|

Other Kalamazoo Companies

in World War Two:

Checker Car Company

Fuller Manufacturing Company

Gibson Guitar

Ingersoll Steel and Disk

Shakespeare Company During World War Two

1896-1970 Kalamazoo, MI

1970-Current Columbia, SC

The Shakespeare Products

Division of the Shakespeare Company made automotive parts including carburetors and control cables. After World War Two

it was re-named the Flexible Controls Division and in 1981 became Spearflex. It remained in Kalamazoo as a separate company until

1989 when it closed operations in Kalamazoo.

This page added

1-5-2022.

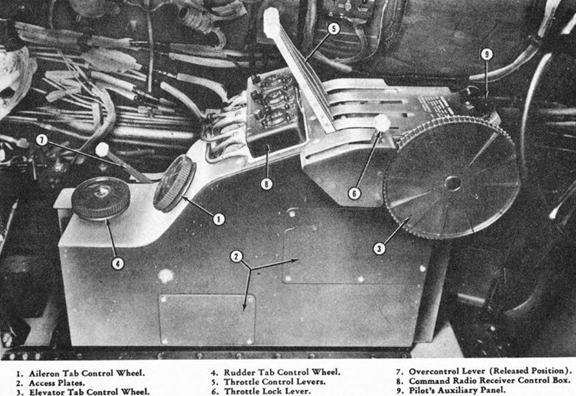

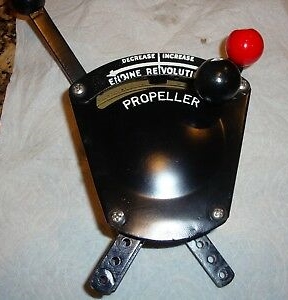

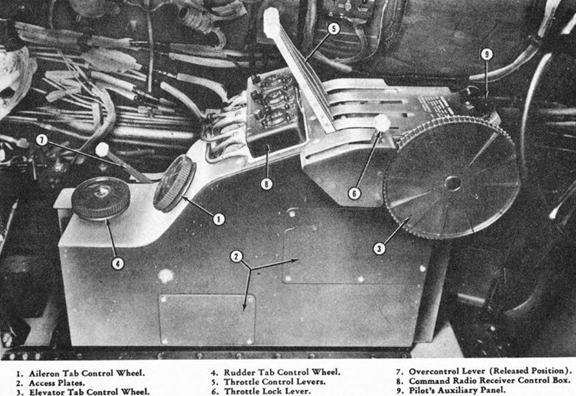

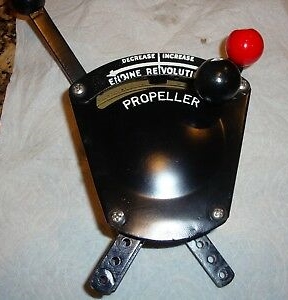

In the early morning of August 6, 1944, Colonel Paul Tibbets firmly pushed

forward the four throttles on the Enola Gay. The overloaded B-29 started

to pick up speed as it headed down the runway on Tinian Island.

The throttles he now held all the way forward had been mounted in its

pilot's stand assembly during its construction at the Shakespeare

Products Division plant of the Shakespeare Company in Kalamazoo, MI.

The Enola Gay lifted off the end of the runway and disappeared into the

darkness. The Enola Gay, equipped with Shakespeare Products-built components

in the aircraft, was on its way to its date with destiny. Author's

photo.

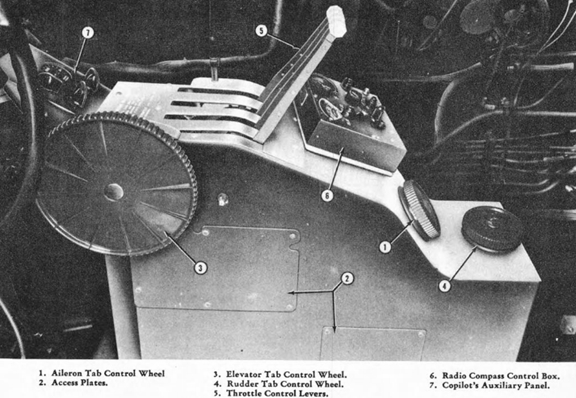

The pilot's throttle quadrant was part of

the larger pilot's stand assembly. Author's photo.

One of the biggest pieces of lost World War

Two industrial history is that a company best-known for the

manufacture of fishing rods and reels was a key supplier of flight deck

components for the B-29 program and specifically the Enola Gay. The Shakespeare

Products Division of Shakespeare produced control and instrument stands

for the Enola Gay. These were just one type of the many products

Shakespeare manufactured to help win World War Two that were totally

unrelated to its line of fishing products and automotive components.

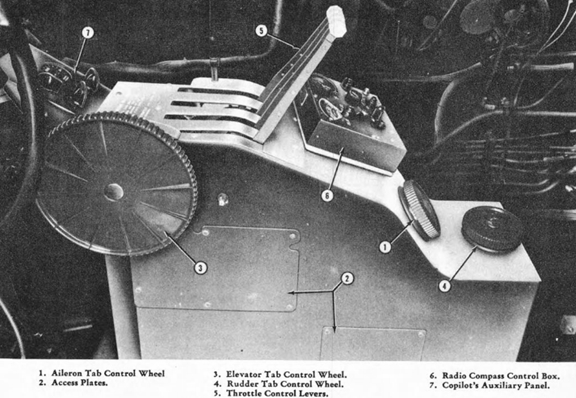

The Shakespeare Products pilot's stand

assembly was a very complex piece of equipment and contained more than

the throttle quadrant.

Four other similar Shakespeare Products-built assemblies were also in the Enola

Gay. These were for the co-pilot, bombardier, flight engineer, and

the pilot's control pedestal.

