|

John

Deere (Deere and Company) in World War Two

Moline, IL

Waterloo, IA (Iowa Transmission Company, Division of John Deere)

1837-Present

This page updated 7-1-2019.

John Deere is the brand name

for Deere and Company, which had its beginnings in 1837 in Grand Detour,

IL. The company originally produced plows. Today,

its iconic green and yellow equipment is seen everywhere in

the United States. It has become an American icon.

John Deere started by making plows with

steel rather than cast iron blades. This kept the rich black,

moist soil of the Midwest from sticking to the blades. This is one

of the many displays at the John Deere Pavilion in Moline, IL.

Author's photo added 7-1-2019.

Authors note:

This is the oldest company listed on this website. What a

long and successful run for this company! DDJ 8-27-2018

Also at the John Deere Pavilion is this 1917

four-wheel drive tractor, one of 90 built, and the most complete one

still in existence. This was John Deere's first tractor.

Author's photo added 7-1-2019.

John Deere equipment with its

distinctive green with yellow trim. Author's photo.

I live in a farming area of Indiana and see many green and yellow John

Deere tractors and combines in the fields during the planting and

harvesting seasons. They are easy to identify versus other farm

equipment from other equipment manufacturers that have changed paint

colors over the years through mergers and new ownerships. I have

also found that farmers owning John Deere equipment are extremely loyal

to the brand. Much of this is due to something that happened 90

years ago; The Great Depression. Many farmers were not able

to make payments on their John Deere tractors due to the hard times the

Depression brought. John Deere worked with the farmers by

extending financing or allowing partial or delayed payments. The

farmers and their decedents who continued to work the farms

remembered this. Today John Deere brand loyalty still runs deep in

many farming families.

