|

Higgins Industries Time Line in

World War Two

Higgins PT-305 Video

Higgins

Industries in World War Two

Includes Higgins

Aircraft, Higgins Engine Company, and Higgins Plastic Corporation

New Orleans, LA

1930-1945

An

American Auto Industry in World War Two Special Edition

This page updated 6-15-2024.

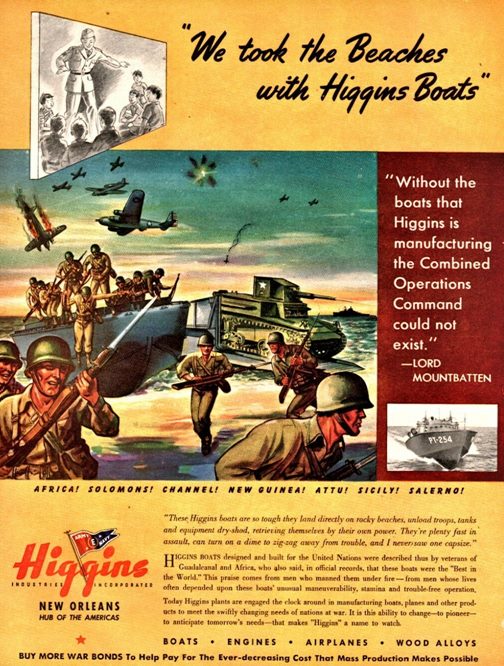

Higgins Industries was not part of the

American Automobile Industry. It was far from it, as the company

was in New Orleans, LA, and the builder of shallow draft wooden boats. The owner of the

company, Andrew Jackson Higgins, was a flamboyant and self assured

entrepreneur, who was always willing to speak his mind. One of the

subjects he quite frequently addressed was the need for proper landing

craft for American marines and soldiers with equipment to use for landing on hostile

beaches. He had a long series of disagreements with the Navy

Bureau of Ships on the proper design of these type landing craft so that

they could land right up on the beach. In the end, it was Andrew

Higgins' final design of the famous "Higgins" landing craft, the Landing

Craft, Vehicle, Personnel (LVCP), and the Landing Craft, Medium (LCM)

that were accepted. The LCVP became the most

produced landing craft of World War Two. But the LCVP was the last

of several design iterations that finally progressed to become the Higgins

boat. The original version still had the soldiers jumping over the

gunwales to get out of the boat, just as they had been doing since men

started landing on hostile beaches.

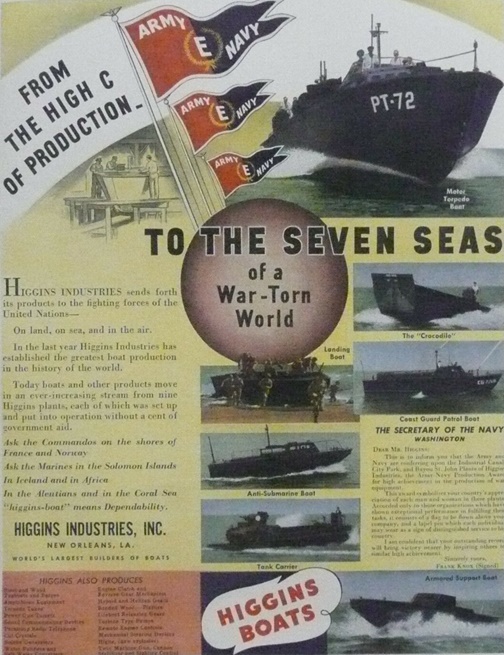

Higgins Industries is also known for

manufacturing Motor Torpedo Boats, more commonly known as PT

boats. While Higgins Industries is most well-known for its design

and production of the Higgins boat landing craft and PT boats, the

Higgins' design of the Landing Craft, Mechanized (LCM) in December 1941

was also an important contribution to the war effort that has been

largely overlooked. The company also built several other types of

boats and ships that have also gone unrecognized. Andrew Higgins

formed several other companies to make non-boat products for wartime use. Late in

the war, as part of a secret project, Higgins Industries produced carbon

parts used in the Manhattan Project at Oak Ridge, TN, to separate U-235

from U-238. He also formed several other companies to build

aircraft and aircraft engines. Neither of these companies

ended up building any appreciable products for the war effort.

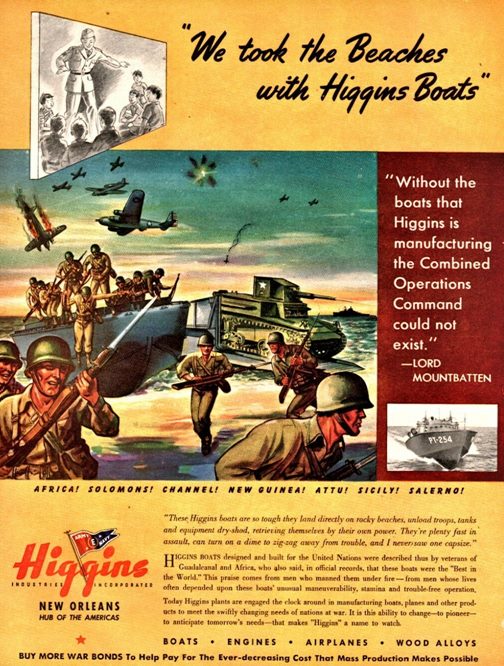

World War Two made household names out of Higgins Industries and

Andrew Higgins. Before the war, his company was a

small boat manufacturer. His design of the Eureka landing boat and

his persistence in getting it accepted made Higgins Industries the

largest manufacturer of boats built in the world.

When the war ended, the demand for thousands of landing craft ceased.

Higgins Industries was taken into receivership, largely due to labor

issues in November 1945. While the company was reorganized as

Higgins Incorporated, the bloom was off. It would never regain the former

glory and importance it had during World War Two.

There was a direct link between the American

Auto Industry in Detroit, MI and Higgins Industries in New Orleans, LA.

Automakers in Detroit built most of the engines that went into the boats

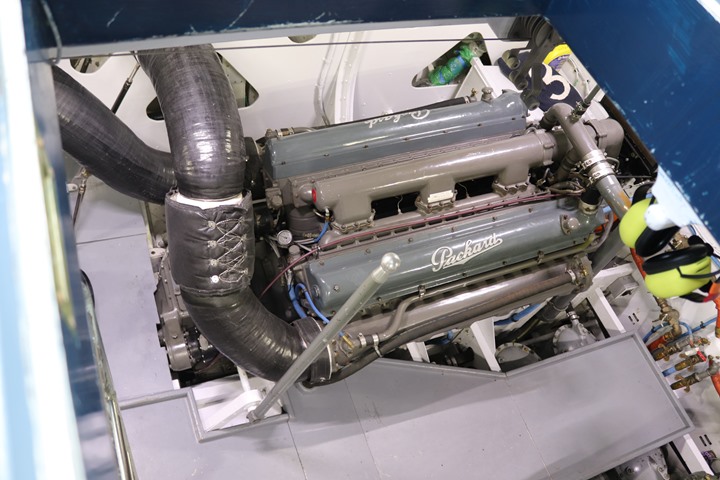

built by Higgins. All of the engines used in

the Higgins built PT boats had three Packard 4M2500 marine engines.

Most of the landing craft Higgins built had Detroit Diesel Division of

General Motors 6-71 diesel engines modified by Gray Marine Motor Company

in Detroit, MI. It was the preferred engine for U.S. landing craft

in World War Two. When Gray/Detroit Diesel engines were not

available, gasoline powered engines built by the U.S. Auto industry were

used.

Author's Note:

Some of the information below are from

"Andrew Jackson Higgins and the Boats that Won World War Two" by Jerry

E. Straham, published in 1994 by the Louisiana University State Press. When

I reference the book below, I will note it as "Higgins Biography."

This 1944 Landing Craft, Personnel, Large (LCP(L))

was the first type of landing craft that Andrew Higgins designed.

This particular boat was built by Higgins Industries in New Orleans in

October 1944, and is currently on display

at the National WWII Museum in New Orleans.

It has returned home for museum visitors to see. It is the

only one on display left in the world. Author's photo.

