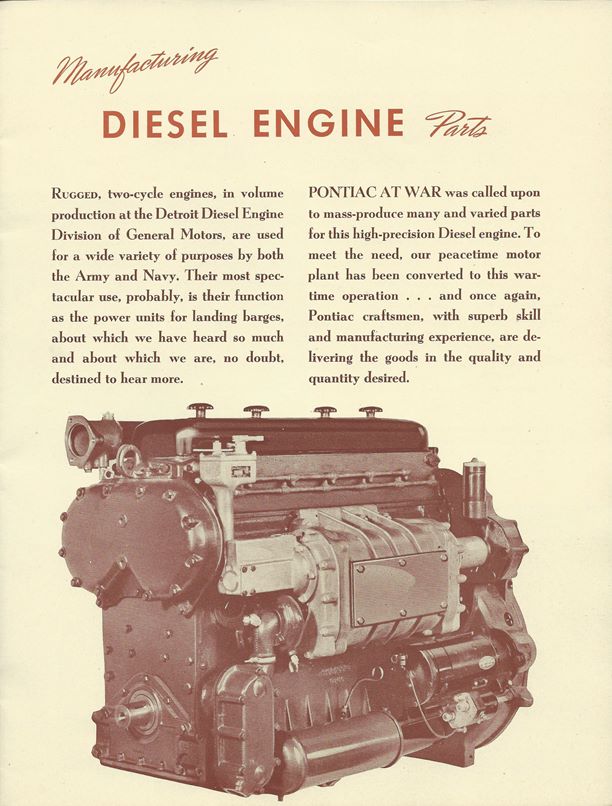

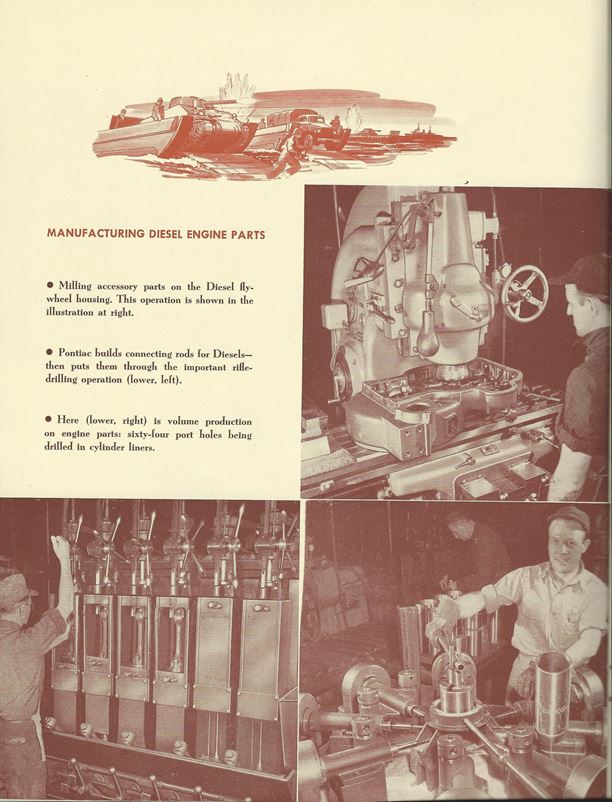

Pontiac's manufacture of diesel engine

parts, as described below, was an important contribution to the war effort.

These engines were used in a variety of landing craft and tanks.

