|

Fisher

Body - Home

Fisher Body Craftsmanship Goes to War

Fisher Body - Craftsmanship

Fisher Body - Aircraft

Fisher Body - Aircraft

Instruments

Fisher Body - Guns

Fisher Body - Tanks

Fisher Body - Miscellaneous

The Plants

Fisher Body WWII Plant Database

Cleveland Plant #1, OH Plant

Cleveland Plant #2, OH Plant

Detroit Aircraft Unit,

Detroit, MI

Detroit Die and Machine Plant

Fleetwood, Detroit, MI Plant

Flint Plant #1, MI Plant

Grand Blanc, MI Tank Arsenal

Grand Rapids, MI Plant

Lansing, MI Plant

Memphis, TN Plant

Ternstedt Manufacturing Division,

Detroit, MI

Grand Blanc Tank Arsenal Built Tanks and Tank Destroyers

Grand Blanc

built M4A2 Sherman Tank Photos

Grand Blanc

Built M4A3 Tank Photos

Grand

Blanc M10 Tank Destroyer Photos

Ternstedt

Manufacturing Division of Fisher Body - General Motors Corporation in

World War Two

Detroit, MI

1917-1983

1983-1994 as part of Fisher-Guide and then the Inland-Fisher-Guide

Division.

This page updated 3-28-2022.

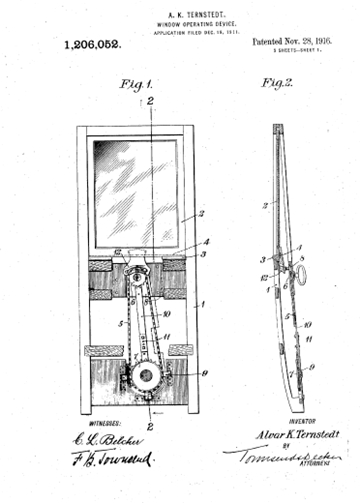

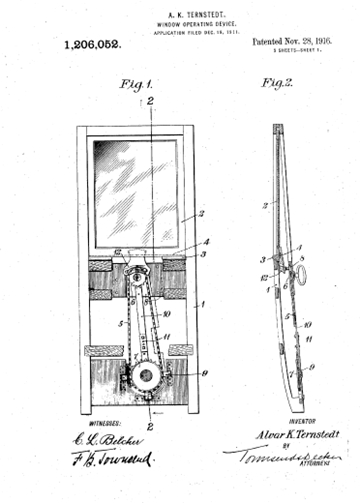

In 1911 Alvar Ternstedt invented a device for

use in the new automobile industry that manually rolled windows up and

down in the doors of the vehicle using a hand crank. This is known

in the industry as a window regulator. Hand crank window regulators

have given way to electrically powered units. In some form

however, they

resemble the one invented by Alvar Ternstedt.

The patent was issued on November 28,1916.

The window regulator used a bicycle chain to move the window up and down

inside a wooden door. Two other inventors of the era, Orville and

Wilbur Wright also used bicycle chains in their aircraft to transfer the

power from the engine to the propellers. It was state-of-the-art

technology at the time.

In 1917, in order to bring his new product to

market, Ternstedt had to enlist the financial assistance of the Fisher Brothers,

who already owned the world's largest auto body building company,

Fisher Body. The Ternstedt Manufacturing Company was formed in

1917 with Alvar Ternstedt as the chairman of the new company. Four

Fisher brothers and three Fisher stockholders formed the rest of the

board of directors of the new company.

Six months later. Alvar Ternstedt passed away.

In 1920 Fisher Body purchased the company. When General Motors

purchased Fisher Body in 1926, Ternstedt, the largest manufacturer of

automotive hardware, was made a division of Fisher Body.

At times General Motors did not seem to know

where to place it in the company's organization, as sometimes it was

part of Fisher Body, and other times its own stand-alone division.

The 1943 and 1944 General Motors Annual

Reports list the Ternstedt Manufacturing Division along with the other

GM Divisions. In the 1945 GM Annual Report, Ternstedt is missing

from that list. The Army-Navy E Award was presented to the Fisher

Body Ternstedt Manufacturing Division during the war. In 1958

Ternstedt became its own Division within General Motors. In 1968

it reverted back to being part of Fisher Body until it was dissolved in

1983. Then it was folded into the new Fisher Guide Division of GM

until it became part of Delphi in 1995. By that time, all

vestiges of its former division had disappeared.

The Fisher Body Ternstedt Manufacturing

Division, Division #9, Detroit, won the Army-Navy E Award two times

during World War Two.

The Fisher Body Ternstedt Manufacturing Division #3, and Plant #16,

Detroit, won the Army-Navy E Award two times during World War Two.

Fisher Body Ternstedt Manufacturing

Division World War Two Production Statistics: 168,000 Sperry aircraft

gyro horizons, 124,000 Sperry aircraft directional gyros, 46,615 Bendix

remote reading compass

transmitters, 76,291 Bendix remote reading compass receivers, 4,724 Bendix

air position computers, 4,716 Bendix air position pumps,

4,725 Bendix air position right angle drives, 4,962 M5 tank turrets,

1,798 M8 tank turrets, 600 T17 Staghound armored car anti-aircraft

turrets, 3,553 M24 tank turrets, 20 LVT 75mm howitzer turrets, various

machined forgings and die castings for the B-25

program, various machined parts for the B-29 program, various

parts for the XP-75 program, M4 Sherman parts, five-inch naval gun

breech housing parts, 90mm anti-aircraft gun parts, 20mm anti-aircraft

gun parts, 75mm tank gun parts, XB-19 aircraft bomber parts, 75mm shell

parts, Dzus fasteners, incendiary bombs, and cutting tools.

