|

Continental Motors in World War Two

Muskegon, MI

(Currently Mobile, AL)

1902-Current

This page updated 11-3-2020.

Continental Motors is most well-known for its

production of the R-975 radial aircraft engine, used in M4 and M4A1

Sherman tanks during World War Two. While the Continental

Motors-produced R-975 was used in a myriad of other American armored

vehicles during the war, it is the Sherman tank engine for which the company

is most associated. There is good reason

for this in that the M4 and M4A1 Sherman tanks served throughout the war

and was with the American Army on every battle front. The

Continental Motors-powered Shermans were with the U.S. Army in North

Africa, Italy, Normandy and all the way to through France, Luxembourg,

Belgium, Holland and Germany until V-E Day. In the Pacific, the M4

and M4A1 Sherman tanks were such places as New Guinea, the Philippines,

the Marianas, Peleliu and Okinawa. U.S. Marines used them

at Cape Gloucester, Bougainville and the Admiralty Islands. The

M4/M4A1 Sherman tanks with their Continental-built engines were found worldwide with

the American Armed Forces throughout World War Two.

The first Sherman tank ever produced was a

M4A1(75)VVSS, assembled by the Lima Locomotive Works in February 1942.

It came with a Continental R-975 engine. Production of the Continental Motors R-975 powered

Sherman tanks continued until August 1945 with the M4A1(76)HVSS. The Continental-powered M4A1 Sherman

tank had the longest production run of the different Sherman tanks

during World War Two.

Continental Motors produced more than just

Sherman tank engines during World War Two. Its engines were used

in self-propelled artillery, tank destroyers, trucks and aircraft.

Continental was a very important supplier of power plants to the U.S.

Military in World War Two.

One of the most interesting things about

Continental Motors during World War Two is the fact that it built four

engines under

license from other manufacturers. There was the

Wright R-975 that was used in the M4 and M4A1 Sherman tank and several

other tracked vehicles. It also built the Pratt & Whitney R-1340 that powered the T-6 and SNJ Texan trainer

aircraft. Towards the end

of the war, it built the Rolls-Royce Merlin aircraft engine that was used

in the P-51 Mustang. Late in the war Continental also started

producing the Ford GAA engine for the M4A3 Sherman tank. While

other companies in the auto industry built at most one aircraft engine

under license, only Continental had the honor of building four in this manner. At the same, time it also built

several engines of its

own design for the war effort.

The story of Continental Motors started in

1902 and continues today, with production facilities at Mobile, AL.

The company has built many engines for all sorts of products from tanks

and military aircraft to garden tractors. In 1933-34 Continental

came out with its own line of automobiles which was to employ 4,000

workers in Muskegon, MI, and another 1,000 in Detroit. It appears

that it only sold 6,500 cars in 1934 which was just not enough to keep the

project going. Continental has many engines for many different

applications over its lifetime. This webpage will focus on its

important contribution to winning World War Two. But first, this

page will look at some early Continental engines. Next will be the pre-World War Two tanks it powered that led to its success in World War Two.

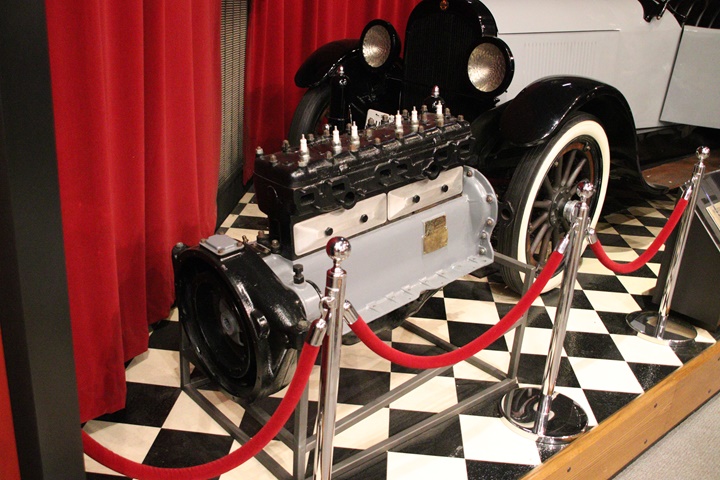

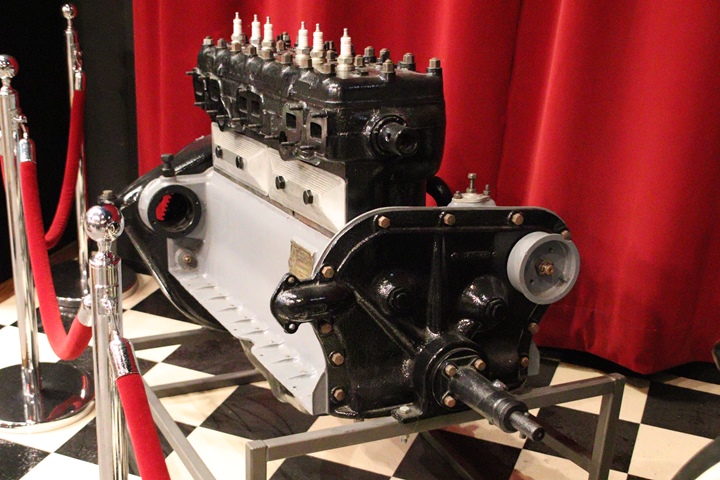

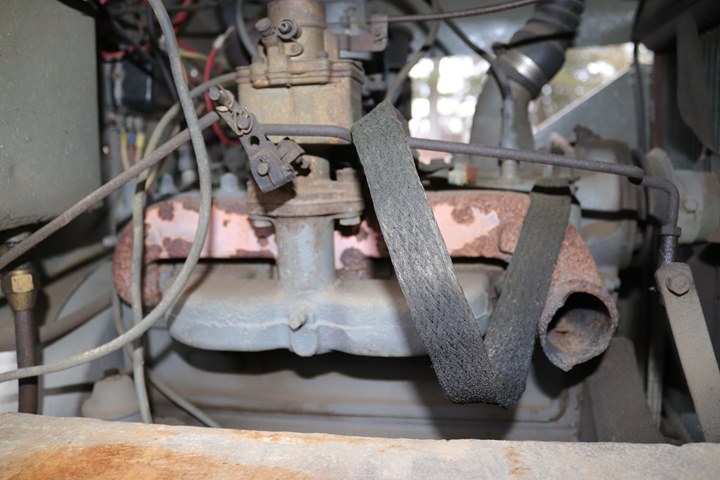

In 2015 this World War One Liberty truck

chassis and drive train were undergoing restoration at the First

Division Museum in Wheaton, IL.

Continental Motors was one of five companies that provided engines for

the standardized Liberty Truck built by fifteen manufacturers to U.S.

Army Quartermaster specifications. The engine shown here is a

Continental. Author's photo added 11-3-2020.

Continental produced 50% of the Liberty

truck engines during World War One. It also provided the

standardized drawings used by the other four manufacturers.

Author's photo added 11-3-2020.

This is what the Liberty truck looked like

after it was restored. This is June 2019. Author's photo

added 11-3-2020.

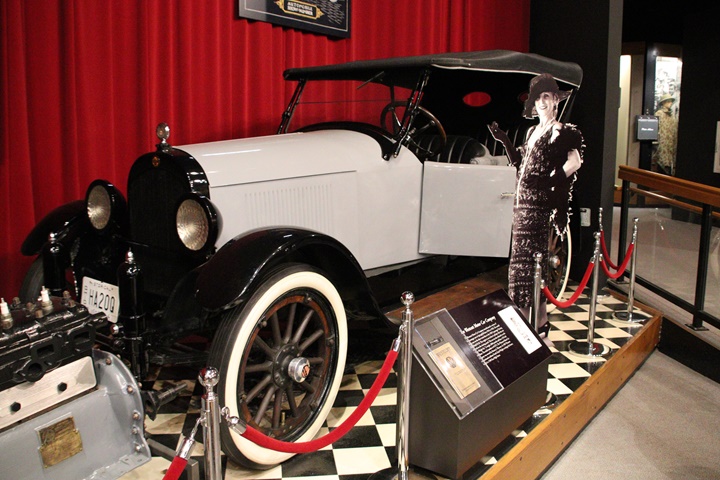

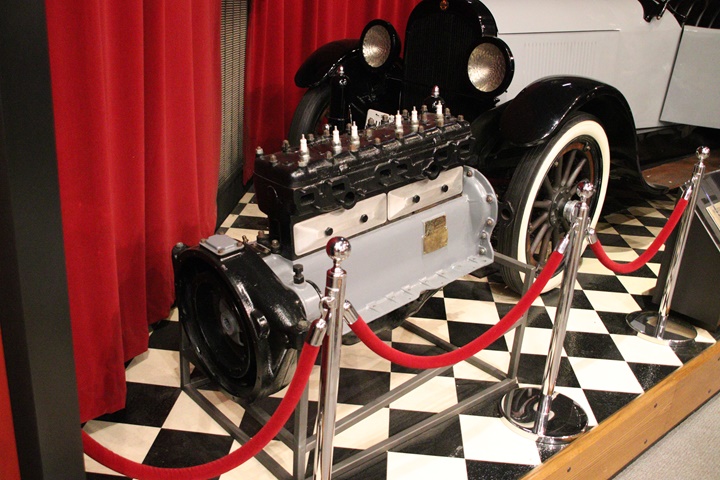

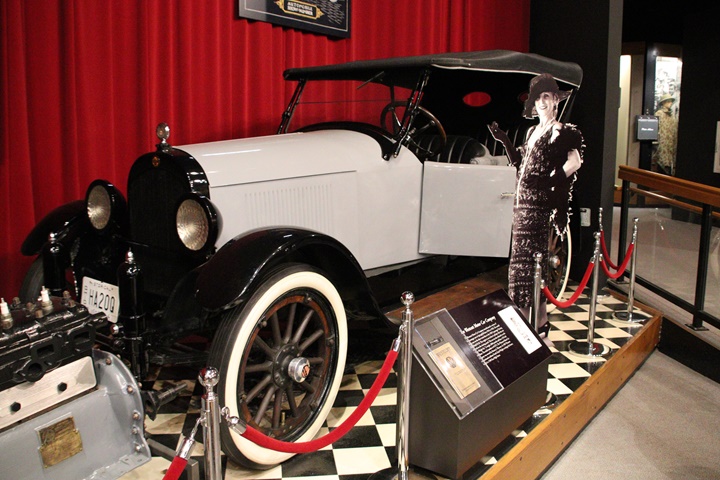

This is a 1920 Westcott five-passenger

touring car, model B-38. It was built in Springfield, OH and is on

display at the Clark County Heritage Center Museum, Springfield, OH.