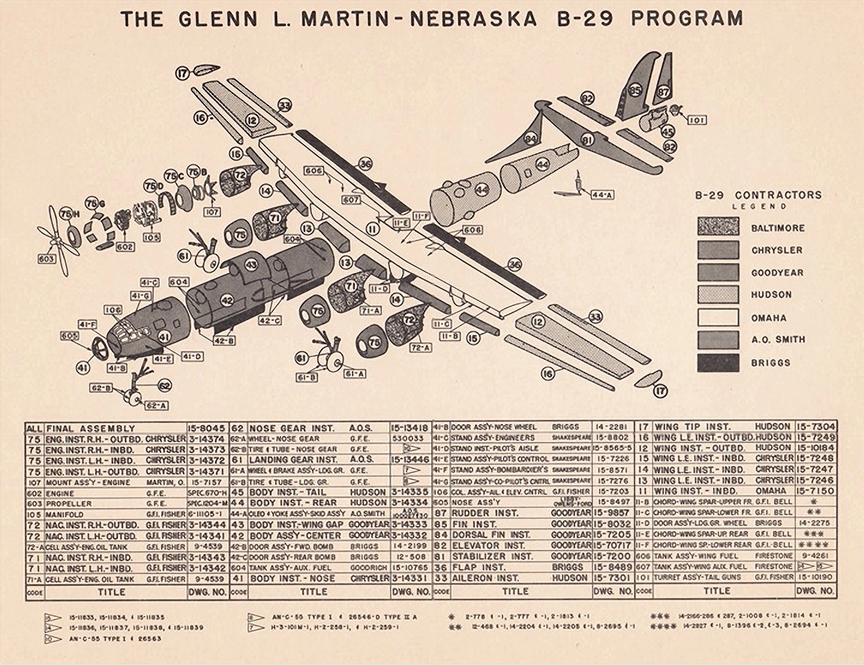

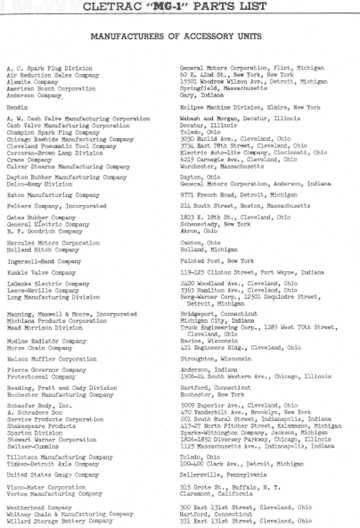

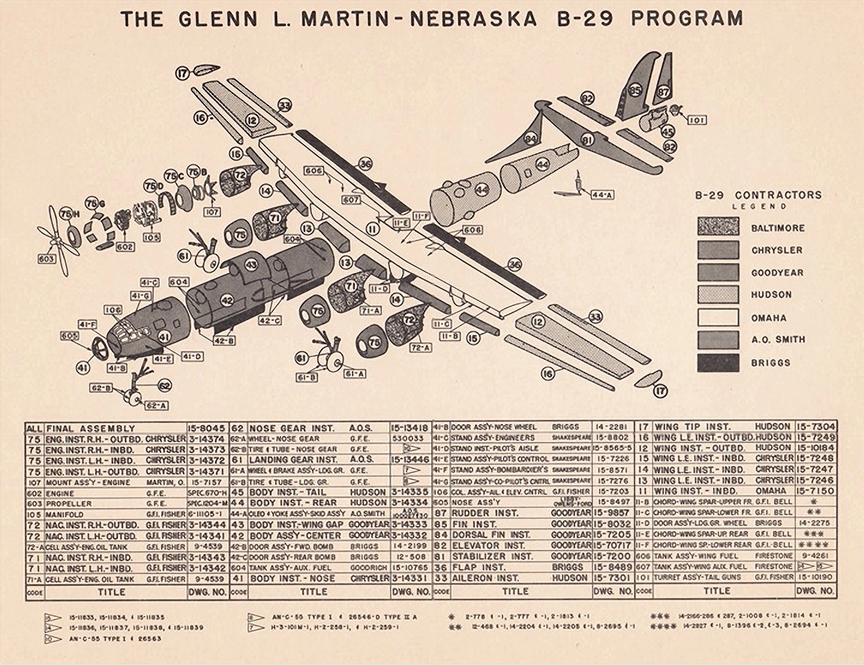

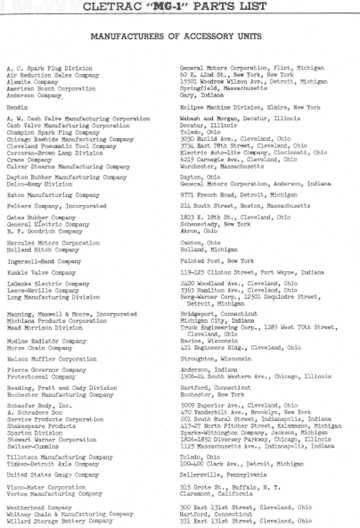

This document shows the major suppliers that

the Glenn L. Martin Company utilized for the B-29s it built in Omaha,

NE. This is the primary source document that ties Shakespeare to

the B-29 Enola Gay. The Enola Gay was one of 531 B-29s built at

the plant. All of the B-29s that were built during World War Two

for the carrying of nuclear weapons were built at Omaha.

The five products that Shakespeare Products

built for the B-29s at Omaha are listed at the top of the third column

from the left. Chrysler was the company that built the nose

section for the B-29s built at Omaha. What is strange is that the

five stand assemblies were not shipped to Chrysler for assembly into the

nose section during its construction. If this had been the case, it would be unknown that

Shakespeare was the manufacturer of the B-29 stand assemblies.

