|

McCord Radiator & Mfg., Company During World War Two

Detroit, MI

1906-1944

9-29-1944 - Mid 1985 as the McCord Corporation

Mid 1985 - Unknown date as a subsidiary of Ex-Cell-O Corporation

This page added 6-6-2023.

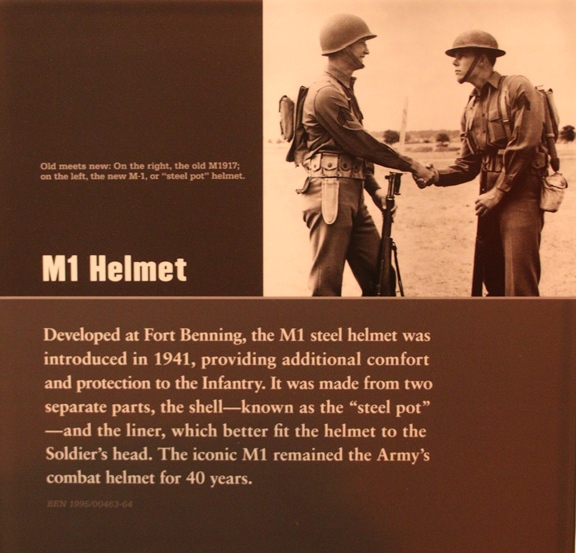

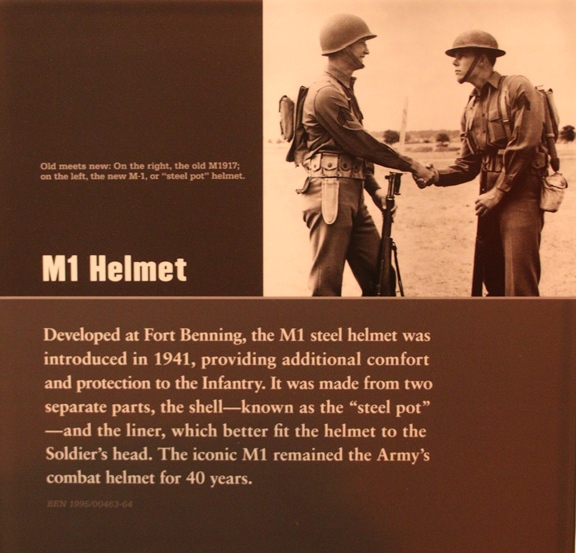

The opening scene from the 1962 movie "The

Longest Day" featured the ubiquitous American M1 helmet. The M1

helmet and the American servicemen and servicewomen of World War Two

were most identifiable as Americans when wearing this helmet. Its

distinct design and shape identified Americans in every combat

theater during World War Two.

Most likely, this M1 helmet was produced by

the McCord Radiator and Manufacturing Company of Detroit, MI. The

company produced 89% of all M1 helmets during World War Two.

This view of an LCVP making its way ashore at Normandy only shows the

back of the soldiers heads and shoulders. However, the distinctive

M1 helmet immediately identifies them as American soldiers.

Members of this 40mm Bofors anti-aircraft

gun crew in this full scale diorama of loading the weapon at Dreger Airfield

in northeast New Guinea during World War Two can be identified as

Americans by their M1 helmets. Several of the crew members are not

in full uniform due to the heat. However, they are all wearing

their M1 helmets.

U.S. Navy and U.S. Coastguardsmen also wore

the M1 helmet. Two of the four-man crew of this LCVP can be seen

wearing the M1 helmet. Most likely, these are members of the U.S.

Coast Guard, as they were the ones that manned most of the small landing

craft during World War Two.

When was the M1 helmet more than a just a

helmet? This was whenever the wearer was not in a combat

situation. The steel pot, as it was more well known to its

wearers, had many other uses.

Shaving was one of the most popular uses of the M1 steel helmet.

In this particular example two steel pots have been set up. One

could be for clean water and the other for soapy water. Or one

could be for shaving and the other for washing.

Cooking was another popular use for the steel

pot. My father boiled potatoes in his steel pot while serving with the 88th

Division in Italy during World War Two. My father and his buddies

came across a a group of unharvested potatoes. They boiled them

in their pots to get something to eat. Like many other infantrymen

and other soldiers on the front lines, my father was not getting enough

to eat. In spite of all of the motorized transportation for which American

forces were known during World War Two, soldiers and Marines on the

front lines were hungry much of the time. The food was not making

it to front line positions that were difficult to reach from the supply areas and

mess tents.

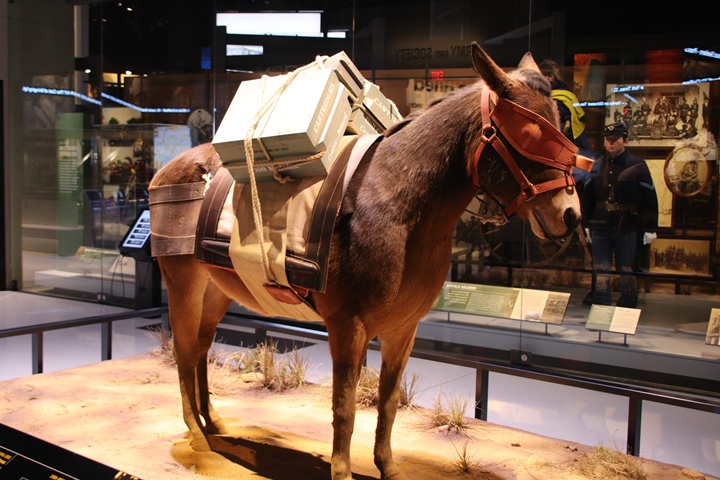

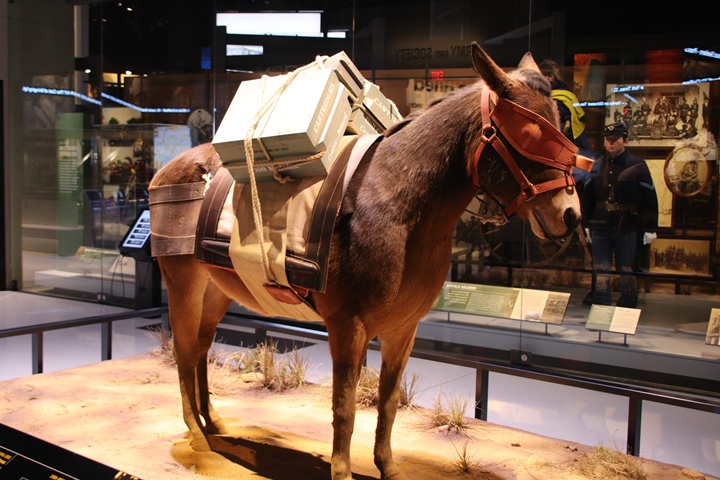

This image from the 88th Division area of operations shows a mule

sharing the muddy road with two GMC CCKWs and a jeep. There were

many places in the mountains that a motorized vehicle could not go, but

a mule could.