As the above listing shows, the Ternstedt

Manufacturing Division built everything from precision aircraft

instruments, with extremely small parts, to welded steel tank

turrets. Like many manufacturers during World War Two, it built

needed war material totally foreign to its peace time products.

Aircraft Instruments:

Ternstedt built both Sperry Instruments and Bendix

aircraft instruments during World War Two. This was a total

departure from the automotive hardware the division had been producing

before the war. Many of the instruments needed to be assembled in

air-conditioned rooms.

Sperry Instruments:

Sperry Instruments had been building gyro

horizons and directional gyros in semi-laboratory conditions in its

plants in New York. When the U.S. Army Air Force first contracted

with Ternstedt in February 1942, the Division decided to use automotive

assembly methods to meet the large number of instruments needed for the

war effort. There were 303,221 aircraft built during World War

Two. Each one required a minimum of one directional gyro and a

gyro horizon. Trainers, cargo aircraft, and bombers with two

pilots needed two of each. The only way to meet the demand for the

number of instruments was to build them with mass production methods.

Initially, there were 3,341 Ternstedt workers involved to make these two

products. As the program progressed, the number of employees was

reduced to 1,473 in June 1944.

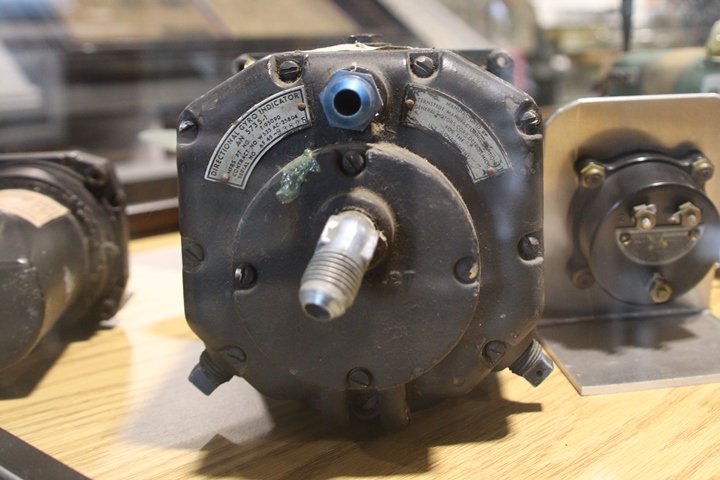

This is the Ternstedt directional gyro

assembly line. Many of the operations had to be done in

air-conditioned rooms to maintain tolerances. The assembly line

only shows a small proportion of the workers needed to build the Sperry

instruments. Most of the employees not seen in the photo were

producing all of the parts that went into the final assembly.