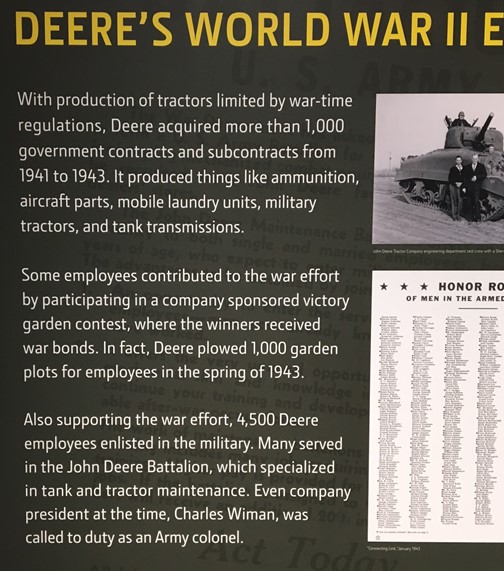

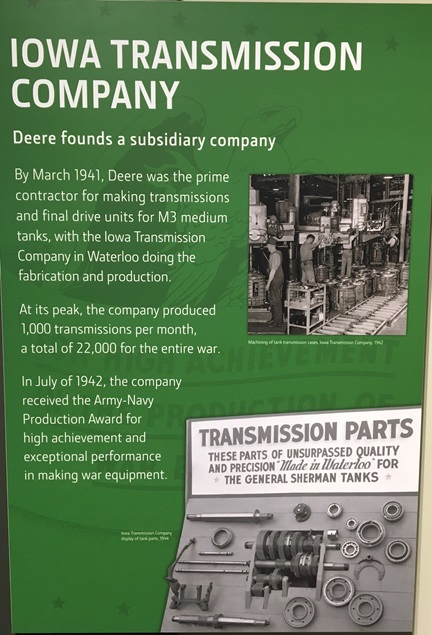

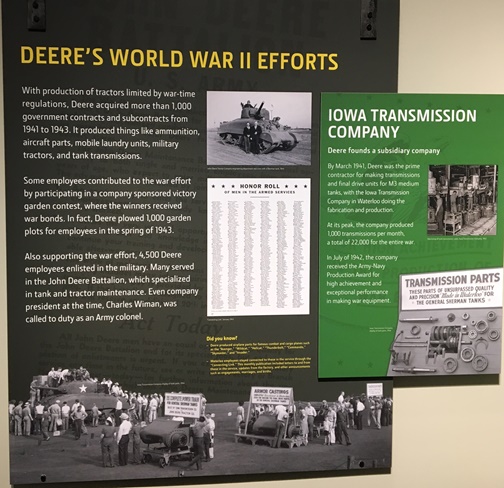

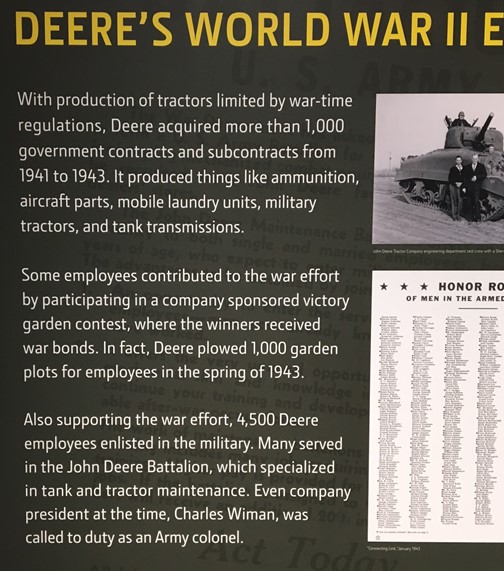

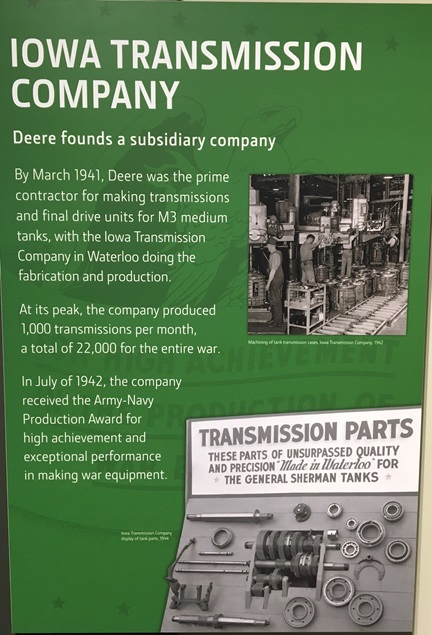

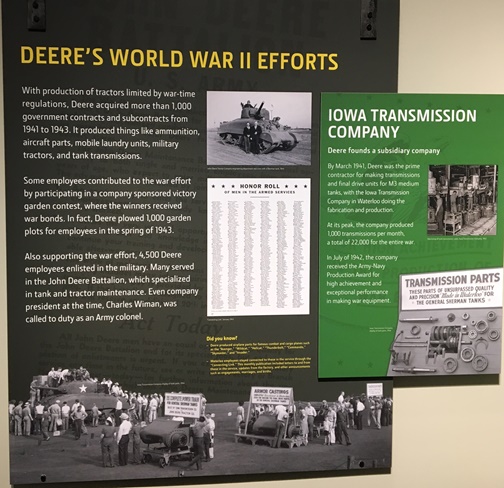

The Iowa Transmission Company, John Deere

Company Plant at Waterloo, IA won the Army-Navy "E" award five times

during WWII. The first award was in July 1942 for the timely delivery of

M3 and M4 tank transmissions.

John Deere

World War Two Production Statistics:

(2,190) High Speed 7-ton M2 Tractors, (5,270) Armored M8 Trailers,

(22,000) transmissions and final drive assemblies for M3 and M4 medium

tanks, ammunition ( Most likely shells or shell casings.), mobile

laundry units and aircraft parts. John Deere had over 1,000

military contracts during the war, so there is no doubt additional

statistics.

Author's Note: Below the first

and second photos from the John Deere Tractor and Engine museum show

that the company made ammunition during World War Two. I have

noted above that most likely this was a component of the ammunition,

either the shell or the shell casing, as were made by other vehicle

manufacturers during the war. Making the actual ammunition would

include assembly of the shell, shell casing, primer, and powder.

This was done exclusively at ammunition arsenals located in

remote areas, due to the possibility of an accidental explosion.