The pack mule was more widely utilized than

in just the Italian Campaign of World War Two. Two thousand were

used in Tunisia to delivere supplies to troops located on the remote

front lines where even a jeep couldn't go. They were also

used in New Guinea, China, and Burma. In the last year of World

War Two, the U.S. Army Quartermaster Corps purchased 20,000 mules. For

my father in Italy, a pack mule like this may have kept him and his

buddies from starving in the Italian mountains. Author's photo

from the National Museum of the United States Army at Fort Belvoir, VA.

But I have digressed. Now back to the

McCord Radiator Company and how it helped to win World War Two.

| |

The McCord Radiator & Mfg. Company won the

Navy "E" award one time, and the award was converted to the

Army-Navy "E" award when it was awarded the second time. In total,

the McCord Radiator & Mfg. Company won the award six times

during World War Two.

The company's first award was the Navy "E"

Award on March 27, 1942.

The company's second award was the Army-Navy "E" Award on August 30,

1942.

The company's third award was the Army-Navy "E" Award on February 26,

1943.

The company's fourth award was the Army-Navy "E" Award on October 30,

1943.

The date of the fifth award is unknown but estimated to have been in

April or May 1944.

The date of the sixth award is unknown but estimated to have been in late

1944 or early 1945.

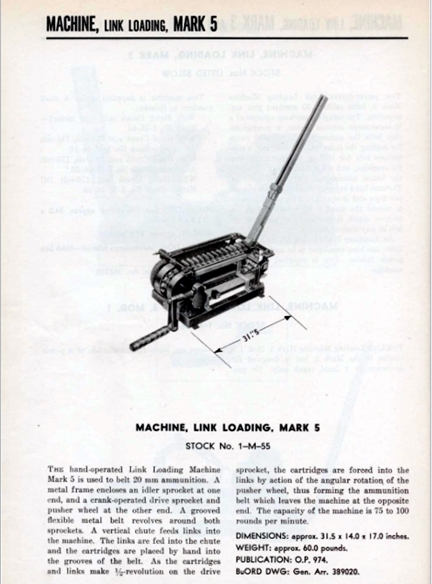

There were 1,000 employees who attended the

first award ceremony on March 27, 1942. It is of interest that the

first award the company won was the Navy "E" flag. While McCord is

best known for being the largest producer of steel helmets ordered by

the U.S. Army, it was the development and production of machine gun

ammunition link machines for the U.S. Navy that generated its first

award. This McCord World War Two product is not as well-known as

its helmet production, but for the U.S. Navy, it was a key product.

The company added 500 employees in 1942 as

there were 1,500 employees that attended the second award ceremony on

August 30, 1942.

McCord Radiator & Mfg. Company World War

Two Products: The company is most well known for being the

primary supplier of M1 helmets for the U.S. military during World War

Two. While it produced 90% of the M1 helmets for the war effort,

Table 1 shows that helmets were only 59% of the major contracts the

company was awarded during the war.

Of interest in the major contracts is that

according to Table 1, the U.S. Navy did not issue any contracts to the

company over $50,000 until January 1942. Yet on March 27, 1942,

the U.S. Navy awarded the company an "E" Award for "production

achievements on Navy ordnance material." Most of the Navy's

contracts with McCord Radiator were for machinery, most of it for

loading machines. It appears that McCord had several contracts

less than $50,000 for this of type equipment and was doing an excellent job

in getting it to the Navy on time and in the quantities required.