The Glenn L. Martin Company in Omaha, NE was

not the only suppler of B-29s. Bell, Boeing, and Lockheed also

built another additional 3,439 B-29s. It is unknown if

Shakespeare Products also produced the stand assemblies of any or all of

the these B-29s.

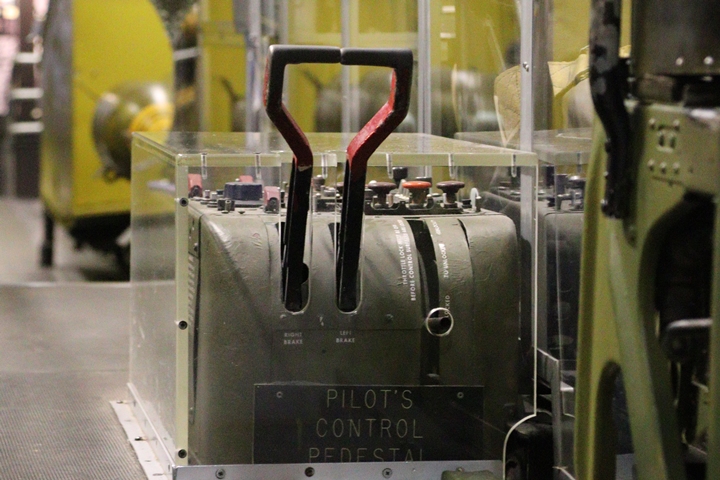

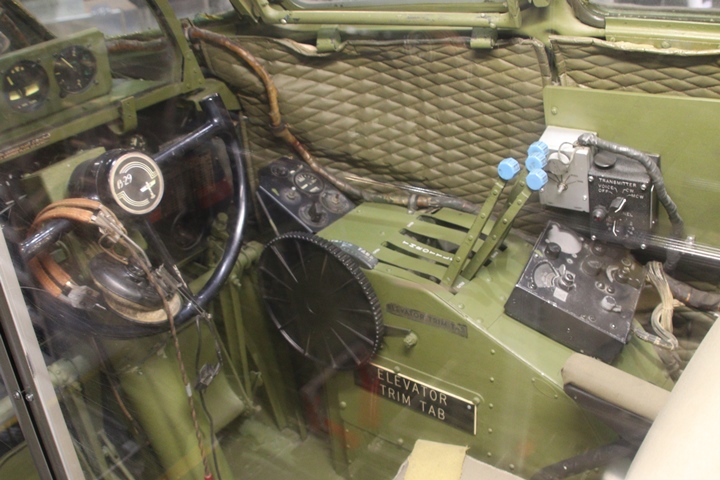

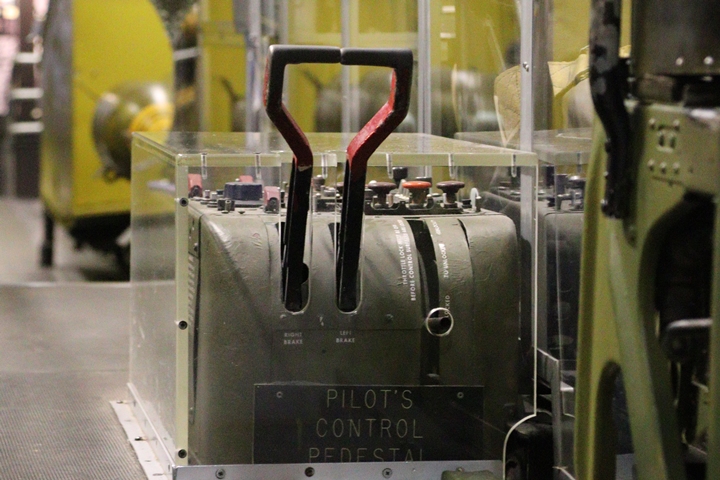

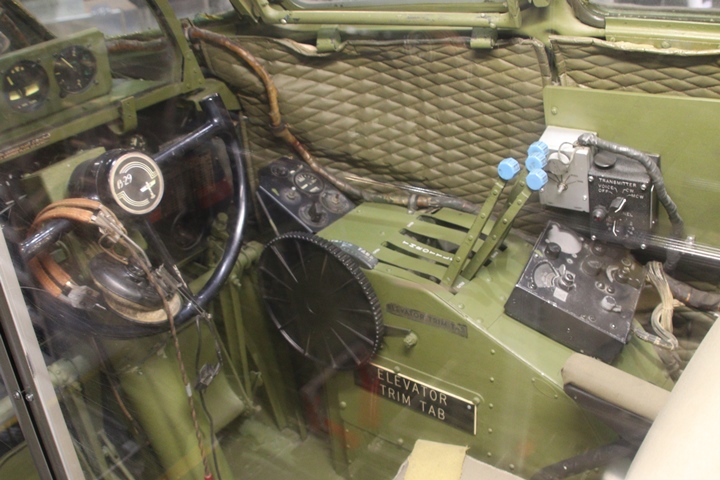

The pilot's control pedestal was located in

the walkway between the pilot and co-pilot. This and the next view

are from the front of the unit. Author's photo.

Author's photo.

