|

Murray

Corporation of America During World War Two

Detroit, MI

1913-1981

1913-1924 as the J.W. Murray

Mfg. Co.

1924-1927 as the Murray Body Corporation

1927-1981 as the Murray Corporation of America

This page added 3-22-2023.

In August 2013, I made a trip to the

Milwaukee Junction area of Detroit to visit the Ford Piquette Avenue

Plant Museum. It was at this plant that Henry Ford first produced

the Model T before moving production to the Highland Park plant.

When I was done, I noticed a large, multi-story factory to the north.

As I made my way towards this old factory, I wondered who's former auto

factory was. I was not able to determine this

information when I returned home after that trip. For almost ten

years, the ones and zeros that digitally represent the photos I took

that day waited on my computer hard drive to be able to turn into photos

on one of my webpages. In March 2023, almost ten years later,

while researching the Murray Corporation of America, I realized this

unknown factory I visited in 2013 was the former home of Murray, one of

the three big automotive body builders of the early automobile industry

in Detroit.

Milwaukee Junction got its name from the

former Milwaukee Railroad tracks that ran through the area. While

the area was quiet on the Sunday afternoon I was there in 2013, one

hundred years before the area was the center of much of Detroit's

growing automobile industry. Many auto companies were located in

the geographic area. Besides Ford and Murray, Anderson Electric

Car Company, Brush Motor Car Company, Cadillac, Dodge, Everitt-Metzger-Flanders,

Fisher Body, Hupp, Packard, Oakland, Studebaker, and Regal all had

factories at Milwaukee Junction. It is considered the cradle of

the Detroit auto industry.

This image is looking north across the former

Milwaukee Railroad tracks towards the former Murray Corporation of

America factory complex. Even from this distance, it can be seen

that this Albert Kahn-designed factory is huge.

In 1915, Albert Kahn designed this seven

building 2,200,000 square foot complex for John William Murray, founder

and president of the Murray Corporation.

The two angled structures coming out of the

third floor of the south side of the west build appear to be the

location where the finished bodies exited the factory and were then

loaded on trailers to be transported to the company's various customers.

Currently, some of the over two million square feet in the complex are

part of the Russell Trade Center.

When it was designed and built, this was a

state-of-the-art factory. The Albert Kahn-designed factories in

Detroit all have an elegance not found in today's big box steel shell

factories.

Even from this distance, it can be seen that

the buildings are in relatively good shape for being nearly one hundred

years old when these photos were taken.

This image is on the north side of the

complex looking east on Clay Street. Again, it can be seen that

the buildings are in very good condition. While the former Packard

complex a mile to the south east of this area is more well known, it is

rather derelict. There are a lot of windows in the building.

Normally, when I visit an old factory like this, many of the windows are

broken out. This is not the case here. Any broken windows

have been repaired.

Just to the east of the power pole is an

entrance into the factory complex. I have seen this type of entrance

at other Albert Kahn factories in the Detroit area.

This image is looking north from inside the

courtyard of the complex. The area is well maintained.

Vehicles were parked at the north end of the courtyard and people were

visiting what shops located there.

This image is looking to the west from the

south end of the courtyard. Notice how small the vehicles look

parked along the building compared to the size of buildings.

Unfortunately, Detroit is known for many of

the dilapidated and derelict buildings that once were proud factories

providing jobs and producing automobiles. The previously mentioned

former Packard plant is an unfortunate and well-known example. In

1960, the former Murray complex was purchased by Packard Properties and

re-named the Russell Industrial Center. Sixty different small

companies moved in and used most of the floor space. However, over

the years, ownership of the complex changed, most of the companies

moved out, and the Russell Industrial Center started to slide into

disrepair. However, Mr. Dennis Kefallinos purchased the complex in

the early 21st century and has spent the necessary money to restore some

of its original elegance.

In 1913, John William Murray and his son John

R. Murray formed the J.W. Murray Mfg. Co. whose main product was

providing steel stampings to the Detroit automobile manufacturers.