Ammunition arsenals encompassed large secure restricted areas. Therefore, I

believe the term ammunition is incorrect in this case. No doubt, John

Deere stamped out or machined ammunition components that were then

shipped to an arsenal for the more dangerous final assembly.

Most likely the John Deere ammunition

components were being shipped to the nearby Ankeny, IA Ordnance Plant

built in 1941, and managed by the U.S. Rubber Company. The plant

made billions of rounds of .30 caliber and .50 caliber machine gun

ammunition during World War Two. In 1947 John Deere bought the

industrial portion of the Ankeny Ordnance plant. Today it is the

John Deere Des Moines Works.

John Deere

World War Two

Vehicles

Accepted by Detroit Ordnance, US Army

The information below comes from "Summary Report of

Acceptances, Tank-Automotive Material, 1940-1945"

Published by Army Services Forces, Office, Chief of

Ordnance-Detroit, Production Division, Requirements and

Progress Branch

January 21, 1946. |

|

Type |

Same as |

1940 |

1941 |

1942 |

1943 |

1944 |

1945 |

Total |

| Tractor, High Speed, 7-ton, M2 |

Cleveland Tractor

Company "Cletrac" |

|

|

31 |

2,159 |

|

|

2,190 |

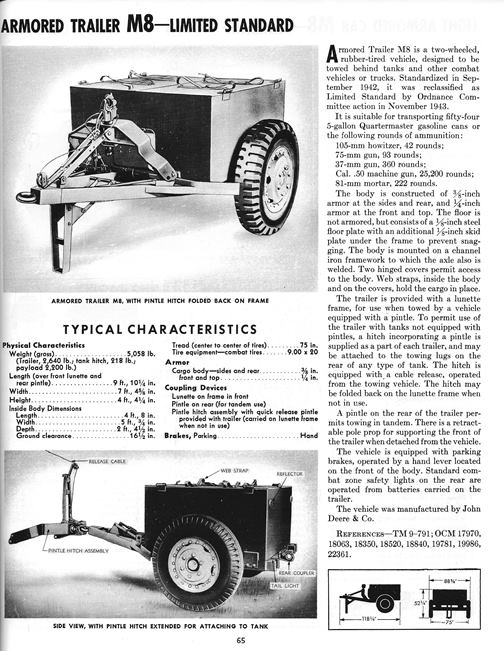

| Trailer, Armored, M8 |

|

|

|

1,704 |

3,566 |

|

|

5,270 |

|

Total |

|

|

|

1,735 |

5,725 |

|

|

7,460 |

Author's Note

and Disclaimer: The Detroit Office

of Ordnance of the U.S. Army was the primary purchasing entity for

vehicles for the U.S. Army during WWII. It also purchased vehicles

for the USMC, US Navy, and for Lend-Lease. However, there were

other organizations that also purchased vehicles including the Army

Corps of Engineers, U.S. Army Air Force, U.S. Army Signal Corps, Navy

Bureau of Ordnance, Navy Bureau of Aeronautics, and foreign countries

making direct purchases.

