|

Simplex Manufacturing Company in World War Two

New Orleans, LA

1935-1975

This page updated 9-17-2024.

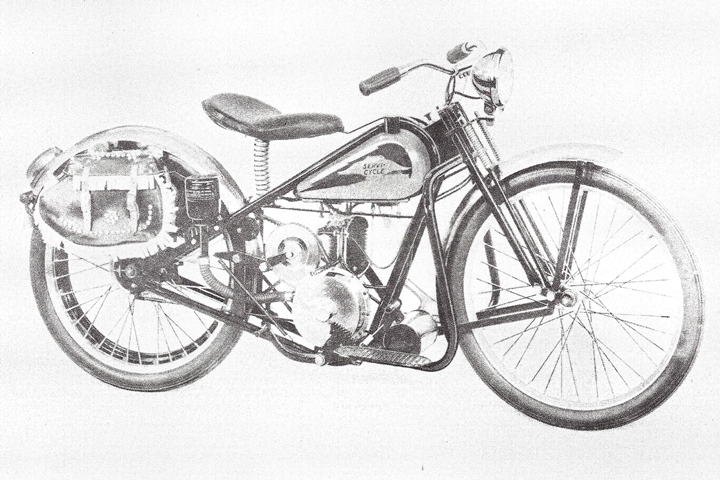

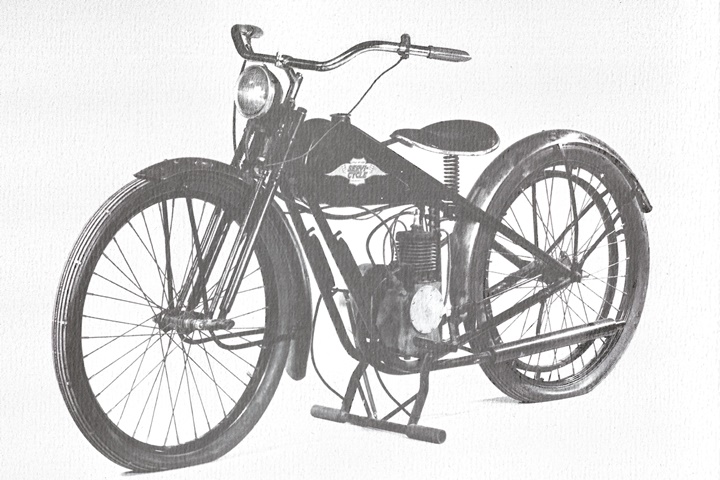

Simplex Manufacturing Company was formed in

1935 by Paul Treen to make a light-weight motorcycle. This was the

Servi-Cycle which was produced until the mid-1950s. After that, the

company made mini-bikes and go-karts until 1975, using engines of its

own design.

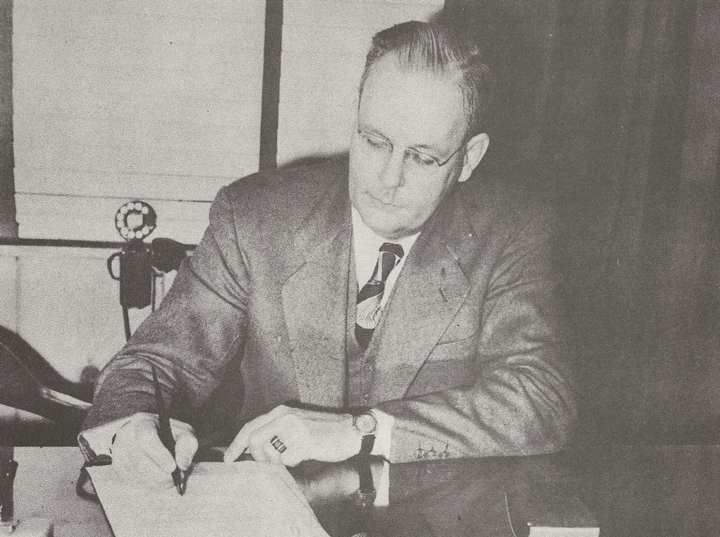

Mr. Paul Treen was the inventor of the Servi-Cycle,

which he began developing in 1928. The primary reason he invented

the Servi-Cycle was to provide a method of low-cost, dependable

transportation. He also realized that in order to do this, he

required a modern factory with the best equipment available. The

outside of just such a factory is shown in the next photo. The

photo above and the factory photo below are from an undated Servi-Cycle

sales brochure which is most likely a post-World War Two document.

This document gives the only known view of the methods used to

manufacture the Servi-Cycle. There are more photos of the plant

operation at the bottom of this page.

Between 1928, when Mr. Treen first designed the

Servi-Cycle and when production began in 1935, Mr. Treen had to overcome

some obstacles. A year after he designed the Servi-Cycle, the

stock market crashed and eventually the country and the world entered

the Great Depression. Somehow, during this time he was able to

find investors to raise the cash needed to buy the necessary tools and

machines, build or lease a factory, and then hire and meet payroll for

his employees. How he did this has been lost to history.

However, the Simplex Manufacturing Company was able to begin business

during the Depression with a new product to help persons with their

transportation needs. This in itself was a huge accomplishment for

the times.

The Simplex factory in New Orleans was a

block long. It's address was 540 North Carrollton Ave.

Mr. Treen saw to it that the factory and its offices were

air-conditioned for the benefit of the employees. A constant

temperature also allowed for more accuracy in machined parts. The

factory also had "occupational" music played in the plant. Photo

added 9-1-2022.

The factory was razed after Simplex went out

of business and the area re-developed into a shopping area. This

Google Maps street view shows the same area today. With the

newness of the buildings, it appears that the factory was razed in the

recent past. Photo added 9-1-2022.

Simplex Manufacturing Company World War Two Production: The

company only had one major contract for its Servi-Cycles used by

paratroopers in World War Two. The 652 Servi-Cycles were

built at a unit cost of $258.59. Most likely the company

engaged in subtracting work for other companies in New Orleans such as

Higgins Industries.

