|

Other

Lansing Companies that contributed to winning World War Two

The road to Centrifugal Fusing providing brake drums for the most advanced combat aircraft of World War Two began in Muskegon, MI in 1932, when Charles W. Dake developed the new centrifugal casting method for the Campbell, Wyant & Cannon Foundry Company. Mr. Dake then patented the process with the patent assigned to the Campbell, Wyant & Cannon Foundry Company. The patent for the method was approved on December 11,1934, under patent number 1983839. The first two paragraphs of the patent are: "This invention relates to brake drums, such as are used extensively on motor vehicles or similar vehicles, and to a novel method of producing the same. Particularly the invention relates to the braking ring or flange portion a brake drum and a novel method of producing the same by centrifugal casting. The objects of this invention are to cast centrifugally the braking ring or flange of a brake drum of a metal alloy such that the brake flange will have the desirable soft positive braking characteristics inherent in cast iron. It is a further object to produce a brake drum flange or ring that will have the required strength against braking or fracture from sudden shock without at the same time necessitating the use of too great an amount and weight of metal. Further objects of the invention are to produce the brake drum ring or flange with a non-porous braking surface and free from pitting or other defects, and one in which the braking ring or flange produced may readily have a supporting back of rolled, pressed or drum metal readily attached thereto." From the first two