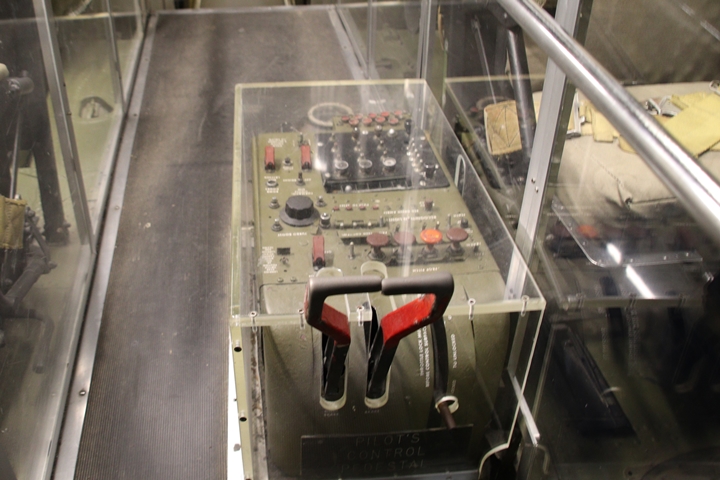

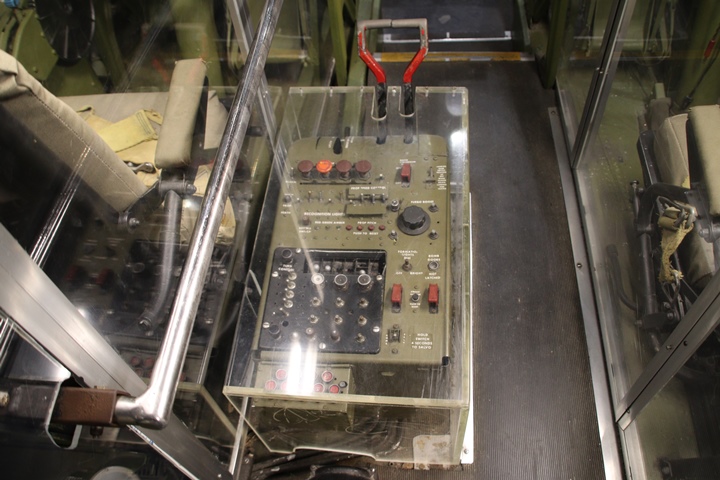

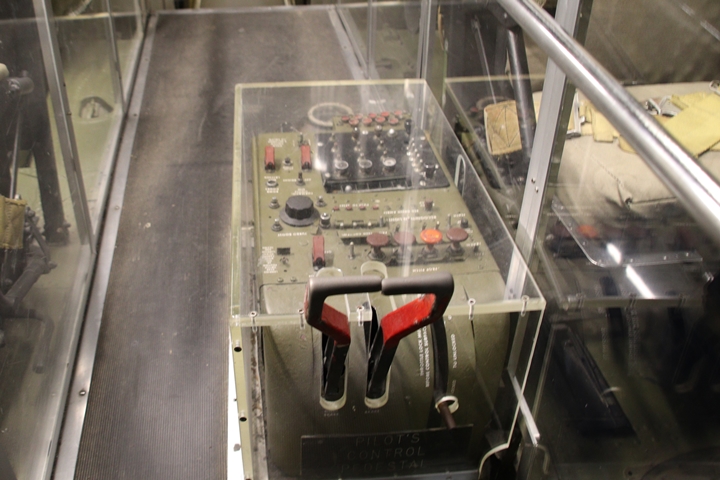

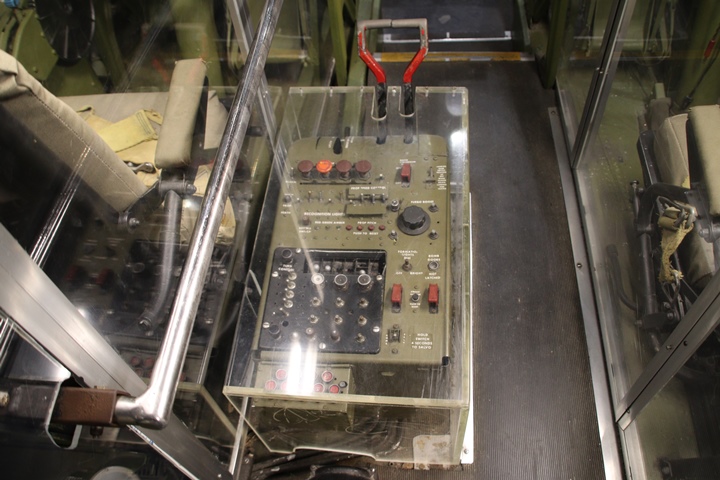

This and the next photo show the unit

looking down from behind the pedestal. Author's photo.

This was a very complicated piece of

equipment that would have a considerable amount of wiring and soldering

involved in its construction. Author's photo.

This is the co-pilot's stand assembly.

Author's photo.

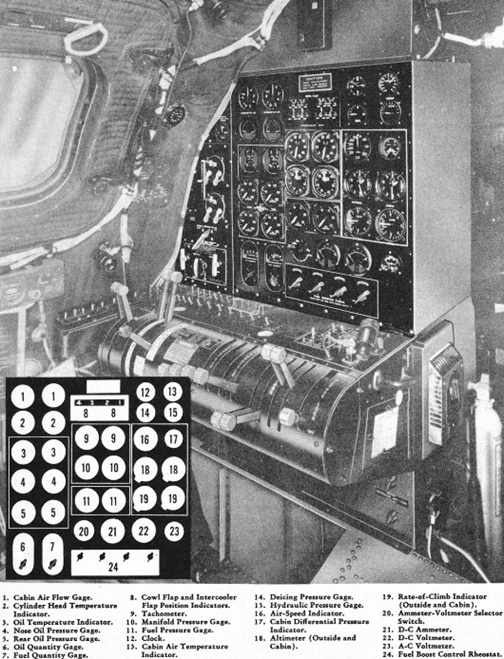

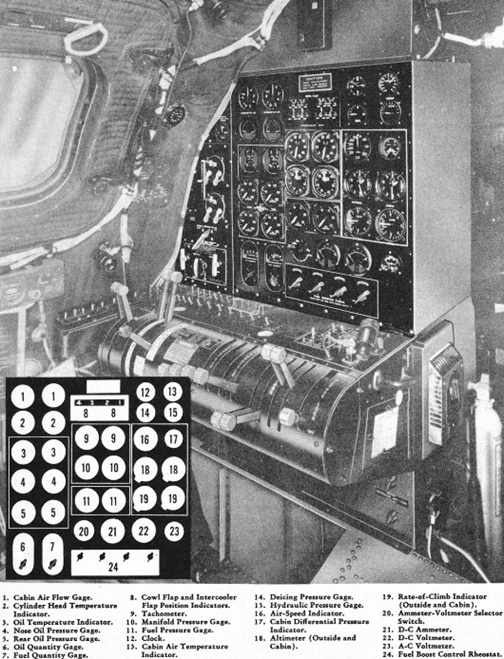

The flight engineer's station on the B-29

was the most complicated of the stands. Author's photo.