Table 1 - McCord Radiator

Company's Major World War Two Contracts

The information below

comes from the "Alphabetical Listing of Major War Supply

Contracts, June 1940 through September 1945." This was

published by the Civilian Production Administration, Industrial

Statistics Division. Table added 4-2-2022. |

|

Product - Customer |

Contract Amount |

Contract Awarded

|

Completion

Date |

| Helmet Body

Assemblies - Army Ordnance |

$1,860,000 |

11-1940 |

3-1942 |

| Helmet

Accessories - Army Ordnance |

$1,822,000 |

6-1941 |

4-1942 |

| Helmets -

Army Ordnance |

$1,578,000 |

11-1941 |

8-1942 |

| Helmet

Accessories - Army Ordnance |

$101,000 |

11-1941 |

4-1942 |

| Liners

Helmets - Army Quartermaster Corps |

$465,000 |

12-1941 |

4-1942 |

| Machinery

Loading - Navy |

$512,000 |

1-1942 |

7-1942 |

| Helmets -

Army Ordnance |

$68,000 |

1-1942 |

9-1942 |

| Helmets -

Army Ordnance |

$615,000 |

1-1942 |

11-1942 |

| Liners

Helmets - Army Quartermaster Corps |

$1,450,000 |

3-1942 |

8-1942 |

| Liners

Helmets - Army Quartermaster Corps |

$69,000 |

3-1942 |

5-1942 |

|

Machines - Navy |

$170,000 |

3-1942 |

7-1943 |

| Helmets -

Army Ordnance |

$1,753,000 |

5-1942 |

12-1942 |

|

Ordnance Material - Navy

Ordnance |

$5,209,000 |

6-1942 |

3-1943 |

| Helmets Steel -

Army Quartermaster Corps |

$89,000 |

6-1942 |

7-1942 |

| Helmets -

Army Quartermaster Corps |

$89,000 |

6-1942 |

8-1942 |

| Liners Fibre

- Army Quartermaster Corps |

$1,495,000 |

7-1942 |

9-1942 |

| Helmets -

Army Ordnance |

$444,000 |

8-1942 |

3-1943 |

|

Liners Helmet - Army

Quartermaster Corps |

$1,080,000 |

8-1942 |

11-1942 |

|

Machines Link Loading - Army

Ordnance |

$205,000 |

8-1942 |

4-1943 |

|

Machines - Army Ordnance |

$234,000 |

9-1942 |

121943 |

|

Helmets - Army Quartermaster

Corps |

$4,740,000 |

1-1943 |

9-1943 |

| Helmets -

Navy Ordnance |

$102,000 |

1-1943 |

2-1943 |

|

Machinery Industrial - Navy |

$85,000 |

2-1943 |

7-1943 |

| Helmets -

Army Ordnance |

$13,940,000 |

5-1943 |

2-1946 |

|

Armor Plates - Army Ordnance |

$3,908,000 |

8-1943 |

11-1945 |

| Target Rocket

Motors - Navy Ordnance |

$316,000 |

8-1943 |

1-1944 |

| Link Belting

Machines - Navy Ordnance |

$89,000 |

8-1943 |

12-1943 |

| Helmets -

Navy Ordnance |

$151,000 |

8-1943 |

11-1943 |

| Link Ejection

Chutes - Navy Ordnance |

$85,000 |

10-1943 |

2-1945 |

| Aviators

Steel Helmets - Army Ordnance |

$921,000 |

12-1943 |

2-1945 |

| Rocket Motors

- Navy Ordnance |

$740,000 |

1-1944 |

7-1944 |

| Helmets -

Navy Ordnance |

$64,000 |

2-1944 |

4-1944 |

| Navy Helmets

Mk2- Navy Ordnance |

$128,000 |

3-1944 |

8-1944 |

| Rocket Motors

- Navy Ordnance |

$1,120,000 |

6-1944 |

7-1945 |

| Rocket Motors

Mk9 - Navy Ordnance |

$1,059,000 |

7-1944 |

6-1945 |

| Helmets -

Navy Ordnance |

$370,000 |

7-1944 |

7-1945 |

| Rocket

Launcher Pts - Army Ordnance |

$132,000 |

8-1944 |

11-1944 |

| Radiators

- USAAF |

$988,000 |

10-1944 |

11-1945 |

| Flyers

Helmets M5 - Army Ordnance |

$637,000 |

2-1945 |

10-1945 |

| Rocket Motors

Mk2 - Navy Ordnance |

$280,000 |

3-1945 |

11-1945 |

| Lubricators -

Treasury Dept |

$152,000 |

5-1945 |

10-1945 |

| Armor Vest

Plates - Army Ordnance |

$350,000 |

5-1945 |

9-1945 |

| Total |

$49,671,000 |

|

|

|

Table 2 - McCord Radiator

Company's Major Product Groups |

|

Product |

Value

|

Percentage |

Number of

Contracts |

|

Helmets - Army and Navy |

$29,472,000 |

59% |

19 |

|

Link Loading Machines - Army and

Navy |

$6,504,000 |

13% |

7 |

|

Helmet Liners -Army |

$4,559,000 |

10% |

6 |

|

Armor Plate and Armor Vest

Plates - Army |

$4,258,000 |

8.6% |

2 |

|

Various Rocket Motors - Navy |

$3,515,000 |

7% |

5 |

|

Radiators - USAAF |

$988,000 |

2% |

1 |

|

Lubricators - Treasury Dept |

$152,000 |

0.3% |

1 |

|

Rocket Launcher Pts - Army

Ordnance |

$132,000 |

0.36% |

1 |

|

Link Ejection Chutes - Navy |

$85,000 |

0.17% |

1 |

| Total |

$49,671,000 |

100% |

43 |

An April 1943 newspaper

advertisement by McCord Radiator listed the following products it

was producing for the war effort:

-

Helmets for Army, Navy,

Civilian Defense, and some Allies.

-

Large Linking Machines of Intricate Design, Smaller Field Machines, and

Hand Linkers.

-

Projectiles for High Explosives.

-

Flame Traps for Marine and Aviation engines.

The company also produced spark plug gaskets for the jeep.

World War Two Steel

Helmets:

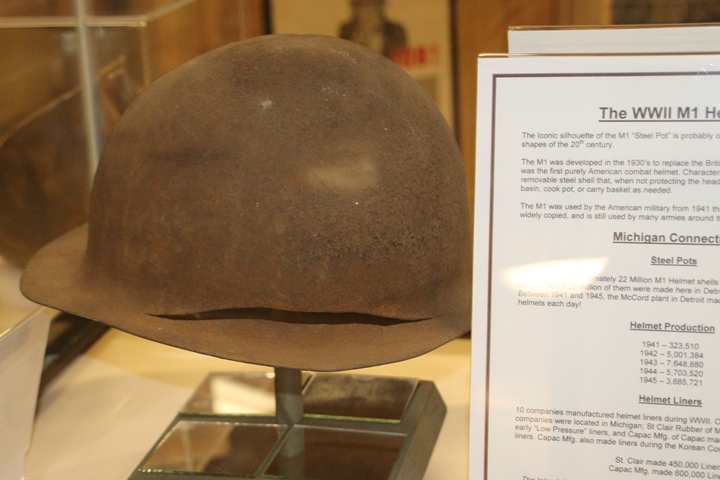

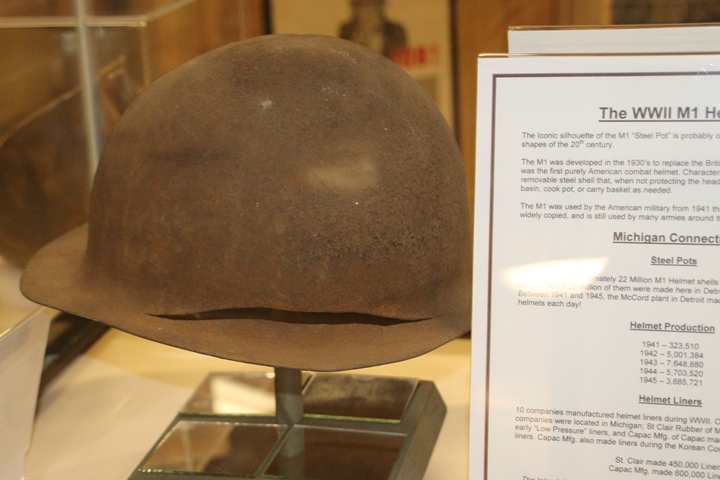

The next four photos were taken at the

Michigan Military Technical & Historical Society in Eastpointe, MI.