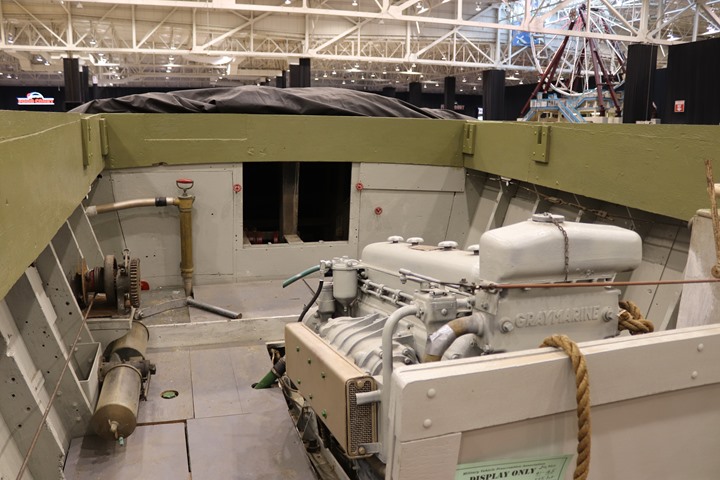

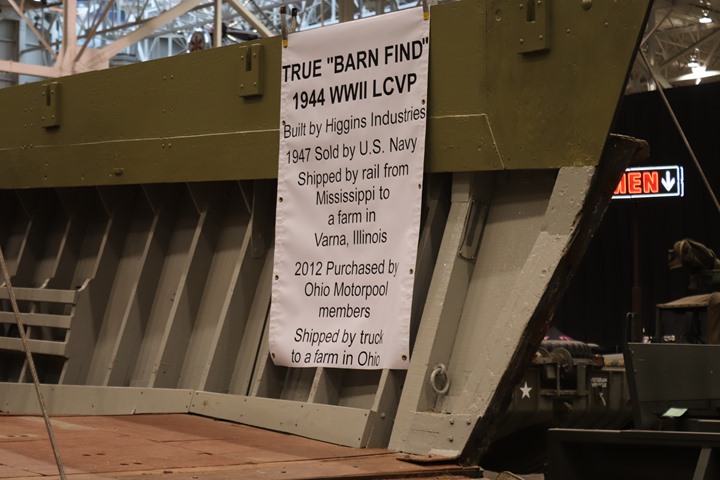

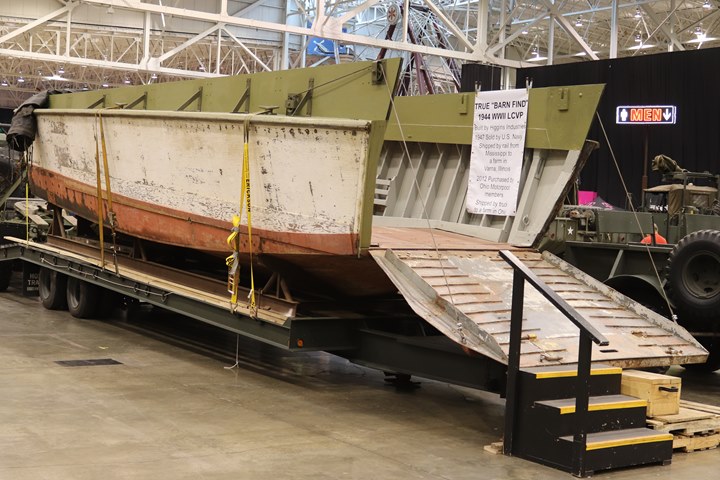

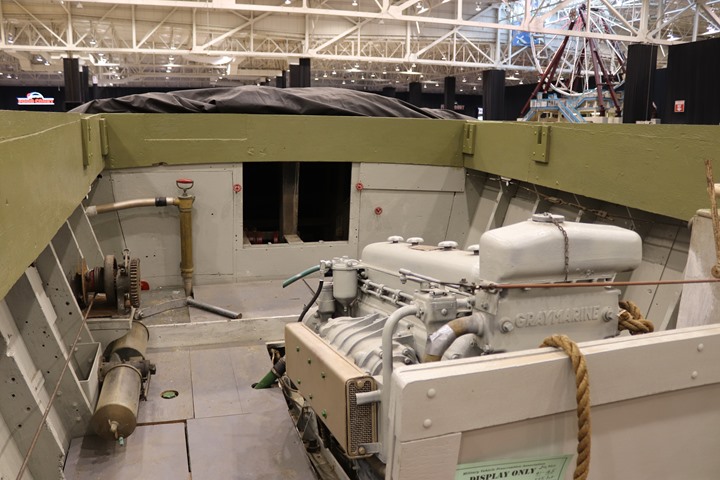

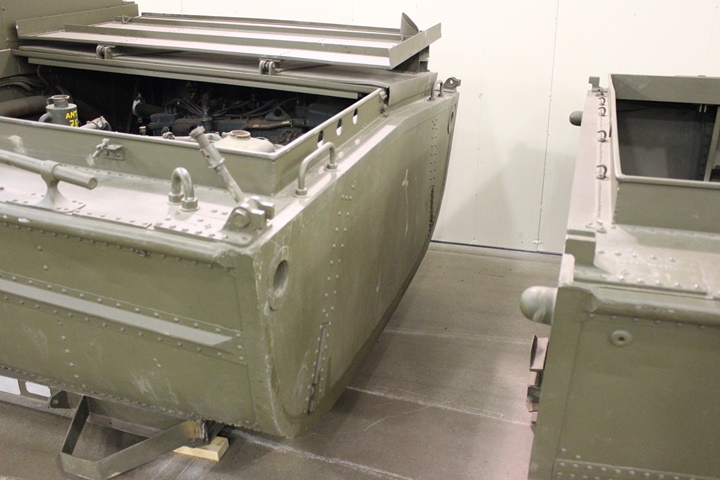

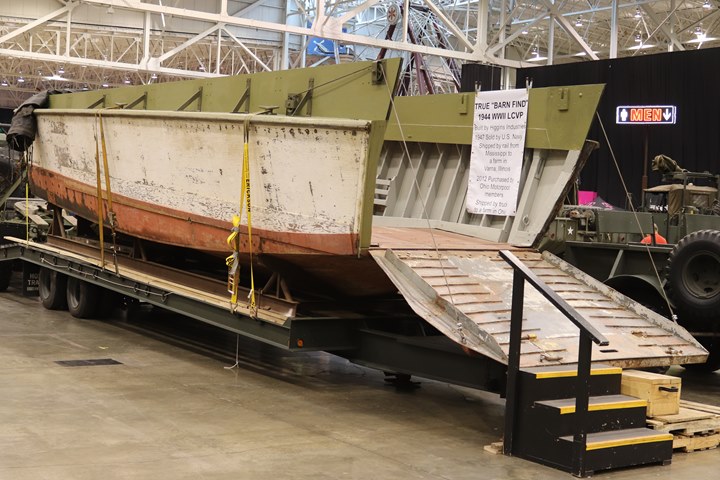

This is Andrew Higgins' most famous landing

craft design, the LCVP or Landing Craft, Vehicle, Personnel. It

was better known as the Higgins boat. Only twelve

original LCVPs still remain of the 23,358 built by seven

different boat manufacturers. Of the twelve remaining original Higgins boats, this is only one of two known to have been built by Higgins

Industries. It is owned by three members of the Ohio Motor Pool.

Author's photo.

Higgins Industries is also known for

building PT boats during World War Two. This is one of only four remaining Higgins-built

PT boats left in the world. It is fully operational and is owned

by the National WWII Museum in New Orleans. It gives rides for

those that want to experience a little bit of what it was like to serve

on a PT boat in World War Two. This photo and others on this page

are from my ride on it in March 2018.

Author's photo.

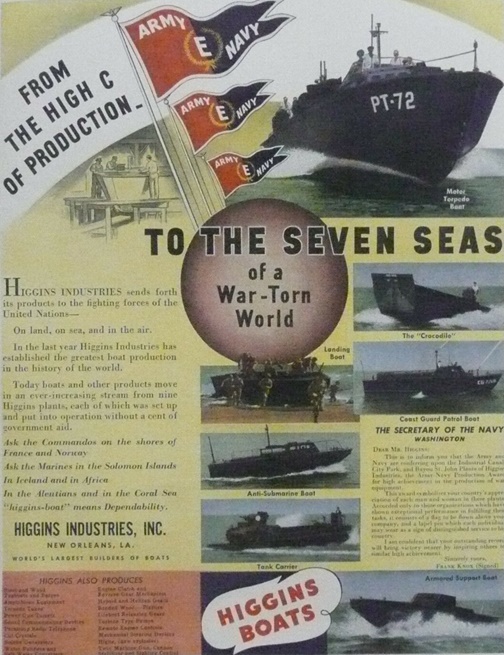

Higgins Industries won the Army-Navy Award

five times.

The award included the Industrial Canal, the City Park, and the Bayou

St. John Plants.

The celebration of the first "E" Award on

September 13, 1942 at the Industrial Canal Plant. An "E" is formed

by students from the Higgins Boat Operators School. The students

are all piloting LCP(L) landing craft.

Four stars on the Higgins Army-Navy "E"

Award Flag. A smiling Andrew Jackson Higgins stands among Navy

officers as his company is given its final "E" award on July 23,

1944. The flag was presented for the initial award. Then a

star was added each time the award was renewed. Not many companies

received so many stars.

Higgins Industries World War Two Production Statistics:

There is some confusion and misinformation regarding the

number of landing craft built by Higgins Industries during World War

Two. Please bear with me as we work through the analysis below.