It was powered by a Continental Model 105-7R six-cylinder inline engine.

Author's photo added 2-7-2020.

This is one of the oldest Continental

engines on display in a museum. Author's photo added 2-7-2020.

Author's photo added 2-7-2020.

The serial number for the Continental 105-7R

is 6056. Author's photo added 2-7-2020.

Pre-World War Two Tanks: Tank

development was sparse during the 1920s and 1930s due to indifference on

the part of army management. After the depression started, there

was a lack of funding. The Rock Island Arsenal in Illinois was the

Army's arsenal for building what few tanks were funded before the start

of World War Two. Production stopped at Rock Island in 1941and shifted to commercial companies

in order to build the huge number of tanks needed for the war effort.

Continental approached the U.S. Army Ordnance

in 1931 about converting its R-670 radial aircraft for use in tanks.

The company had developed over several years from its A-70 seven-cylinder

radial aircraft engine with 165 hp. Army Ordnance was in agreement

with this, so Continental was tasked with converting the

aircraft engine for use in tanks. Continental referred to this

modified tank version of the engine as the W-670, but in today's

literature it is normally known as the R-670. The first

application of the Continental W-670 engine was in the M1 Combat Car

built by Rock Island Arsenal in 1932. With the installation of the

W-670 engine into the M1 Combat Car, Continental became the only

supplier of the preferred radial tank engine for both light and medium

American tanks until engines produced by the American auto industry

superseded it in the middle of World War Two. Continental Motors

W-670 and R-975 engines would see worldwide service throughout World War

Two.

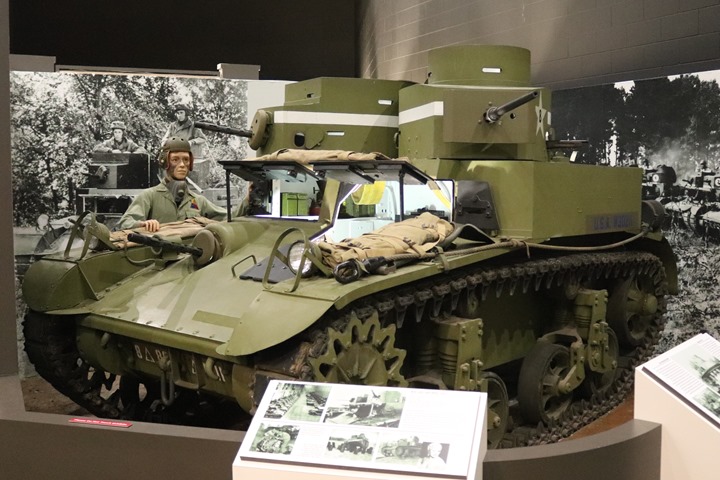

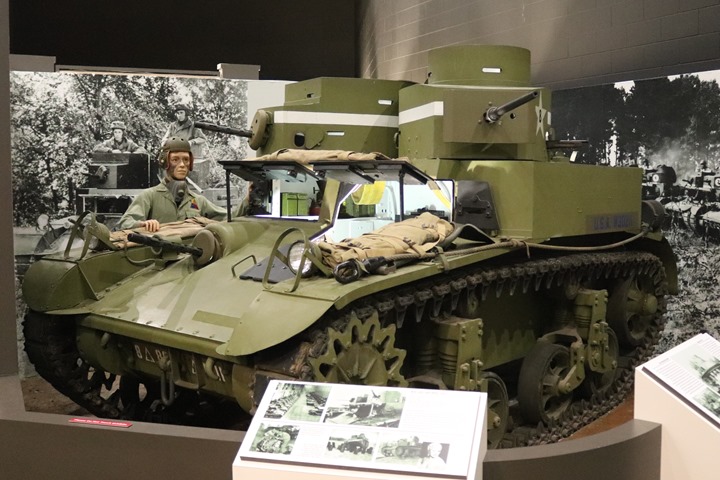

The M2A2 light tank was powered by a

Continental W-670 engine. Seventy-three were built. This one

is on display at the Mississippi Armed Forces Museum at Camp Shelby, MS.

Author's photo.

The

M2A3 was a M2A2 that was converted to an infantry tank in 1935 and

retained the W-670 engine. Several tanks at the end of the M2A2

production run were converted. Author's photo from the U.S. Army

Armor and Cavalry Collection at Fort Benning, GA.

This

T5E1 was the only one produced by Rock Island and was the first of what

became the M2 series medium tanks. It weighed 15 tons and was

armed with two 37mm main guns and four .30 caliber machine guns.

Built in 1937, it was powered by the Continental R-975 radial engine.

Note the similarities between this tank and the M2A1 below. They

look very much alike, but the M2A1 is six tons heavier. Author's

photo.

Note the machine gun reflectors over the

rear of the tracks. The idea behind these was that after the tank

rolled over an enemy's trench work or foxhole, the rear gunners could

fire the machine guns at the reflector plates which would deflect the

bullets down and into any enemy soldiers in the trenches.

This was all based on World War One trench warfare. The German

invasion of France showed that the tanks were fighting a different war.

Author's photo.

Author's photo.