Table 1 - Simplex Manufacturing

Company's Major World War Two Contracts

The information below

comes from the "Alphabetical Listing of Major War Supply

Contracts, June 1940 through September 1945." This was

published by the Civilian Production Administration,

Industrial Statistics Division. |

|

Product |

Contract Amount |

Contract Awarded

|

Completion

Date |

|

Bicycles, Motor Driven |

$136,000 |

5-1943 |

9-1943 |

|

Total |

$136,000 |

|

|

Table 2 -

Simplex Manufacturing Company Bicycles, Motor Driven

Accepted by Detroit Ordnance, US Army

The information below comes from "Summary Report of

Acceptances, Tank-Automotive Material, 1940-1945."

Published by Army Services Forces, Office, Chief of

Ordnance-Detroit, Production Division, Requirements and

Progress Branch,

January 21, 1946. |

|

Type |

1940 |

1941 |

1942 |

1943 |

1944 |

1945 |

Total |

Bicycles, Motor

Driven

(Servi-Cycles) |

|

|

152 |

500 |

|

|

652 |

|

Table 3 -

Simplex Manufacturing Company Products

Information in this table was provided by Alex Schmidt.

Table added 8-29-2022. |

| Model

Type |

Dates

of Production |

|

Prototypes |

1933, 1934, 1935 |

| 1935

Model |

11-1935 through 4-1936 |

| 1936

Model |

5-1936 through late 1936 or early 1937 |

| 1937

Model |

Late

1936 or early 1937 through 9-1937 |

| 1938

Model |

10-1937 through late 1938 or early 1939 |

| 1939

Model |

Late

1938 or early 1939 through late 1939 or early 1940 |

| 1940

Model |

Late

1939 or early 1940 through 3-1940 |

| G

Model |

4-1940 through 12-1944 |

| H

Model |

1-1945 through 9-1947 |

| 48

Model |

10-1947 through 8-1948 |

| J

Model |

9-1948 through 1-1949 |

| K

Model |

2-1949 through 6-1949 |

| L

Model |

7-1949 through 12-1951 |

| M

Model |

1-1952 through late 1960 |

|

Scooters and Go-Karts |

Early

1961 through early 1972 |

In March 2022, I photographed this Simplex

Manufacturing Company-built Servi-Cycle at the National Museum of World

War Two in New Orleans, LA. I was surprised to see this as it had

not been on display when I previously visited the museum in 2017.

Also, until I saw this display I was unaware that American paratroopers

used this type of vehicle in World War Two. Therefore, this was a

new discovery for me and was one of several new things I learned on my

repeat visit to the Museum.

Mr. Dave Johnson of New Orleans restored this

vehicle for the owner, who has loaned it to the museum for display.

Mr. Johnson has verified that this unit was built in 1945. This is

because it has an "H" serial number. This particular unit has

crash bars, indicating it may have been built after the war ended.

It is hard to see in this photo, but

the first letter is an "H." The serial number on the vehicle is

H6269. Author's photo added

8-29-2022.

This image shows Servi-Cycle H6269 in Mr.

Dave Johnson's shop at the beginning of his restoration. Image

courtesy of Mr. Dave Johnson added 9-17-2024.

This image clearly shows the "H" in

the serial number. Image courtesy of Mr. Dave Johnson added

9-17-2024.

Restoration complete! Image

courtesy of Mr. Dave Johnson added 9-17-2024.

Mr. Johnson advised me that the

United States Army Air Forces purchased Servi-Cycles for post-war bomber

crews to assist in traveling the long distances at air force bases.

This may well have been one of those. Image courtesy of Mr. Dave

Johnson added 9-17-2024.

Since my last visit, the National Museum of

World War Two has added a special display of Louisiana companies that

contributed to the winning of World War Two. Included in the

display is the Servi-Cycle H6269. Image courtesy of Mr. Dave

Johnson added 9-17-2024.

This photo is part of the information

from the Servi-Cycle placard at the National Museum of World War Two.

It shows Chaplain Francis L. Sampson of the 501st Parachute Infantry

Regiment on a G-A-1 Servi-Cycle in Holland. Note that the G-A-1

does not have the crash guard on it. Image added 8-29-2022.

This photo was taken on September 17, 1944,

as these paratroopers and C-47 aircrew wait to load for Operation Market

Garden. A G-A-1 Servi-Cycle is in the photo. Photo added

8-29-2022 courtesy

of Alex Schmidt.

The vehicle does not have a crash guard.

Photo added 8-29-2022 courtesy of Alex Schmidt.

Mr. Alex Schmidt has also provided me with

information on the Servi-Cycle. According to his research, there are

only two known G-A-1s still in existence. He owns one which is

waiting to be restored and the other is at the Dead Mans' Corner Museum

in France. Below are eight photos of this vehicle courtesy of Alex

Schmidt of the Dead Man's Corner Museum's G-A-1. These were all

added 8-29-2022.

There is no crash guard on this unit.

