|

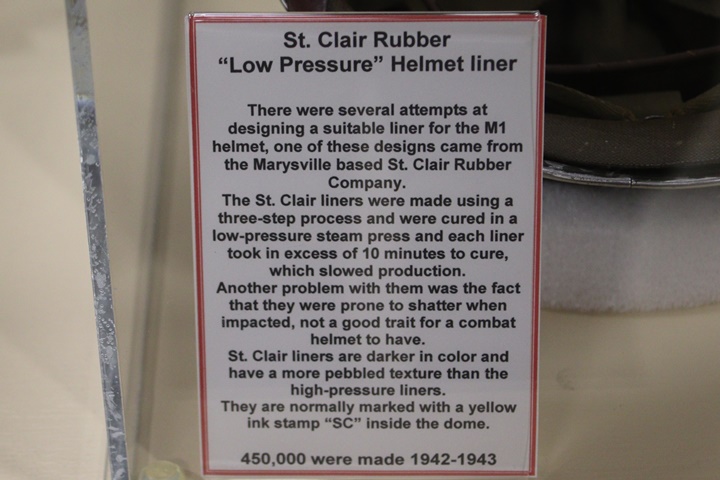

St. Clair Rubber Company During World War Two This page added 4-18-2023. In 1923, the St. Clair Rubber Company was started by Detroit businessman Hugo Scherer to manufacture rubber products for the automobile, aircraft, and boating industries. Marysville, MI is an industrialized town along the St. Clair River that separates the United States and Canada. The town is south of Port Huron, MI. The company's location allowed it to provide its products to the automobile industry in Detroit, MI, and also to the boating industry downriver in Algonac, MI. Boat makers Chris-Craft and GarWood were both located in Algonac. During peacetime before World War Two, the company typically employed 175 workers. One product manufactured by the workers at St. Clair Rubber was automotive rubber floor mats. St. Clair Rubber Company World War Two Products: The company had four major contracts for helmet liners for the M1 steel helmet totaling $3,098,000. According to an article in the June 27, 1945, Port Huron, MI Times Herald, the St. Clair Rubber Company produced 2,000,000. The unit cost per helmet liner was $1.56. The manufacture of 2,000,000 helmet liners required 750 workers for this operation.

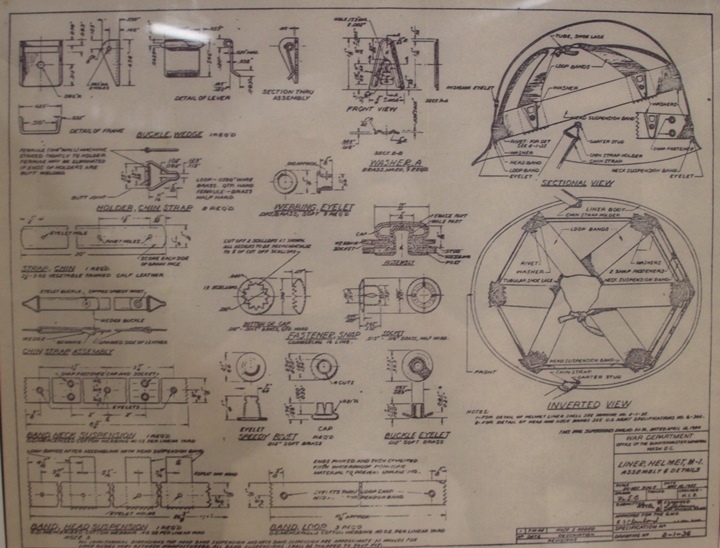

The next three photos were taken at the Michigan Military Technical & Historical Society in Eastpointe, MI. Among its many excellent displays, this museum has a display on the Michigan companies that made the World War Two M1 steel helmet and plastic helmet liner.