Author's photo.

The Shakespeare Company was formed in 1896 by

William Shakespeare, Jr. What an interesting name! He was

named after the most famous playwright in English history.

A brief chronological history of Shakespeare

Company

-

1896 - William

Shakespeare Jr. was granted a patent for the level winding

reel.

-

1896 - William

Shakespeare Jr. formed the William Shakespeare Company in Kalamazoo

MI. The new company occupied one floor of a four story

warehouse on Water Street.

-

1905 - The company was

incorporated.

-

1913 - The company

moved to 419 S. Pitcher Street, Kalamazoo.

-

1921 - William

Shakespeare's first major diversification was into the automotive

products industry. He formed a subsidiary named Shakespeare Products

Company, later to become the company's Automotive Products Division.

This division of the company produced flexible control components

used in internal combustion engines. During World War Two

these were used for the hand throttle cable assembly in the M5

Stuart tank.

-

1933 - William

Shakespeare Jr. was elected Mayor of Kalamazoo. He remained in

politics until 1939.

-

1970 - The headquarters

of The Shakespeare Company moved to Columbia, SC. although the Flexible

Controls Division remained in Kalamazoo. The current product line

of Shakespeare Company, LLC in Columbia, SC is not at all similar to

the fishing rods and reels it for which it was famous. Today, the

company makes polymers, lawn equipment, and marine and military

electronics. Columbia, SC re-named the road the factory is on

to

Shakespeare Road. The factory is not far from where I did my

basic training at Fort Jackson, SC.

-

1979 - The Shakespeare

Company became a wholly-owned subsidiary of California-based Anthony

Industries, Inc.

-

1981 - Speareflex

bought the assets of Shakespeare’s cable operations and

took over the Kalamazoo location.

-

1989 - Speareflex

abandoned the Kalamazoo site. Several older buildings on the north end

of the property have been demolished, but the two buildings that face

Kalamazoo Avenue have been redeveloped for other uses.

Shakespeare and the Shakespeare

Products Division won the Army-Navy "E" award three times during World

War Two.

Both the parent company, Shakespeare, and its automotive parts

division, Shakespeare Products Division, were considered to be one entity

by the U.S. military in World War Two.

Shakespeare Company World War Two Products:

B-29 flight crew stand assemblies, PT-17, PT-22, BT-13, and T-6

throttle quadrant assemblies, Norden bomb sight components, Sperry .50

caliber automatic computing gun sight components, aircraft machine gun

turret power take-off shafts and speed reducer shafts, M5 Stuart tank

hand throttle cable assemblies, M2 Cletrac throttle cable/choke cable

assemblies, and choke cable assemblies for the Clark Equipment

Planeloader forklift trucks.

The company had one major contract for guns

sight kits for the U.S. Navy totaling $810,000.

Table 1 - Shakespeare Company's

Major World War Two Contracts

The information below

comes from the "Alphabetical Listing of Major War Supply

Contracts, June 1940 through September 1945." This was

published by the Civilian Production Administration,

Industrial Statistics Division. |

|

Product - Customer |

Contract Amount |

Contract Awarded

|

Completion

Date |

| Gun Sight Kits -

Navy |

$810,000 |

1-1945 |

12-1945 |

| Total

|

$810,000 |

|

|

Ryan Aeronautical Corporation built 1,048

PT-22 trainers with Shakespeare throttle quadrant. Author's photo.

A PT-22 throttle quadrant.

The PT-17, BT-13, and AT-6 were the most used

training aircraft used by both the U.S. Navy and U.S. Army Air

Forces in World War Two. Shakespeare Products built throttle

quadrants for all three types of aircraft.

The PT-17 is the most famous of the American

World War Two primary trainers. Author's photo.

The BT-13. Author's photo.

The AT-6. Author's photo.

A Shakespeare-built AT-6 throttle quadrant.

Cadillac, the Southern California Division

of General Motors, and Massey-Harris built a total of 6,810

M5/M5A1 Stuart tanks. Each on came equipped with a Shakespeare

throttle hand control assembly part number PM1106. Author's photo.

Cadillac built 1,778 M8 75mm gun carriages that also used Shakespeare

part number PM1106. Author's photo.