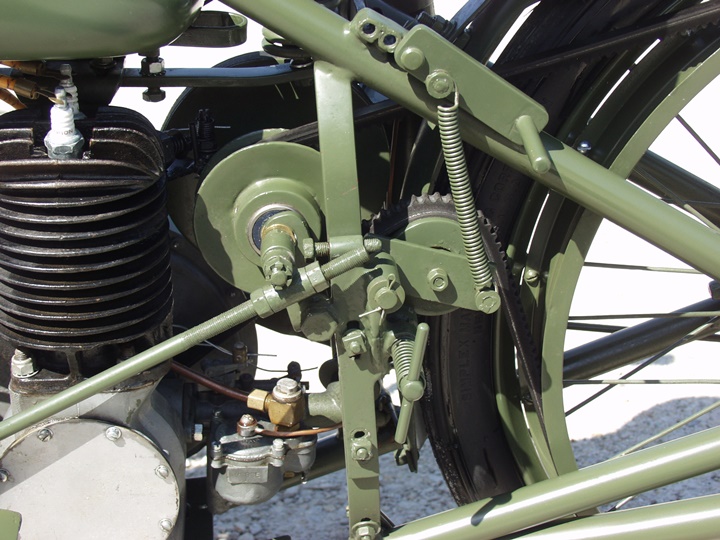

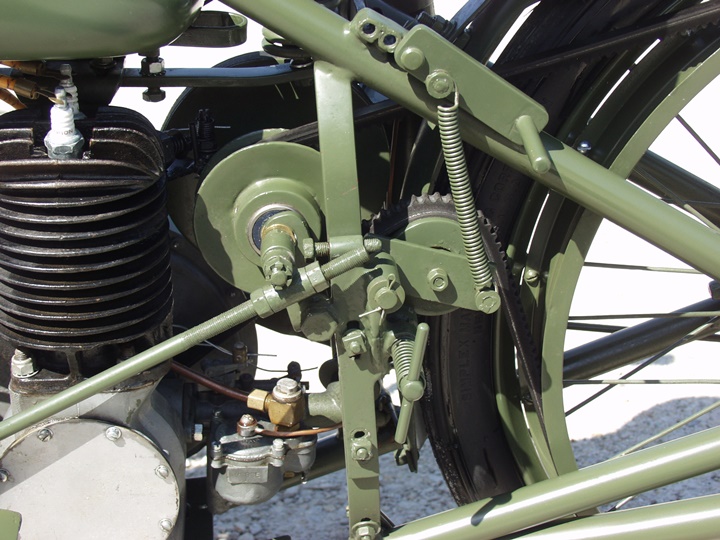

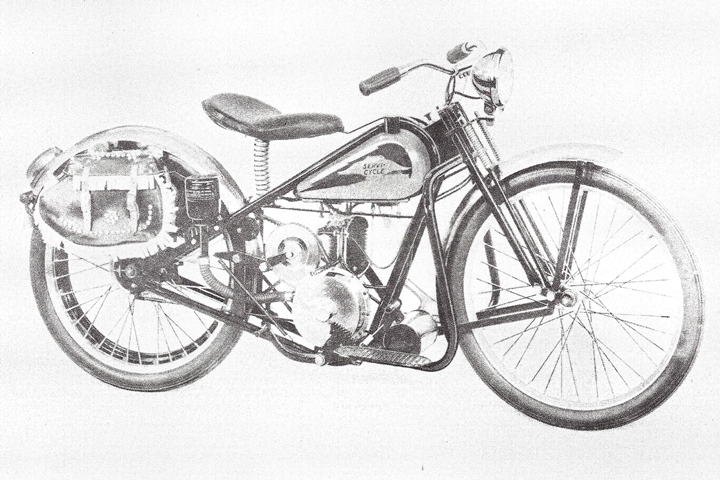

The G-A-1 Servi-Cycle was powered by a

2-stroke engine that had a range of 250 miles on 2.5 gallons of

gasoline. It had a top speed of 30 miles per hour. The

engine had twin sparkplugs and had a Simplex-designed magneto for the

dual ignition system.

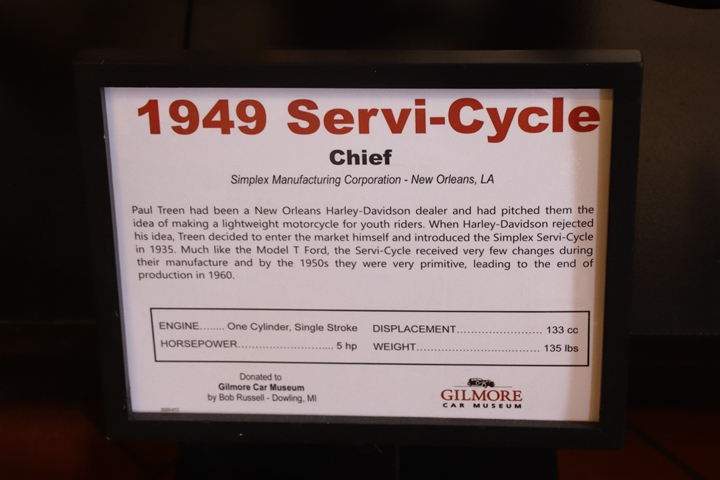

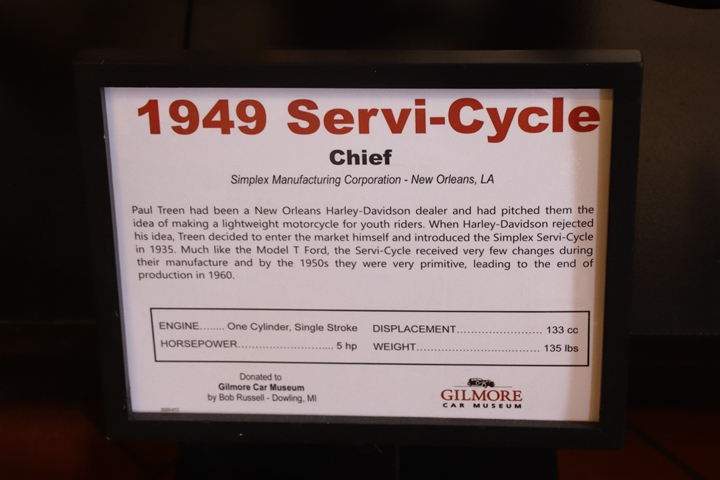

This 1949 "Chief" Servi-Cycle is on display

at the Gilmore Car Museum in Hickory Corners, MI. Author's photo

added 9-14-2024.

Author's photo added 9-14-2024.

Author's photo added 9-14-2024.

Author's photo added 9-14-2024.

Author's photo added 9-14-2024.