Among its many excellent displays, this museum has a display on the

Michigan companies that made the World War Two M1 steel helmet and

plastic helmet liner. A trip to the Historical Society got me

interested in the McCord Radiator and Mfg. Company and its contributions

to the winning for World War Two.

This 1944 era McCord-built M1 helmet was

found in the 1990's in a civil defense warehouse. It is a brand

new and unused helmet. Author's photo.

Author's photo.

It took multiple strikes with progressive

dies to produce the final steel helmet. Author's photo.

Sometimes the material tore during the

process. Author's photo.

|

Table 3 - McCord Radiator

Company's 1945 Scheduled M1 Helmet Production |

|

Month/Quarter |

Scheduled Amount |

Quarterly Accumulative

Totals |

|

First Quarter |

919,480 |

919,480 |

|

April |

308,000 |

|

|

May |

400,000 |

|

|

June |

400,000 |

2,027,480 |

|

July |

380,000 |

|

|

August |

300,000 |

2,707,480 - End of War |

|

September |

250,000 |

2,957,480 |

|

October |

250,000 |

|

|

November |

225,000 |

|

|

December |

90,000 |

3,522,480 |

|

Total |

3,522,000 |

3,522,480 |

Table 3 shows the maximum scheduled production

for 1945 was in

the months of May and June. Assuming the company was on a seven

day production schedule in May 1945, it was scheduled to produce 12,903

M1 helmets per day. If it had cut back to a five day a week

production schedule, it would have produced 17,391 per day.

Production would have ended in the middle of

August 1945 with the cessation of hostilities with Japan.

Production for 1945 would have been approximately 2,707,000 units.

|

Table 4 - World War Two M1

Helmet Production by Year |

| Year |

Quantity |

| 1941 |

323,510 |

| 1942 |

5,001,384 |

| 1943 |

7,648,880 |

| 1944 |

5,703,520 |

| 1945 |

3,685,721 |

| Total |

22,363,015 |

Table 4 shows the production of the

M1 helmet during World War Two. McCord Radiator was the

exclusive supplier of M1 helmets during 1941 and 1942. The

first 5,324,894 M1 helmets were produced by the McCord Radiator &

Mfg. Company.

Table 5 - World War Two M1

Helmet Production by Company

The amounts are rough estimates of production for each

company. The Percentages are based on the Estimated

Total of 22,060,000. |

|

Company |

Amount |

Percentage |

|

McCord Radiator |

20,000,000 |

90.7% |

|

Schlueter Manufacturing Company |

2,000,000 |

9.07% |

|

Parrish-Reading |

60,000 |

0.27% |

|

Estimated Total |

22,060,000 |

~100% |

|

Actual Total |

22,363,015 |

|

Table 5 shows estimated production of

M1 helmets by the three companies that produced them during World

War Two. The U.S. Army began accepting M1 helmets from McCord

Radiator in February 1942. The Schlueter Manufacturing Company

began the production of helmets in January 1943, and Parrish-Reading

began production in June 1945. It is a mystery why Army

Ordnance brought on Parrish-Reading so late in the war.

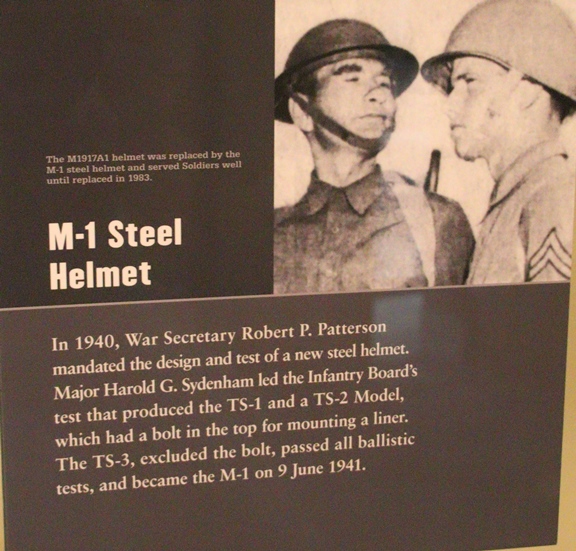

Earlier I stated that the American soldier

during World War Two could be identified by his M1 helmet. This is

not entirely correct. Troops in overseas locations at the start of

World War Two were still equipped with the M1917 helmet. This was

based on the British helmet of World War One and also used by the

British Commonwealth soldiers during World War Two. This mannequin

on display at the National Museum of the United States Air Force in

Riverside, OH depicts a former airman who was turned into infantryman in

the Philippines. The soldiers in the Philippines called themselves

"The Battling Bastards of Bataan." Many of those that weren't

killed in combat died in the Bataan Death March or in POW camps during

the war. Author's photo.

Unlike the M1 helmet of World War Two, there

was no helmet liner and the suspension was attached to the inside of the

steel helmet. U.S. Marines at the Battle of Midway in June 1942

were also equipped with the Model M1917 helmet. However, when the

Marine First Division landed at Guadalcanal August 7, 1942, its Marines

were equipped with the M1 Helmet. From that time forward, American

servicemen and women were equipped with the M1 helmet. McCord

Radiator was not involved with the manufacture of the M1917 helmet.