paragraphs of the patent number 1983839 it appears that there may have

been performance issues with other type brake drums cast by other

methods at the time, and the new method was seen as a way to cast a more

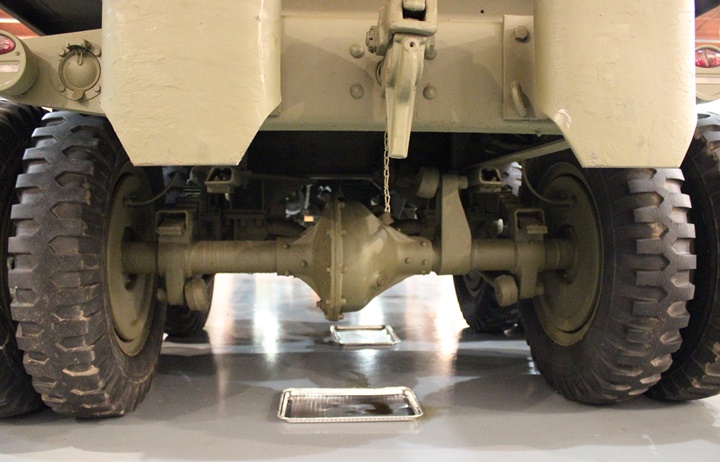

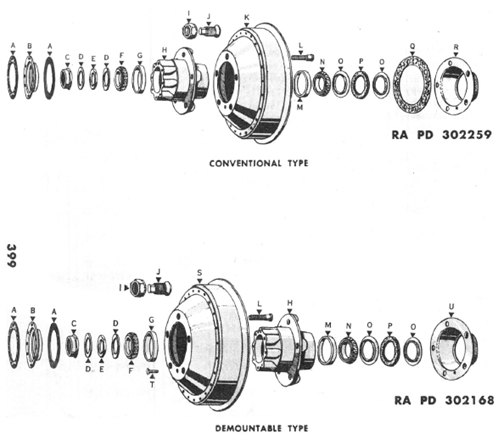

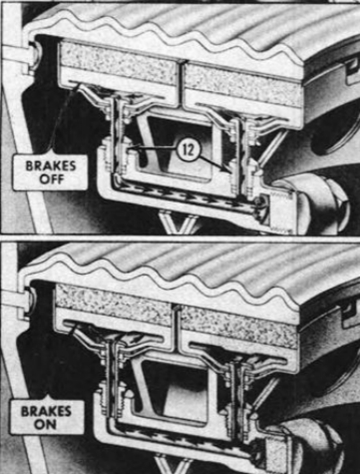

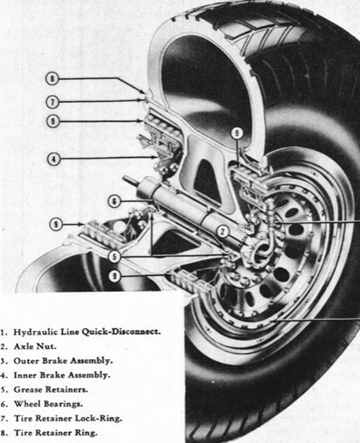

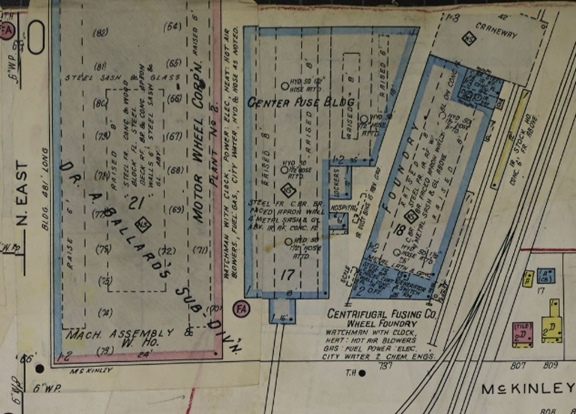

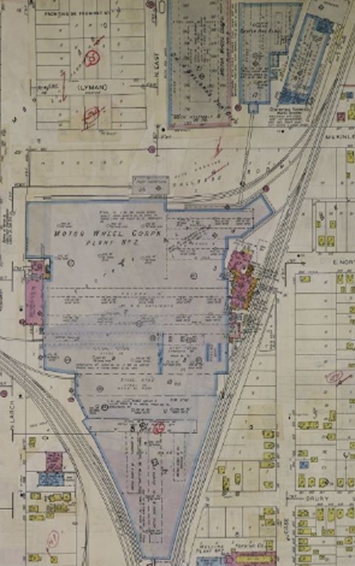

robust brake drum. Motor Wheel Corporation in Lansing must have seen the advantages of the centrifugal casting method as it became the exclusive user of these type castings in the brake drums it manufactured. From 1932 until 1937, the castings were produced by the Campbell, Wyant & Cannon Foundry Company. In 1937 Motor Wheel built a foundry on McKinley Street in Lansing, north of its Plant Two and leased it to the newly formed Centrifugal Fusing Company. Centrifugal Fusing was formed for the sole purpose of supplying centrifugally cast brake drums to Motor Wheel. The new Centrifugal Fusing Company produced the castings under license from the Campbell, Wyant & Cannon Foundry Company for the duration of the patent. In August 1937, production began in the new foundry owned by the Motor Wheel Corporation and leased to Centrifugal Fusing under a long term contract. The new foundry had a capacity of 30,000 tons of iron per year for brake drums. Between 1937 and 1948 Centrifugal Fusing cast 48,000,000 brake drums, many of which were used in World War Two. The centrifugal casting method used by the Centrifugal Fusing Company currently continues in Chattanooga, TN at the present day Motor Wheel. The company makes several lines of truck brake drums utilizing centrifugal casting. This company is a combination of the casting process and the former Motor Wheel Corporation of Lansing, MI brake machining operations. Centrifugal Fusing in World War Two: Because Centrifugal Fusing supplied brake castings exclusively to the Motor Wheel Corporation, its production of brake drums was dependent on how well Motor Wheel could market and sell its brake drums. This held true for World War Two, when Motor Wheel produced brake drums for the GMC CCKW truck series and for the B-17, B-24, B-29, and P-47 aircraft. Motor Wheel was one of two suppliers that supplied brake drums for the GMC CCKW series of trucks. It all depended on which of type axle was used in the vehicle. Timken-Detroit Axle Company was the primary supplier of axles for the CCKW. These were known as split axles due to the type of differential it used. Motor Wheel supplied the rear brake drums and hub assemblies for this type of rear axle. Timken-Detroit supplied the front drums on this type of axle. However, the Timken-Detroit Axle Company was not able to supply all of the axles required. Chevrolet also supplied axles for the CCKW series trucks. These were known as banjo axles, again due to the type of differential manufactured by Chevrolet. These axles did not use Motor Wheel brake drums. An estimated 50% of the CCKW series trucks were assembled with Timken-Detroit axles. Centrifugal Fusing supplied an estimated 1,097,044 rear brake drums for the vehicle.

Centrifugal Fusing was most likely the exclusive supplier for the B-29 brake drum castings. While this is not specifically stated in the historical record, when Centrifugal Fusing workers went on strike in 1945, brake production for the B-29 came to a halt. It was only after the U.S. Army made plans to take over the plant and restart production that the workers returned to work. Based on this, Centrifugal Fusing would have produced a minimum of 30,104 brake drums plus spares. Each B-29 had two sets of brakes on its four main wheels. Brake drums on the B-29 were a high maintenance item and there would need to be a constant flow of spare parts for replacement.

The Centrifugal Fusing Foundry at 737 McKinley Street in Lansing, MI:

|