Boats:

Higgins Industries is credited with building 20,094 total "boats" in

World War Two. This is based on the photo below.

Author's Note: Higgins Industries

did not build LSTs or Liberty Ships during World War Two.

Several inaccurate historical websites claim Higgins built these type

ships. There were plans for Higgins to build 100 Liberty Ships,

but this project was cancelled. The company built several

varieties of ships and boats as shown below.

The question arises. What does the "20,094th boat built by Higgins"

actually include? Some sources imply that these were Higgins-built

36-foot wooden landing craft (LCP(L), LCV, LCVP).

See Table 1 below. Production numbers

for LCP(L), LCP(R), LCV, and LCVP for most manufacturers are incomplete

or non-existent. Table 1 shows that Higgins Industries built

around 14,800 36-foot landing craft during World War Two. This was

49% of the total built. For more information Chris-Craft

production numbers, visit my Chris-Craft Page.

|

Table 1

36-foot Landing Craft built during World War Two |

|

Column A |

Column B |

Column C |

Column D |

Column E |

|

Type |

Higgins Production |

Known Production by Other

Manufacturers |

Columns B+C |

Total Production by all

Manufacturers by Year |

|

LCP(L) |

~1,100 |

Chris-Craft=1,200

Matthews Company=see subtotal below

Owens Yacht Company=see subtotal below

Richardson Boat=see subtotal below |

2,300 |

1941- 564

1942- 307

1943- 282

1944 - 547

1945 - 493

Total - 2,193 |

|

LCP(R) |

0 |

Chris-Craft=1,773

Matthews Company=see subtotal below

Richardson Boat=see subtotal below |

1,773 |

1942 - 1,563

1943 - 24

1944 -705

1945 - 339

Total - 2,631 |

|

LCV |

~1,200 |

Chris-Craft=1,425

Owens Yacht Company=see subtotal below |

2,645 |

1941- 110

1942 - 1,891

1943- 365

Total - 2,366 |

|

LCVP |

12,500 |

Chamberlain=?

Chris-Craft=8,602

Dodge Boat and Plane=74

Matthews Company=496

Owens Yacht Company=see subtotal below

Richardson Boat=604 |

21,176 |

1942- 215

1943- 8,027

1944 - 9,290

1945 - 5,826

Total - 23,358 |

|

Owens Yacht Co |

|

Owens Yacht Co=2,150 total LCP(L), LCV, LCVP |

2,150 |

|

| Richardson Boat

Company |

|

Richardson Boat

Company=~1,000 total LCP(L), LCV, 604 LCVP |

1,000 |

This number may well

include the LCMs that Richardson built. The Tonawanda

Heritage Center was not able be discern the difference between

Higgins boats and LCMs in photos. |

| Matthews Company

|

|

Matthews Company =~

2,555 total LCP(L), LCV, 496 LCVP |

2,555 |

At the end of the

war Matthews was producing two landing craft a day or 730 boats

per year. Over a three and a half year period this would be

2,555 landing craft of all types. This is the best

estimate for this company at this time. |

| Totals for 36-Foot

Wooden Landing Craft |

14,800 |

15,224 |

33,599 |

30,548 |

Column A

Type |

Column B

Higgins Production |

Column C

Known Production by Other Manufacturers |

Column D

Columns B+C |

Column E

Total Production by all Manufacturers by Year |

Calculation of the number

of Higgins-built LCVPs in World War Two - The figure 12,500 is the

number that is found on several sources for the total number of LCVPs

that Higgins Industries built during World War Two. Is this an

accurate number considering the lack of supporting data? I have

found it is by putting several pieces of data together and using

information from Table 1A below.

Method One:

-

July 1943 production of

LCVPs is 600 from "Higgins Biography." Total production of

LCVPs for July 1943 was 1,073 from Table 1A. Higgins was

building ~60% of the LCVPs. This is fairly correct based on the

fact that Chris-Craft was building around 40%. The number of LCVPs

built by the other four manufacturers were small and can be

ignored in this analysis.

-

July 1943 production of

1,072 LCVPs was a one-time event. Looking at the available

data of LCVPs built between August 1943 and May 1944 shows that an

average of 850 were being built per month. 8,499/10= 849.9

rounds up to 850. Assume Higgins continued to build 60% of

LCVPs. This is 510 units per month. Without doing the

calculations, I had estimated Higgins Industries was building around

500 a month.

-

October 1944 - 7,000th

LCVP built from "Higgins Biography."

-

There were still 10.5

months of production left until the end of World War Two in the

middle of September 1945.

-

Assume the same rate of

production of LCVPs of 850 total units until the end of the war.

-

510 Higgins LCVPs built

per month X 10.5 months = 5,355 LCVPs built in that time period.

-

7,000 + 5,355 = 12,355.

This is very close to the 12,500 given by other sources.

Higgins Industries built 53% of all of the LCVPs built during World

War Two.

Method Two:

-

Assume Higgins

Industries built 60% of the LCVPs during World War Two as noted in

Method One.

-

From Table 1A as of May

1944 12,354 LCVPs had been built. Another 11,004 remained to

be built. 23,358 total LCVPs built - 12, 354 built through May

1944 = 11,004 LCVPs left to be built.

-

11,004 X .6 (60%) =

6,602

-

7,000 + 6,602 = 13,602.

This is higher than the 12,500 given by other sources but still

within reason.

This has been a "sanity

check" to determine if the total 12,500 Higgins-built LCVPs given by

other sources has any logical basis. Yes, it does. It also

reconciles with the LCVP information in Table 1 that estimates 2,182

LCVPs (23,358-21,176 = 2,182) were built by Chamberlain, Matthews and

Richardson. Based on their total production, this reconciles rather

well.

|

Table 1A

Higgins Designed Landing Craft Monthly Production January

1942-May 1944 - All Manufacturers |

|

Month-Year |

LCM(3) and LCM(6) |

LCP(L) and LCV |

LCVP |

Totals for LCP(L) and LCV and LCVP |

Comments |

|

Jan-1942 |

18 |

116 |

0 |

|

|

|

Feb-1942 |

10 |

0 |

0 |

|

|

|

Mar-1942 |

0 |

117 |

0 |

|

|

|

Apr-1942 |

1 |

174 |

0 |

|

|

|

May-1942 |

27 |

248 |

0 |

|

|

|

Jun-1942 |

35 |

344 |

0 |

|

|

|

Jul-1942 |

118 |

480 |

0 |

|

|

|

Aug-1942 |

307 |

600 |

0 |

|

|

|

Sep-1942 |

131 |

477 |

0 |

|

|

|

Oct-1942 |

203 |

394 |

0 |

|

|

|

Nov-1942 |

244 |

466 |

75 |

|

|

|

Dec-1942 |

168 |

345 |

140 |

|

|

|

Totals 1942 |

1,262 |

3,761 |

215 |

3,976 |

|

| |

|

|

|

|

|

|

Jan-1943 |

114 |

37 |

205 |

|

|

|

Feb-1943 |

156 |

44 |

319 |

|

|

|

Mar-1943 |

406 |

18 |

655 |

|

|

|

Apr-1943 |

143 |

57 |

405 |

|

|

|

May-1943 |

236 |

0 |

416 |

|

|

|

Jun-1943 |

146 |

0 |

567 |

|

|

|

Jul-1943 |

244 |

0 |

1,073 |

|

|

|

Aug-1943 |

401 |

0 |

812 |

|

|

|

Sep-1943 |

502 |

0 |

943 |

|

|

|

Oct-1943 |

585 |

50 |

836 |

|

|

|

Nov-1943 |

563 |

50 |

921 |

|

|

|

Dec-1943 |

523 |

50 |

875 |

|

|

|

Totals 1943 |

4,019 |

306 |

8,027 |

8,333 |

|

| |

|

|

|

|

|

|

Jan-1944 |

578 |

50 |

833 |

|

|

|

Feb-1944 |

641 |

50 |

932 |

|

|

|

Mar-1944 |

594 |

50 |

811 |

|

|

|

Apr-1944 |

470 |

50 |

744 |

|

|

|

May-1944 |

487 |

50 |

792 |

|

|

|

Totals 1944 |

2,770 |

250 |

4,112 |

4,362 |

|

|

Grand Total |

8,051 |

4,317 |

12,354 |

16,671 |

Totals including 564 LCP(L)

built in 1941 and the 2,633 LCVs built from 1941-1943 totals

19,898 "Higgins" landing craft of all types. |

Link to:

10,000 "Higgins Boat" Ceremony, July 23, 1944

The page in the link above from The National World War Two Museum

shows an LCV as the 10,000th Higgins boat landing craft built on July

23, 1944. From the information in Table 1, there were no LCVs

built in 1944. Production stopped in 1943. The landing craft

in the photo can be identified as an LCV by the fact that the coxswain's

steering position was located on the stern deck above the cargo deck.