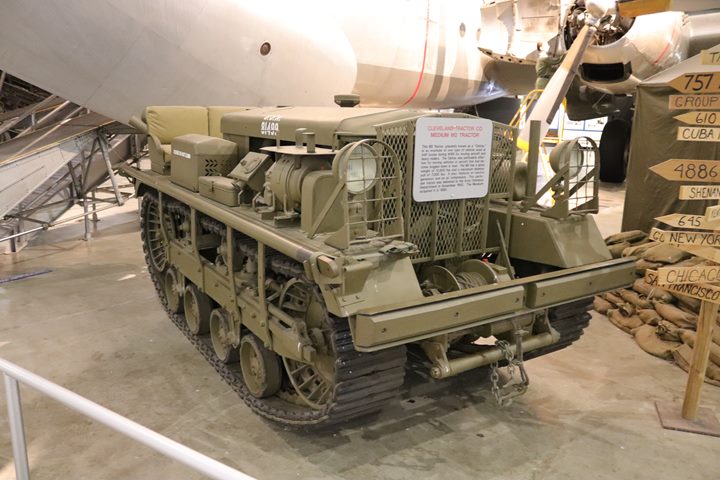

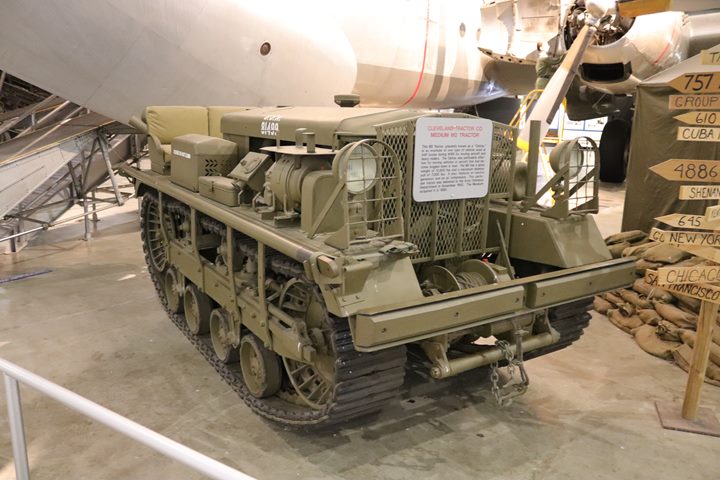

The Cleveland Tractor Company designed the

7-ton M2 High-Speed tractor for the U.S. Army to be used as an artillery

prime mover. However, the "Cletrac" as it came to be known, was

used extensively by the USAAF to move aircraft at unprepared airstrips.

Between John Deere and the Cleveland Tractor Company a total of 8,510

were built. John Deere's production of 2,190 was 26% of the total

units produced. Pictured here is a Cleveland Tractor built M2 on

display at the Museum of the United States Air Force. Author's

photo.

Author's photo.

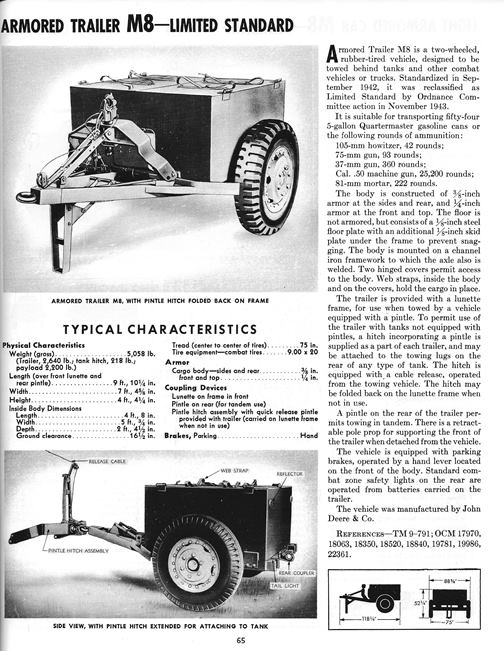

John Deere was the only producer of the M8

Armored Trailer.

John Deere Tractor and Engine Museum,

Waterloo, IA World War Two Display: My early attempts to find

information on John Deere produced virtually nothing. Then in July

of 2018, my son made a business trip to one of the John Deere plants in Waterloo,

IA. Afterwards, he went to the museum which had the World War Two

display shown below. With this and some other new information I

had just recently obtained, I have been able to assemble this page on

John Deere in World War Two.

\ \

Photo courtesy of David D. Jackson, Jr.

Photo courtesy of David D. Jackson, Jr.

As noted above, the Iowa Transmission

Division of John Deere in Waterloo, IA was the prime

transmission and final drive assembly contractor for the M3 medium tank.

5,958 M3 medium tanks were produced in 1941-1942. The display

above also references the M4 Sherman medium tank which started

production in 1942, replacing the M3 on the assembly lines. The

22,000 transmissions and final drive assemblies produced at Waterloo

were spread over the two types of tanks and one type of tank destroyer,

the M10 Wolverine. The transmissions

and final drive assemblies were interchangeable between the two tanks

and the M10.

John Deere and its Iowa Company Transmission plant had combined total

contracts for transmissions and final drive assemblies worth $6,139,050

in World War Two. Photo courtesy of David D. Jackson, Jr.