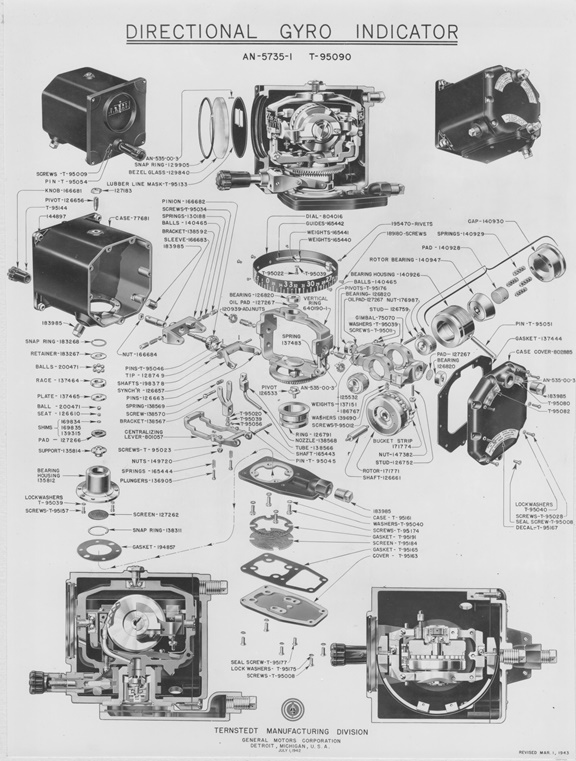

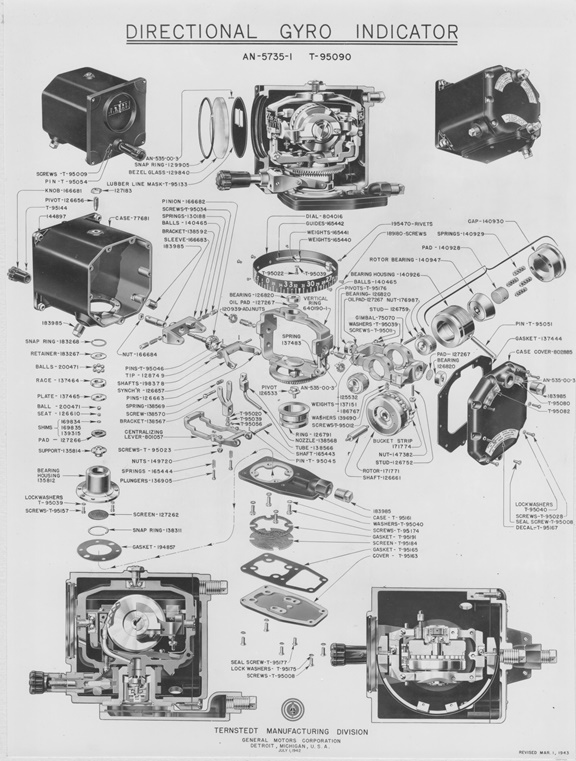

This is the directional gyro that the

workers are assembling in the photo. This was a very important

instrument as it indicated the direction the pilot was flying. It

had to be accurate and reliable.

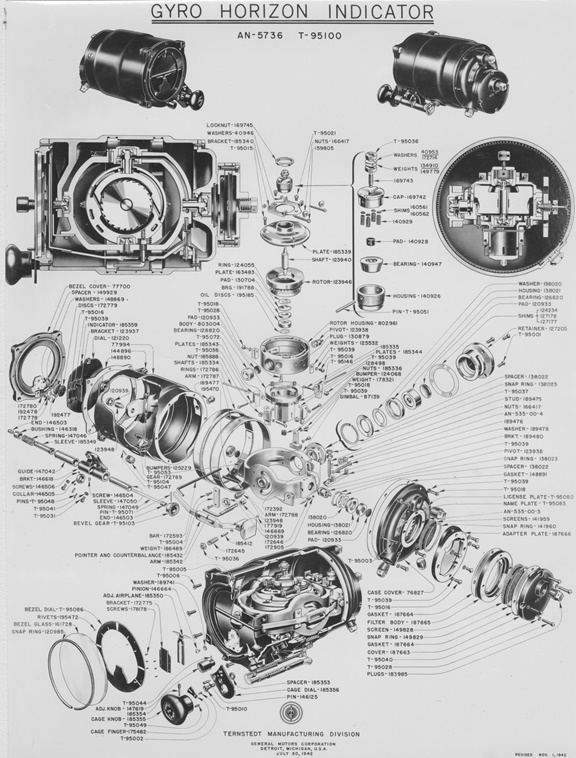

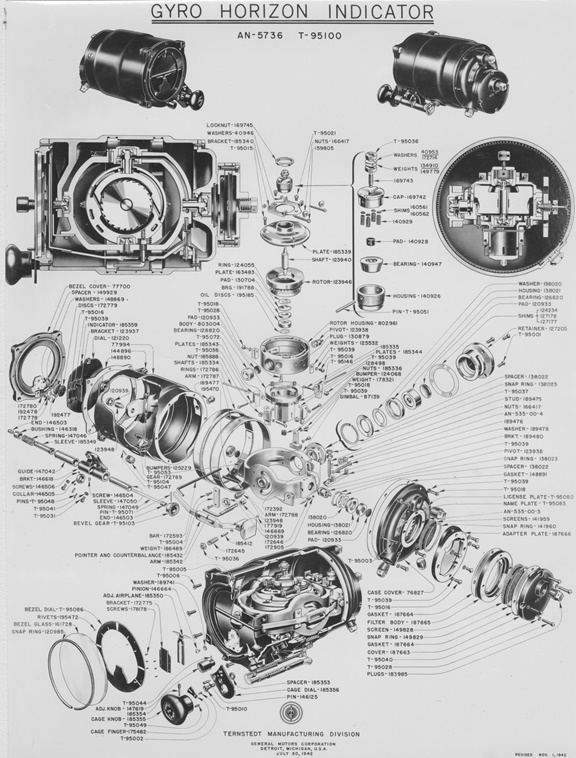

This diagram shows the complexity of the

instrument and all of the small parts that went in to it.