The company's products included fenders, hoods, cowls, and frames for

Ford, Hudson, Hupmobile, King, and Studebaker. In 1924, the J.W.

Murray Mfg. Co. merged with the C.R. Wilson Body Co., Towson Body Co.,

and the J.C. Widman Co. to form the Murray Body Corporation. The

C.R. Wilson Body Co. had a large customer base for its bodies that

included the Ford Motor Company. With the merger the new company

produced upwards of 70,000 bodies per year. Both of the original

Murrays left the company after the merger and new corporate inept

management sent the company into receivership in 1925. When the

company finally emerged from receivership in 1927, it was renamed the

Murray Corporation of America and had new management. The new

company continued to produce automotive bodies for various auto

companies until 1952. However, by then General Motors, Ford, and

Chrysler all had their in-house body making capacities, and Murray's

other customers slowly went out of business one by one. The company had

previously diversified into other products including plumbing and

household appliances. This portion of the company continued at

least through the early 1980s.

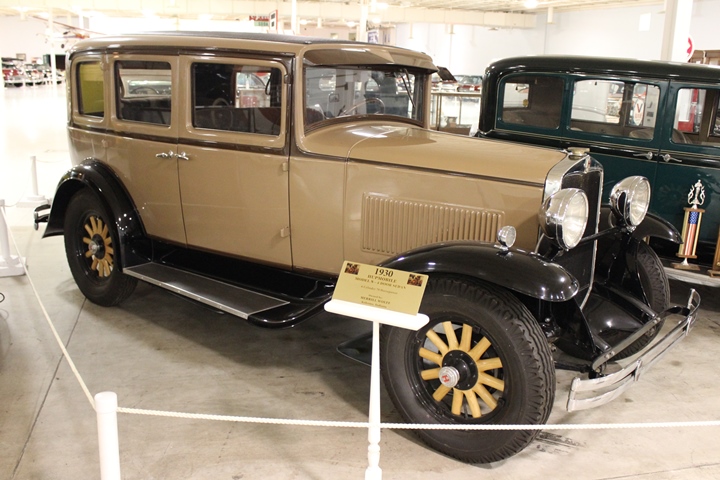

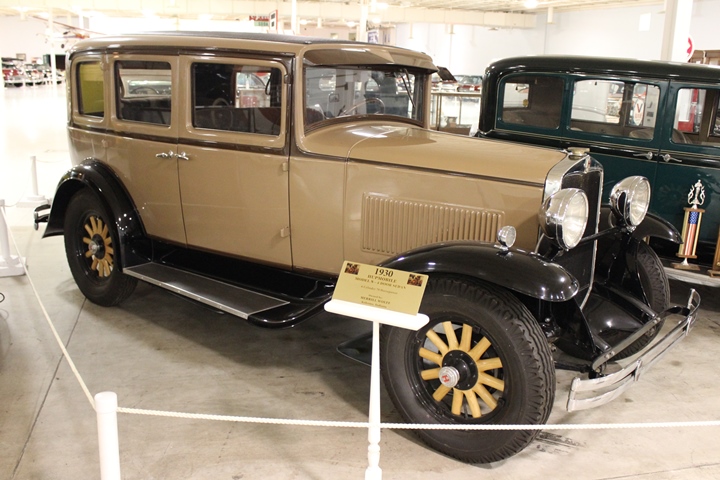

This 1930 Hupmobile has a Murray body.

Author's photo.

Crosley was another of Murray's costumers.

This 1939 Crosley has a Murray body. Author's photo.

Author's photo.

This view shows the interior of the

Crosley passenger cabin. Crosley went out of business in 1953.

Some of the last bodies Murray made were for Crosley. It had

finally run out of

customers. Author's photo.

This former display at the Studebaker Museum

illustrates the body drop. The body manufacturers installed all of the

carpeting, seats, door hardware, and windows along with all of the

upholstery. Author's photo.