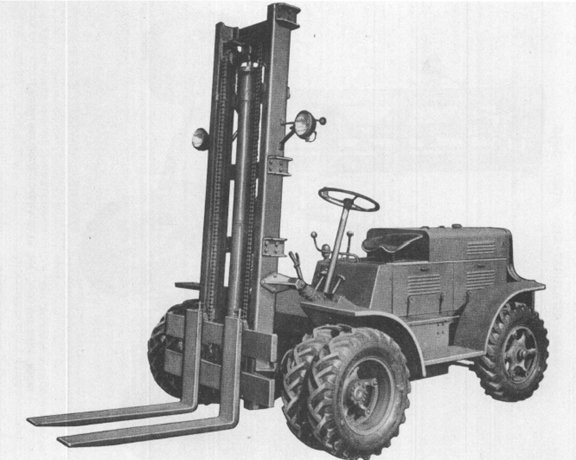

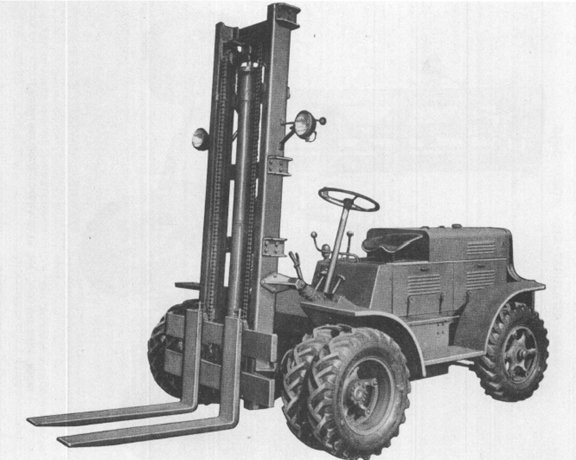

The M2 "Cletrac" was a high speed

tractor that was designed and primarily built by Cleveland Tractor

of Ohio. John Deere was also built the M2 for a total of 8,610

units built. The U.S. Army Air

Force used them to move aircraft around at its bases all over the world. Author's photo.

The Shakespeare Company of 417-427 North

Pitcher Street in Kalamazoo, MI is listed as a supplier in the parts manual

for the M2 high speed tractor. The actual part or parts supplied

by Shakespeare are not explicitly defined in the manual. Most

likely, the company supplied either a manual throttle or choke cable

assembly or both.

Shakespeare supplied the manual choke controls for the Clark Planeloader Forklift truck built in nearby Battle Creek, MI. This

was its Model 1192-M-8 cable assembly.

The Ward LaFrance M1A1 had two Shakespeare

Products components on it.

These were a hand control throttle part number SHA-8136256-T and

distributor spark control part number SHA-8136256-P. Ward LaFrance built

4,925 M1 and M1A1 wreckers during World War Two. Kenworth built

another 840 M1A1s for a total of 5,765 total units built. Author's

photo.

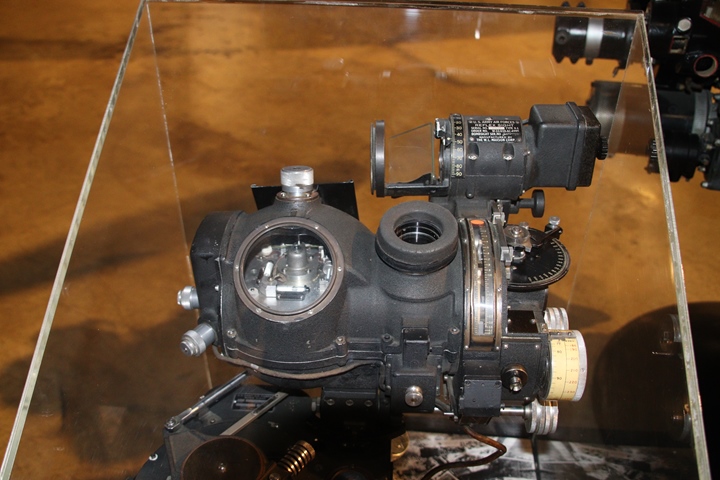

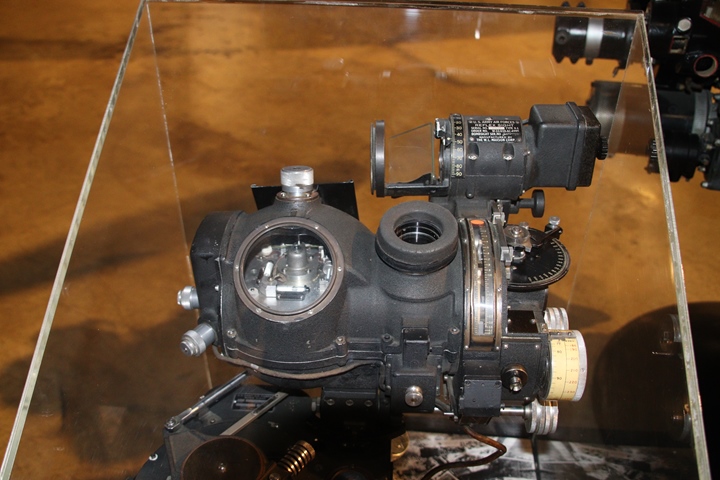

The Norden M9 bombsight had over 2,000 parts

in it, many of which were made by Shakespeare. Author's photo.

There were 52,083 M9 Norden bombsights

produced by six different companies during World War Two. Author's

photo.