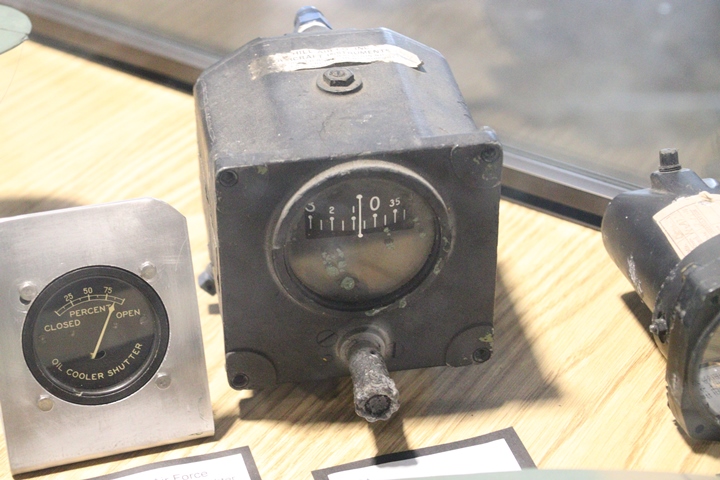

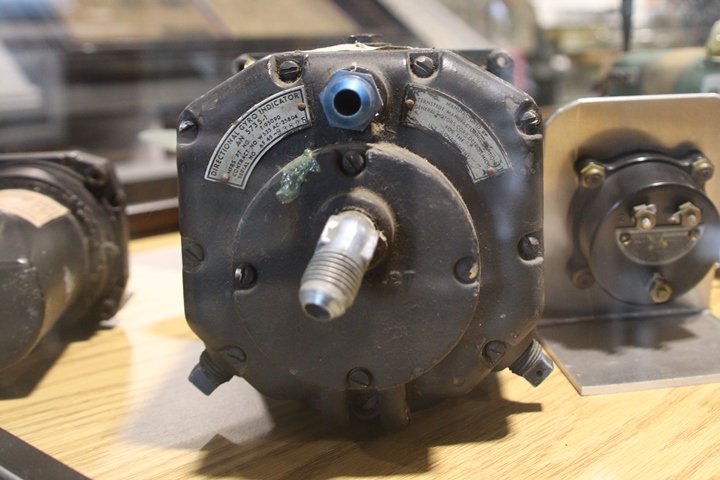

This Ternstedt-built directional gyro is on

display at the Regional Military Museum in Houma, LA. Author's

photo added 3-28-2022.

Author's photo added 3-28-2022.

Author's photo added 3-28-2022.

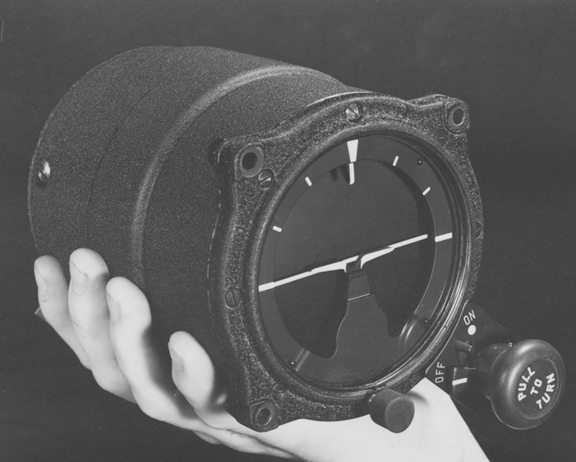

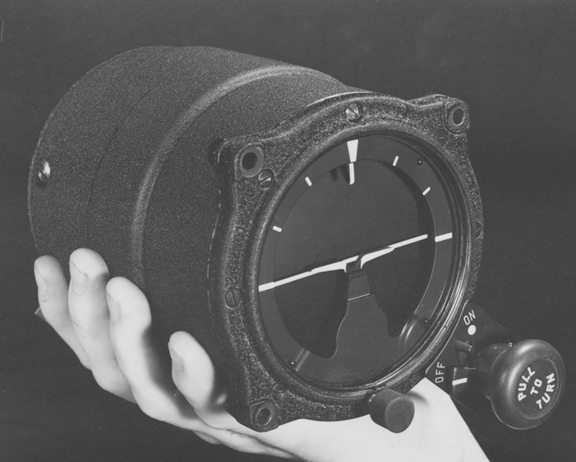

The gyro horizon, or artificial horizon as

it is known to pilots, is used during instrument conditions. It is

used to keep the aircraft in level flight when the ground cannot be seen

due to weather conditions. It also has to be accurate and

reliable.

It is also a complex instrument with many

small parts.

Table 1 - Ternstedt World War Two Shipments of Sperry Gyro Horizons and Directional