Murray Corporation of America World War Two

Products:

In January 1941, Murray accepted a

$26,000,000 contract from Douglas Aircraft for the manufacture of

A-20 inboard wings. Murray was the first company to utilize

automotive mass production techniques for the production of aircraft

parts. It used the same methods and presses for making aluminum

parts as it did for making steel auto bodies. Each A-20

inner wing section consisted of 5,400 parts and 55,000 rivets. The

contract was completed ahead of schedule in 1942. Author's photo.

In May 1941, the United States Army Air

Forces notified the Boeing Company that requirements for B-17s had

become larger than Boeing's ability to build them. This led to

the Douglas Aircraft Company and the Vega Division of Lockheed coming on

board as builders of the B-17 under license from Boeing. This was

during the same time period that the American aircraft industry was

going to Detroit to fabricate airframe components for many of the new

military aircraft being built. Because of the A-20 inner wing

project, Douglas chose Murray to build the outer wings, wings tips, and

engine nacelles for the B-17F model. As was typical of the era, it

took both Douglas and Murray a year to tool up and begin production.

During that period, Douglas added two new buildings for production of

the B-17 at its Long Beach, CA facility. The first Douglas B-17F

came off the Long Beach assembly line in late June 1942. For the

next year, Murray delivered 605 B-17 outer wings and wing tip sets to

Douglas. It also produced 2,420 engine nacelles. With the

introduction of the B-17G model at Douglas in June 1943, Murray's contract

was not renewed. For whatever reason, this contract went to

Murray's chief competitor, Briggs.

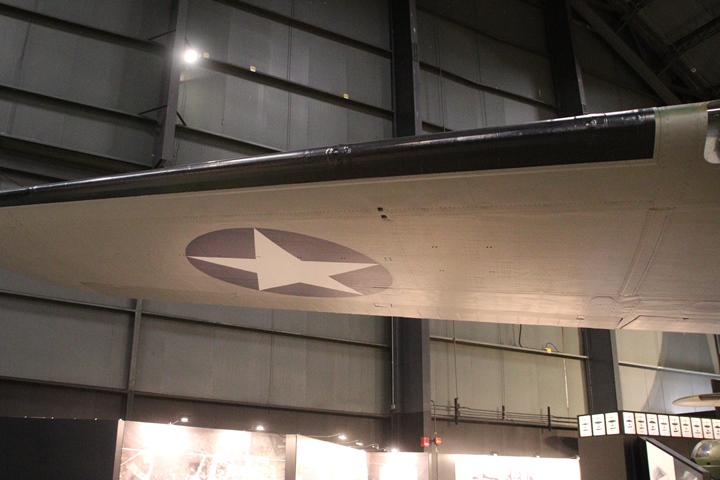

This is the B-17F "Memphis Belle" at the

National Museum of the United States Air Force in Riverside, OH.

The "Memphis Belle" was built by Boeing but is identical to the ones

Douglas made. Author's photo.

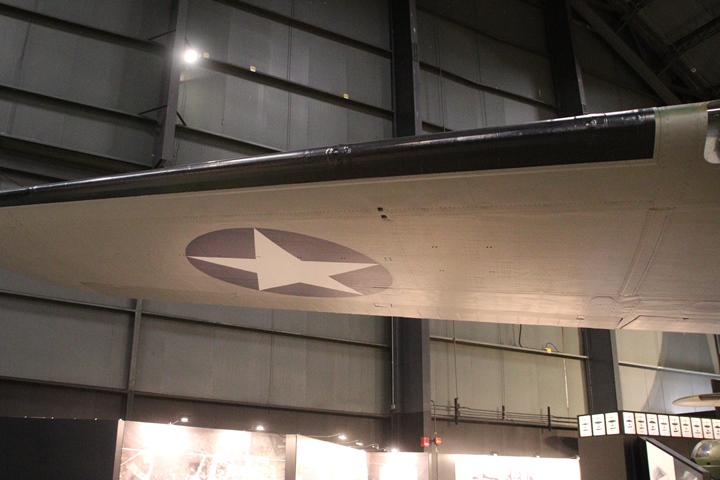

There are two seams in the wing that

separate the outer wing from the wing center section and the wing tip.