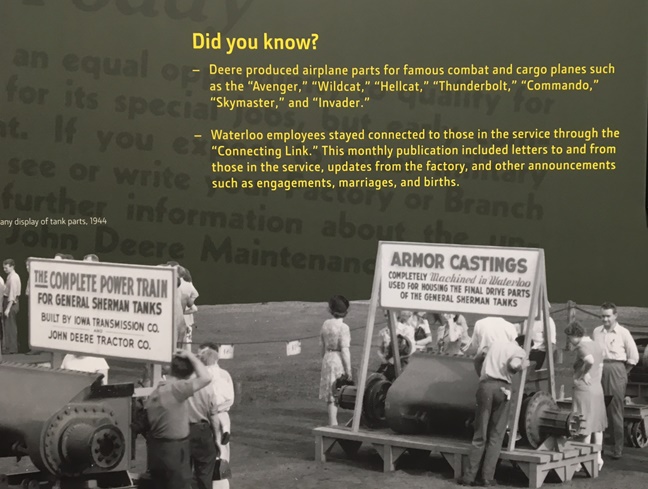

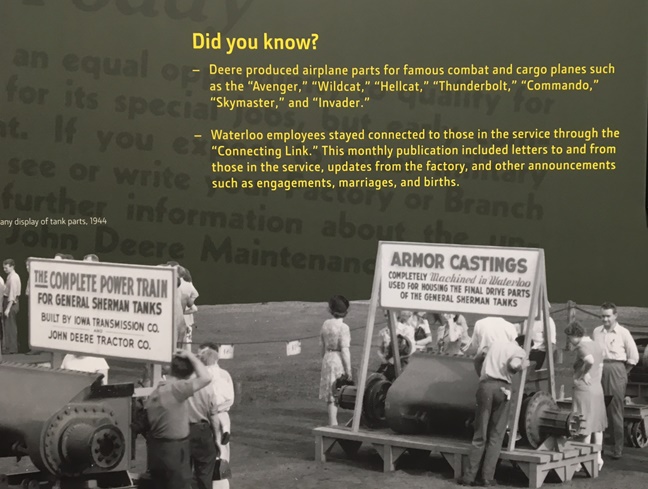

The top section of the display shows that

John Deere also made aircraft parts for several very important and

famous American military aircraft. The right portion of the photo

correctly implies that Waterloo purchased the final drive armor casting

and only did the machining. Other companies made the castings. The left display in the photo implies

that some of work for the transmissions and final drive assemblies was

done in its plants in Moline, IL. Photo courtesy of

David D. Jackson, Jr.

The tank in the photo is a M4A1 Sherman tank

with a 75mm main gun. Photo courtesy of David D. Jackson, Jr.

John Deere Pavilion, Moline, IL:

I was able to find out more information at the John Deere Pavilion in

June 2019. There were several new pieces of information found

here.

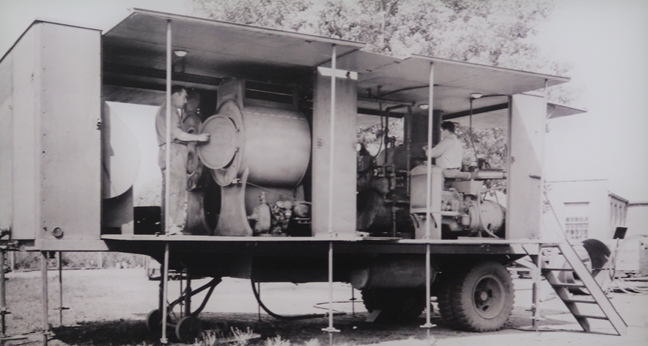

In 1943 the John Deere

Harvester Works in East Moline, IL was making aircraft parts.