This was not the case for the LCVP, where the steering position was down

next to the engine.

Table 2

Various Boats built by Higgins Industries for the U.S.

Army during World War Two |

|

Type |

Designation |

Number built |

Dates built |

Comments |

| 170

and 180-foot Steel FS Coastal Freighters |

FS-135 to FS-234 |

100 |

9-43

to 3-45 |

575

Tons |

| J

Boats |

J |

335 |

4-41

to 6-44 |

These

came in three lengths: 27, 36 and 37 feet. Uses:

Shallow-Draft, Patrol, Utility and Fireboat |

|

36-foot CL Landing Boats |

CL-1

to Cl-130 |

130 |

1-41

to 4-43 |

|

|

Barges |

BSP

395, BK 101-400, TKL-9, BK |

316 |

5-42

to 5-45 |

These

came in four lengths: 53, 63, 50 and 80 feet. Uses:

Balloon, Tank, and Knock-Down |

|

Small Tugs |

ST 204-213 |

10 |

3-43 to 6-43 |

|

|

Various small boats |

Various |

18 |

1941 to 1944 |

33 to 53 feet long |

|

Total |

|

909 |

|

|

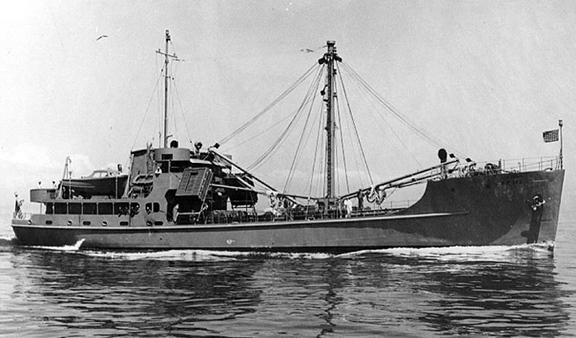

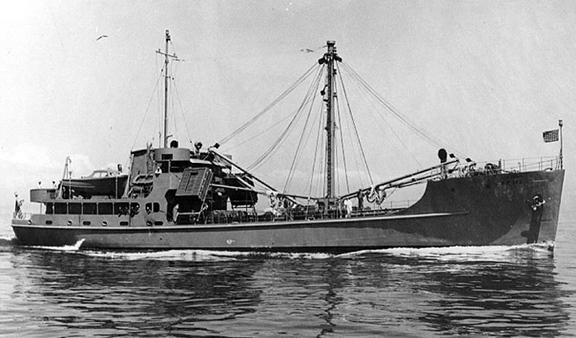

Higgins Industries built 100 170/180-foot coastal freighters like

this one for the U.S. Army. In the southwest Pacific the Army

had its own navy.

|

Table 3

Higgins World War Two PT Boat Production by Month January

1941 - October 1945

Below is a tabulation

of the 216 PT boats built by Higgins Industries during World

War Two. |

|

Month-Year |

Number built |

PT- Number |

Length |

Comments |

|

Jan-1941 |

1 |

6(1) |

81-foot Prototype |

Built at the St. Charles Avenue Plant. |

|

Feb-1941 |

1 |

6(2) |

81-foot Prototype |

Built at the St. Charles Avenue Plant. |

|

Mar-1941 |

1 |

5 |

81-foot Prototype |

Built at the St. Charles Avenue Plant. |

|

Sep-1941 |

1 |

70 |

72-foot Prototype |

Built at the St. Charles Avenue Plant. |

|

Unknown |

1 |

7

(See Note Below) |

81-foot Prototype |

Built at the St. Charles Avenue Plant. |

|

Unknown |

1 |

8

(See Note Below) |

81-foot Prototype |

Built at the St. Charles Avenue Plant. |

|

Total 1941 |

6 |

|

|

|

| |

|

|

|

|

|

Jul-1942 |

2 |

71, 72 |

78-foot Production |

Production begins at the City Park Plant |

|

Aug-1942 |

4 |

73,

74,75,76 |

78-foot Production |

|

|

Sep-1942 |

4 |

77, 78, 79, 80 |

78-foot Production |

|

|

Dec-1942 |

13 |

82, 83, 84, 85, 86, 87, 88, 89, 90, 91, 92, 93, 94 |

78-foot Production |

PT-88, 90-93 served with Royal Navy in the Mediterranean at

MTB 419-423. |

|

Total 1942 |

23 |

|

|

|

| |

|

|

|

|

|

Jan-1943 |

11 |

81, 197, 198, 199, 200, 201, 202, 203, 204, 205, 206 |

78-foot Production |

|

|

Feb-1943 |

10 |

207, 208, 209, 210, 211, 212, 213, 214, 215, 216 |

78-foot Production |

|

|

Mar-1943 |

16 |

217, 218, 219, 220, 221, 222, 223, 224, 225, 226, 227, 228,

229, 230, 231, 232 |

78-foot Production |

|

|

Apr-1943 |

8 |

233, 234, 235, 236, 237, 238, 239, 240 |

78-foot Production |

|

|

May-1943 |

11 |

241, 242, 243, 244, 245, 246, 247, 248, 249, 250, 251 |

78-foot Production |

|

|

Jun-1943 |

6 |

252, 253, 254, 279, 280, 564* |

78-foot Production |

*PT-564 70-foot Hellcat Prototype |

|

Jul-1943 |

10 |

277, 278, 281, 282, 283, 284, 285, 286, 287, 288 |

78-foot Production |

|

|

Aug-1943 |

9 |

265, 266, 267, 268, 269, 270, 271, 289, 290 |

78-foot Production |

|

|

Sep-1943 |

9 |

272, 273, 274, 275, 276, 291, 292, 293, 294 |

78-foot Production |

|

|

Oct-1943 |

6 |

295, 296, 297, 298, 299, 300 |

78-foot Production |

|

|

Nov-1943 |

4 |

301, 302, 303, 304 |

78-foot Production |

|

|

Dec-1943 |

3 |

305, 306, 307 |

78-foot Production |

|

|

Total 1943 |

103 |

|

|

|

| |

|

|

|

|

|

Jan-1944 |

6 |

308, 309, 310, 311, 312, 313 |

78-foot Production |

|

|

Feb-1944 |

5 |

450, 451, 452, 454, 455, |

78-foot Production |

|

|

Mar-1944 |

8 |

453, 456, 457, 458, 459, 460, 461, 462 |

78-foot Production |

|

|

Apr-1944 |

8 |

463, 464, 465, 466, 467, 468, 469, 470 |

78-foot Production |

|

|

May-1944 |

3 |

471, 472, 473 |

78-foot Production |

|

|

Jun-1944 |

4 |

474, 475, 476, 478, |

78-foot Production |

|

|

Jul-1944- |

4 |

477, 479, 480, 481, |

78-foot Production |

|

|

Aug-1944 |

4 |

482, 483, 484, 485 |

78-foot Production |

|

|

Dec-1944 |

2 |

625, 626 |

78-foot Production |

|

|

Total 1944 |

44 |

|

|

|

| |

|

|

78-foot Production |

|

|

Jan-1945 |

3 |

627, 628, 629 |

78-foot Production |

|

|

Feb-1945 |

2 |

630, 631 |

78-foot Production |

|

|

Mar-1945 |

5 |

632, 633, 634, 635, 636 |

78-foot Production |

|

|

Apr-1945 |

6 |

637, 638, 639, 640, 641, 642 |

78-foot Production |

|

|

May-1945 |

7 |

643, 644, 645, 646, 647, 648,

649 |

78-foot Production |

|

|

Jun-1945 |

4 |

650, 651, 652, 653 |

78-foot Production |

|

|

Jul-1945 |

5 |

654, 655, 656, 657, 658 |

78-foot Production |

|

|

Aug-1945 |

2 |

659, 660 |

78-foot Production |

|

|

Sep-1945 |

2 |

791, 792 |

78-foot Production |

|

|

Oct-1945 |

4 |

793, 794, 795, 796 |

78-foot Production |

|

|

Total 1945 |

40 |

|

|

|

|

Grand Total |

216 |

|

|

|

Additional Author's

Note: Most historical PT sources state 199 or 209 Higgins

PT boats built. I do not know how the 199 was derived.

I have never seen the data as to how 199 was derived. For the

209, the sources use the same information provided in Table 3 minus

PT-7 and PT-8, which are only documented on this website.

Therefore, the total number should be 214, not 209. The

original author who did the work made a mathematical error.

Then all the persons who followed who used the table above, copied

the information without checking the addition for correctness,

and continued to propagate the error over and over again.

|

Table 3A

Higgins World War Two PT, MTB, and MGB Production for

foreign countries during World War Two

|

|

Type |

Month-Year |

Number built |

Designation |

Length |

Comments |

| Dutch

Anti-Submarine |

1941 |

6 |

OJR 1-6 |

70 foot |

These six

boats arrived in the Dutch East Indies between December 16,

1941, and March 2, 1942. All were either scuttled or

lost in a gasoline explosion during the Japanese invasion.