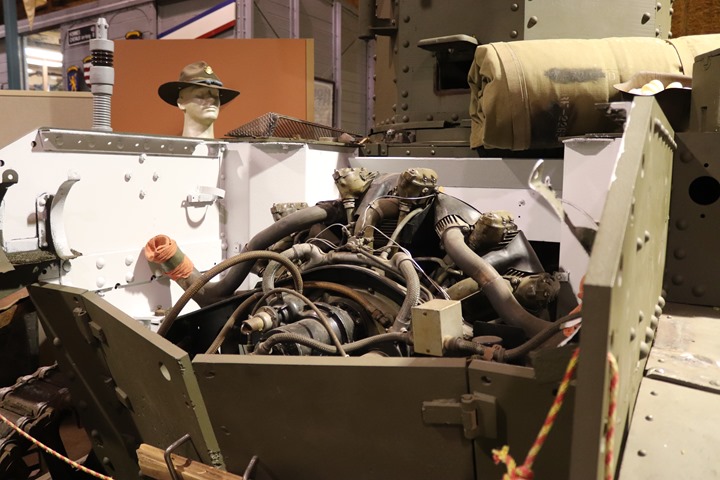

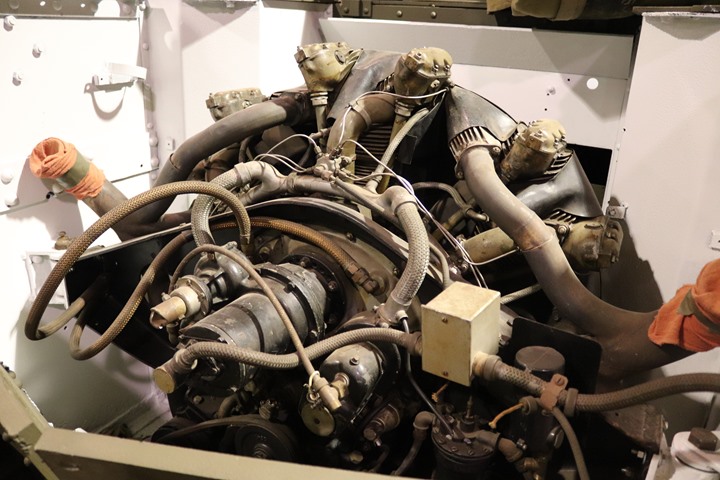

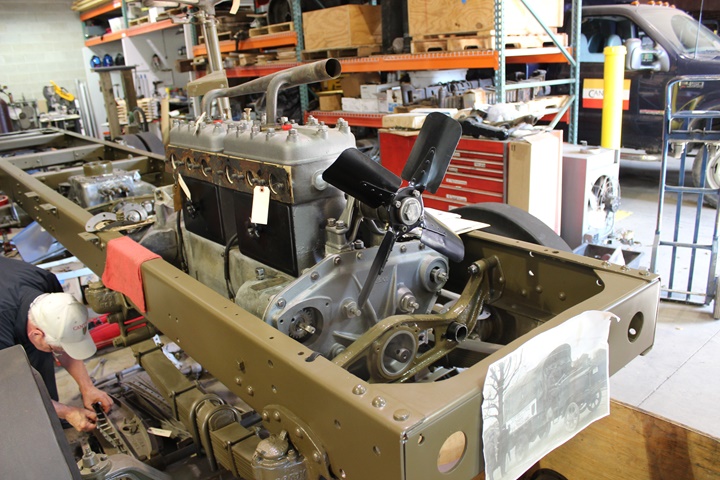

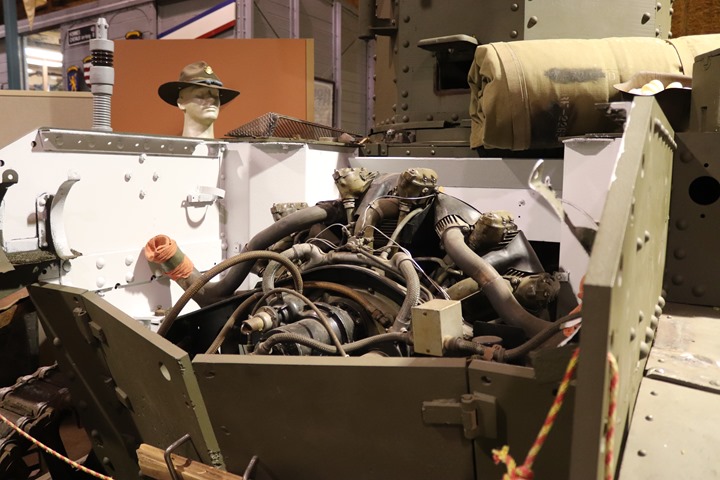

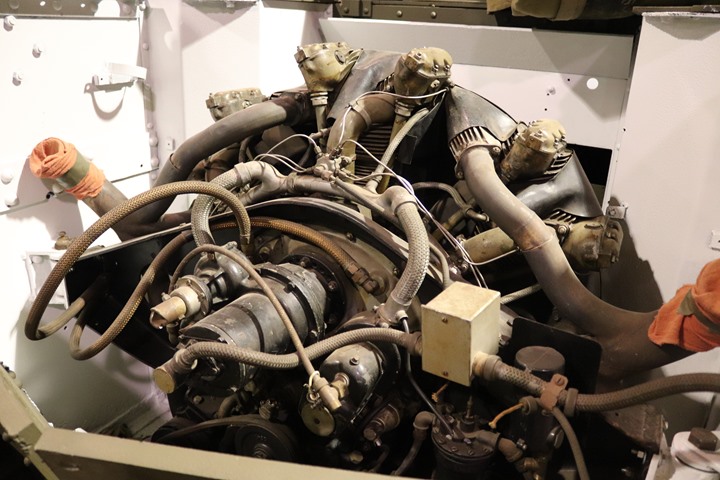

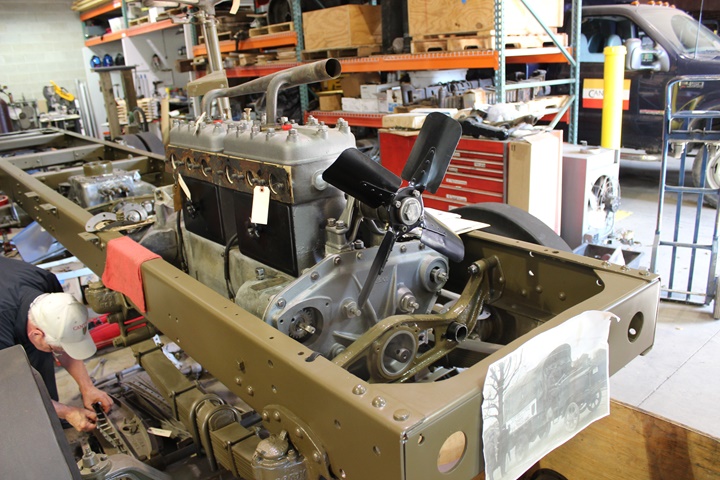

This is a 1939 M2A1 Medium tank, forerunner of the M3 and M4 medium

tanks. It was photographed in the restoration area of the U.S.

Army

Armor and Cavalry Collection at Fort Benning, GA. The M2A1,

weighing in at almost 21 tons, needed a larger engine than the smaller

previous light tanks. Continental was responsible for modifying the

larger Wright R-975 aircraft engine for use in tanks. This was the

first of over 54,000 Continental-built R-975 engines that would be used

in over 34,000 tanks and other armored vehicles during World War Two.

Author's photo.

The 37mm main gun and .30 caliber machine gun in the turret have been

removed during the restoration.

Author's photo.

Author's note: This was the medium tank with which the

U.S. Army originally planned to go to war with. After 94 of them were produced

by Rock Island Arsenal, production was passed on to

Chrysler to build at the new Detroit Tank Plant in what was then

Centerline, MI, and now Warren, MI. Within a short time, cooler heads

prevailed. The M2A1 was cancelled, and the M3 Lee/Grant tank took its

place. No M2A1 medium tanks were ever produced at the Detroit Tank

Plant. The M2A1 was armed with one 37mm main gun and eight .30

caliber machine guns. Lessons learned from the tank warfare going

on in Europe made the 37mm gun inadequate for modern warfare. The

M3 Lee/Grant had the more effective 75mm cannon for its main armament.

Besides the Army's Rock Island Arsenal,

several companies attempted to get into the tanks business in the 1930s.

One of the most prominent was Walter Christie. He had several

tanks of various design which were evaluated by the U.S. Army in the

early 1930s. This 1932 T4 convertible medium tank was built by the Rock

Island Arsenal using Christie suspension. It was powered by

the Continental W-640 engine and is one of 16 produced in 1932.

Author's photo from the U.S. Army Armor and Cavalry

Collection at Fort Benning, GA.

The term "convertible" is used in the tank's

description because the tracks could be removed, and the vehicle

converted to an armored car that ran on the large rubber-coated road

wheels. Author's photo.

World War Two:

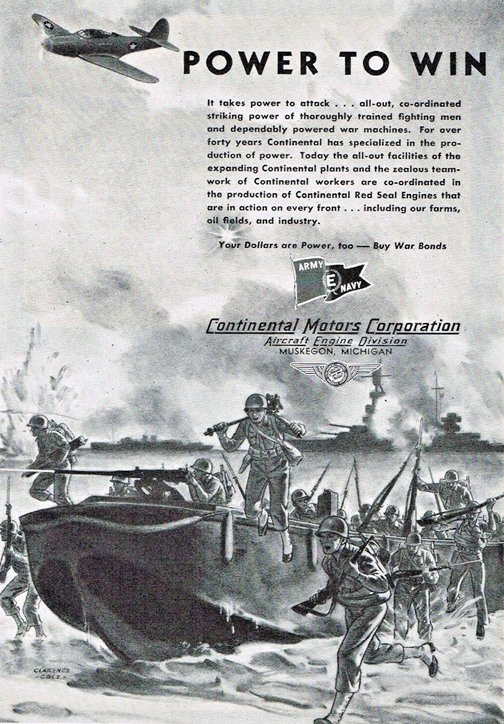

In 1902, 20-year old Ross Judson started a small machine shop on South

Clinton Street in Chicago to build small combustion engines. The small

company grew and expanded and moved several times while in the Chicago

area. In 1905, the company, as Continental Motors, moved to Muskegon, MI where

it was able to obtain favorable conditions from the Chamber of Commerce to continue its business.

A new 16,000 square foot factory was built at the corner of Market and Water Streets in downtown Muskegon

near Lake Michigan. During World War Two, the company had three plants in

Michigan and one in Texas. These four plants would produce over

131,000 tank and aircraft engines of ten different types during the war.

This is comparable to amount of aircraft engines Curtiss-Wright and

Pratt & Whitney produced during the war.

Continental was in the big three of World War Two engine production in

the United States.

The Continental Motors Detroit, MI plant won

the Army-Navy "E" Award two times.

The Continental Motors Muskegon Plant won the Army-Navy "E" Award one

time.

|

Continental

Production World War Two Production Plants |

|

Plant Location |

Products |

Comments |

|

Downtown Muskegon, MI |

W-670 parts and final assembly, R-670 220 hp

radial aircraft engine parts and final assembly,

O-170/A65 four-cylinder aircraft engine parts and final

assembly, R-600 six- cylinder 230 hp Inline engine parts and final assembly |

|

|

Getty Street Plant

Muskegon, MI |

R-1340

aircraft engine parts and final assembly, V-1650-7 Merlin

V12 aircraft engine parts and final assembly, I-1430 parts

and final assembly |

Construction on this $5 million Government-built plant to

produce aircraft engines began in July 1941. One

of the main products was to be the I-1430 twelve-cylinder,

1,000 hp engine for Army Air Forces fighter aircraft.

This engine project never came to fruition. |

|

Detroit, MI |

R-975

parts and final assembly, GAA parts and final assembly |

In November 1940 this plant underwent a $8 million

renovation and retooling project to produce the R-975

engine. By the

fall of 1944, only one third of the plant was necessary to

produce the needed R-975 engines and spare parts. At

that time, retooling began for production of the GAA engine.

At its peak, this plant employed 5,000 persons. |

|

Garland, TX |

R-975

parts and final assembly, GAA pistons, cylinder sleeves and connecting rods |

This government-owned plant was originally built to produce

the Guiberson diesel medium tank engine. This project

was cancelled February 1942. Continental then leased

the building from the government in September of the same

year, and re-tooling began for production of the R-975.

In late 1944 it began tooling-up for producing parts for the

GAA engine. |

|

Continental Engines Built during World War Two |

|

Engine type |

Number Built |

Plant Location |

Applications |

Comments |

|

Ground Vehicle Engines |

| R-975

Nine Cylinder 420 hp Radial Tank Engine |

54,104 |

Detroit, MI Plant and Garland, TX |

(4,424) M3 Lee/Grant Tanks, (300) M3A1 Lee/Grant Tanks, (12)

M3A2 Lee/Grant Tanks, (8,389) M4 Sherman Tanks, (9,707) M4A1

Sherman Tanks, (188) M4A1 Grizzly Tanks, (6) T7E2 Medium

Tank Prototypes, (7) M7 Medium Tanks, (50) Ram I Tanks,

(1,815) Ram II Tanks, (84) Ram II Observation Posts, (2,507)

M18 Hellcat Tank Destroyers, (3,490 ) M7 Priest Gun Motor

Carriages, (2,150) Sexton Gun Motor Carriages, (100) M12

Motor Gun Carriages, (418) M40 Motor Gun Carriages, (100)

M30 Cargo Carriers, (40) M39s, (24) M43 Motor Gun Carriages |

The total usage was of the Continental R-975 was 33,811

engines. This allowed for 20,293 engines for spares.

The R-975 was produced from 1941 through 1945. By the

fall of 1944, only one third of the plant was necessary to

produce the needed R-975 engines and spare parts. At that

time, retooling began for production of the GAA engine. At

its peak, this plant employed 5,000 persons.

Note: The first 500 production M3 Lee/Grant tanks had Wright-built R-975

engines. See the note below this table.* |

| W-670 Seven

Cylinder 250 hp Radial Tank Engine |

30,000 |

Downtown Muskegon, MI |

(365) M2A4 Light Tanks, (4,526) M3 Light

Tanks, (4,410) M3A1 Light Tanks, (3,427) M3A3 Light Tanks,

(2,962) LVT-2s, (510) LVT(A)-1s, (450) LVT(A)-2s, (1,890)

LVT(A)-4s, (8,351) LVT-4s |

The total usage

was of the Continental W-670 was 26,891 engines.