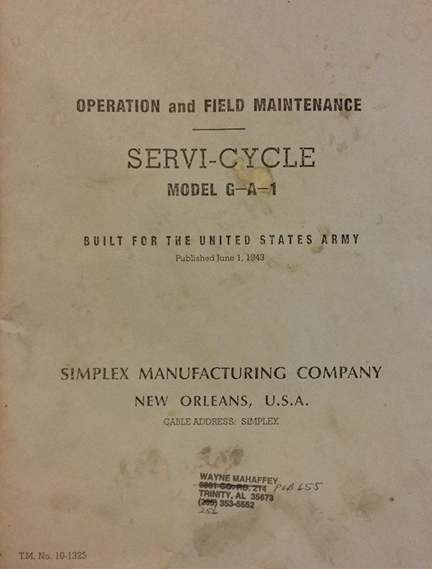

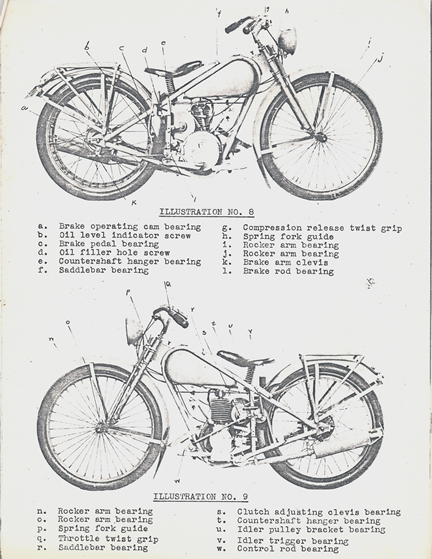

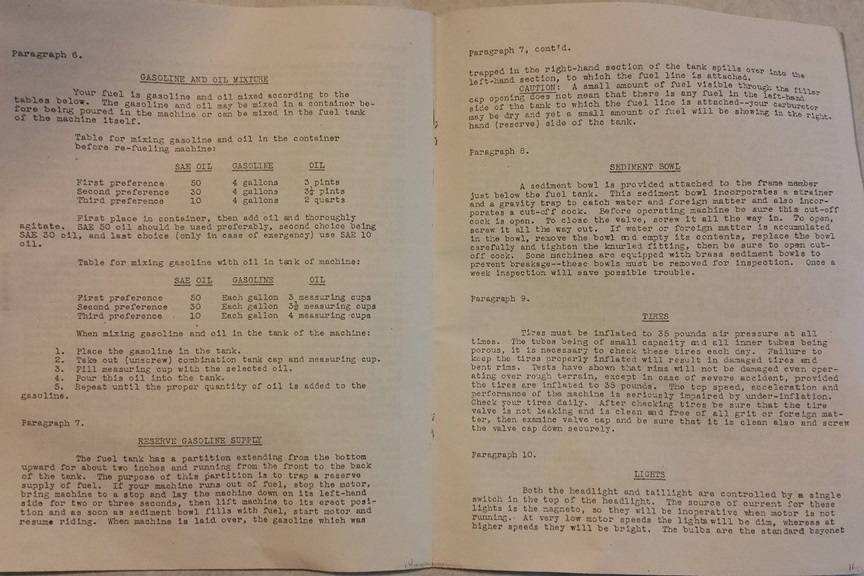

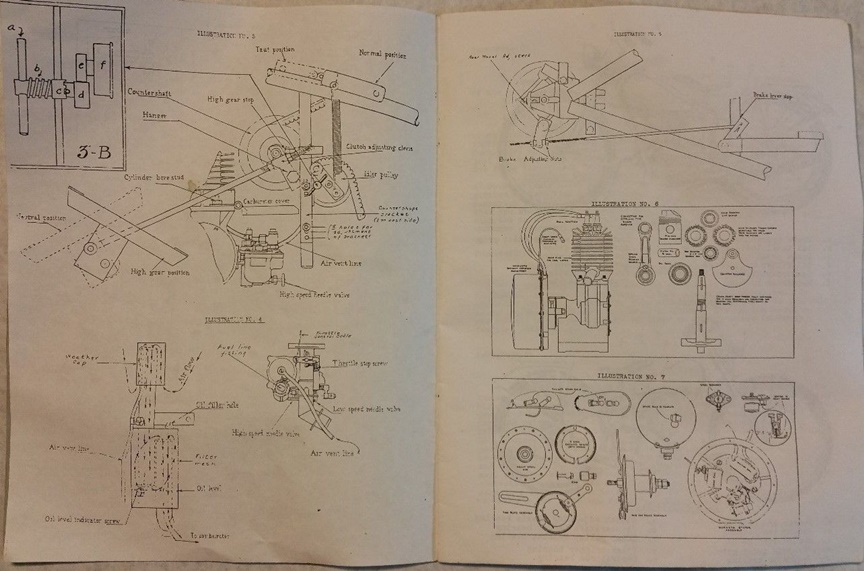

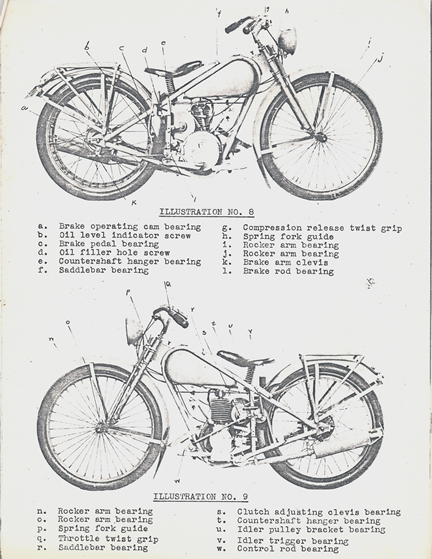

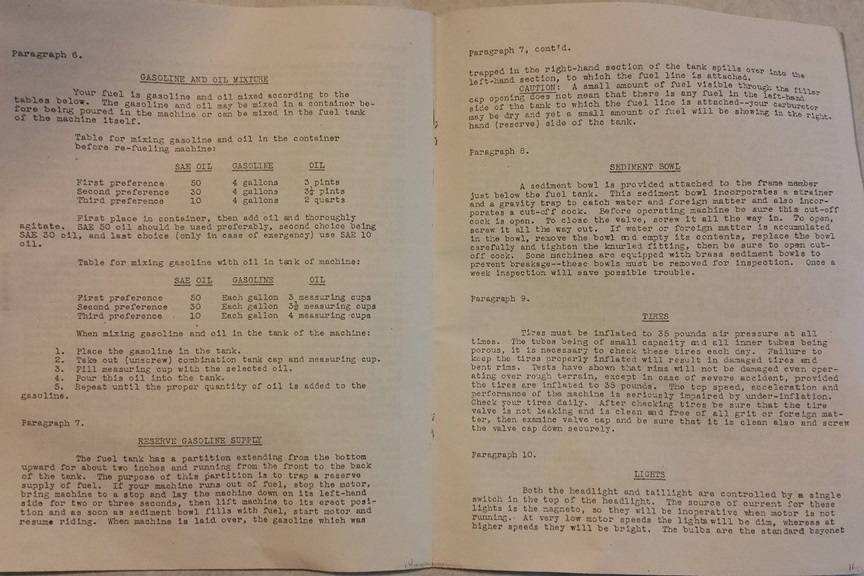

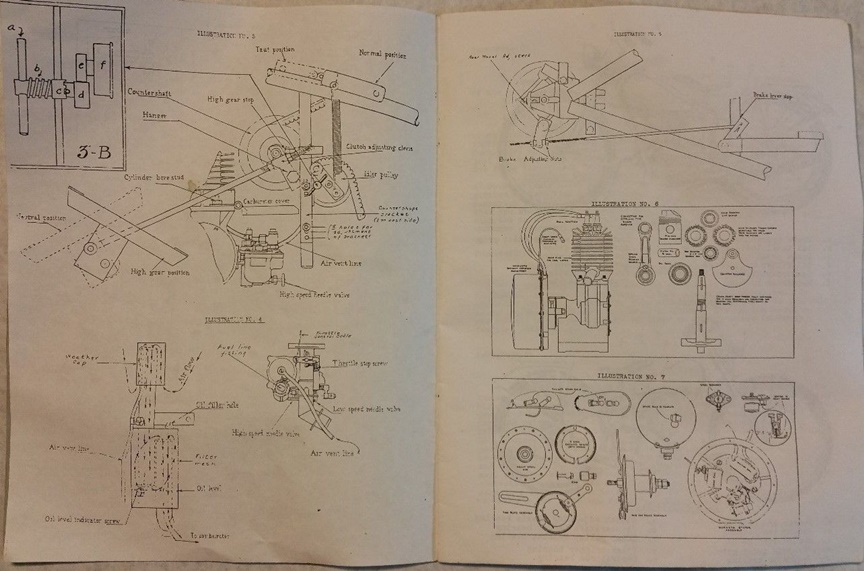

The several pages from the manual for the

G-A-1 below were also provided by Mr. Alex Schmidt and added 8-29-2022.

The photo from the manual shows that there

is no crash guard on the G-A-1.

Post-World War Two Simplex Manufacturing

Company Military Servi-Cycles:

Interestingly enough, the day before I

received Mr. Schmidt's July 2022 email, I was at the National Museum of

the Mighty Eighth Air Force in Pooler, GA. While there I

photographed a Servi-Cycle on display under the wing of the Museum's

B-17. I was able to determine that this was a 1953

unit because of the date on the data plate. This data plate also

indicates this unit was purchased by the U.S. Army.