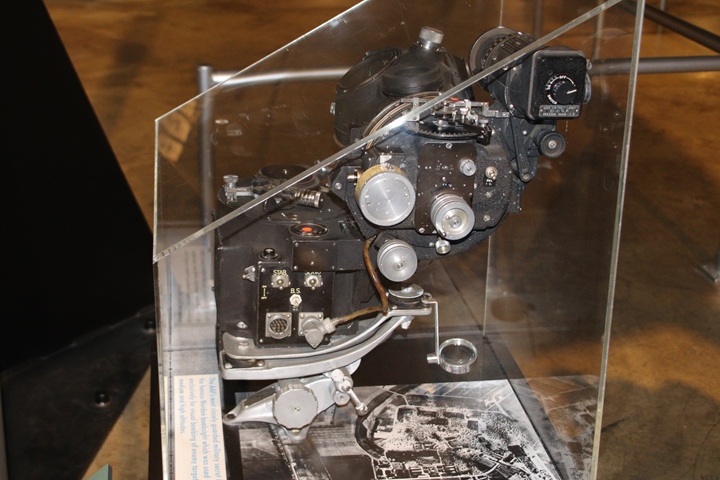

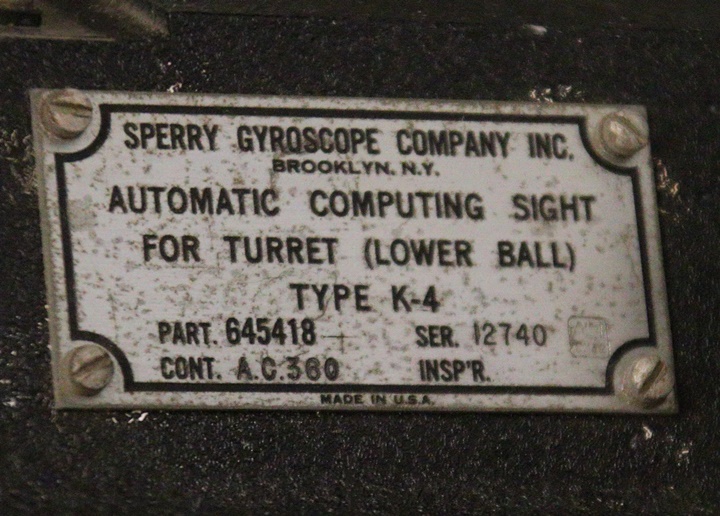

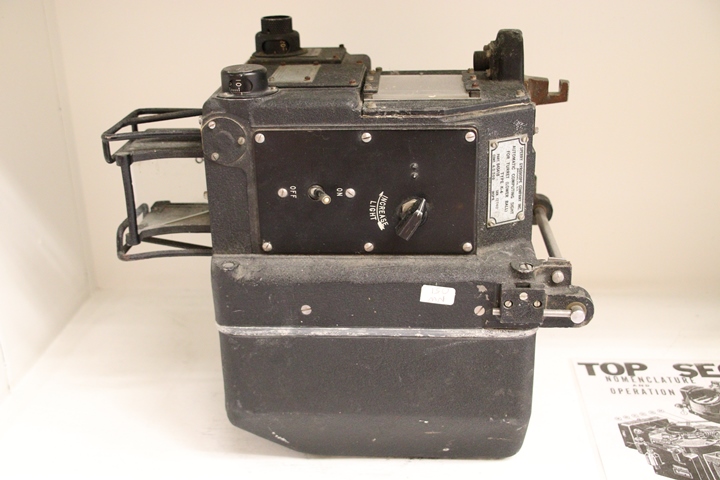

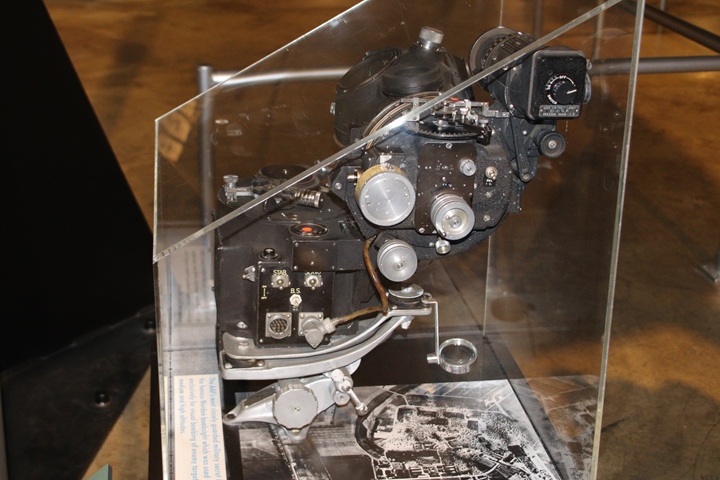

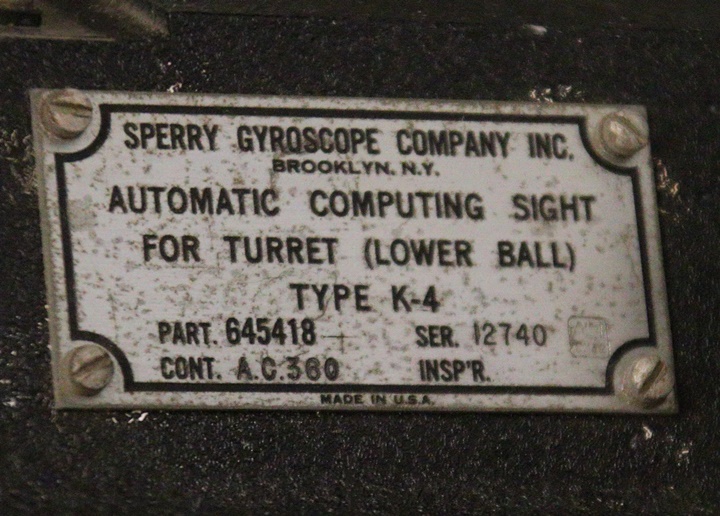

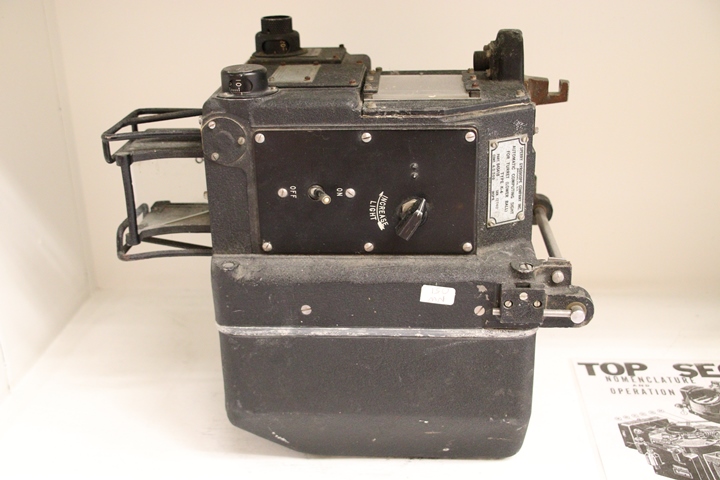

Shakespeare made parts for the Sperry Type

K-4 automatic computing gun sight that was used in the lower ball

turrets of the B-17 and B-24. Author's photo.