One can be seen next to the landing light and the other out towards the

tip of the wing. Author's photo.

The seam where the outer wing joins the center

section can be seen in the right side of the photo. Author's photo.

This shows the seam between the outer wing

and the wing tip. Murray produced both components for the

Douglas-built B-17F. Author's photo.

This Vega-built B-17G "Champaign Lady" is undergoing total restoration

at the Champaign Aviation Museum in Urbana, OH. Author's photo.

The wings for the "Champaign Lady" are being

built from scratch by museum volunteers. This view of one of the

outer wing sections shows the details of the construction. Author's photo.

Author's photo.

This and the next two images were taken at a

later date. Author's photo.

Author's photo.

Author's photo.

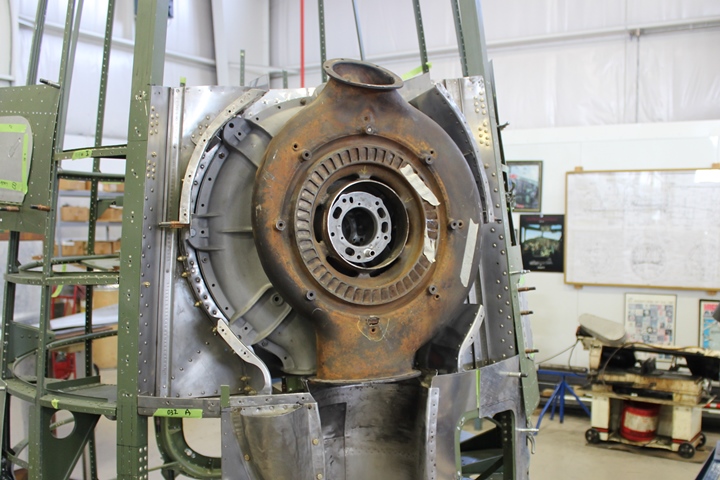

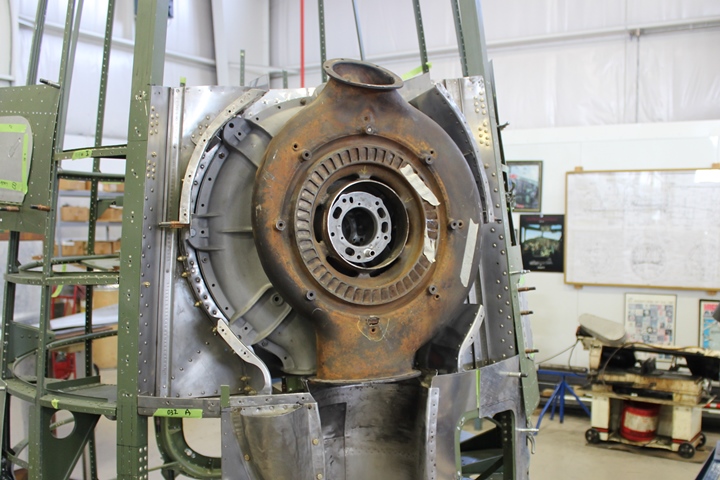

This B-17 engine nacelle shows the

construction of the unit. Author's photo.

Author's photo.

Each engine had a General Electric turbo

supercharger to allow it to fly at high altitude. This image shows

the location of the unit in the bottom of the nacelle. Author's photo.

A partially assembled turbo supercharger has

been installed, showing how it fits into the nacelle. Author's photo.

This is an interior view of the engine

nacelle. Author's photo.

This image shows three nacelles awaiting

installation. Once the wings are completed, the nacelles can be

installed on them. Author's photo.

This image shows two the port side engine

nacelles on the "Memphis Belle." Author's photo.