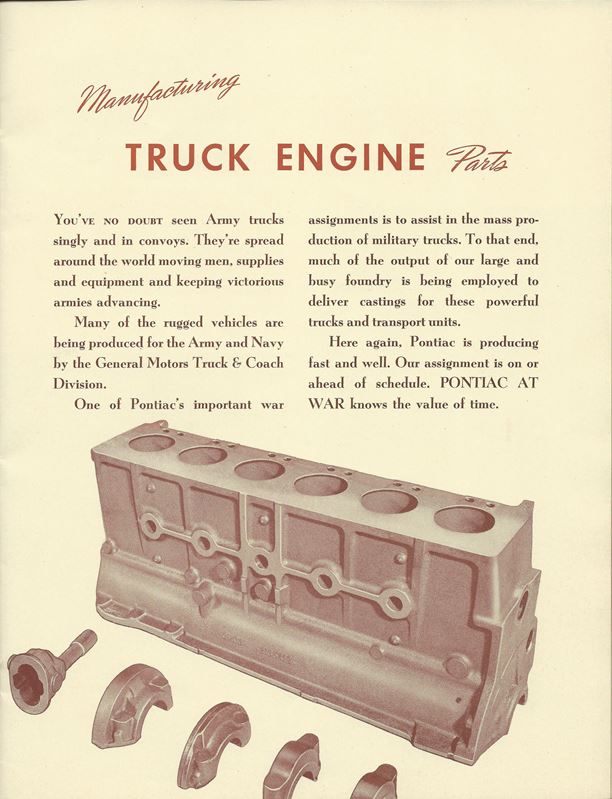

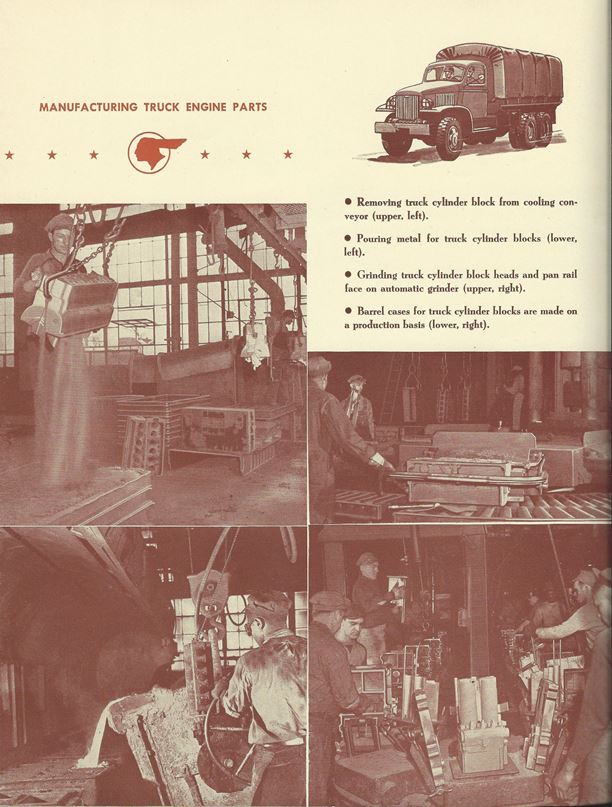

Pontiac's casting of engine blocks for

GMC trucks and DUKWs is described below.

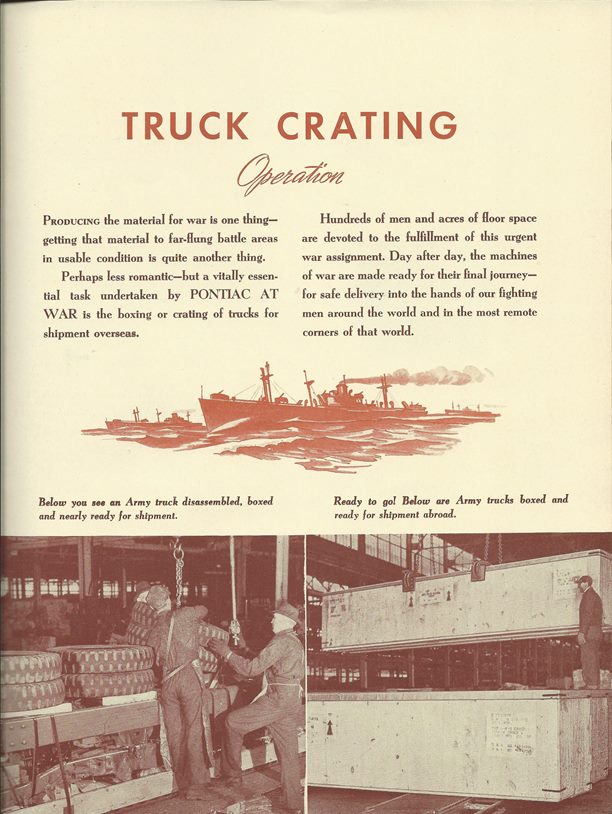

Pontiac and GMC were both located in

Pontiac, MI. Pontiac was able to assist in the war effort by

crating for overseas shipment the 2-1/2 ton 6x6 GMC trucks. This allowed

GMC to focus on the important assembly of trucks for the war effort.