Either OJR-1 or OJR-4 was raised by the Japanese and

commissioned August 4, 1943 as Auxiliary Submarine Chaser

101. It was sunk by American forces on April 8, 1945.

So for two years a Higgins built boat was fighting for the

Japanese. |

| Dutch

Anti-Submarine |

1942 |

2 |

H 7-8 |

70 foot |

These two

craft arrived in the Dutch West Indies on August 26,1942 and

served on anti-submarine patrol. Both boats were

stricken in early 1946.

Photos of these two boats are

shown below. |

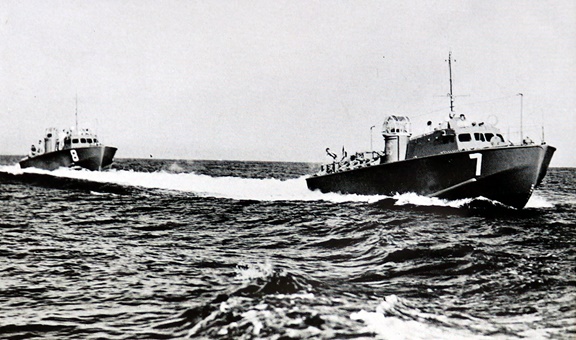

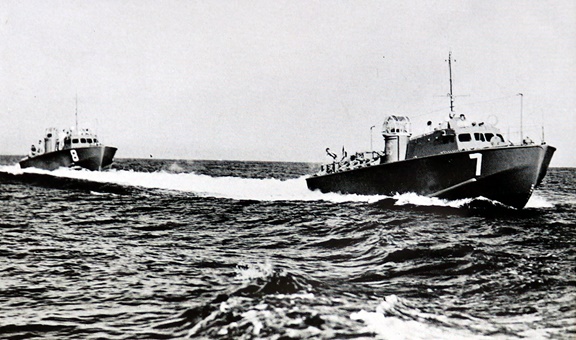

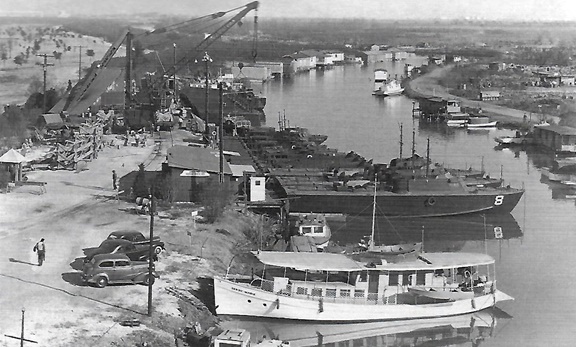

Note the number 8 and the Dutch flag on

the stern of the boat. H-8 was a 70-foot anti-submarine boat

armed with 16 depth charges and four .50 caliber machine guns in the

two turrets. It was used by Dutch forces in the Caribbean

after August 1942. Photo added 5-22-2019.

H-7 and H-8 running together.

H-8 is clearly visible at Bayou St.

John in this photo. H-7 looks to be moored behind H-8.

Both boats were delivered to the Dutch in the Caribbean in August

1942. This photo was taken at Bayou St. John earlier in the

year.

PT-72 was laid down on March 2, 1942,

launched on July 6, 1942, and completed on July 23, 1942. PT-72

served throughout World War Two with combat duty in the Aleutians.

Then from May 1944 to October 1944 it was part of MTBRon 2(2) which was

assigned to the OSS for special operations in the English Channel.

Table 4

Pre-1942 landing boat orders documented in the "Higgins

Biography" not comprehended in the above tables |

| Date |

Number |

Type |

Customer |

| Oct 1940 |

138 |

Eurekas |

British |

| Nov 1940 |

335 |

Eurekas

with a flatter bottom design |

US Navy |

|

Total |

473 |

|

|

|

Table 5

Total of all Types of Boats built by Higgins Industries in World

War Two |

|

Type |

Number built |

| 36-Foot Landing

Craft - Table 1 |

14,800 |

| Various Types of

Boats- Table 2 |

909 |

| PT Boats- Table

3 |

216 |

| Landing Craft,

Mechanized - |

1,400 |

| LCS(S) Total

built, may not all be Higgins |

558 |

| RAF Air-Sea

Rescue Boats. Higgins built "hundreds." Estimated

at 300 |

300 |

| B-17 life boats -

Estimated at 100 |

100 |

| Pre-1942 Landing

Boat Orders |

473 |

|

Totals |

18,756 |

Summary: My

calculations and estimates for the total number of boats built by

Higgins Industries in World War Two is 18,756. This is 1,338 short

of the 20,094 painted on the side of the boat at the beginning of this

section. In reference to the estimated 300 RAF Air-Sea Rescue

boats, the "Higgins Biography" states Higgins built "hundreds." I

have not been able to verify that with any other documentation

concerning RAF boats of this type. The "Higgins Biography" makes

several references to the production of the LCS (Landing

Craft, Support) boat. There were two types of LCS built during

World War Two. The LCS(L) (Landing Craft, Support, Large) was

built by several shipyards, and Higgins was not one of them.

However, the Landing Craft, Support, Small (LCS(S) was a small wooden

boat of similar size to the landing craft that Higgins was building.

I think the rocket boat and LCS referred to in the "Higgins Biography"

were actually one and the same LCS(S). I assumed that all of

the 558 LCS(S) types were built by Higgins.

-83w-1.jpg)

The "Higgins Biography" mentions rocket

boats twice and LCS several times. They are one and the same.

Higgins built the LCS(S) in both Houma and New Orleans,

LA. The 36-foot boat was armed with rocket launchers on each side

of the cockpit. A total of 558 of these are documented as having

been built during World War Two. These appear to have been built

off of the Eureka design, as they are the same length and have the blunt

nose of the LCP(L) designed by Higgins. The advertisement at the

bottom of the page best shows the blunt nose of the craft.

rocket-52w-1.jpg)

In its wartime advertisements, Higgins

Industries show photos of the Coast Guard 38-foot picket boat as being

built during the war. It is unknown how many were built by

Higgins.

Other products built by

Higgins Industries in World War Two: Higgins has been

identified as building the following products in "History in a Hurry -

The Story of Higgins of New Orleans." While these products are

listed to show the company's diversification, for all intents and

purposes, Higgins Industries built boats. 20,094 of them during

World War Two. Several of the products listed below, like the

torpedo tubes and gun turrets, were for internal use on its PT boats.

Other products, like the marine engines and aircraft, were not built in

significant numbers. Two products that were built in significant numbers were the

air-dropped life boat and carbon parts for the Manhattan Project.

Products: Torpedo tubes, power gun turrets for PT boats, sound communicating

devices, paratroop radio telephones, frequency crystals, smoke

generators, water purifiers and salt water converters, engine clutch and

reverse gear mechanisms, hypoid and helical gears, plastic bonded wood

products, life boat releasing gears, turbine type pumps, remote engine

controls, mechanical steering devices, twin-machine gun turrets, cannon

stabilizer and sighting controls, marine engines. (1) C-46,

300 A-1 lifeboats, carbon parts for the Manhattan Project.

Tucker Aviation: Higgins purchased the Tucker

Aviation of Ypsilanti, MI in March 1942, and formed Higgins-Tucker

Aviation to

build engines and gun turrets for PT boats and for landing craft.

Many of the products listed above, besides the gun turrets, may have also

come along with the purchase. Tucker Aviation had $250 million in

military contracts when it was purchased. At the end of the war,

several marine engines had been tested and were production ready.

The war was over, and the shortage of Packard engines for the PT boats

never materialized.

C-46 Commando:

Higgins Aviation was contracted to build 500 Curtiss C-46 Commandos at the aircraft

assembly plant in Michoud. These were serial numbers 43-43339

through 43-43338. By the time Higgins was ready to build

the C-46, the faster than expected progression of the war in the Pacific

reduced the need for the aircraft. The contract with Higgins was

cancelled, with only two C-46s produced at Michoud. These were

43-43339 and 43-43340. This was the

second aircraft contract cancelled on Higgins. The first was for 1,200

Curtiss C-76 Caravan wood construction transports. Beginning in October 1943,

Higgins Aircraft started building wing

assemblies for the C-46 which were shipped to the Curtiss C-46 assembly

plants in Louisville, KY and St. Louis, MO. Author's Photo.

This is one of the two Higgins-built C-46s and has

final work being performed on it at the Michoud

aircraft plant.

