|

Samson

United Corporation in World War Two The Samson Cutlery Company was well known in the late 1920s for its cutlery. However, the company saw a market for many new electrical devices that could be sold in the consumer market and changed its name to the Samson United Corporation. Its products included air heaters, soldering irons, "Safe-Flex" rubber-bladed fans with no guard around them, toasters, irons, waterproof heating pads, curling irons, two burner portable electric ranges, and UV sunlamps. Company officials also predicted a 400% increase in its commercial business from its prewar business with all the pent-up demand for its products after World War Two. However, the company had difficulties after the war in obtaining raw materials and components for its products. It also was purchasing new equipment for the plant for products that were not selling as well as expected. In 1948 Samson United became the sole manufacturer of the Land Polaroid one-minute camera developed by Edwin Land. The local newspaper indicated that Samson United had a $3,000,000 contract to produce the camera. It also took out a $100,000 mortgage on its property to purchase the necessary equipment to manufacture the new product on a mass production basis. Apparently, sales of the new camera did not match the expectations of both Mr. Land and the Samson United Corporation, as there was only one more article in the newspapers on the product. It stated that there was an impending redesign of the camera due to the customers not operating the camera properly. While the new camera may have looked to have been a great opportunity for the company, it may have well brought about its demise. In 1949 Samson United stopped paying out dividends for its preferred stock. In 1950 the factory at 1700 University Avenue in Rochester, NY was empty of work and employees. On April 21, 1953, the company was declared insolvent by a federal judge and the assets of the company were awarded to the Bickford Brothers of Rochester. This was a sad end for a company that contributed so much to the wining of World War Two. It should be noted that Samson United is the proper spelling of the company name. However, in many historical documents it is spelled as Sampson United. The local Rochester newspaper spelt it both ways, depending on the day of the article. In one instance, it was spelt both ways within the same article.