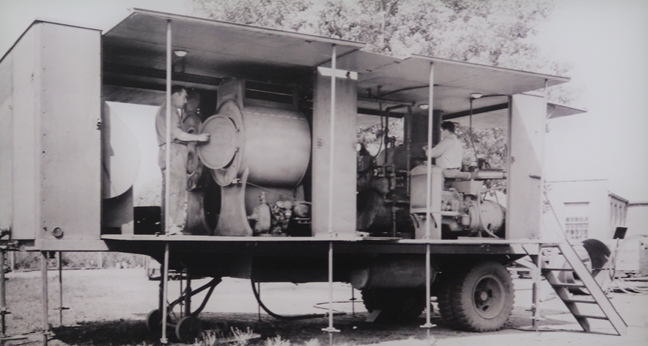

Mobile laundries were built at John Deere Wagon Works

in Moline, IL.

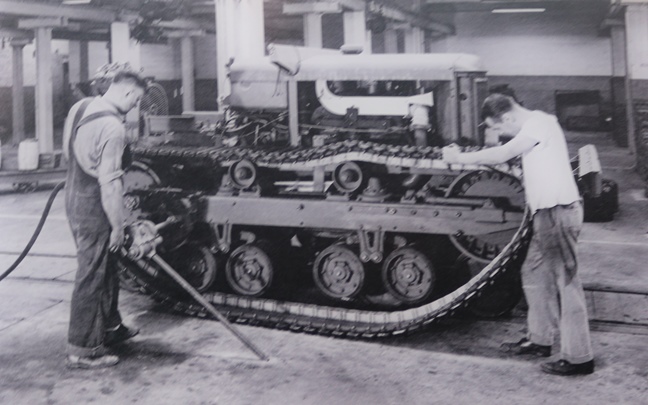

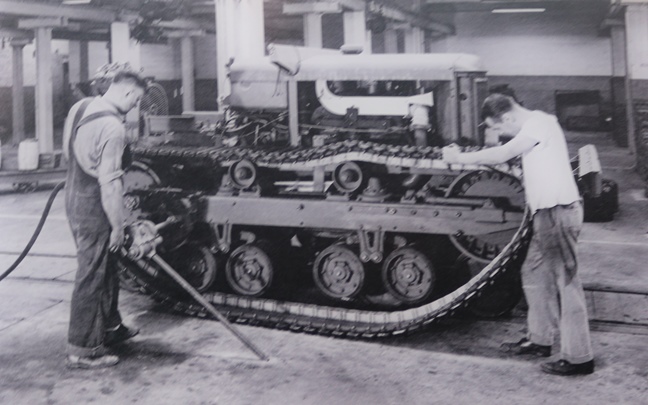

Workers are assembling a M2 High Speed

Tractor at the Moline War Assembly Plant in 1943.