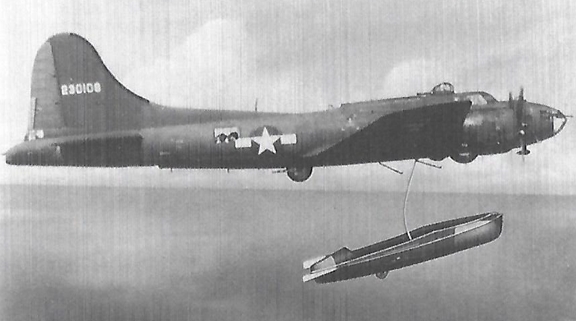

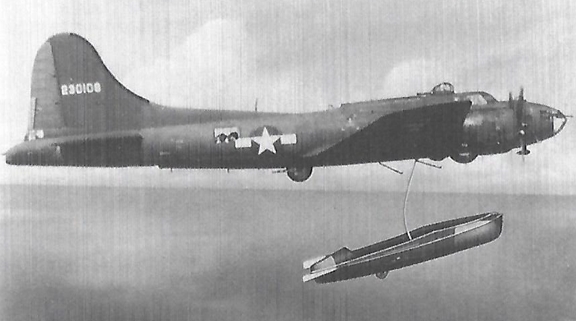

Higgins A-1 Air Droppable Lifeboat:

Design work began in November 1943. By the spring of 1944, the A-1 was

in production. The original order was for 600 A-1s; but the order

was changed and 300 were built. Higgins Plastic Company produced the 27-foot long

3,300-pound boat out of laminated mahogany at the Michoud Plant.

It contained 20 internal waterproof compartments that would keep the

vessel afloat even if it tipped over. Included in the supplies for

the A-1 was a Gibson Girl survival radio and enough food and water to

last twelve survivors twenty days. Equipped with two air-cooled

gasoline powered engines, it had a range 1,500 miles running at eight

knots. There was also a small, simple sail that could be used if

needed. Its design allowed it to be dropped with three parachutes

from a B-17 still equipped with a ball turret. When the A-1 hit

the water, small rockets would fire and pull lifelines out from the boat. The A-1 was

replaced by the A-3 in 1947.

There was also an 18-foot version of the A-1

to be dropped by a U.S. Coast Guard PBY Catalina. It could hold no

more than eight persons.

The Higgins A-1 lifeboat attached to a

SB-17G.

The Higgins A-1 lifeboat during a drop test

from a B-17 that still had the ball turret installed. This allowed

the A-1 to be dropped by any operational B-17.

An A-1 under sail. With waterproof

compartments, even if it was swamped and turned over, it would stay

afloat. For a B-29 crew that had to ditch in rough waters off the coast of Japan on May 29, 1945, this was a life saver. After

ditching, the B-29's crew was only able to find a five-man and one-man

life raft from the B-29, which failed immediately. A B-17 found their location

and dropped a Higgins A-1 attached to three parachutes. They swam

to the A-1 and found dry clothes, blankets and other gear.

However, as the seas turned rougher, the A-1 was swamped and turned

over. It stayed afloat and the crew was able to survive by

hanging onto the straps attached to the side of the A-1. Sixteen

hours later, the crew was rescued by a submarine. When Andrew

Higgins visited Guam at the end of the war, the crew wanted to thank him

personally for being saved by his lifeboat. Unfortunately, he was

unaware of this, and did not learn about their situation until he

returned home.

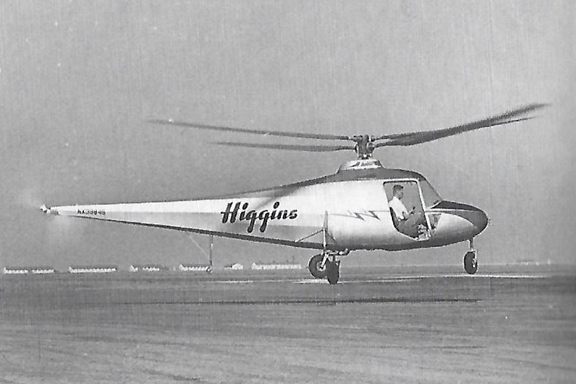

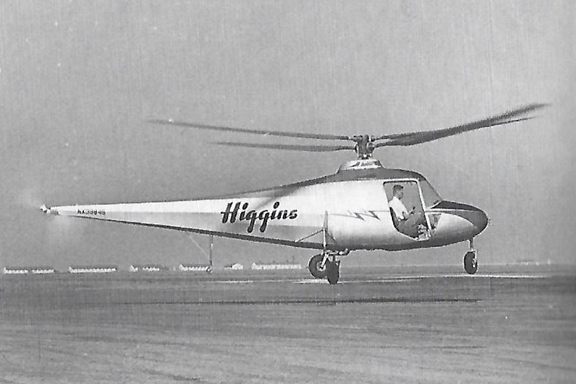

Helicopters:

Higgins aviation also built two experimental helicopters during World

War Two. Andrew Higgins ceased work on the project after a pilot

was killed while testing

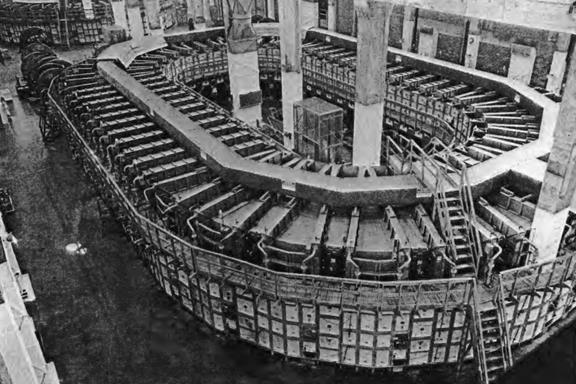

Manhattan Project Carbon Parts:

In August 1944 Andrew Jackson

Higgins was

invited to the White House for a meeting with President Franklin D.

Roosevelt. During the meeting, the President told Higgins that a

very important military project was having difficulty obtaining a

reliable supplier. For seven months, other suppliers had failed to

deliver the product to specifications. The President requested

Higgins Industries become involved in "the most vital project of the

war." The project was carbon parts for the Manhattan Project,

although Higgins and his employees were told they were parts for radio

and radar communication for security reasons. Until the Little Boy bomb

was dropped on Hiroshima in August 1945, the 2,500

employees making the carbon parts at Michoud were unaware of the

importance of their work.

Higgins Industries did not make anything

that went in the weapon itself. Instead, the carbon parts were

used in the equipment to separate the fissionable U-235 from U-238.

This replica of the Little Boy bomb that was dropped on Hiroshima needed

132 pounds of U-235. Author's photo.

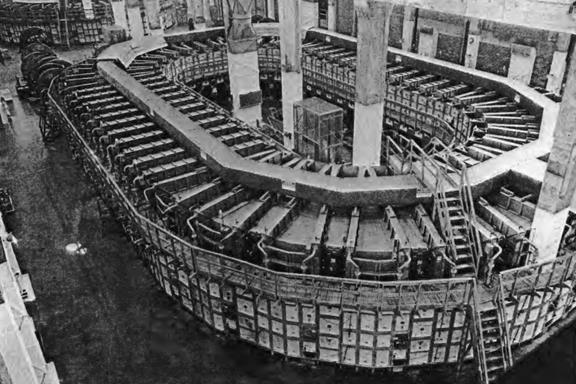

This is one of the many electromagnetic

racetrack separation machines in the Y-12 plant at Oak Ridge, TN.

Higgins' 2,500 employees at Michoud worked ten hours a day, six days a

week to keep up with the increasing demand for the carbon parts as the

Y-12 plant expanded and brought new machines online. Over the

1944-45 holidays, the Michoud employees worked Christmas and New Year's

days.

Higgins Plastics:

Truck Remanufacturing:

The remanufacture of the trucks was done in the Michoud plant.

Table 6 - Higgins

Plastics Incorporated Remanufactured Trucks

Accepted by Detroit Ordnance, US Army

The information below comes from "Summary Report of

Acceptances, Tank-Automotive Material, 1940-1945."

Published by Army Services Forces, Office, Chief of

Ordnance-Detroit, Production Division, Requirements and

Progress Branch,

January 21, 1946. |

|

Type Truck |

1944 |

1945 |

Total |

| 1/4-ton 4x4

Command |

170 |

1,680 |

1,850 |

| 2-1/2-ton

6x6 LWB w/w |

|

187 |

187 |

| 2-1/2-ton 6x6 SWB

w/w |

|

17 |

17 |

| 2-1/2-ton 6x6 SWB

wo/w |

|

37 |

37 |

|

Total |

170 |

1,921 |

2,091 |

Among the 2,091 trucks that Higgins Plastics remanufactured, 187

were 2-1/2-ton 6x6 long bed GMC-353s with winches. Author's Photo.

PT Boat Gun Turrets: Higgins

made a number of PT boat turrets.

This PT boat gun turret is on display at the Indiana Military Museum

in Vincennes, IN. I was not able to find any manufacturer's

identification on it. Higgins may have built it. If not, the

Higgins-built units were very similar to this. Author's Photo.