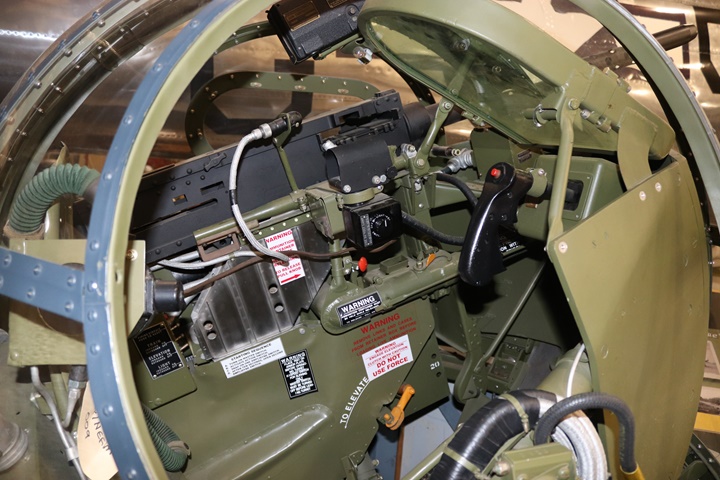

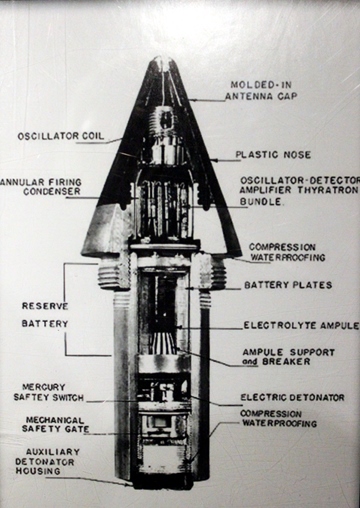

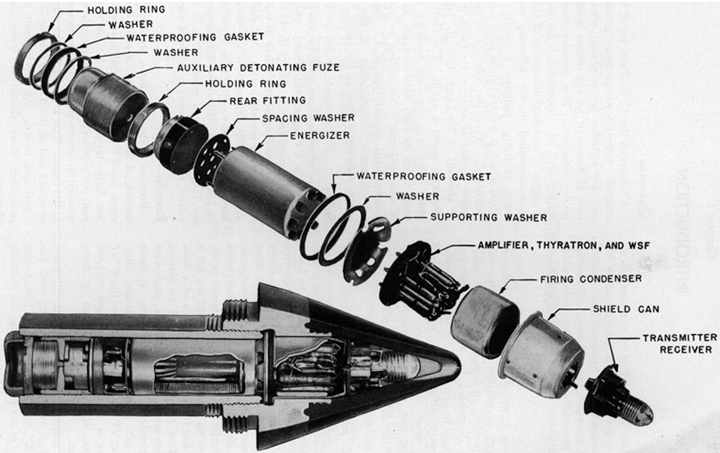

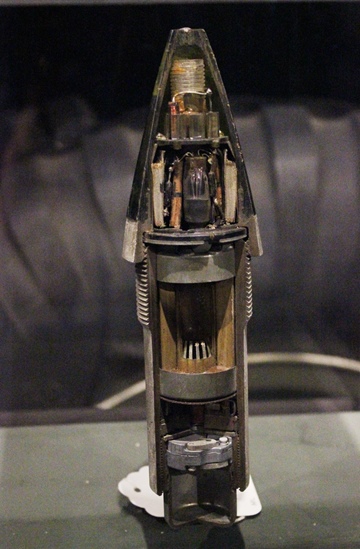

Samson United Corporation World War Two Products: The company had $14,434,000 in major contracts from foreign governments, the U.S. Army, and U.S. Navy. It manufactured various products, mostly for the U.S. Navy. The company's most identifiable product was the rear gun turret for both Grumman TBF and the later Eastern Aircraft Division of General Motors license-built TBM Avengers torpedo bomber. Grumman produced 2,293 TBFs before turning over production to Eastern Aircraft, which built 7,546 TBMs. This totaled 9,839 Avengers built during World War Two. Samson United had $4,796,000 or 33% of its contracts for TBF/TBM turrets. The company had another $545,000 in various components and spare parts for the turrets. Samson United was one of two companies that built the rear gun turrets for the TBF/TBM. By the end of the war, the company had built 5,000 TBM gun turrets. This was 50% of the total TBF/TBM turrets made. In 1942, Grumman delivered 642 TBFs, of which approximately 320 were equipped with turrets furnished by Samson United. In May 1945, it was announced the company was awarded a $1,000,000 contract to build powered nose gun turrets for the Consolidated PBY patrol aircraft. Full production of the turret was to begin on August 15, 1945. This may have well been for the PBY-6A of which 600 were ordered in early 1945. However, production ceased in September 1945 after 175 PBY-6As had been built. This was the last type of PBY built. The company also built components for the top secret VT proximity fuze. Most likely it was subcontracting component assemblies to Eastman Kodak of Rochester, NY which manufactured 2,443,914 of the units. Samson United made a capacitor, resistor, and two other parts identified as the turret and tab. Fifty employees worked on the project in Rochester and another 350 in the company's Oswego, NY factory. The company had two classified contracts with the U.S. Army awarded in December 1944 and January 1945. It was announced in 1946 that the Samson United Corporation had been the producer of an infrared device that allowed paratroopers to assemble quickly once they had landed. This device was also produced for the U.S. Navy which appears to have been the "Optical Devices" contract issued 5-1945. Employment at the Rochester, NY plant peaked at 1,260 during the war. The Oswego, NY plant had 380 employees.

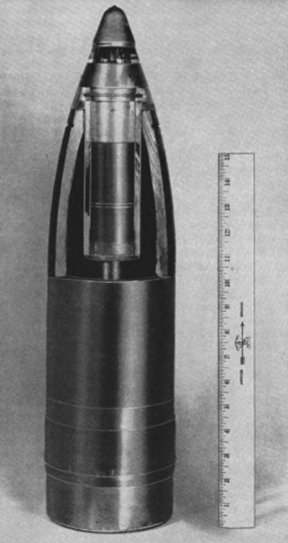

The TBF/TBM Powered Rear Turret: The U.S. Navy designation for this turret was 150 SE. This stood for one .50 caliber machine gun, spherical turret, and electrically powered. Grumman Aircraft designed the turret but did not have the capacity to produce them. The U.S. Navy contracted with both Samson United and Emerson Electric to provide the turrets.

The VT Proximity Fuse: The VT proximity fuze program was one of three top secret programs the United States had during World War Two. It was the only one that remained secret throughout the war and was never discovered by the enemy in action nor through spies. The Manhattan Project was penetrated by spies. The VT fuze consisted of a small radio transmitter and receiver of several miniature electronic tubes, electronic components, and safety devices that were mounted in the nose of anti-aircraft shells. When fired at an attacking aircraft, the VT shell would detect a change in the received frequency when near an enemy aircraft, and the VT fuze would detonate the shell. This was far superior to the other method of pre-setting the time-to-detonation of a fuze of an anti-aircraft shell before the shell was loaded in the anti-aircraft gun. This was problematic at its best in attempting to predict, in the heat of an aerial attack, how long it would take a shell to reach the area of fast moving enemy aircraft. For the U.S. Navy, the VT fuze is considered to be one of the main reasons it was able to progress so quickly back across the Pacific during World War Two. It was shown at Pearl Harbor and the sinking of HMS Repulse and HMS Prince of Wales three days later that aircraft were the biggest threat to the American fleet in the Pacific. With the aid of the VT fuze built by Crosley, Eastman Kodak, McQuay-Norris, RCA, and Sylvania, it is estimated that the U.S. Navy's Pacific campaign advanced months faster than it would have without it. Many lives were saved, and fewer ships were sunk than if the VT fuze had not been produced by these companies. Samson United Corporation was a supplier to Eastman Kodak, which made 2,443,914 of the VT proximity fuzes. Samson United made a capacitor, resistor, and two other parts identified as the turret and tab. Fifty employees worked on the project in Rochester and another 350 in the company's Oswego, NY factory.

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||