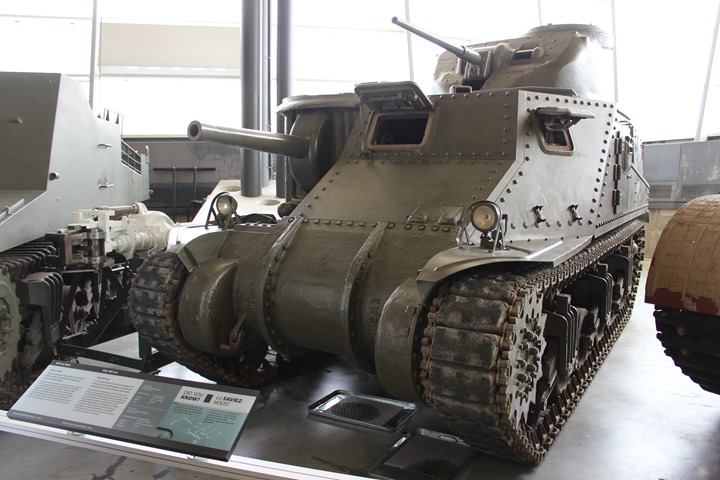

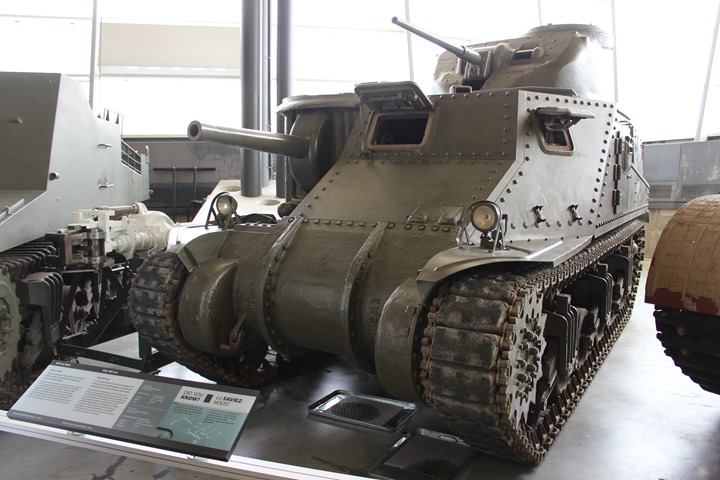

This M3 Medium tank has the original three-piece casting for the final drive assembly. As the war progressed,

it was replaced with the one-piece casting shown in the photo below.

Author's photo.

This Fisher Body built M4A2(76) was one of

49,234 M4 series tanks built during World War Two. This has the

more modern one-piece casting for the final drive assembly.

Author's photo.

This is a cutaway of a M4A2 Sherman tank at

the Canadian War Museum in Ottawa, ONT. It allows an in-depth look

at the transmissions and final drive assemblies that John Deere

manufactured. The engine was in the rear of the tank, and a drive

shaft came through the crew compartment to the rear of the transmission.

From there, the power was transmitted to the tracks by the final drive

assembly. The front axle assembly can be seen here. Author's

photo.

The driveshaft from the engine can be seen

in the lower left. The internal gears that John Deere manufactured

can be seen assembled into the transmission. Author's photo.

Here the gearing can be seen in the final drive assembly. Author's

photo.

The driver side disk brakes for the Sherman

tank can be seen in the back of the photo. Author's photo.

The M10 Wolverine used the same transmission

and final drive assembly as the M3 and M4 tanks. Author's

photo.

Aircraft Components: As noted in the John Deere Tractor and

Engine Museum display shown above, John Deere made aircraft parts for

the Grumman TBM Avenger, Grumman F4F/FM-2 Wildcat, Grumman F6F Hellcat,

Republic P-47 Thunderbolt, Curtiss C-46 Commando, Douglas C-54 Skymaster,

and the Douglas A-26 Invader. This is a very impressive list of

American World War Two aircraft, for which John Deere manufactured

parts.

While the type and number of parts are

unknown, below are photos of the types of aircraft with which John Deere

was involved.

Grumman TBM Avenger. The TBM was

designed by Grumman but the Eastern Aircraft Division of General Motors

built the aircraft. The TBM was the American Navy's main torpedo

bomber during World War Two. Author's photo.

Grumman FM-2 Wildcat. The Wildcat was designed by Grumman, but the

Eastern Aircraft Division of General Motors built the FM-2 version of

the aircraft like this one. Author's photo.

Grumman F6F Hellcat. Grumman was the exclusive builder for the

F6F. John Deere parts in the F6F Hellcat helped it destroy more

Japanese aircraft than any other plane during the war. The Grumman

Hellcat shot down 5,160 Japanese warplanes. Author's photo.

The Republic P-47. Republic built the

P-47 in both Farmingdale, NY and Evansville, IN. It was the

biggest and most heavily armed American fighters of World War Two.

Author's photo.

The Curtiss C-46 Commando. This was the largest twin engine

transport of World War Two. Author's photo.

The Douglas C-54 Skymaster was the only

American four-engine transport during World War Two. Author's

photo.

The Douglas A-26 Invader arrived late in the

war and saw limited service. The John Deere components in the

aircraft helped the A-26 fly later in both the Korean and Vietnam

conflicts. Author's photo.

Current Military Products:

This John Deere front end loader was seen at

the 2019 MCAS Beaufort, SC airshow. It appears to be one of 300

front end loaders built for the USMC and designated at 624J TRAM.

TRAM is a military acronym for tractor, rubber-tired,

articulated-steering, multi-purpose vehicle. Author's photo added

7-1-2019.

Author's photo added 7-1-2019.

|

\

\