Author's Photo.

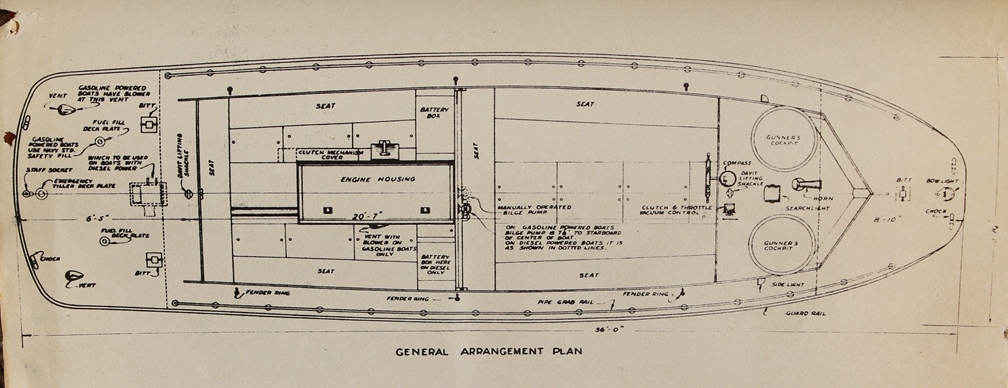

Landing Craft Personnel, Large (LCP(L)) -

The Eureka Boat - Andrew Jackson Higgins applied for a patent on

December 24, 1937 for the design of the hull of what became known as the Eureka Boat. This same hull design then carried over

to the later landing craft designed by Higgins and Higgins Industries.

It was patented on January 17, 1939 with US Patent Number 2,114,111.

This was also referred to as the Eureka Boat as it was based on an

experimental boat by Higgins with this name. Unfortunately, the

term Eureka was sometimes used as a generic term for the other three

landing craft Higgins designed using this patented hull configuration.

This makes it difficult to understand exactly which landing craft is

being referenced.

US Patent Number

2,114,111

Shown here is the only known restored

surviving Higgins-built LCP(L). It is on display at the National

Museum of World War Two in New Orleans, LA, and was built five miles

away at the former Higgins City Park Plant in October 1944. The

date of manufacturer of October 1944 may seem strange. By this point

in the war the LCVP was the desired

landing craft with the big ramp on the front for easy troop egress.

However, there was still a demand for a good solid work boat that could navigate shallow waters and

carry four tons of cargo or 25 troops. That kept the LCP(L) in production to

the end of war. In the Pacific during invasions the LCP(L)s were

used as control boats by the navy.

According to the "Higgins Biography," the

U.S. Navy changed the design of the hull when they accepted the boat.

This example has a flatter bottom front section than the V-shaped Eurekas

that Higgins was selling to the British. In U.S. Navy tests, the

flatter front section allowed for faster retraction from the beach while

still meeting the Navy's speed requirement. Author's Photo.

Author's Photo.

There is a hole in the rudder, so when

it is turned 90 degrees, the propeller shaft can be pulled out after the

propeller is removed. Author's photo.

Author's Photo.

According to a Higgins engineering drawing

in the December 1941 Operators Manual, Eureka landing boat, the LCP(L)s

of that era were built with rounded stern chines. The design

changed as the war progressed. Author's Photo.

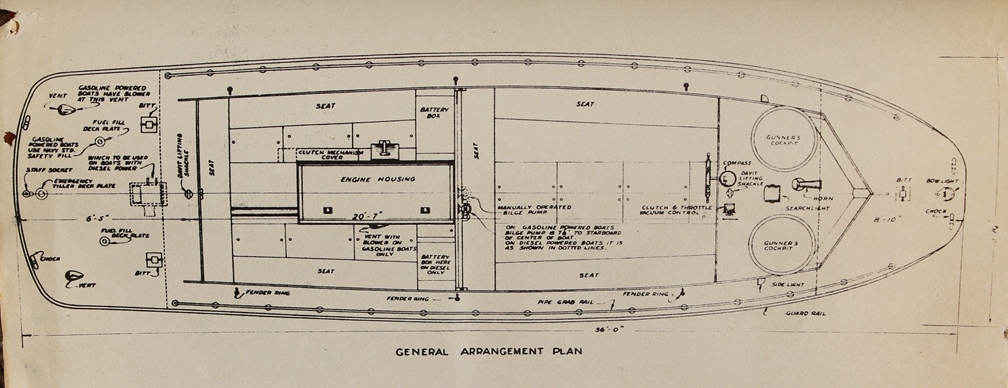

Note the location of the coxswain's steering

station and the two gun tubs for mounting self-defense machine guns.

Note also that the 25 armed troops the craft could carry were in two

different sections of the boat. Author's Photo.

This photo from "History in a Hurry" shows

that the LCP(L) could get the troops up on the beach, but they still had

to jump over the gunwales to exit the boat.