Author's photo.

|

Table 6 - World War Two Helmet Types |

|

Type |

User |

Application |

McCord Production |

Comments |

|

M1 |

All services |

Ground Combat |

20,000,000 |

|

|

M2 |

U.S. Army |

Paratroopers |

118,000 to 392,000 |

These are part of the M1 20,000,000 production. They

were special versions for the paratroopers. |

|

M3 |

USAAF |

Bomber Air Crews |

210,000 |

1942-1944 Issued to ETO bomber crews starting in

December 1943 |

|

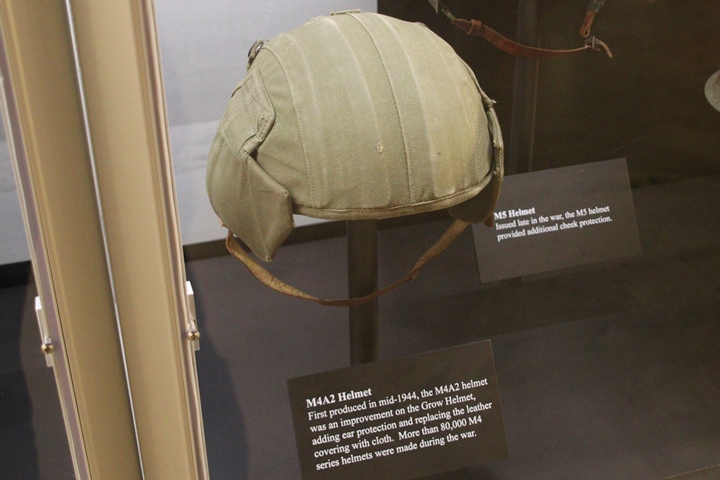

M4A2 |

USAAF |

Bomber Air Crews |

Not a McCord Product. 80,000 were produced by other

companies. |

Introduced to bomber crews starting in June 1944. This

was a 3-piece steel helmet wrapped in fabric and leather for

warmth. |

|

M5 |

USAAF |

Bomber Air Crews |

Unknown |

Introduced in January 1945. |

|

Mk 2 |

U.S. Navy |

Navy Talker Helmet |

400,000 |

1942-1945 |

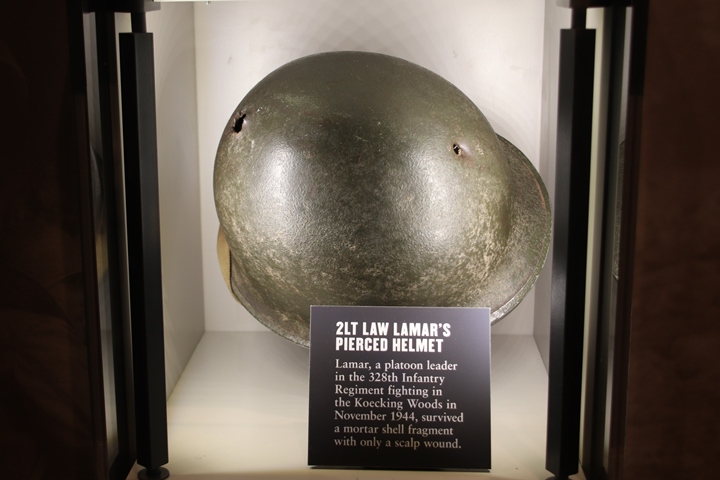

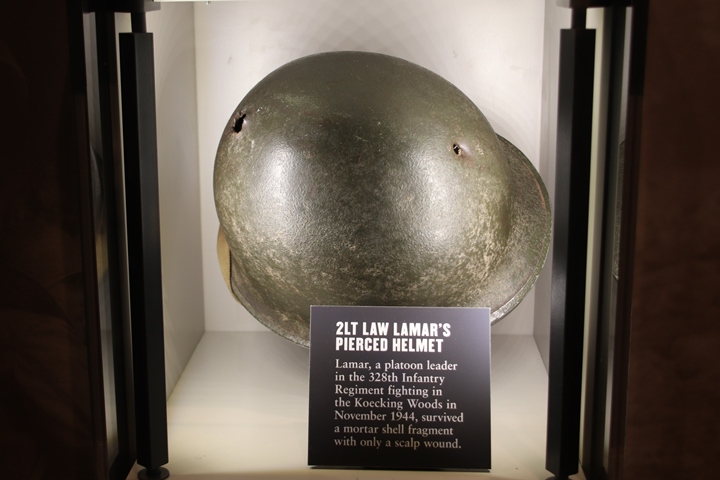

There were several variations of the M1

helmet during World War Two. Two of them are shown here in this

display at the National Museum of the United States Air Force.

This display shows several helmets that were produced for bomber air

crew head protection during World War Two. From left to right

there is the M2A2, the M5, the M1, and the M3 helmets. Author's

photo.

The standard M1 helmet was the first type

worn by bomber crews. However, this was not optimal as it did not

fit properly over the crewmen's headphones. Also, there was not

enough room in the ball turret for it to be worn by the gunner in that

position. However, it was what was available and expedient.

Author's photo.

McCord made 210,000 of these between 1942 and 1944. It had its

own built-in suspension system and did not need a helmet liner. It

also had an exterior flock coating to keep the airman's skin from

sticking to the helmet at the freezing temperatures to which they were

subjected. This example in the display at the museum was hit by

flak. The wearer survived the attack. Author's

photo.

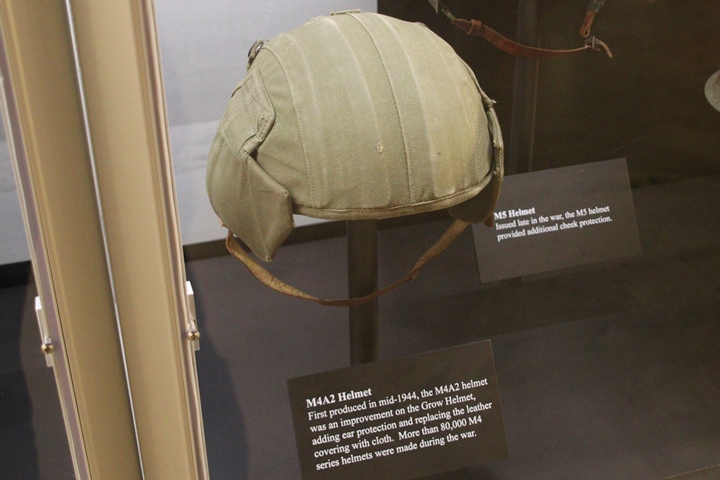

The M4A2 series bomber crew helmets were not produced by the McCord

Radiator & Mfg. Company. However, this helmet is important in the

lineage of protective helmets designed specifically for use by bomber

crews. They were of three piece steel construction with the helmet

and two ear flaps. They were cloth covered to help keep the

wearer warmer than with just a steel helmet. Author's

photo.