Gyros

This table shows both the contracted amounts by month and

year and the actual production. No monthly data is available

for April through July 1945. Only the total number

of instruments built by July 1945 is available. |

|

Date |

Gyro horizon |

Directional Gyro |

|

1942 |

Contract |

Actual |

Contract |

Actual |

|

August |

206 |

206 |

183 |

183 |

|

September |

764 |

764 |

681 |

681 |

|

October |

1,913 |

1,913 |

1,092 |

1,092 |

|

November |

3,000 |

3,000 |

2,044 |

2,044 |

|

December |

4,412 |

4,412 |

3,314 |

3,314 |

| 1943 |

|

|

|

|

|

January |

5,520 |

5,520 |

4,604 |

4,604 |

|

February |

5,151 |

5,151 |

6,176 |

6,176 |

| March

|

4,976 |

4,976 |

5,785 |

5,785 |

| April

|

7,170 |

7,170 |

6,512 |

6,512 |

| May

|

5,664 |

5,664 |

6,168 |

6,168 |

| June

|

6,000 |

6,344 |

6,000 |

6,153 |

| July

|

6,000 |

6,024 |

6,000 |

6,080 |

|

August |

6,000 |

6,000 |

6,000 |

6,040 |

|

September |

6,000 |

6,002 |

5,500 |

5,506 |

|

October |

6,000 |

6,000 |

5,000 |

5,000 |

|

November |

6,000 |

6,000 |

4,300 |

4,300 |

|

December |

5,500 |

5,500 |

4,300 |

4,300 |

| 1944 |

|

|

|

|

|

January |

5,000 |

5,000 |

3,500 |

3,500 |

|

February |

4,000 |

4,000 |

2,750 |

2,750 |

| March

|

3,000 |

3,000 |

2,750 |

2,750 |

| April

|

2,750 |

2,750 |

2,750 |

2,750 |

| May

|

2,750 |

2,750 |

2,750 |

2,750 |

| June

|

2,750 |

2,750 |

2,750 |

2,750 |

|

Totals |

100,526 |

100,896 |

90,909 |

91,188 |

| |

|

|

|

|

| July

1944 - March 1945 |

25,174 |

25,174 |

24,591 |

24,591 |

|

Totals though March 1945 |

125,700 |

126,070 |

115,500 |

115,779 |

|

Totals though July 1945 |

|

168,000 |

|

124,700 |

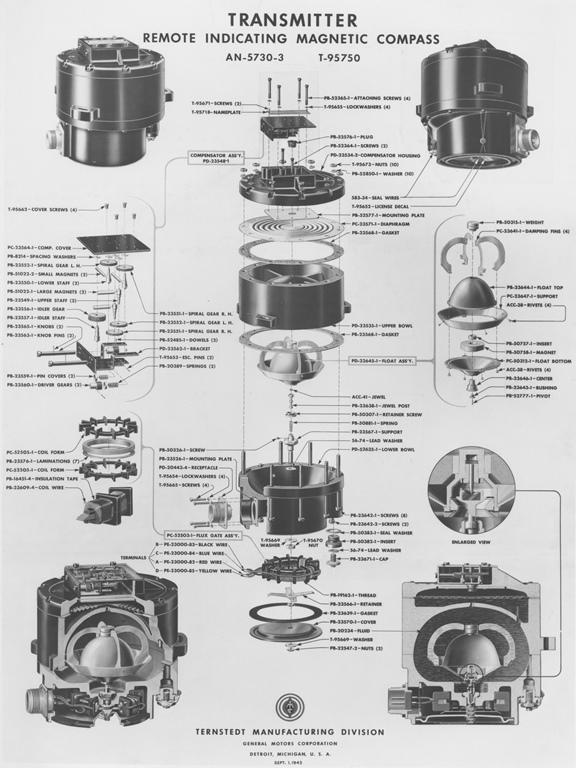

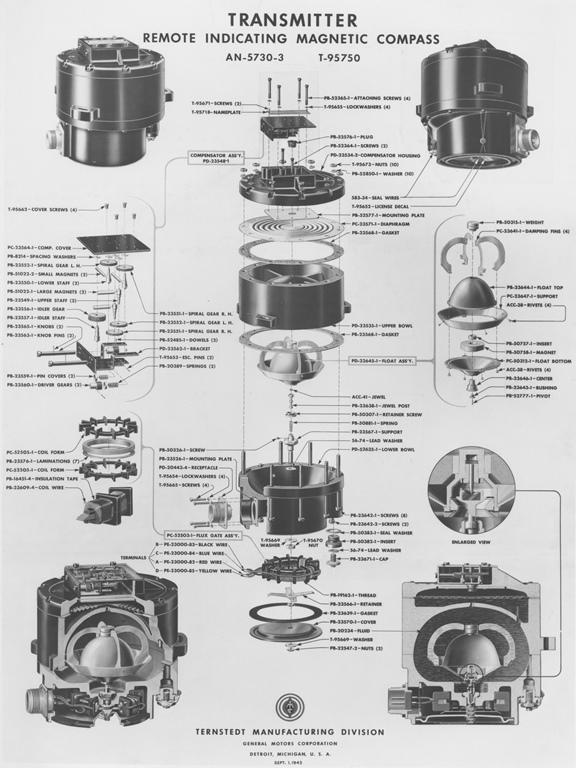

Bendix Instruments: The USAAF

contracted with Ternstedt to produce two of the three components of the

Bendix Remote Reading Compass. These were the transmitter and the

indicator. The third component, the inverter, was not produced by

Ternstedt. When production began on this project there were 682

employees dedicated to this project. This was later reduced to 388

in June 1944.

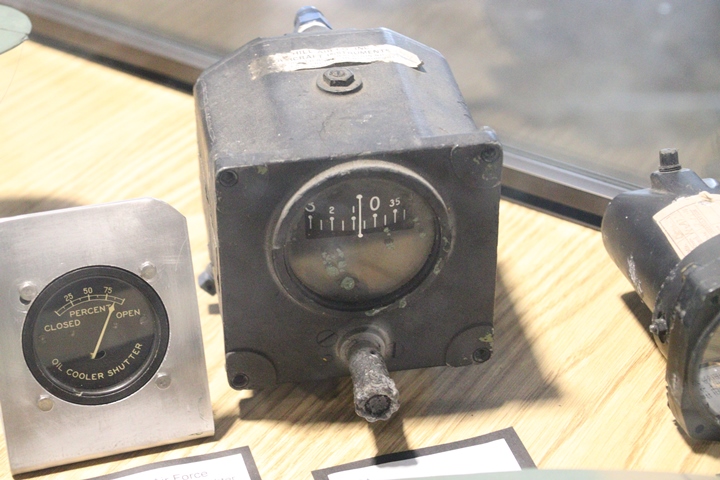

The indicator is in the lower left and the

transmitter in the upper right.