Next, Murray began the production of wings for the Republic P-47G

Thunderbolt. This was the Curtiss-Wright Corporation's

license-built version of the P-47. Only 354 were built.

Author's photo.

This Ford-built B-24J is on display at the Barksdale Global Power Museum at Barksdale AFB in Bossier City,

LA. Murray produced an unknown quantity of various subcomponents

for the 6,792 B-24s that Ford at the aircraft assembly plant in nearby

Willow Run, MI. Ford also made 955 knock-down B-24s that were

assembled by Douglas in Tulsa, OK and 939 knock-downs that were

assembled at the Consolidated plant in Fort Worth, TX. Ford also

made enough spare parts to make another 452 aircraft. There was

plenty of opportunity for Murray to use its stamping facilities and

workforce to fabricate sheet metal parts and then assemble into

subassemblies for the Ford-built B-24s. Many of these components

were stainless steel stampings.

Murray was also contracted by Curtiss-Wright

for the manufacture of rudders for the SB2C dive bomber. The SB2Cs

were assembled by Curtiss in Columbus, OH. Author's photo.

Murray also made steel stampings for

anti-aircraft search lights. It substituted steel stampings for

the replacement of aluminum castings which saved 100,000 lb. of aluminum per month. There were two different companies that made search

lights during World War Two. One was made by General Electric as

shown above. It is unknown for which company Murray made the

search light parts for. Author's photo.

The Sperry Gyroscope Company built

search lights like the one shown here. Author's photo.

The Ford Motor Company produced 12,782

amphibious jeeps during World War Two. Murray produced the frames

for these vehicles. Author's photo.

Dodge built 43,224 WC-62/WC-63 Dodge 6x6 1-1/2 ton

trucks at its Mounds Road Plant in Warren, MI. Murray Company

officials noted that Murray also made frames or frame parts for this

truck. Author's photo.

Murray also had $4,676,000 in major contracts

during World War Two.

Table 1 - Murray Corporation of

America's

Major World War Two Contracts

The information below

comes from the "Alphabetical Listing of Major War Supply

Contracts, June 1940 through September 1945." This was

published by the Civilian Production Administration, Industrial

Statistics Division. Table added 2-5-2023. |

|

Product - Customer |

Contract Amount |

Contract Awarded

Date |

Completion

Date |

| Burlap Jute -

Army Corps of Engineers |

$354,000 |

1-1942 |

1-1942 |

|

Gun Parts - Army Ordnance |

$400,000 |

4-1942 |

9-1942 |

| Flash Hiders

M1923 - Army Ordnance |

$83,000 |

12-1943 |

5-1944 |

| Cartridge

Cases M13 - Army Ordnance |

$3,839,000 |

5-1944 |

1-1946 |

| Total

|

$4,676,000 |

|

|

This image shows an M1923 flash hider on

the end of a .30 caliber machine gun barrel. Murray redesigned

the M1923 to utilize stampings instead of the part being a machined

part. This was as more cost effective design.

Murray Corporation of America World War Two

Scranton, PA Plant: In early 1944 Murray was designated to begin

building B-29 outer wing sections. While the company had floor

space at its plant in Detroit, there was a critical labor shortage in

the area. This was not the case in Scranton, PA, so Murray built a

government owned factory in Scranton, PA for production of B-29 outer

wings. During 1944, the company had use of a local armory to train

employees so they would be prepared to start the manufacture of wings in

early 1945 when the plant opened. After World War Two Murray

purchased the plant and produced gas and electric stoves, sinks, and

bathtubs.

This image courtesy of the Detroit Public

Library National Automotive History Collection shows final

assembly of B-29 outer wing sections at Murray's Scranton plant.

This Google Maps satellite view shows the

plant as of today.

This is the Google Maps street view looking

to the south from the end of South Washington Street.

One last look at the Murray plant in

Detroit, MI.:

This Google Maps street view shows the

massive elegance of the Murray plant in Detroit.

|