The last of the series of helmets for bomber

crews was the M5 series of helmets. These had longer ear flaps for

more side protection for the wearer. McCord made an unknown number

of these starting in January 1945. Author's

photo.

This and the following photo show a

McCord-built M3 helmet that is on display at the National Museum of the

United States Army at Fort Belvoir, VA. Author's

photo.

Author's

photo.

This image of the inside of an M3 flak

helmet shows how the webbing was attached to the interior of the helmet.

The McCord Radiator & Mfg. Company was the

only supplier of 400,000 M2 talker helmets for the U.S. Navy. This

rare example is on display at the Central Ohio Military Museum in

Harrisburg, OH. Author's photo.

The helmet was large enough so the operator

could wear a set of headphones inside the helmet. Author's photo.

The McCord-produced M2 talker helmet was used for many years after World

War Two by the U.S. Navy. This photo shows two talkers on the USS

Missouri during the Korean War.

Author's photo from the National Infantry

Museum.

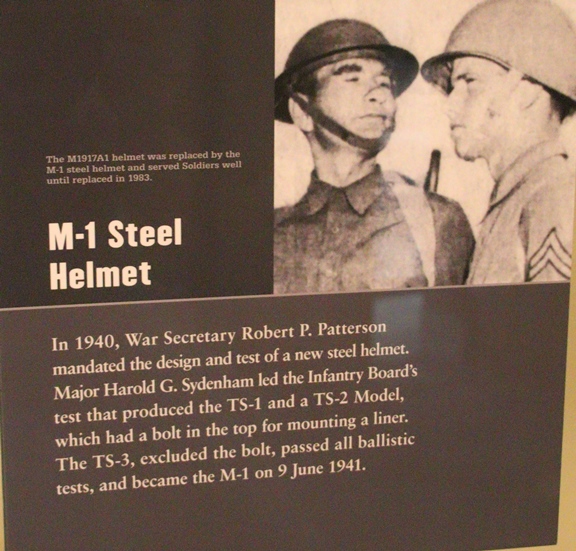

While production of the M1 helmet began at

the McCord Radiator and Mfg. Company, initial development took place at

the former Fort Benning, GA. Author's photo from the National

Infantry Museum.

Author's photo from the National Infantry

Museum.

Body Armor:

The company also made armored vests for Army

Ordnance during World War Two. The company had two different

contracts for the product that comprised 8.6% of its total contracts.

This body armor on display at the Veterans Memorial Museum in

Germantown, OH, is the type that bomber gunners were issued.

Author's photo.

This body armor was issued to bomber crew

members whose functions in the bombers required them to sit. This

body armor is not as bulky as the gunner armor. This example is on

display at the National Museum of the United States Air Force.

Author's photo.