Author's photo.

Author's photo.

Author's photo.

This is the B-17F Memphis Belle on May 17,

2018, 50 years to the date that she completed 25 combat missions over

Europe. This photo was taken several hours after the dedication of

the Memphis Belle at the National Museum of the United States Air Force. Author's photo.

The ball turret on the B-17 Memphis Belle was where the K-4 gun sight was

located. Author's photo.

One source indicates that Shakespeare built

the steel tube frames for the CG-4A gliders built by Gibson Refrigerator

Company in nearby Greenville, MI. The glider shown here is Gibson

Refrigerator Company-built CG-4A serial number 45-27948. It

was one of 1,078 built by Gibson and is on display at the National

Museum of the United States Air Force. Author's photo.

Shakespeare could have made fuselage

sub-assemblies where they were welded together into complete units at

the Gibson plant. Shakespeare could have also made complete

assemblies. Author's photo.

Author's photo.

Author's photo.

The Shakespeare Plants:

Part of the Shakespeare plant on the north

side of downtown Kalamazoo, MI still exists. The five-story red

brick building was one of several factory buildings that were in this

location. The tan stone building was the company headquarters and

offices. This view is looking northeast from Kalamazoo Avenue.

Author's photo.

Currently, the former Shakespeare office

building is a bar. Author's photo.

Shakespeare's Pub opened for business in

July 2003.Author's photo.

The name of the Shakespeare Company is still

a part of the building. Author's photo.

The next photos are looking at the west side

of the former Shakespeare headquarters building. Author's photo.

Author's photo.

This view is looking at the north side of

the two remaining Shakespeare buildings. Author's photo.

The street that borders the east side of the

five story building is North Pitcher Street. During World War Two,

the address given in U.S. Army documents show the address of Shakespeare

as

being 417-427 Pitcher Street, which was this building. Author's

photo.

Author's photo.

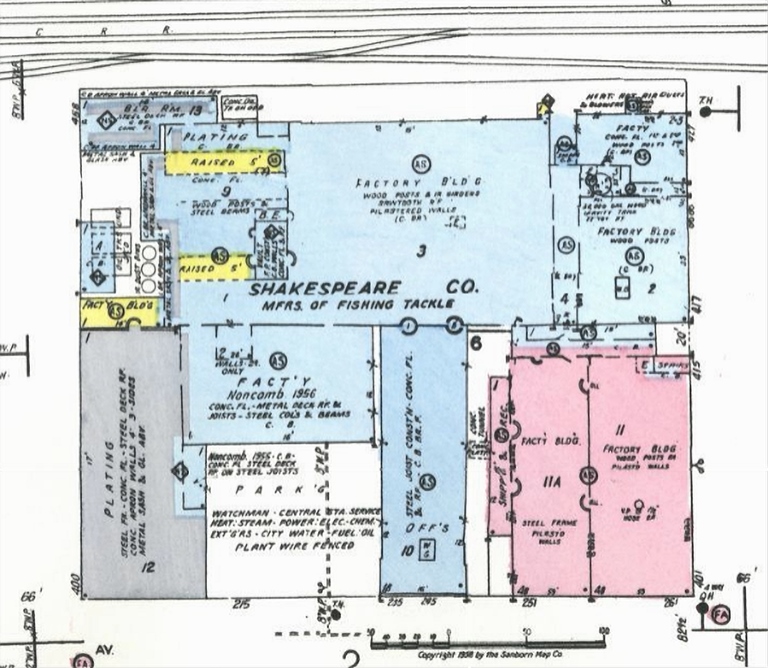

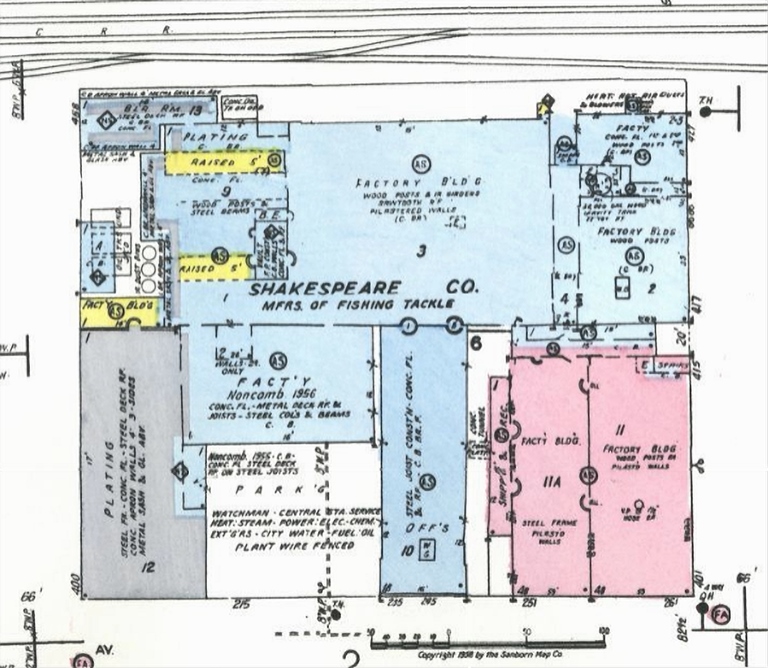

This 1958 Sanborn map shows that Shakespeare

took up a whole city block.

|