Table 2 - Ternstedt World War Two Shipments of Bendix Remote

Reading Transmitters and Indicators

This table shows both the contracted amounts by month and

year and the actual production. No monthly data is available

for July 1944 through July 1945. Only the total number

of instruments built by July 1945 is available. |

| Date |

Transmitters |

Indicators |

| |

Contract |

Actual |

Contract |

Actual |

|

1943 |

|

|

|

|

|

July |

200 |

439 |

200 |

386 |

|

August |

900 |

1,259 |

600 |

423 |

|

September |

1,900 |

1,344 |

1,090 |

954 |

|

October |

3,000 |

3,000 |

2,600 |

3,900 |

|

November |

3,000 |

3,000 |

4,000 |

4,227 |

|

December |

3,000 |

3,000 |

4,000 |

4,000 |

|

1944 |

|

|

|

|

|

January |

3,000 |

3,000 |

3,000 |

3,000 |

|

February |

3,000 |

3,000 |

3,000 |

3,000 |

|

March |

2,500 |

2,500 |

3,500 |

3,500 |

|

April |

2,500 |

2,500 |

3,500 |

3,500 |

|

May |

2,500 |

2,500 |

4,000 |

4,000 |

|

June |

2,500 |

2,500 |

6,500 |

6,500 |

|

Totals |

28,000 |

28,042 |

35,990 |

37,390 |

|

Totals though July 1945 |

|

46,615 |

|

76,291 |

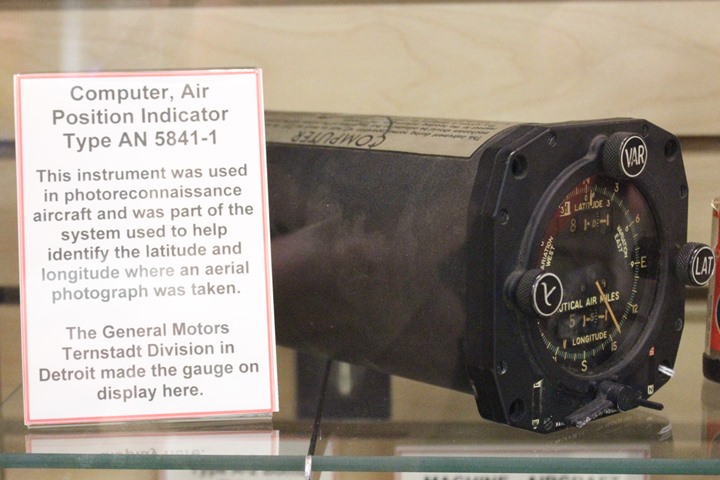

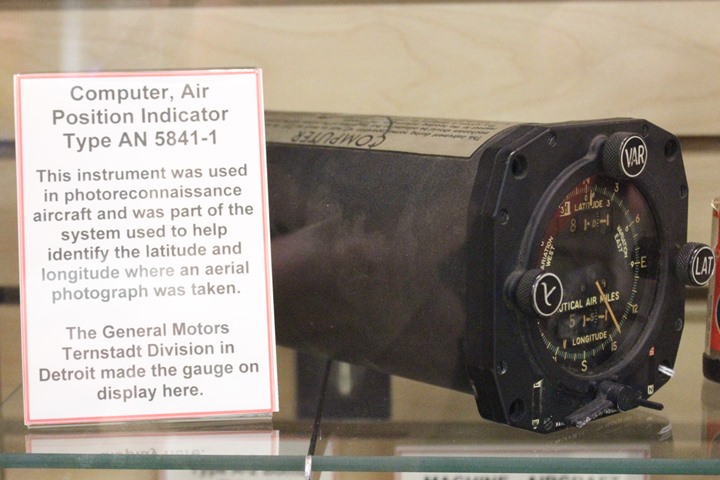

The Eclipse-Pioneer Division of Bendix

Aviation Corporation developed a new navigation method in World War Two. It contracted with the Ternstedt

Manufacturing Division of Fisher Body to build some of the components of

the system. The Ternstedt-built AN 5841-1 Air Position Computer

was part of the larger 12580-3-B Air Position Indicator System Computer

which gave the miles flown and the current longitude and latitude of the

aircraft in the air. The longitude and latitude of the aircraft

would be set at its base before takeoff. Once airborne, the

navigator then plotted the aircraft's position on a map that factored in

wind direction and velocity. This is the wind vector and when

plotted on the map gives the ground position of the aircraft. This

was a huge advancement in navigation during World War Two. This

system was introduced into late model B-29s that had to fly from the

Tinian, Guam, and Saipan to bomb Japan. This navigation system was

on the B-29 Enola Gay as it flew the 1,361 miles over open ocean to

Hiroshima, Japan.

Ternstedt built 4,571 Bendix Air Position

Indicators. This rare example of the Ternstedt-built AN 5841-1 Air

Position Indicator is on display at Michigan Military Technical and

History Museum. Author's photo.

The computer was set to the proper longitude

and latitude at the aircraft's home base just before departure.

The computer then calculated the aircraft's position in the air based on the

initial setting. The navigator then took the readings from this

instrument and applied the wind vector. This then gave the ground

position of the aircraft. Author's photo.