The history of Continental only shows 15,000 W-670 engines

being built. My analysis based on the known

applications is more than 11,500

more than the 15,000. This does not include any spare

engines. The build must have been at

least 30,000 engines. |

| R-600 Six

Cylinder 230 hp Inline Engine |

12,000 |

Downtown Muskegon, MI |

(5,290) M5 High

Speed Tractors, (582) M5A1 High Speed Tractors, (1) M5A3

High Speed Tractors, (5,765) M1 and

M1A1 10-Ton Wreckers, (?)Fire Trucks |

The total usage

was of the Continental R-600 was 11,628 engines.

I will estimate the company built 12,000 to include spares.

|

| GAA 1000 cu.in.

500 hp V8 Tank Engine |

~20 |

Final assembly

was at the Detroit plant.

Garland, TX supplied pistons, cylinder sleeves and

connecting rods.

Muskegon, MI built the camshafts and crankshafts for the GAA

engine. |

M4A3 Sherman

Tank |

Tooling began in

fall 1944. A very small number were built starting

February 1945. First deliveries occurred in July 1945

and the war ended a month later. The few that were

completed by war's end were insignificant compared to all of

the other engines the company delivered during World War

Two. |

|

Y112 Four Cylinder Gasoline Engine |

567 |

Downtown Muskegon, MI |

LeTourneau D4 Airborne Turnapull

scraper |

There may have been more uses for this engine during the

war. It is unknown. |

|

Aircraft Engines |

| R-1340 |

5,100 |

Getty Street

Plant, Muskegon, MI |

T-6, SNJ |

The R-1340 was

produced from April 1943 through November 1944. A

resumption of this contract was restarting when the war

ended. |

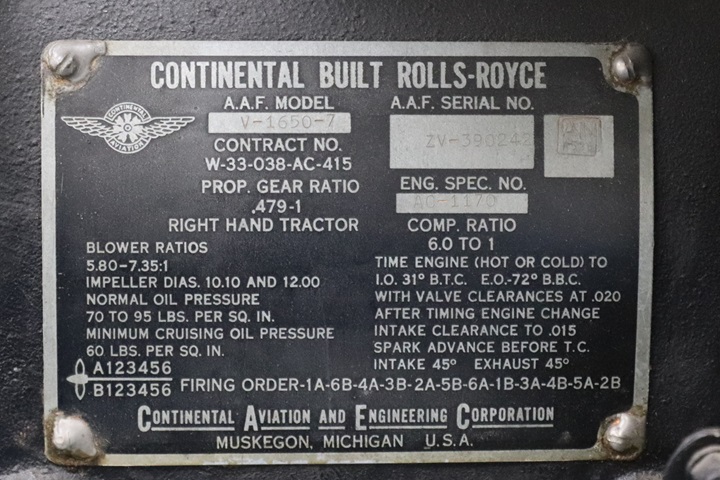

| V-1650-7 Merlin

V12 Aircraft engine |

797 |

Getty Street

Plant, Muskegon, MI |

P-51 |

A contract was

signing in February 1944 to produce 8,500 V-1650 Merlin

aircraft engines. Fifteen Million dollars were needed

to tool up the Getty Street plant for the engine. The

V-1650 was produced from July 1944 through May 1945.

The contract was cancelled at the end of May 1945.

Continental history indicates that a third or 2,800 engines

had been delivered. Army Air Force records show only

797 being accepted. |

| O-170/A65

four cylinder engines |

16,977 |

Downtown Muskegon, MI |

(5,611) Piper

L-4s and (230) NE-1s, (1,439) Aeronca L-3s, (1,942)

Taylorcraft L-2s |

16,977 O-170/A65 engines are credited to Continental by Army

Air Forces. 9,222 are known to have been used in the

four aircraft described to the left. |

| R-670 220 hp

Radial Aircraft Engine |

11,828 |

Downtown Muskegon, MI |

(3,519

) PT-17s |

11,828 R-670 aircraft engines are credited to Continental by

Army Air Forces. 3,519 are known to have been used in

the PT-17 aircraft described to the left. There were

several other versions of this type aircraft, but they used

engines from different manufacturers. |

| I-1430

1000 hp twelve cylinder Aircraft Engine |

23 |

Getty Street

Plant, Muskegon, MI |

(2)

McDonnell XP-67 twin-engine interceptors. |

This aircraft was known as the "Bat" or "Moonbat." It

probably sounded like a good idea at the time, but it never

worked out. |

|

Total |

131,416 |

|

|

This is an estimate total based on the known information.

This was a lot of engines. |

*Note: On September 9, 1940,

Continental Motors signed a contract with Army Ordnance to build R-975

engines at a rate of 200 per month by October 1941. Several days

later the company was asked to pull that schedule forward to meet the

production of M3 medium tanks that would be coming off several assembly

lines in early 1941. No doubt there were several other requests to

start production earlier than October 1941 and at higher run rates.

Continental actually started production in a record seven months in May

1941 which would have been in time for the first M3s coming off the

assembly lines a month later. The ramp-up of the M3 tank build was

aggressive and impressive. In order to meet the production

schedules for the combined M3 and M4 series medium tanks shown below,

Army Ordnance obtained 500 Wright-built R-975s to fill the gap as

Continental came up to full production. Continental did develop

enough capacity to supply all of the engines needed for M4/M4A1

production.

The table below shows the number of R-975s

needed from June 1941 to September 1942. In October 1941

Continental Motors took over supplying the R-975 engine for the M3.

It supplied 4,736 engines for the M3 Lee/Grant tanks and all of the

R-975 applications after this. Note that in May 1942 a total of

689 R-975 engines were needed to keep both the M3 series and M4 series

production lines operating. By this time Continental was able to

supply engines for both types of tanks in the quantities needed.

|

Demand for R-975 Engines for the M3 Medium tank series and early

M4/M4A1 production |

| |

6-1941 |

7-1941 |

8-1941 |

9-1941 |

10-1941 |

11-1941 |

12-1941 |

1-1942 |

2-1942 |

3-1942 |

4-1942 |

5-1942 |

6-1942 |

7-1942 |

8-1942 |

9-1942 |

Total |

| M3,

M3A1, M3A2 |

10 |

26 |

80 |

193 |

249 |

309 |

475 |

537 |

522 |

609 |

587 |

578 |

596 |

387 |

78 |

0 |

5,236 |

| M4,

M4A1 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

1 |

11 |

59 |

111 |

23 |

174 |

323 |

340 |

1,042 |

|

Total |

10 |

26 |

80 |

193 |

249 |

309 |

475 |

537 |

523 |

620 |

646 |

689 |

619 |

561 |

401 |

340 |

6,278 |

An estimate of Continental's average rate of

production can be made. In the fall of 1944 the Detroit plant was

running at one third capacity to fulfill its orders for the Pressed

Steel-built M4A1(76)s of around 200 per month and M18 production of 150

per month. This totals 350 per month. Multiplying by three

gives an approximate full capacity of 1,050 R-975 engines per month.

Another way to figure this is to assume in

October 1944 the production schedule was cut back to the one-third

level. There were another 1,879 Pressed Steel M4A1(76)s that were

built through July 1945. 157 M18s needed engines in October 1944.

Therefore another 2,036 R-975 engines were needed. Subtracting

this from the total 54,104 R-975s built by Continental during the war

equals 52,068. Continental built 4,736 of the M3 medium tank

engines. Subtract this from 52,068 to give the number of engines

Continental built from January 1942 through September 1944. This

is 47,332. Divide this by 33 months to get the R-975 average

monthly production between January 1942 through September 1944.

This gives an estimated average of 1,434 units per month.

Therefore, Continental was able to produce well in excess of 1,000

engines per month during World War Two when it was fully tooled up.

American Car and Foundry built 365 M4A2

light tanks and 12,263 M3 Stuart light tanks powered by the Continental

Motors W-670 tank engines. The photo above shows an M3 in road

march between two M2A4s on the island of Guadalcanal. Continental

engines were in the thick of the fighting during World War Two.

Using a small Continental engine in the D4 Airborne Turnapull

and Carryall Scraper is the opposite extreme to a Sherman tank.

The next three photos were taken at the National Construction Equipment

Museum in Bowling Green, OH. This excellent museum has a rare LeTourneau D4 Airborne Turnapull

scraper on outside display. It is rare in that

only 567 of these units were built. The entire unit consisted of a

D4 Tournapull, a model Q Carryall, a model P cable power control unit,

and on the front an AD Tiltdozer. The unit shown below does not

have the AD Tiltdozer on it. This particular product was designed

to be brought into a primitive landing zone by Waco CG-4A glider, C-47,

or C-46. The Carryall was carried in one aircraft or glider, and

the scraper in another. Once assembled in the field, Army Airborne

Aviation Engineers used the D4 to enlarge the landing strip for normal

flight operations.

Author's photo.

The Continental Y112 engine was normally

used in industrial applications such as fort lift trucks. Author's

photo.

Author's photo.