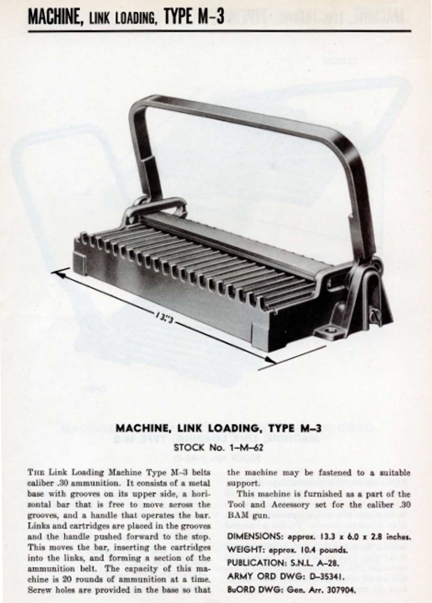

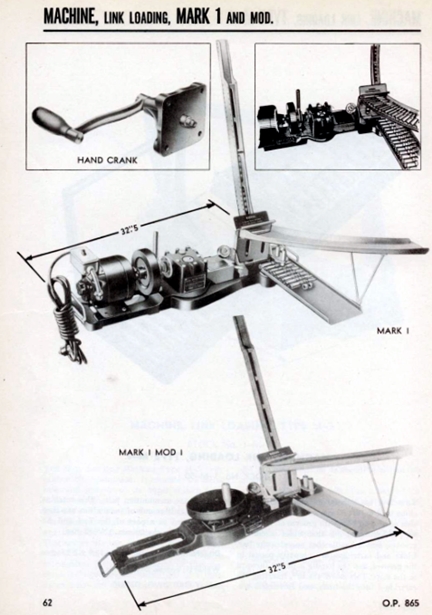

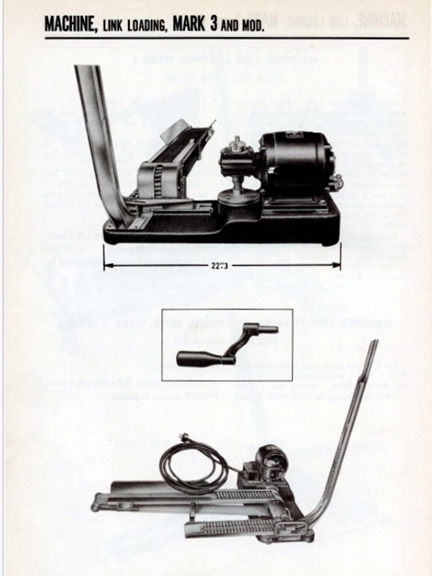

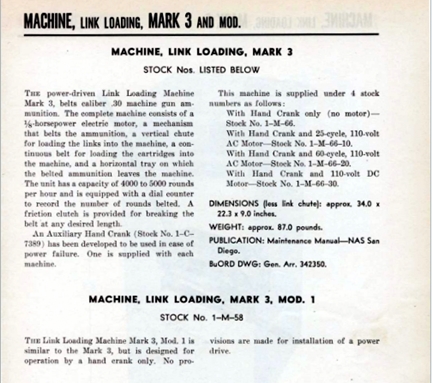

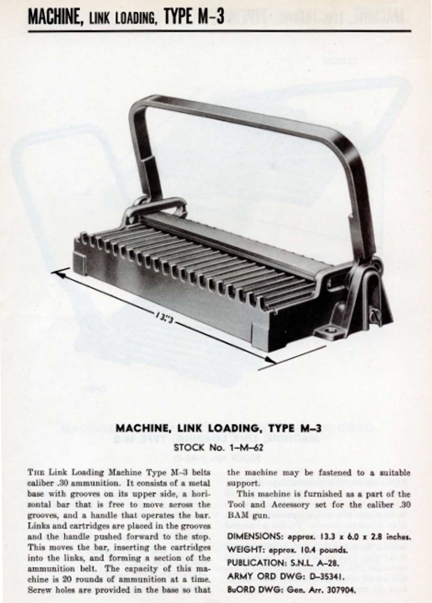

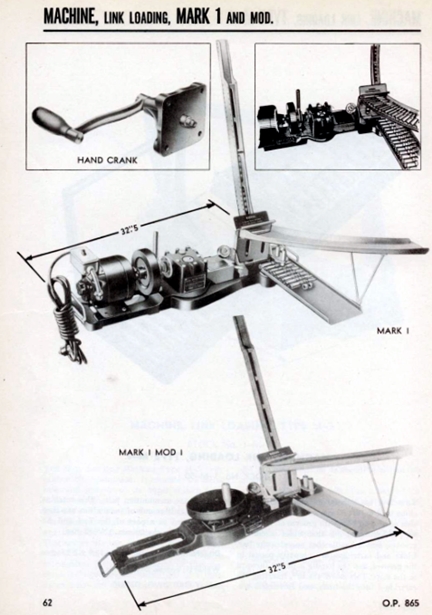

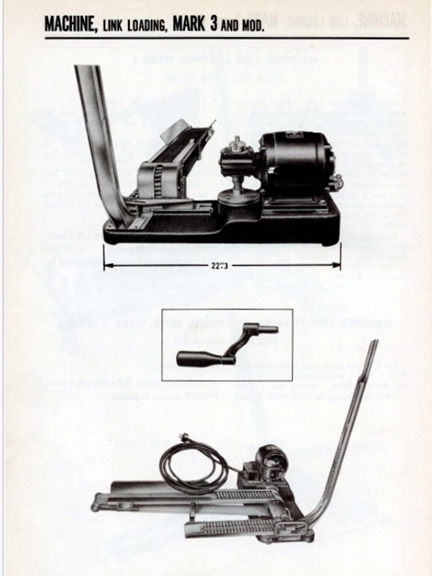

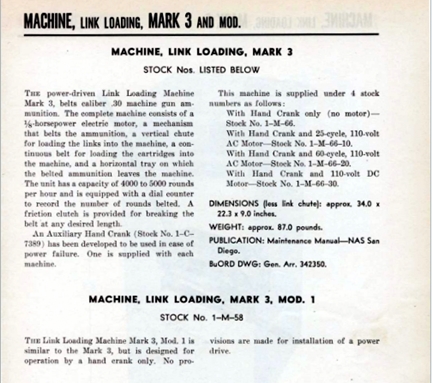

Link Loading Machines: McCord

won its first E Award for the development and production of linking

loading machines for the U.S. Navy. This was the second largest

product group the company manufactured after the M1 series of steel

helmets. It had seven contracts from the U.S. Navy valued at $6,504,000

for this type of product. There are several types of Navy linking

machines shown below. While only one example of a Type M-2

produced by McCord has been found, the company most likely developed and

produced the other types of linking machines shown below.

This image shows a McCord Radiator & Mfg.

Company-built .50 caliber hand linking machine.

The name McCord is on the bottom of the cast

iron base.

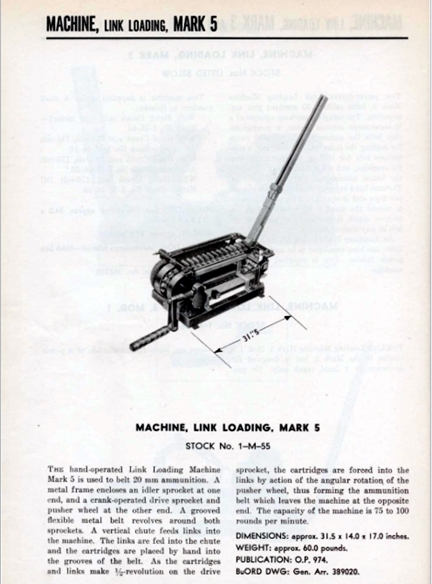

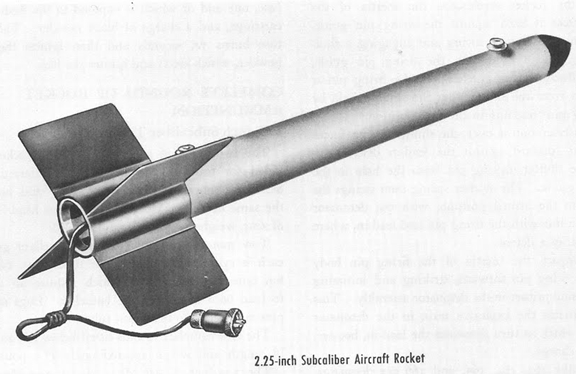

Rockets:

McCord also had five contracts valued at $3,515,000 for rocket motor

production during the later stages of World War Two.

The Mark 2 was a 2.25 inch subcaliber

aircraft practice rocket. It had all of the ballistic

characteristics of the larger 3.5 inch and 5 inch rockets but was more

cost effective for training purposes. McCord had one contract late

in World War Two for $280,000 to produce rocket motor for this practice

device.

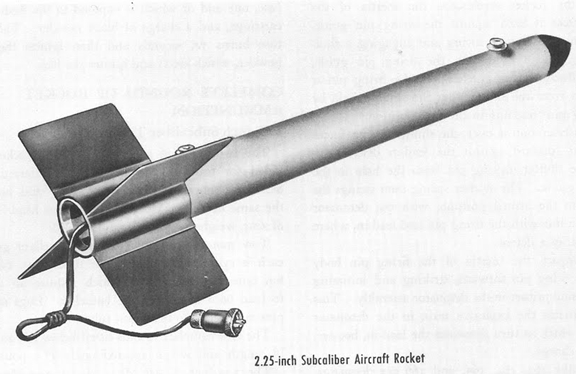

Other Country's World War Two Helmets:

The National Infantry Museum at Fort Moore, GA has several displays that

show the helmets the British Commonwealth, German, and Italian soldiers

wore during World War Two. This section gives a comparison of the

different styles of helmets used by these countries during the war.