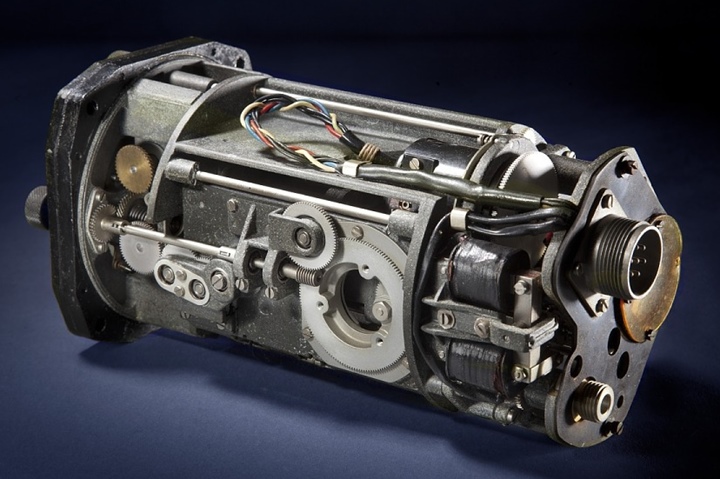

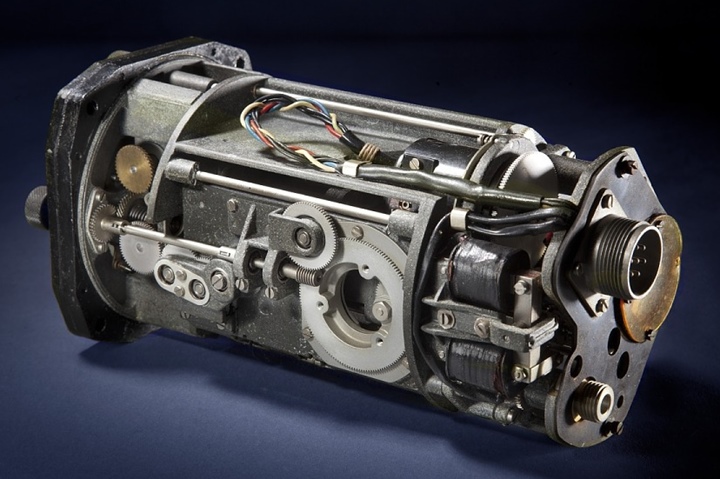

This and the following photo show some of

the internal parts of the AN 5841-1. Photo courtesy of the

National Air and Space Museum.

Photo courtesy of the National Air and Space

Museum.

The Enola Gay had an AN 5841-1 Air Position

Computer in it as part of the larger 12580-3-B Air Position Indicator

System Computer. It may still be in the restored aircraft on

display at the Udvar-Hazy Center of the National Air and Space Museum. Author's photo.

Because of Ternstedt's excellent performance

and experience in building Sperry and Bendix instruments, the Army Air

Force requested in April 1944 that it also build parts of the 12580-3-B

Air Position Indicator System Computer. This was the highest form

of compliment the division could receive.

The 12580-3-B Air Position Indicator System

Computer was composed of four main components. They were the

computer, controller, air mileage pump, and amplifier. There was also an

optional right angle drive for the system. The Ternstedt

Manufacturing Division was contracted by Bendix to build three of these

components. Table 2 gives the build schedule for the computer,

pump, and right angle drive.

Table 3 - Proposed Build

Schedule for Bendix 12580-3-B Air Position Indicator System

Computer Components

Based on a Bendix Purchase Order dated 6-9-1944.

The actual build was 4,724

computers, 4,716 pumps, and 7,425 right angle drives. |

|

Date |

Computer and Air Position Pump |

Right Angle Drive |

|

1944 |

|

|

|

October |

50 |

100 |

|

November |

200 |

400 |

|

December |

350 |

700 |

|

1945 |

|

|

|

January |

500 |

1,000 |

|

February |

525 |

1,050 |

|

March |

525 |

1,050 |

|

April |

525 |

1,050 |

|

May |

525 |

1,050 |

|

June |

525 |

1,050 |

|

July |

525 |

1,050 |

|

August |

321 |

642 |

|

Totals |

4,571 |

9,142 |

XP-75 Project: Ternstedt provided

a number of components for the Fisher XP-75 built in Cleveland, OH.

The only surviving Fisher XP-75 is on

display at the National Museum of the United States Air Force in Dayton,

OH. Author's photo.