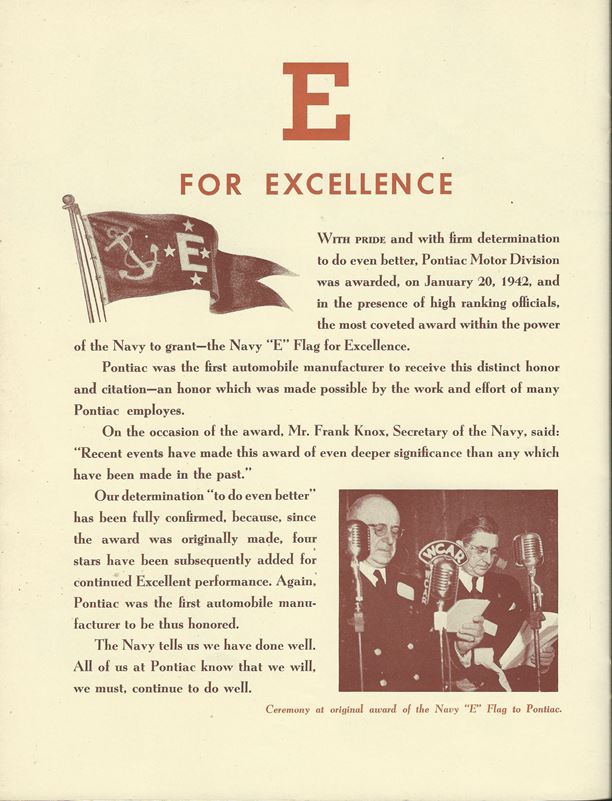

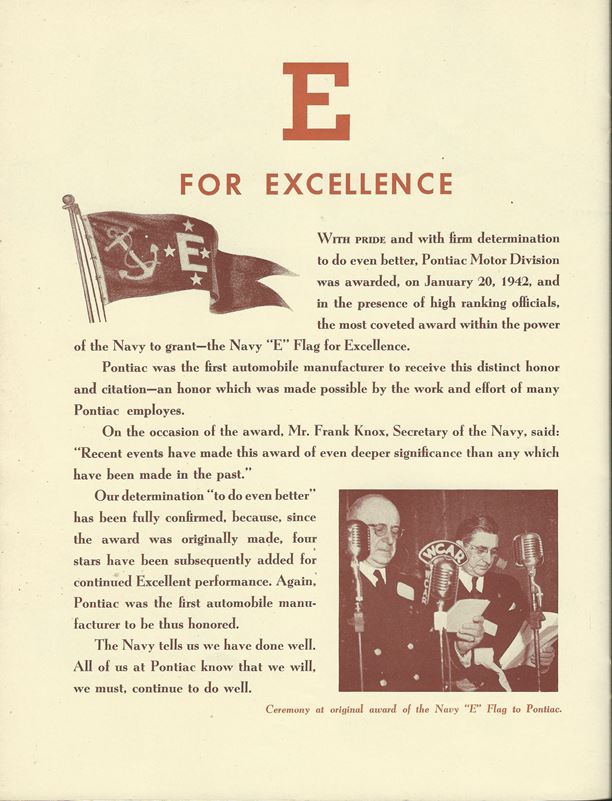

The above page gives more details on the

continued awarding of Navy "E" award, and the four stars

added by November 1943. These would be for manufacture of the 20mm Oelikon anti-aircraft cannon. This would imply that the awards for

the Torpedo Plant and Plant 14 came later. These would have been

the combined Army-Navy "E" awards.

Pontiac Post WWII Military Products

Pontiac Motor Division of General Motors

built 35,000 M39 20mm aircraft cannon from 1951 to 1975. This type

cannon was used in the F86H, F-101A, F-101C, and the F-5. Author's

photo added 5-5-2019.

|