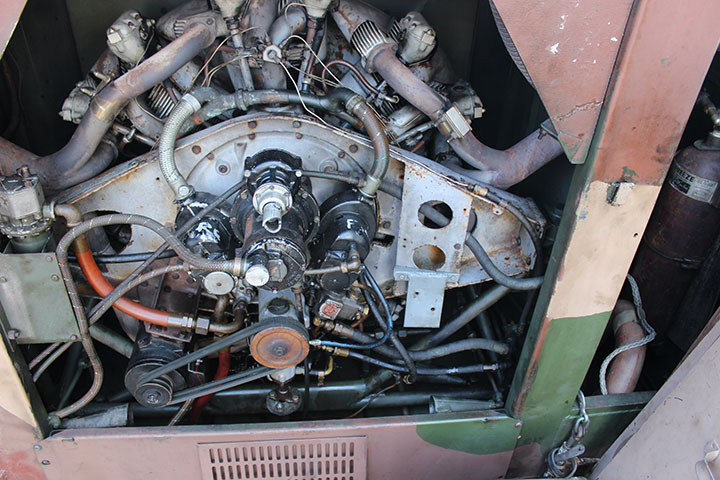

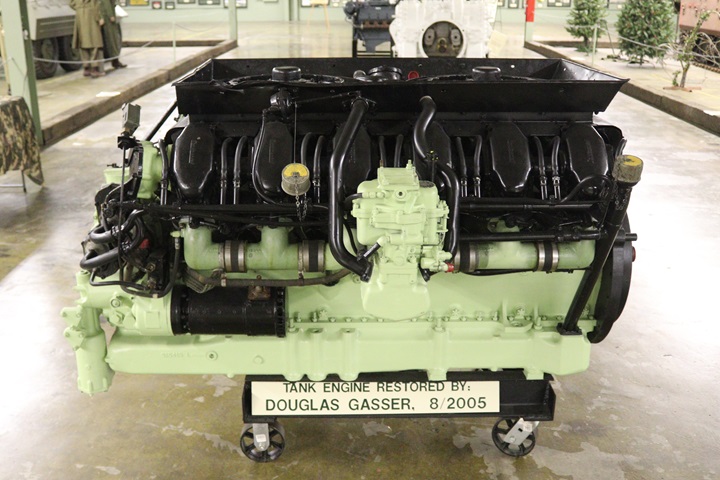

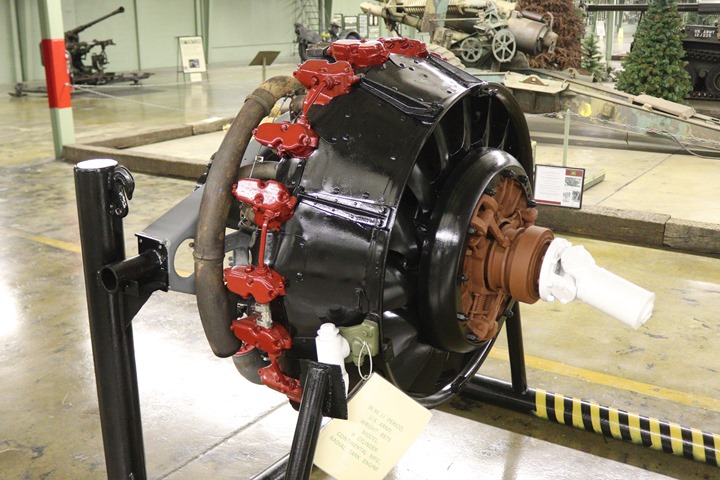

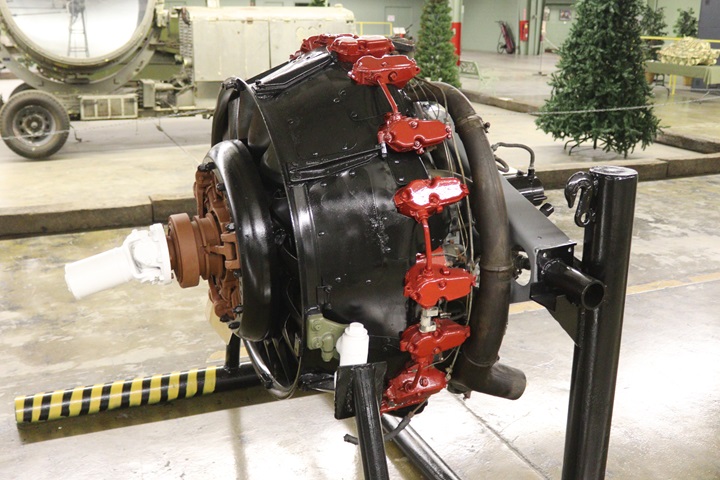

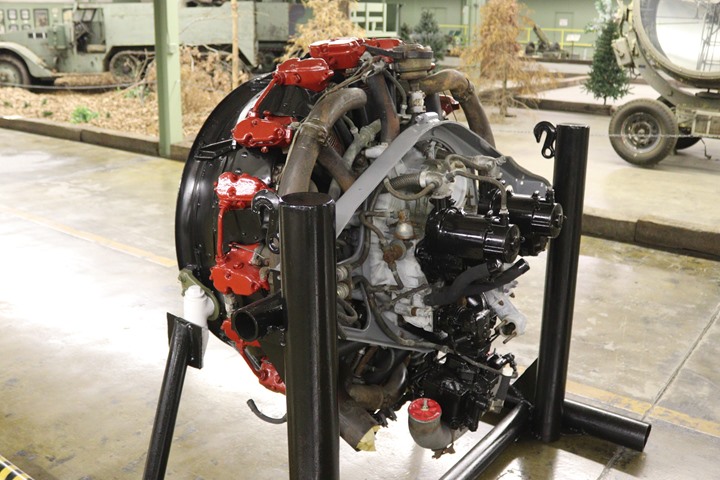

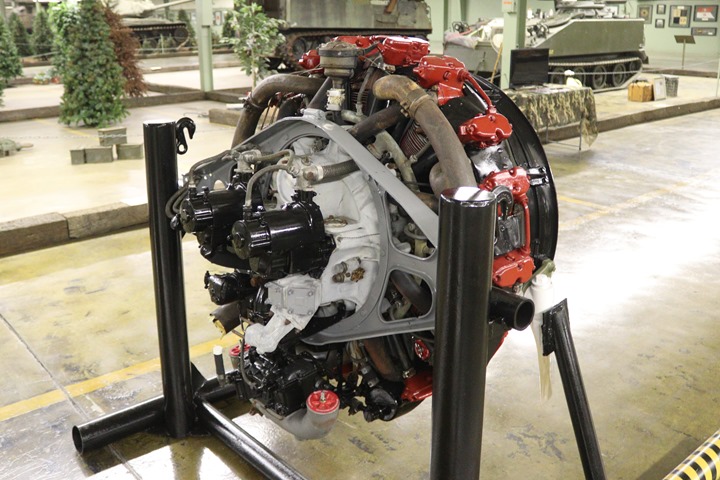

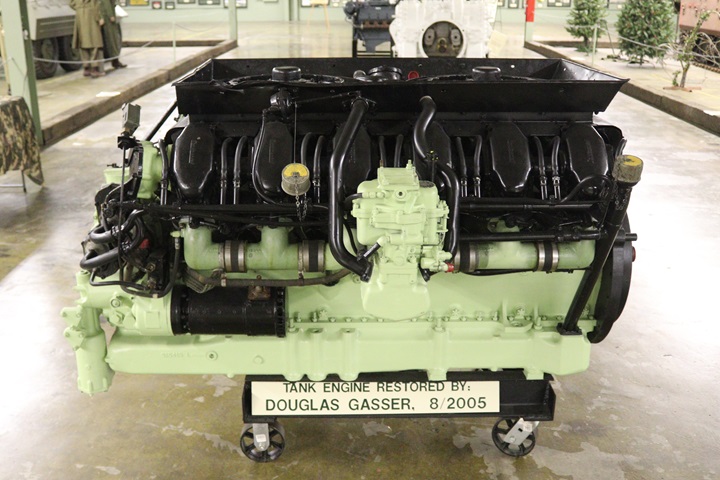

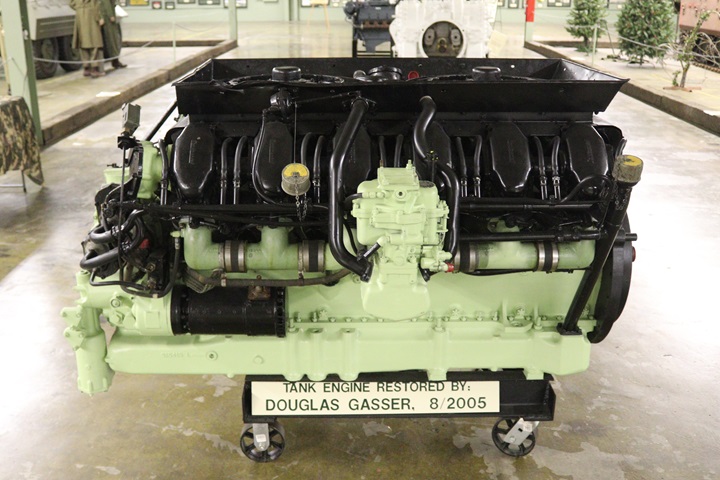

Continental R-975 Radial Tank Engine:

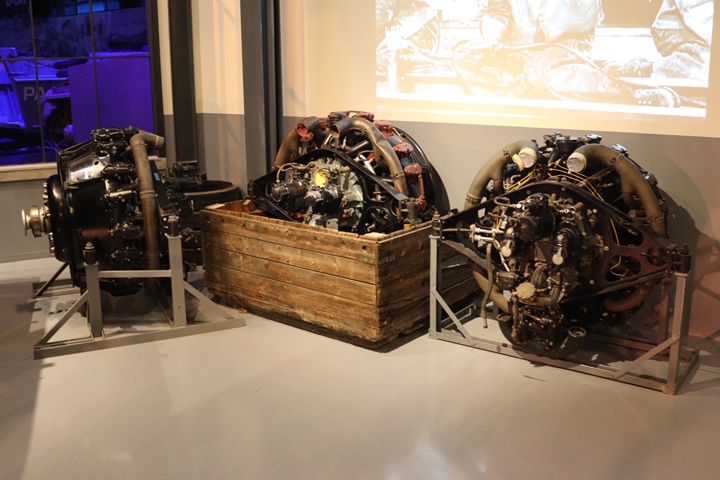

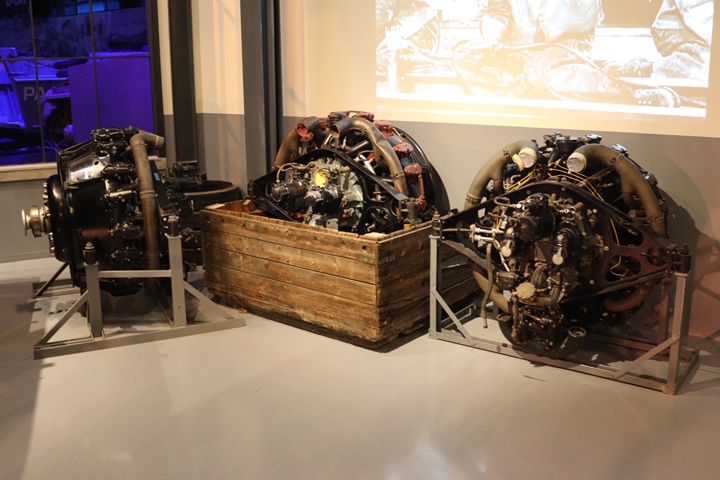

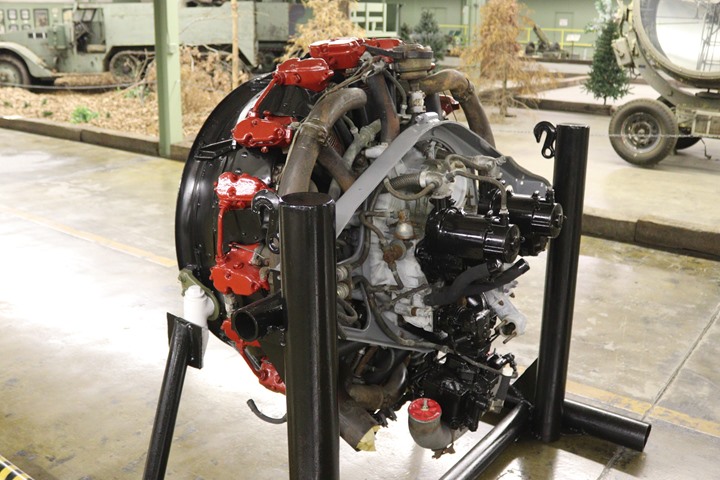

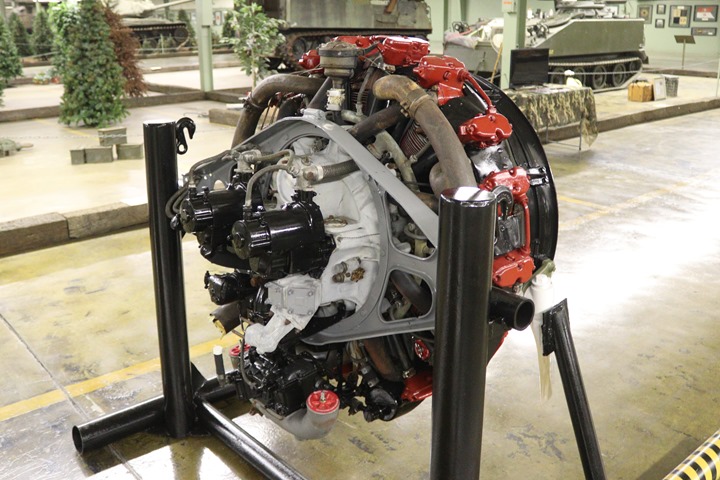

These three Continental R-975 engines are on display at the American Heritage

Museum in Hudson, MA. Author's photo.

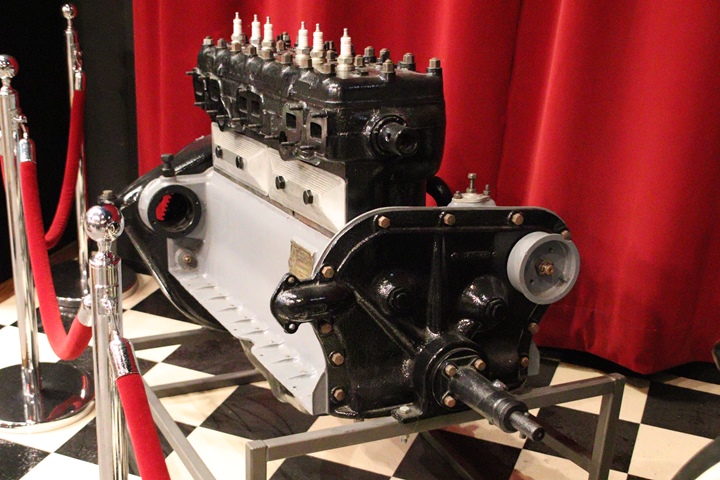

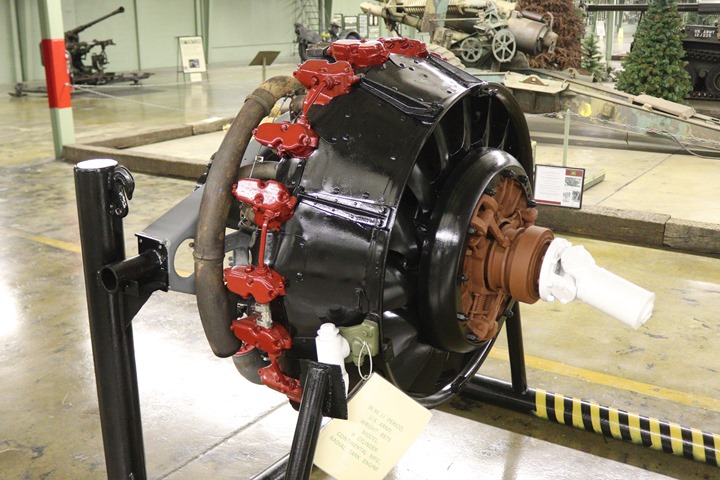

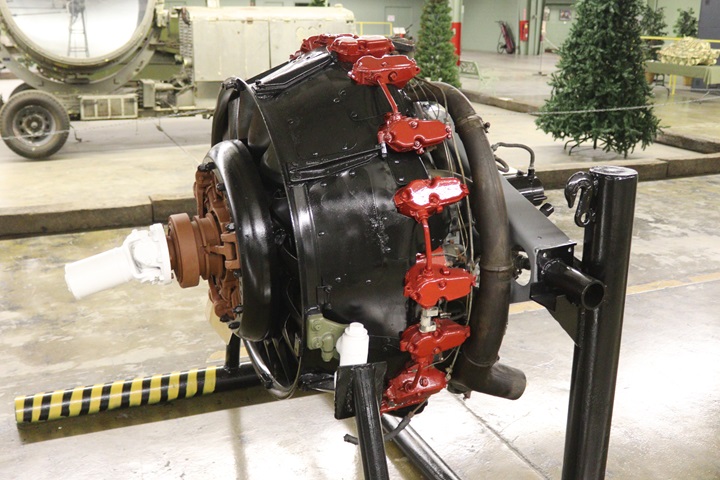

Inside the AAF Tank Museum in Danville, VA is this pristine restoration

of one of the 54,104 R-975 radial tank engines that Continental built

during World War Two. Author's photo.

Author's photo.

Author's photo.

Author's photo.

The M3 Lee/Grant series medium tanks were

the first to utilize the R-975 engine. The M3 served with both

British and American Forces in North Africa until being superseded by

the M4 Sherman medium tank series. The M3 continued to give

service with British forces in Burma until the end of the war. The

Continental R-975 engine was a world traveler during the war.

Author's photo from the American Heritage Museum in Hudson, MA.

4,924 M3 Lee/Grant Tanks, 300 M3A1 Lee/Grant

Tanks and 12 M3A2 Lee/Grant Tanks were built with Continental R-975

engines. Author's photo.

Continental supplied the 9,707 engines for

the M4A1. Pressed Steel Company built this small hatch M4A1 in

July 1942, just four months after the company began production of the M4A1. Serial number 192 is the oldest known M4 series tank by

serial number still in existence. It is also the oldest Pressed

Steel-built M4A1 survivor. Author's photo taken at the Virginia

Museum of Military Vehicles.

This M4A1(76)HVSS was built by Pressed Steel in January of 1945. This has all the

refinements of war experience in the tank. It has wider tracks, a

larger turret for the 76mm main gun, removal of the direct vision ports,

the more pointed transmission housing, wet ammunition storage and the 76

mm main gun. The Sherman tank had been a work in progress during

World War Two. This is Serial Number 67984 and it is on display at

the National Guard Armory in Huntington, IN. Author's photo.

This one of only nine

M4A1s built by the Lima Locomotive Works during World War Two that

survive today. A total of 1,655 were built by the company.

Author's photo taken at the Fort Leonard Wood Museum complex.

Montreal Locomotive Works built 188 M4A1

versions of the tank named Grizzly. This one

is owned by WW2 Armor in Osteen, FL. Author's photo.

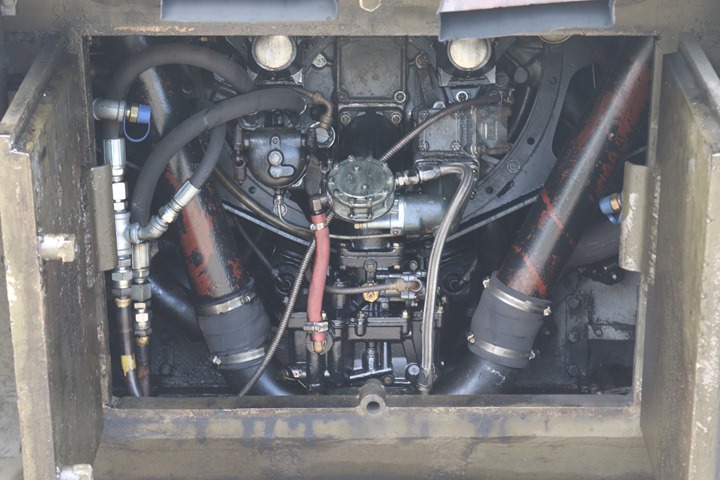

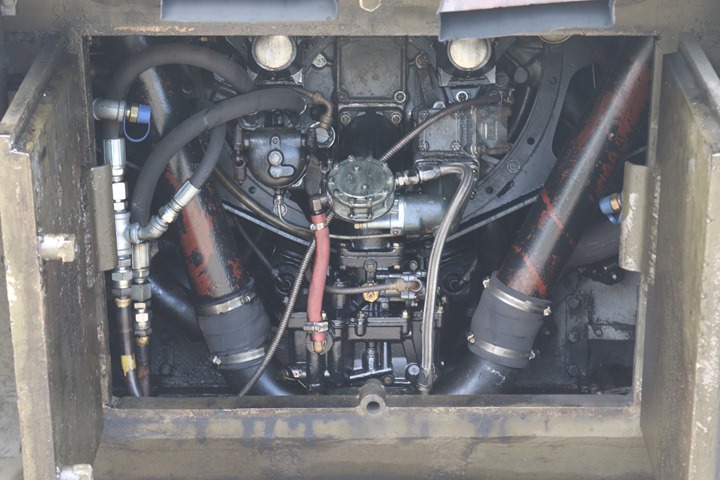

The back doors were open for inspection of

the Continental R-975 engine in the Grizzly. Author's photo.