This display shows the Allies' uniforms.

The British Commonwealth soldier is on the left side of the display.

Unfortunately, the Russian soldier in this display is wearing only a

soft garrison type hat on rather than a helmet. Author's photo.

This display shows the Axis soldiers.

Author's photo.

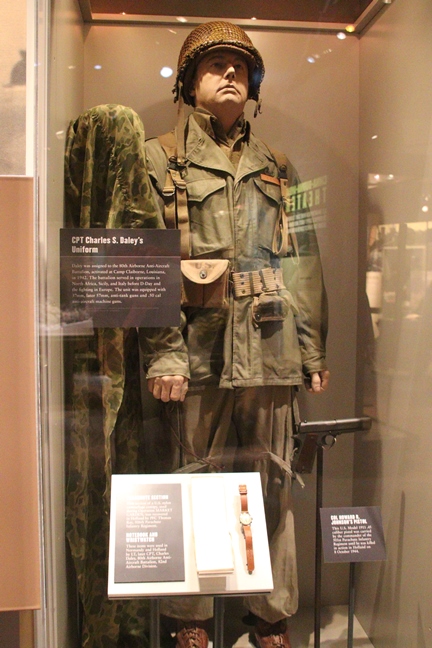

For completeness, I have included a display

of an American soldier. Author's photo.

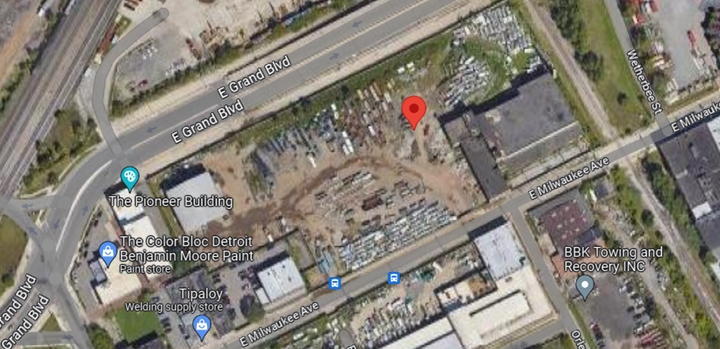

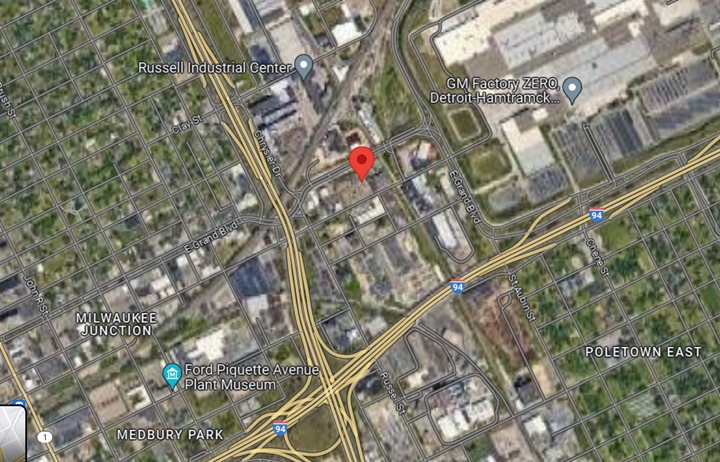

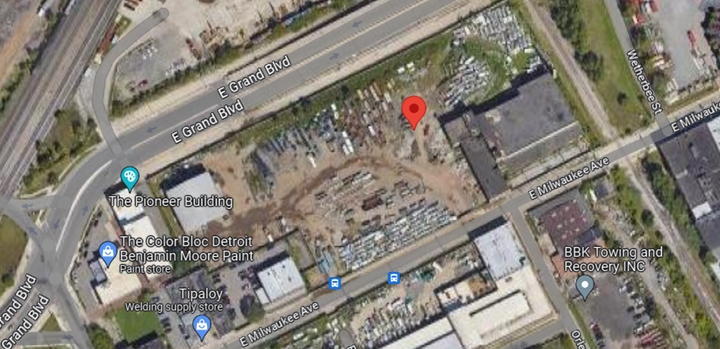

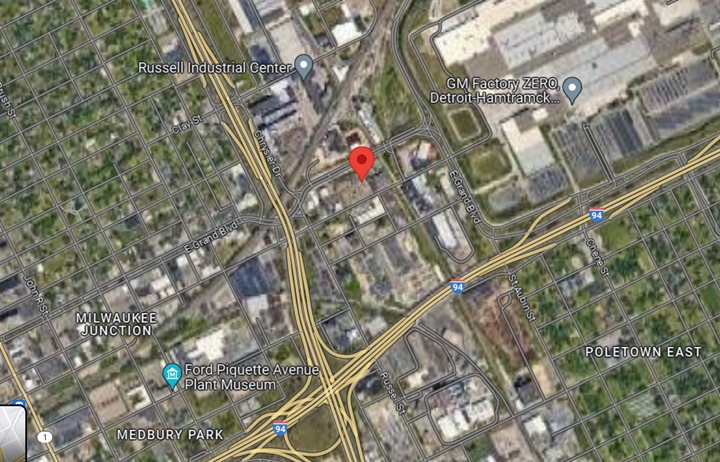

The McCord Radiator & Mfg. Company's

World War Two Factory: The factory was located at 2587 East

Grand Blvd. in the Milwaukee Junction industrial area of Detroit.

From the Google Maps views shown below, the former plant has been

largely razed.

There is still one building standing along E

Milwaukee Avenue and the railroad tracks. This could be the only

remnant of the former McCord Radiator and Mfg. Company factory complex.

This street view shows the building along

East Milwaukee Avenue.

This view shows the plant was north of I-94

and east of I-75, which is not marked in this photo.

|

|

|