Author's photo.

Note the Army Ordnance inspector's stamp and

the date of August 1953. This shows that the U.S. Army purchased a

number of these in the 1950s. This is serial number M138835

indicating that the Army was buying the standard commercial M model.

It is Ordnance type ORD-16697.

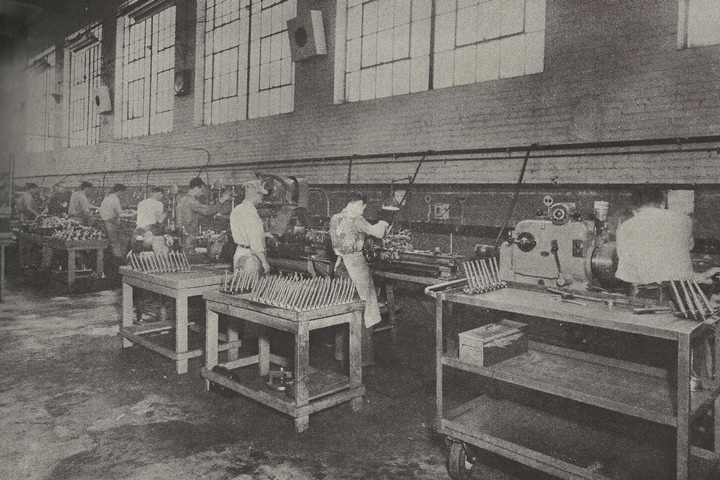

The Simplex Manufacturing Process:

The undated Servi-Cycle sales manual was used to show the

manufacturing process to prospective distributors, such as bicycle and

motorcycle shops, so they would know they would be selling a quality

product to their customers. The sales manual is the only known

information available on this unique company's product. All of the

photos below were added 9-1-2022.

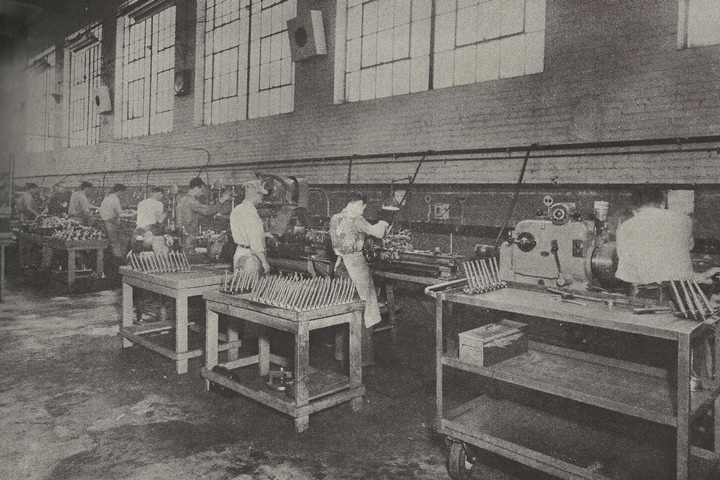

This is the machine shop. Note the

speakers on the wall to play "occupational" music.

Farther along the wall these operators are

machining cylinder heads.