8,389 M4 Sherman tanks were built by several

companies for the war effort. This Pressed Steel

M4E9(75) with Continental R-975 engine is on display at the USS Alabama

in Mobile, AL. Author's photo.

-fortbenning-2018-107w-1.jpg)

M4 Alco Serial Number 3949 April 1943 was

built in April 1943 with a Continental engine. It is part of the

U.S. Army Armor and Cavalry Collection at Fort Benning, GA.

Author's photo.

A total of 3,490 M7 105mm Howitzer Motor Carriages

were built by Alco and Federal Machine and Welder during World War Two.

This version of the M7 was powered by the R-795. This one is owned

the Virginia Museum of Military Vehicles and was built by Alco in November 1942.

It is

Serial Number 1364. Author's photo.

The Sexton was the Canadian version of the

American M7 but was armed with a 25-pounder gun. The driver was

located on the right side of the vehicle. It too was powered by a

Continental R-975. This Sexton is part of the collection of the

Wheels of Liberation located in New Oxford, PA. The very nice

restoration includes an all-weather tarp, which is a nice addition to

the vehicle. This was on display at the 2019 MVPA convention.

Montreal Locomotive Works produced 2,150 during the course of World War

Two. Author's photo.

The Buick-built M18 Hellcat was the fastest

American armored track laying vehicle of World War Two, and it was

powered the Continental R-975 engine. The engines were built in

Detroit and shipped to the near north side of Flint for installation on

the Buick assembly line. Author's photo taken at the Virginia

Museum of Military Vehicles.

This M18 is one of 2,507 built and is part

of the collection of theU.S. Army Armor and Cavalry Collection at Fort Benning,

GA. When photographed by the author, it was undergoing

restoration. Author's photo.

Buick engineers designed the Hellcat so that

the Continental R-975 engine could slide out of the back for easy

maintenance. Author's photo.

Fisher Body, under sub-contract to Buick,

rebuilt 600 M18s into M39 cargo carriers. Fisher Body also built

forty brand-new M39s. All had the Continental R-975 engine.

Author's photo from the American Heritage Museum in Hudson, MA.

Twenty-four M43 203mm Howitzer Motor Gun

Carriages were produced by Pressed Steel at the end of World War Two.

The Continental R-975 engine was the power plant for the vehicle.

Author's photo.

Continental W-670 Radial Engine:

The W-670 radial engine built by Continental is most identified with the

M3 light tank. In fact, it had several other important

applications that assisted in winning World War Two for the Allies.

The W-670 was used in both the LVT-2 and

LVT-4. This LVT-4, was on display at the Portland, IN MVPA

gathering in September 2015. 8,351 LVT-4s were built during World

War Two. Author's photo.

A total of 14,163 LVTs of all types

were built with Continental engines. Author's photo.

The Continental W-670 engine was mounted

right behind the driver's station. This allowed for the ramp to be

installed in the rear. In the LVT-2 with the W-670 the engine was in

the back of the vehicle. Author's photo.

The LVT(A)-4 was the fire support version of

the LVT-4 and came armed with a 75mm howitzer. Author's photo

from the American Heritage Museum in Hudson, MA.

Author's photo.

This LVT(4)-A is part of the U.S. Army Armor

and Cavalry Collection at Fort Benning, GA. Author's photo.

This is M3 Stuart light tank Serial Number

1343 and is part of the U.S. Army Armor and Cavalry Collection at Fort Benning,

GA. It was built in August 1941 by American Car and Foundry.

Author's photo.

This is one of 12,363 Continental W-670

engines that the company provided for all models of the M3 light tank,

and is

on display behind the tank. Author's photo.

M3 Serial Number 156 is on display at the U.S. Veterans Memorial Museum

in Huntsville, AL. It has an early riveted turret. It was built in May 1941 by American Car and Foundry at its Berwick, PA

plant. Author's photo.

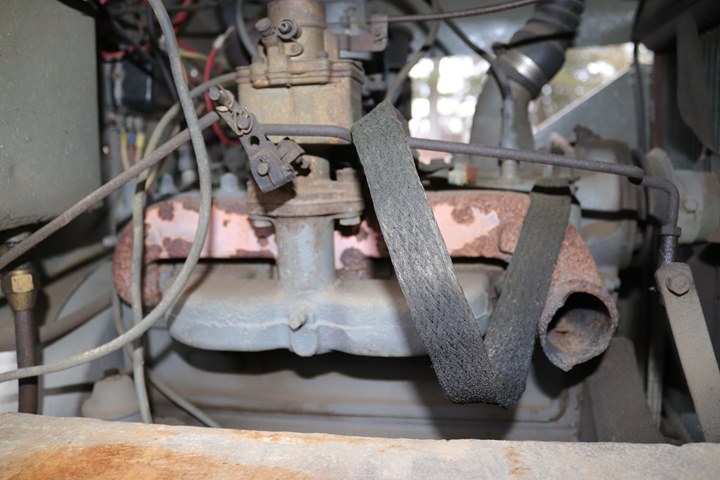

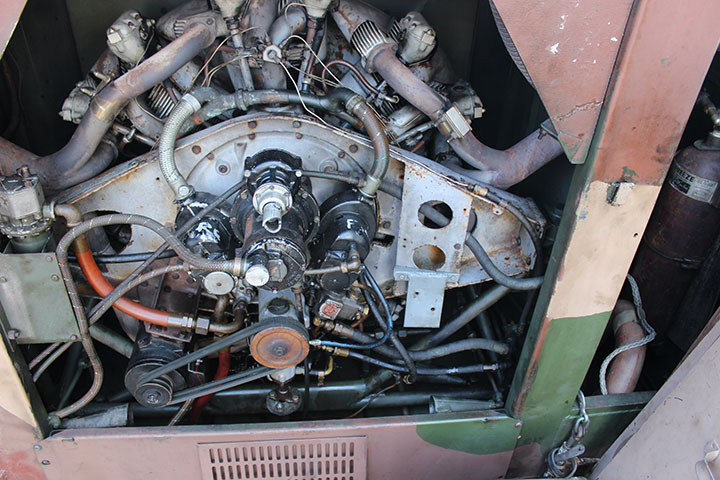

This and the next photo show how the

Continental W-670 engine was installed in the M3 Stuart. Author's

photo.

Author's photo.

R-600 Six Cylinder 230 hp Inline Engine: The M1 series 10-ton

wreckers and M5 series high speed tractors were powered by the

Continental R-600 inline engine.

There were

5,765 M1 and M1A1wreckers built by Ward-LaFrance and Kenworth

during World War Two. Author's photo from the 2019 MVPA

Convention.

This newly restored International-Harvester

M5 High Speed Tractor was on display at the 2019 Thunder over Michigan

Airshow. 5,872 of the M5 series high speed tractors were built

with the Continental R-600 engine during World War Two. Author's

photo.

Continental history indicates the R-600

engine was used in landing craft. Use of this engine in landing

craft was limited, as there is only one other reference to its use for

that purpose in the literature. The R-600 may have been used very

early in the landing craft program when there was an engine shortage,

and limited to the LCP(L), as shown in this advertisement.

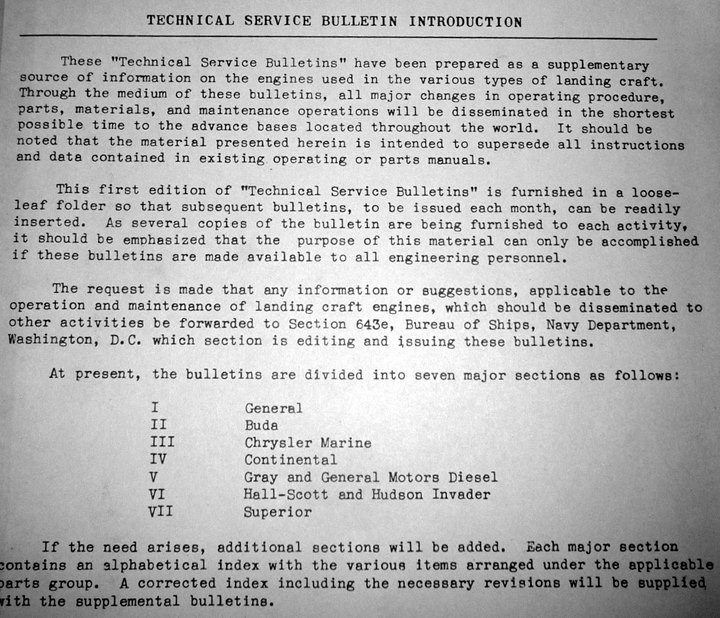

This is from a 1944 Technical Service

Bulletin manual. It is the only other source showing a Continental

engine being used in landing craft.

This is an LCP(L) similar to the one

in the advertisement above. Author's photo from the National WWII

Museum in New Orleans.