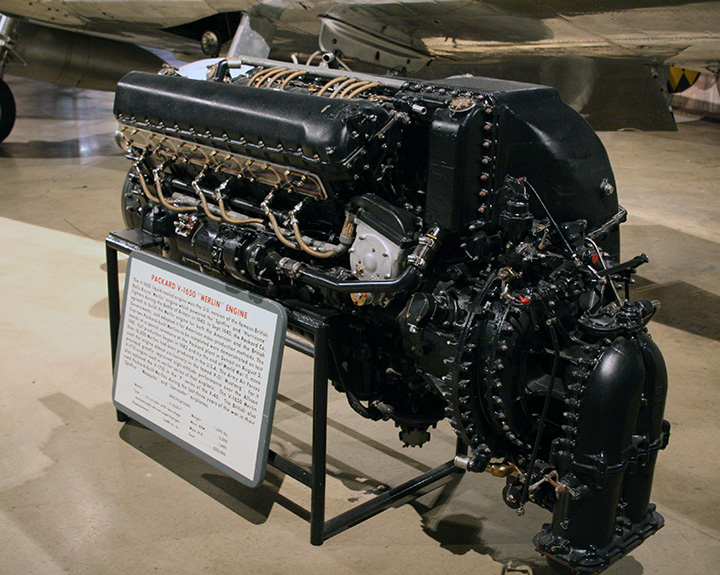

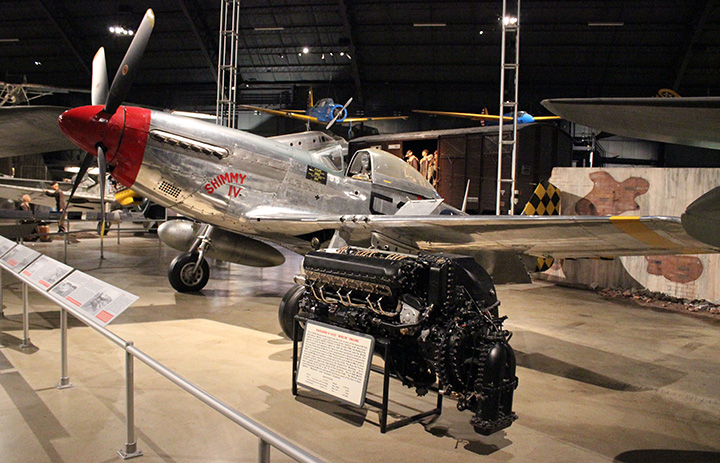

After losing the helmet liner contract, employment at the plant dropped to less than 200 employees. For the duration of the war, employment ranged between 175 and 200 employees. The St. Clair Rubber Company supplied a variety of rubber products for the war effort. Previous to World War Two, the company had developed its own rubber adhesives for attaching rubber to metal, plastic, or another piece of rubber. In March 1945, the company shipped 150,000 gallons of synthetic rubber and rubber cement for use by the U.S. Army and Navy. The company also produced a special rubberized felt that was used in self-sealing aircraft fuel tanks. It made aircraft engine gaskets that were shipped to the Packard Motor Car Company in Detroit, MI for installation in the Rolls-Royce 1650 Merlin aircraft engine Packard was building under license.

The company was involved in the manufacture of 3,000 gallon fiberglass tanks used in the Pacific. St. Clair Rubber Company received sheets of fiberglass from its manufacturer. It then coated them with a synthetic rubber and shipped them to a third company that made the rubber coated fiberglass into the final product. The company also coated aircraft flotation devices and compounded rubber under sub-contract for Goodyear that was used for tank treads. It also processed special sheet rubber for Goodyear for use in its aircraft products. The company also was a supplier of rubber parts and adhesives for gas masks. The former St. Clair Rubber Company Plant: The original factory located at 1765 Michigan Avenue in Marysville, MI was built in 1919 by the Athol Manufacturing Company. St. Clair Rubber purchased it in 1923 and remained there until it went out of business in 1988.

|

|||||||||||||||||||||||||||||||||||