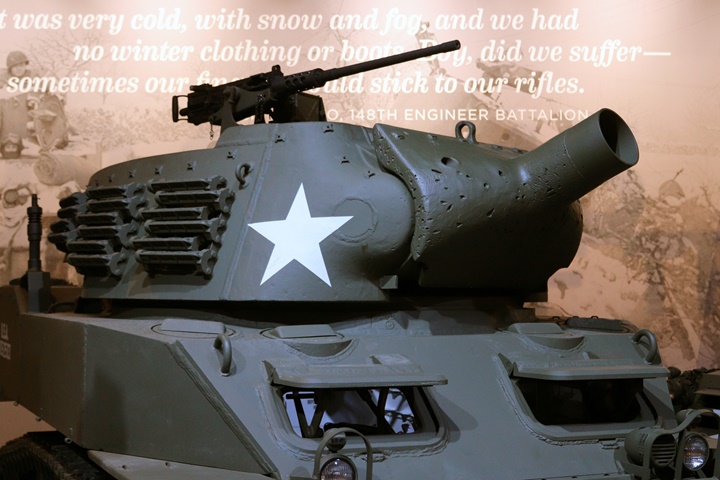

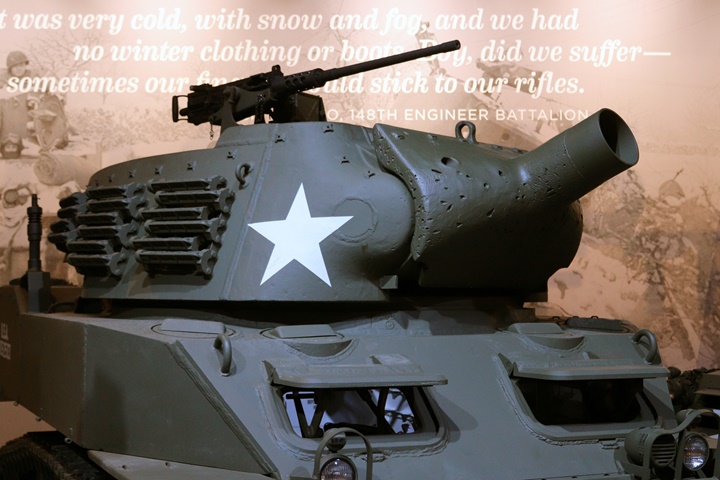

Tank and Landing Vehicle, Tracked (LVT)

Turrets: Ternstedt

specialized in building turrets for the Cadillac light tanks. It

built 4,962 M5 light tank turrets, 1,798 M8 self-propelled

gun turrets, and 3,553 M24 light tank turrets. It also built 600 T17

anti-aircraft gun turrets for Chevrolet and 20 75mm LVT turrets while

transferring the tooling and work to Fisher Body Grand Rapids in

February 1944.

This Cadillac-built M5A1 is on display at

the Ohio National Guard training base at Port Clinton, OH. The

three photos of this tank show three sides of the Ternstedt-built

turret. Author's photo.

Author's photo.

Ternstedt produced 4,962 of the M5 tank

turrets. Author's photo.

Cadillac also produced the M8 75mm Gun Motor

Carriage during World War Two. Ternstedt manufactured 1,798

turrets for this self-propelled howitzer. Author's photo.

Author's photo.

This photo shows that the M5 and M8 turrets

were constructed of heavy formed steel plates and welded together.

Author's photo.

In February 1944, the U.S. Navy requested 2,596

M8 75mm howitzer turrets to arm its LVTs. Due to the work load at

Ternstedt, it was unable to build these turrets and the tooling and work

was transferred to Fisher Body Grand Rapids. However, Ternsdedt

produced twenty turrets on an emergency basis to provide the Navy with

turrets while Grand Rapids began production. This LVT-(A)4 is on

display at the American Heritage Museum in Hudson, MA. Author's

photo.

Author's photo.

Author's photo.

After production of the M5 light tank

stopped at Cadillac, it began producing the M24 Chaffee light tank with

Ternstedt turrets. Author's photo.

Author's photo.

Author's photo.

The T17E2 was the anti-aircraft version of

the Chevrolet-built Staghound armored car for the British.

Ternstedt built 600 turrets for the T17E2. This turret was of

sheet metal construction.

This photo shows a restored T17E1 Staghound

with a 37mm gun turret. The construction of the turret is

different than the T17E2. Author's photo.

Author's photo.

Other Ternstedt World War Two Products:

Ternstedt furnished components to the Fisher

Body Grand Blanc, MI tank plant for the M4A3(76)HVSS Sherman tank.

Author's photo.

Fisher Body built 6,342 gun breech housings

for the five-inch naval gun during World War Two. Ternstedt made

components for the breech which was built in the Detroit Die and Machine

Plant. Author's photo.

Fisher-Body Pontiac built 2,359 90mm

anti-aircraft guns with Ternstedt-built parts. Author's photo.

Oldsmobile built 21,849 75mm cannons for the

M3A(75)VVSS Sherman tank. Ternstedt was a supplier to Oldsmobile

for components in the weapon. Author's photo.

The Pontiac Motor Division built 47,026 20mm

anti-aircraft cannons for the U.S. Navy that included parts built by the

Ternstedt Manufacturing Division of Fisher Body.

The Ternstedt Trenton, NJ Plant:

This plant was built in 1937 to provide more capacity for Ternstedt.

It was also close to several General Motors assembly plants on the east

coast. During World War Two General Motors folded the Trenton

plant into the Eastern Aircraft Division which built Grumman designed

Wildcat fighters and Avenger torpedo aircraft. Trenton was the

final assembly point for 7,546 TBM torpedo bombers.

The TBM was the largest aircraft that

operated from U.S. Navy aircraft carriers for most of World War Two.

The Ternstedt Trenton plant went from making automotive hardware parts

in 1941 to the huge TBM in 1942. Author's photo.

|