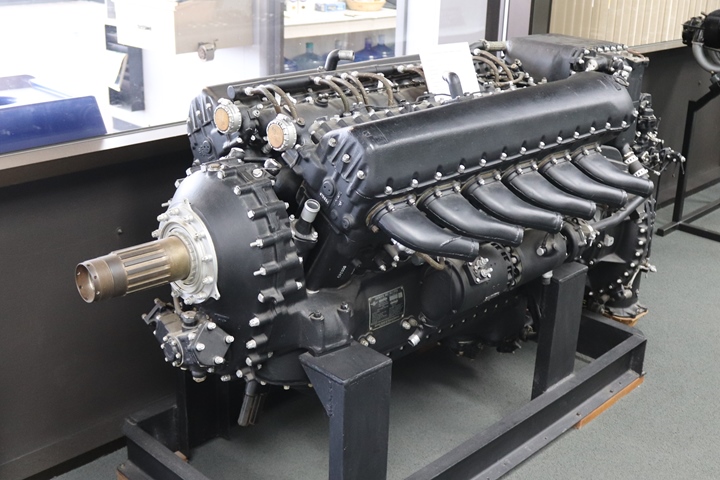

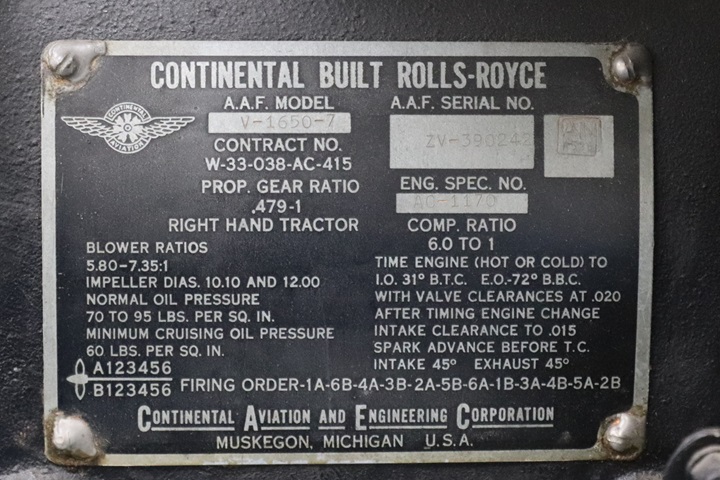

Rolls-Royce V-1650-7 Merlin

V12 Aircraft Engine: Production started in late

1944 and continued through May 1945.

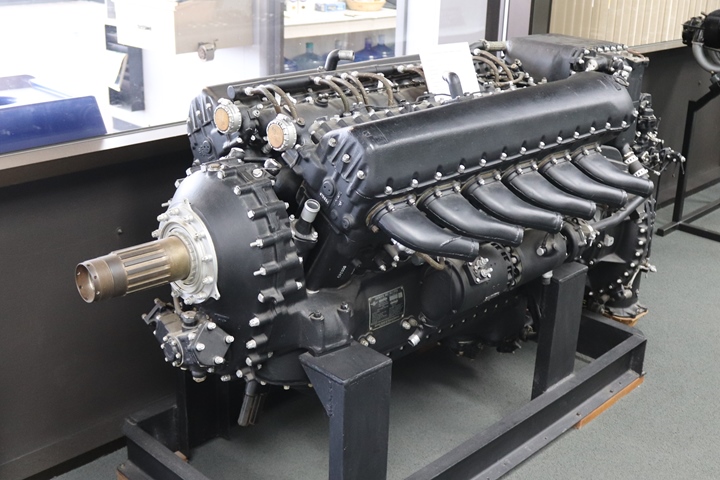

This Continental-built Rolls-Royce

V-1650-7 Merlin is on display at the Air Zoo Aerospace and Science

Experience in Portage, MI. Author's

photo added 10-13-2020.

The V-1650-7 was used in the P-51D/K

Mustang. This engine is serial number ZV-390242. Author's

photo added 10-13-2020.

Author's photo added 10-13-2020.

Author's photo added 10-13-2020.

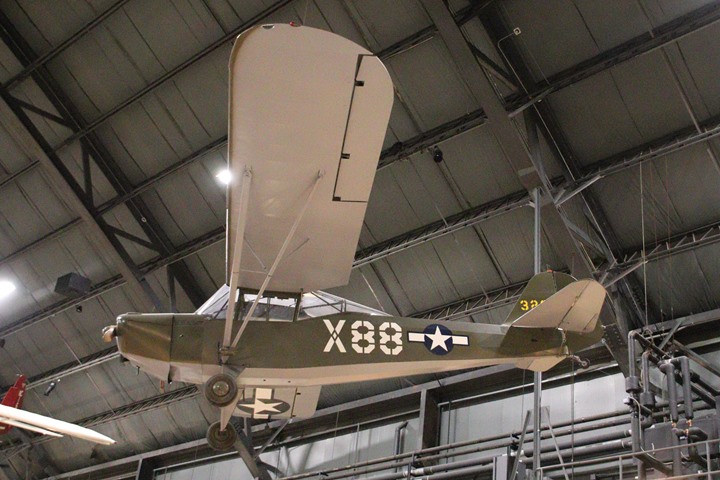

The North American P-51was the fighter of

choice for the Army Air Force in the last year of World War Two.

Continental was added as an engine supplier to make sure there

were enough engines to finish the end of the war. Author's photo.

I-1430 1000 hp Twelve Cylinder Aircraft

Engine:

The McDonnell XP-67 "Bat" was the only know

application for the I-1430 engine. One burned from an engine fire

and work on the second one stopped when it was realized the aircraft had

no advantages for the current fighters already in service with the Army

Air Force.

R-1340 Radial Aircraft Engine:

The T-6/SNJ series advanced trainers were an important part of flight

training for both the U.S. Army and Navy during the war.

Continental was brought on as a supplier to make sure there were enough

engines to keep up with production of the aircraft.

Author's photo.

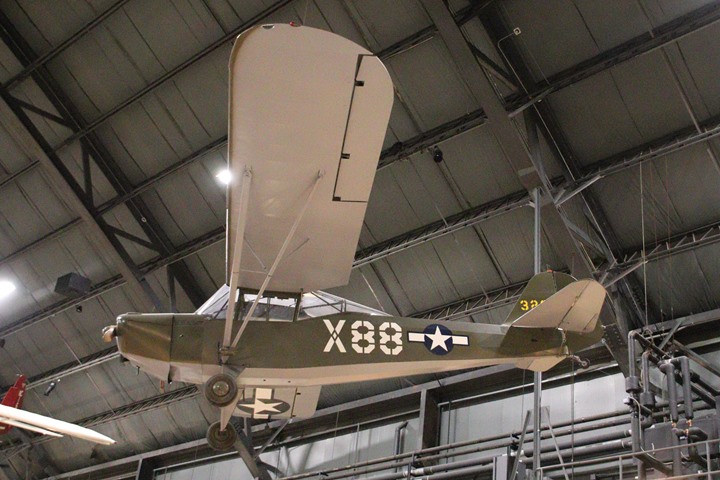

O-170/A65 Four Cylinder Opposed Cylinder

Aircraft Engines: Three different types of Liaison aircraft

used 9,222 of these versatile little engines during the war.

1,439

Aeronca L-3s were powered by the Continental O-170/A65 engine.

Author's photo.

1,942

Taylorcraft L-2s were powered by the Continental O-170/A65 engine.

Author's photo.

5,611

Piper L4s were powered by the Continental O-170/A65 engine.

Author's photo.

Author's photo.

R-670 220 hp

Radial Aircraft Engine: 3,519 Boeing PT-17s were

built with this engine.

Author's photo.

Post-World War Two: After the war,

Continental Motors would continue to supply a variety of of tank and

aircraft engines until the end of the Vietnam War. It also built

engines for helicopters, civilian aircraft, and jet engines for the USAF

T-37 trainer. This is in itself a huge topic, but is beyond the scope of

this webpage. However, we will look at the most important post-war

tank engine that Continental produced for the U.S. Armed Forces.

"What goes around comes around," as the

saying goes, and the Continental AV-1790-5B on display at the AAF Tank

Museum in Danville, VA is a prime example of this. During World

War Two, the Ford GAA V-8 engine replaced the Continental R-975 as the

preferred power plant in the Sherman tank. At the end of the war, Ford produced a different version of the GAA

for the M26 Pershing Heavy Tank. This was the GAF engine which was still a V-8

producing 500 hp. It had a lower profile than the GAA so it would

fit into the engine compartment of the M26. While the 500 hp was adequate for the 32-ton

Sherman, it was underpowered for the 46-ton M26 Pershing.

The U.S. Army had never really had an engine

designed specifically for use in tanks. It looked to Continental to

develop such an engine. The company responded with a series of

air-cooled engines of various displacements and configurations, the

AV-1790 at 810 hp being the one that would power many American tanks up to

the introduction of the M1 Abrams. Author's photo.

Author's photo.

Author's photo.

Author's photo.

Author's photo.

Author's photo.

Author's photo.

The first application of the Continental

AV-1790 was replacing the Ford GAF in the M26, resulting in the

M46. This M46 is on display at Fort Indiantown Gap, PA.

Author's photo.

This M47 on display at Camp Atterbury, IN

was powered by the Continental AV-1790. It is one of 8,576 produced.

Author's photo.

The AV-1790 was the engine originally

installed in the M48 Patton tank. Continental developed a diesel

version of the engine that was designated the AVDS-1790 and retrofitted

it into M48A1s like this one on display at the Army Reserve Center in

Jeffersonville, IN. The new diesel-powered designation for the M48

was the M48A3. It was this version that served with the U.S. Army

in Vietnam. There were 11,703 M48s built by Chrysler, Fisher Body

and Ford. Author's photo.

Chrysler built 300 M103 Heavy Tanks at its

Newark, DE tank arsenal from 1950-1953. They were powered by the

Continental AV-1760 gasoline powered engine. In 1964 153 of them

were converted to the AVDS-1790 diesel engine. This one at the

Shively, KY public library is a diesel conversion. Author's

photo.

The end of the line. The M60 was the

last tank that used a Continental engine, ending a long and important

series of tanks that were used in the American arsenal dating from 1932.

The M60s were equipped with the AVDS-1790 diesel engine. When the

last of 15,000 came off the assembly line at the Detroit Tank Arsenal in

1983, an era ended. There would be no more Continental-powered

tanks built. This M60A1 is on display at the Terre Haute, IN

National Guard Armory. Author's photo.

It wasn't that Continental didn't try to

continue as the engine supplier for the M1 Abrams main battle tank.

It teamed up with General Motors with a proposed tank that would have

been powered by a Continental ACVR-1360-2 supercharged 1,500 hp diesel

engine. In the end, the Chrysler/Lycoming entry with a turbine

engine won the competition.

This is the General Motors/Continental

Motors entry for the new main battle tank. The XM1 had an Allison

X-1100 transmission. Allison was the GM Division lead division for

General Motors in the competition.

|

-fortbenning-2018-107w-1.jpg)