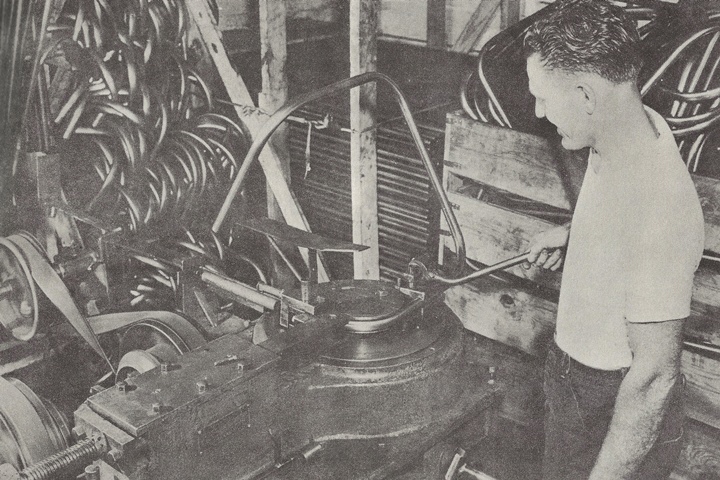

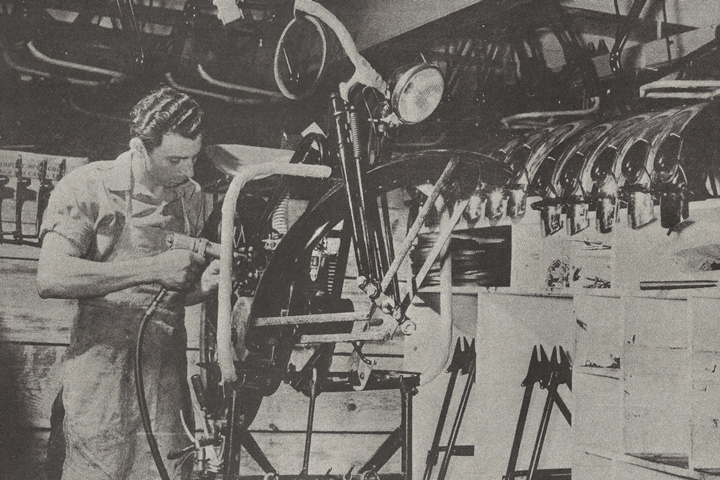

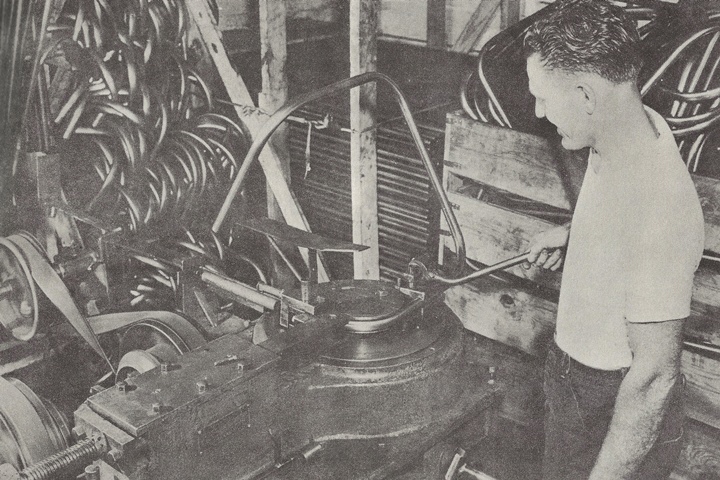

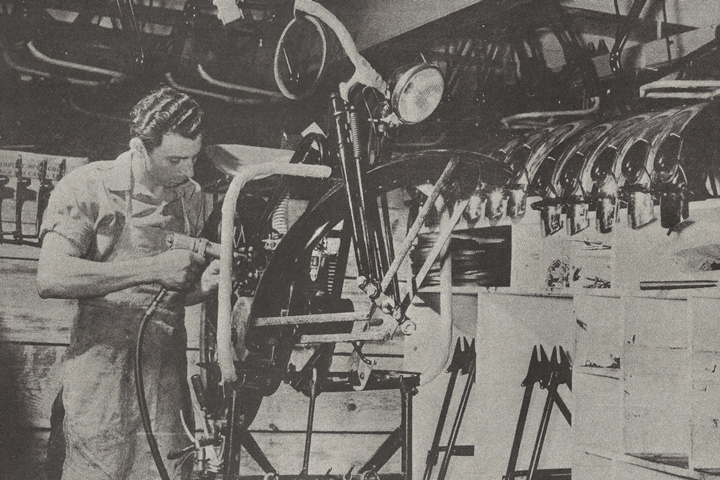

In this operation, the worker is bending the

leg-guard from one inch steel tubing. This operation was not

required for World War Two G-A-1 model for the U.S. Army.

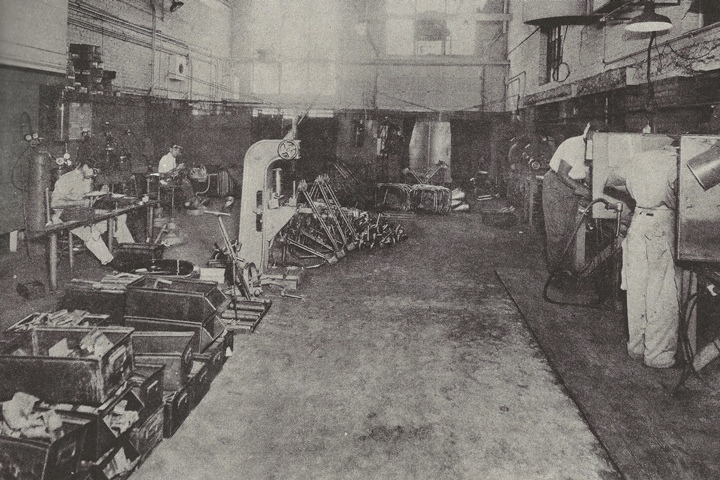

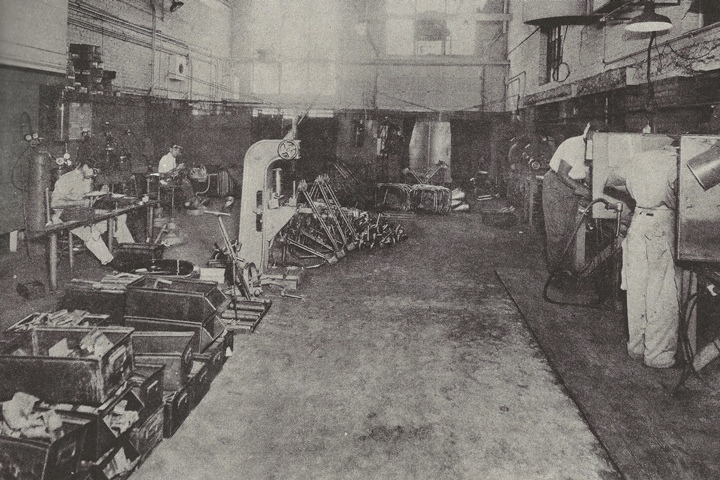

In the welding shop, the frames of the Servi-Cycles

are welded. There is a speaker mounted to the wall to play music.

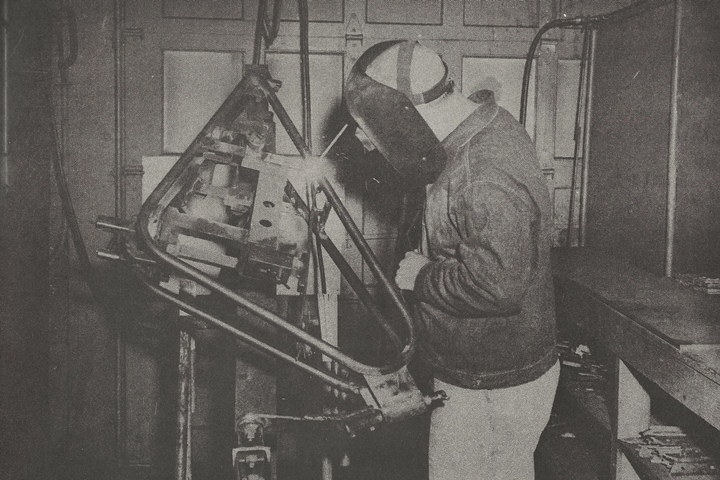

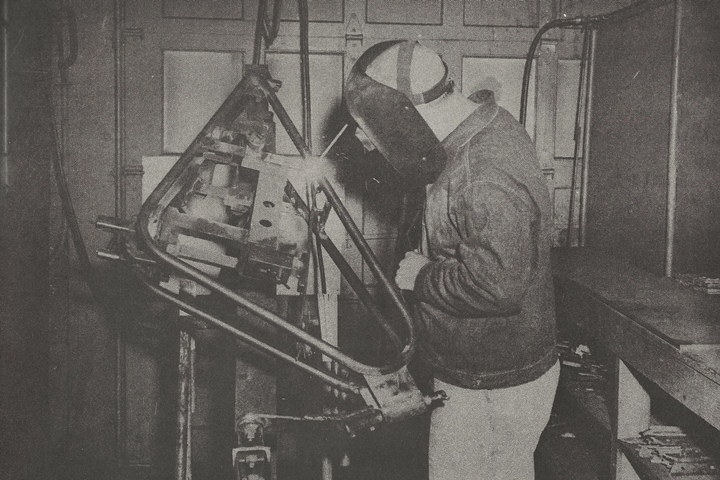

The frame is being welded Inside a welding

booth.

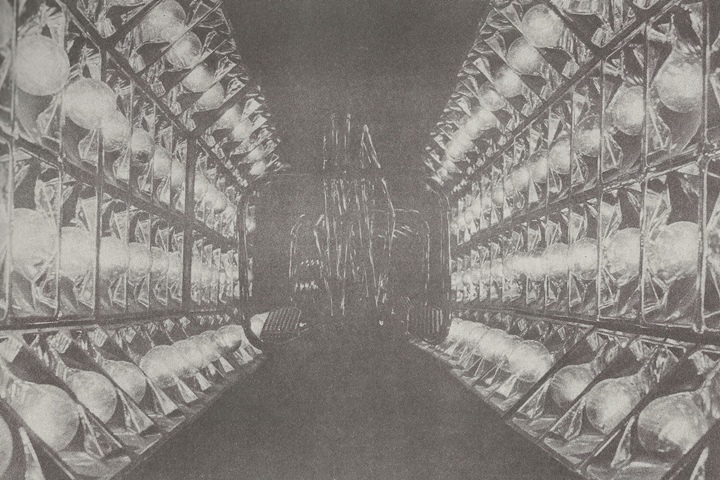

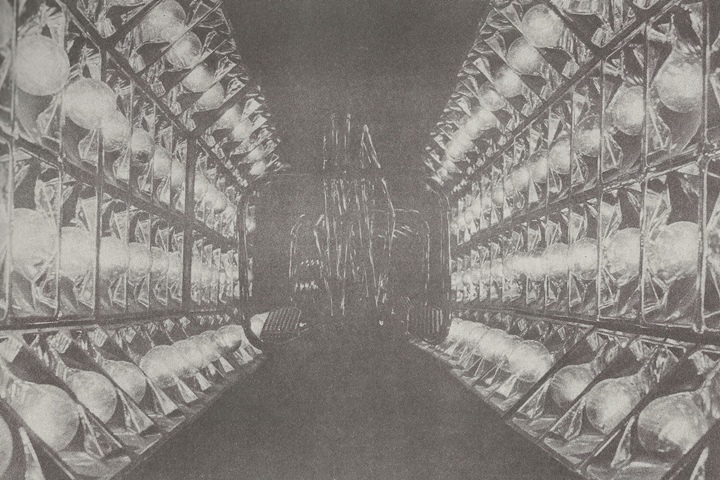

Once the frames are welded, they are run

through a paint dip tank while hanging on a conveyor. Then they go

through the infra-red heat lamps of the drying oven which dries the

parts in eight minutes.

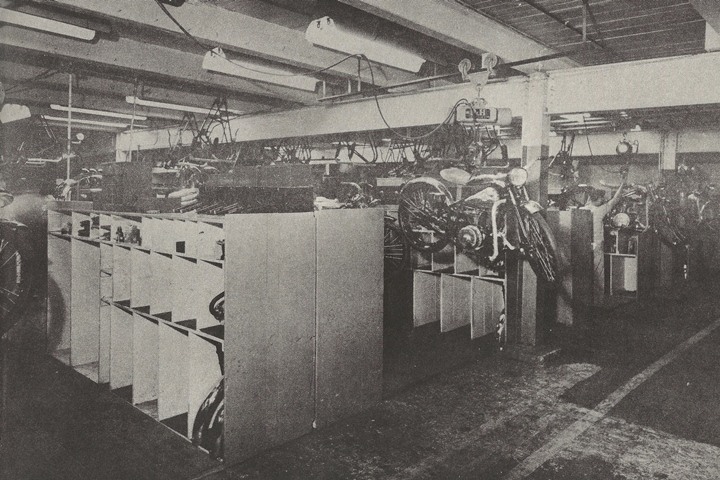

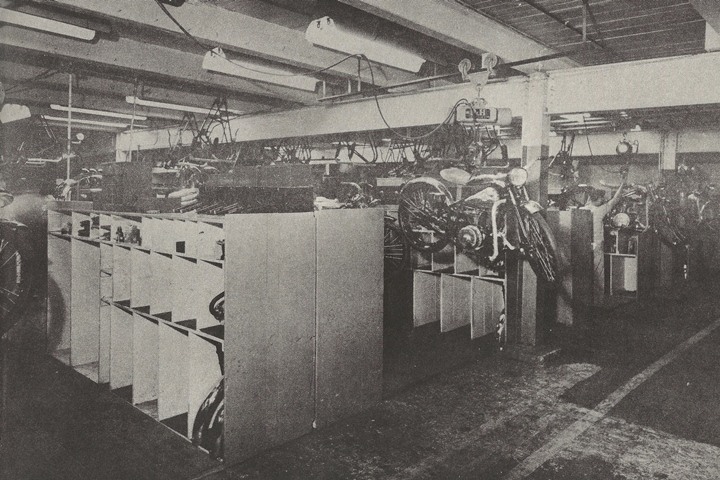

In final assembly, twenty different

subassemblies come together to make a Servi-Cycle.

The plant has at least three final assembly

lines.

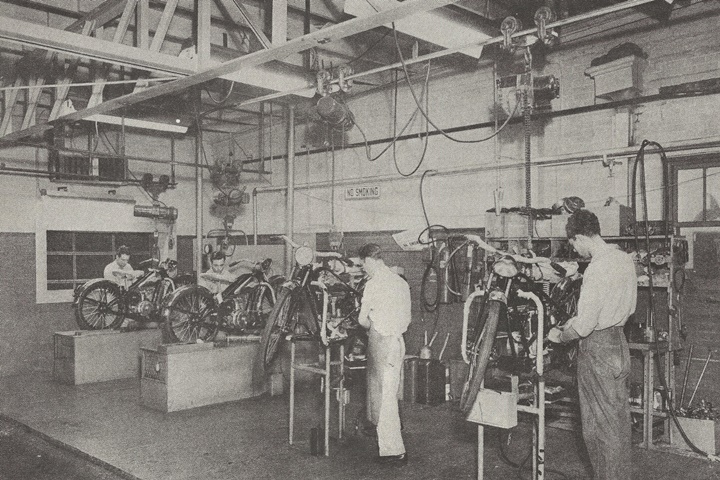

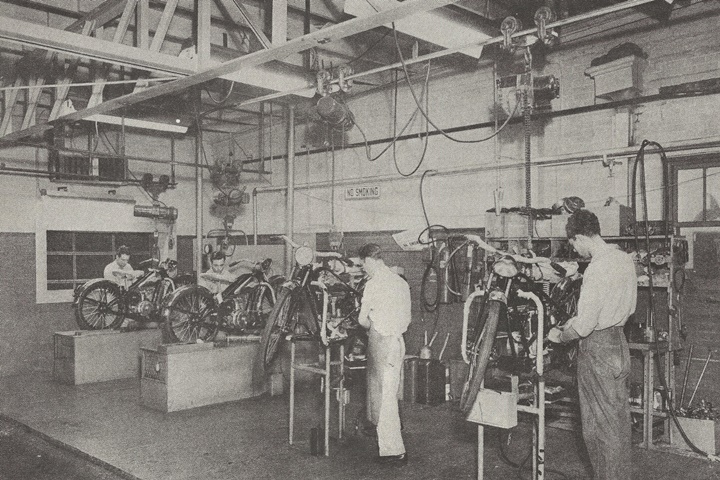

Once the Servi-Cycles come off the final

assembly line, they are put on one of the two dynamometers shown at the

back of the room. Here they are run up to full speed and given a

full functional testing of all of the systems. Any repairs that

are needed are made by the two repairmen in the foreground. These

would have been the most experienced mechanics in the factory.

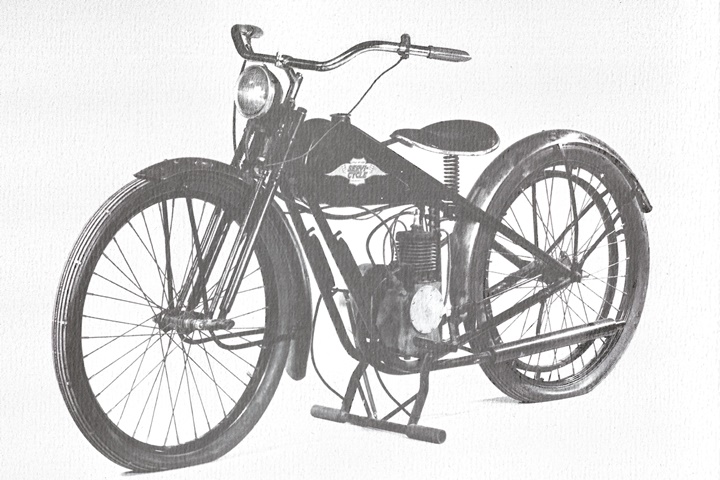

When the process is complete, another Servi-Cycle

is ready to ship to the customer. This appears to be a base unit

as it does not have a leg guard on it. The rear tire also needs

some air.

Or one could purchase the super-deluxe model

with lots of chrome parts and saddle bags with fringe. This one even

has the tires pumped up.

In 1947 a standard Model H cost $278.25 and

a deluxe mode $300.

The Model H came out before I was born.

However, later models were produced while I was a youngster and going to

grade school. I think I remember seeing teenagers in the

neighborhood driving Servi-Cycles on the streets.

In 1964 both The Beach Boys and The Hondells

had hits with the song "Little Honda." The arrival of Japanese

motorcycles and the sales they generated in the United States may well

have played a part in the demise of the Simplex Manufacturing Company

and the Servi-Cycle. This 1966 Honda 50 is on display at the

Gilmore Car Museum. Author's photo added 9-17-2024.

|