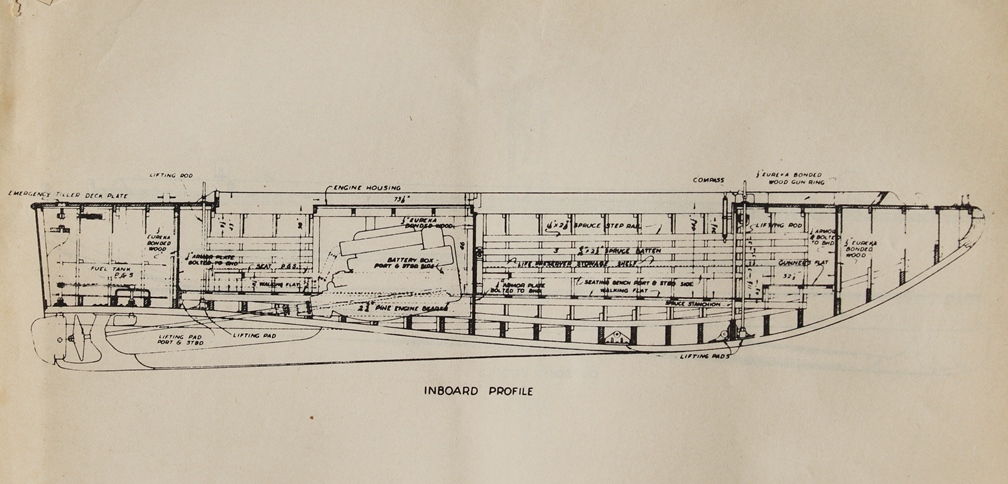

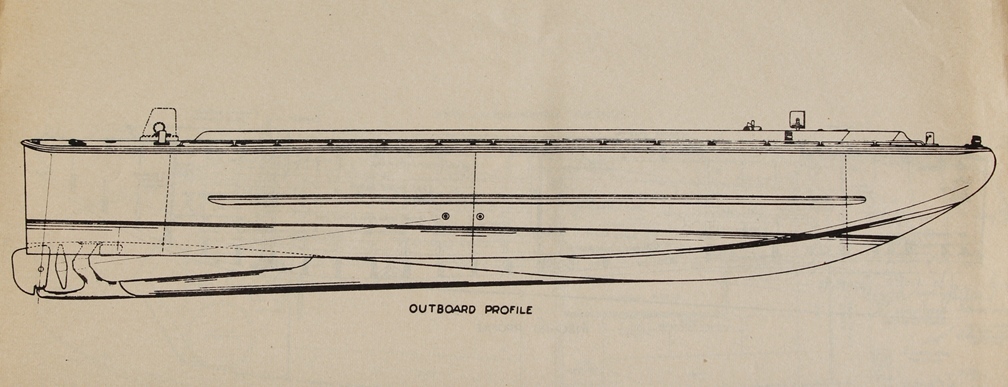

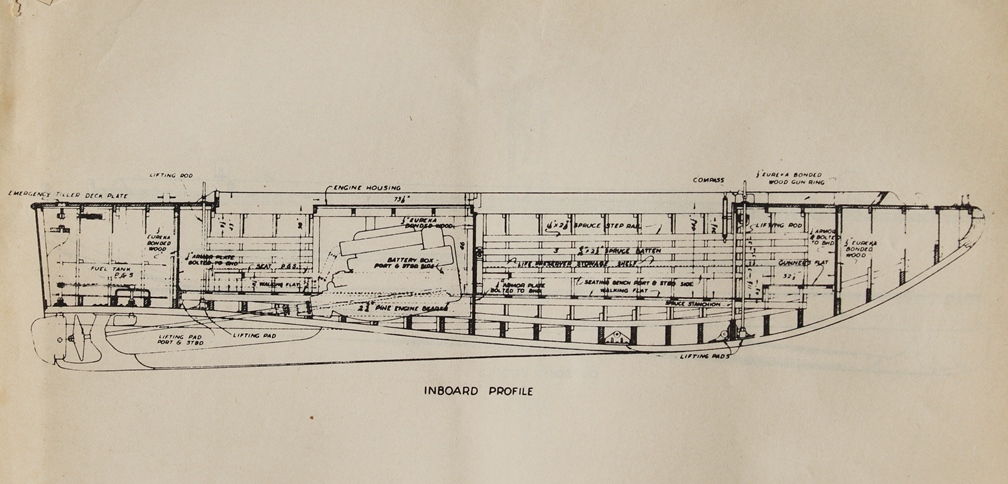

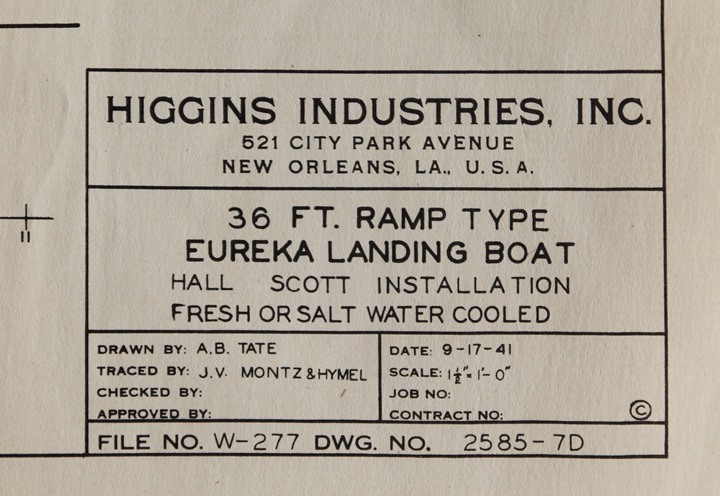

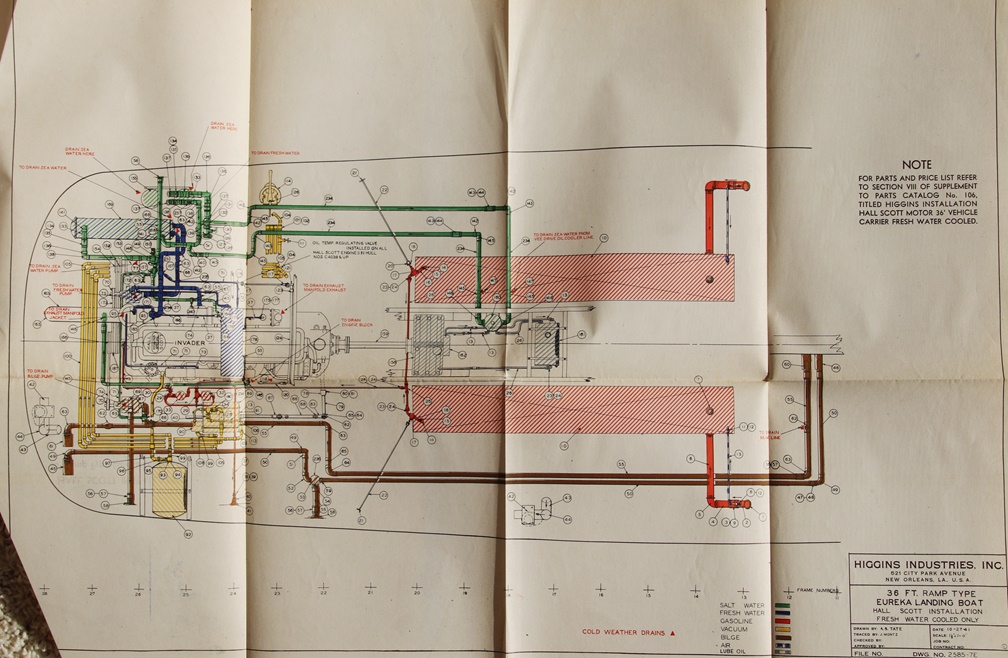

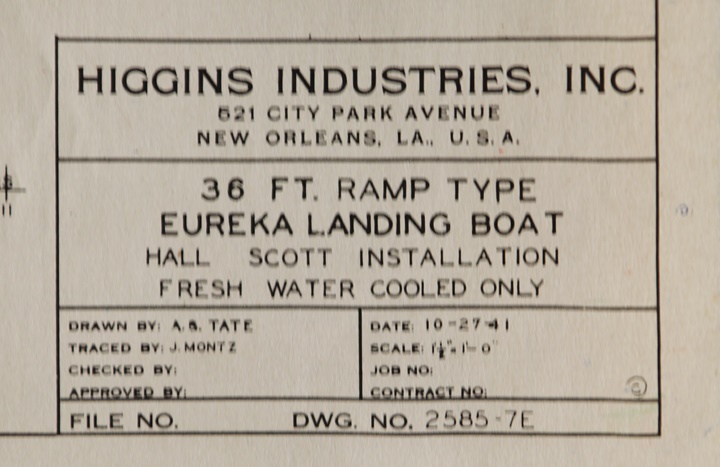

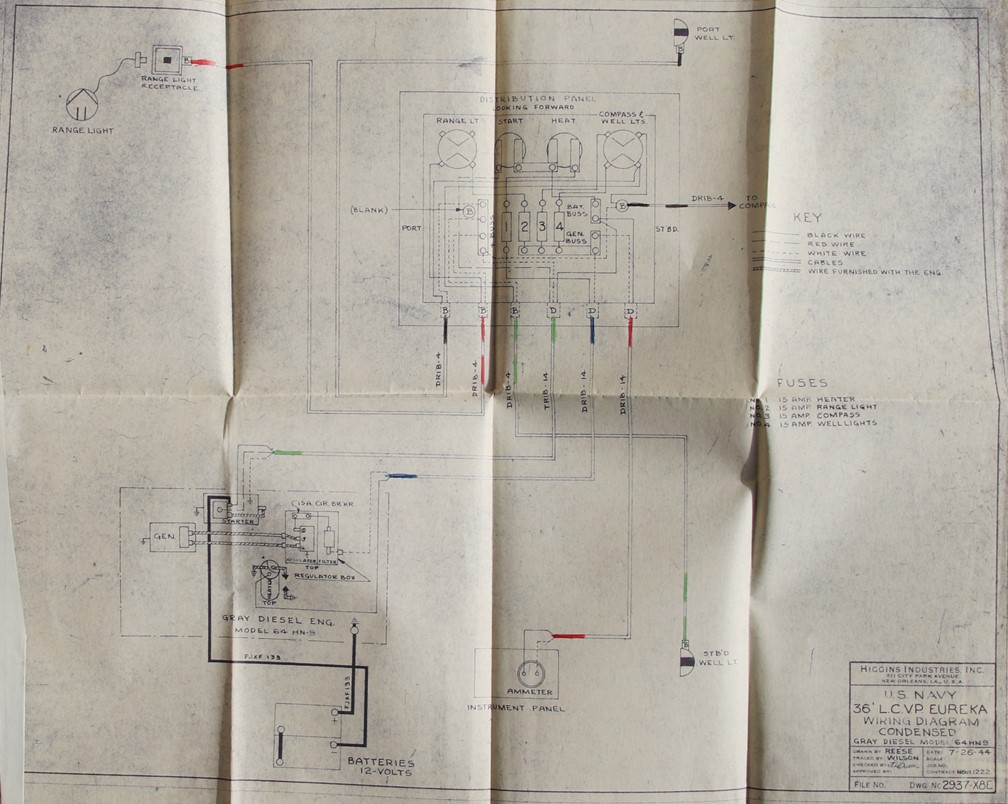

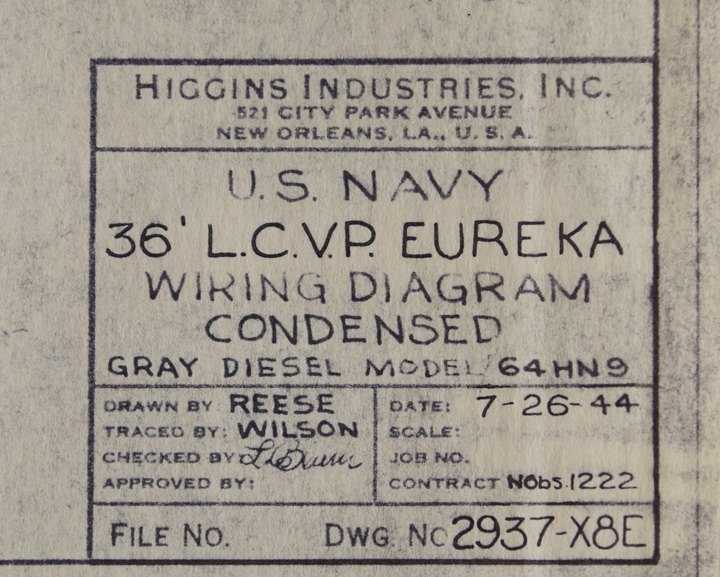

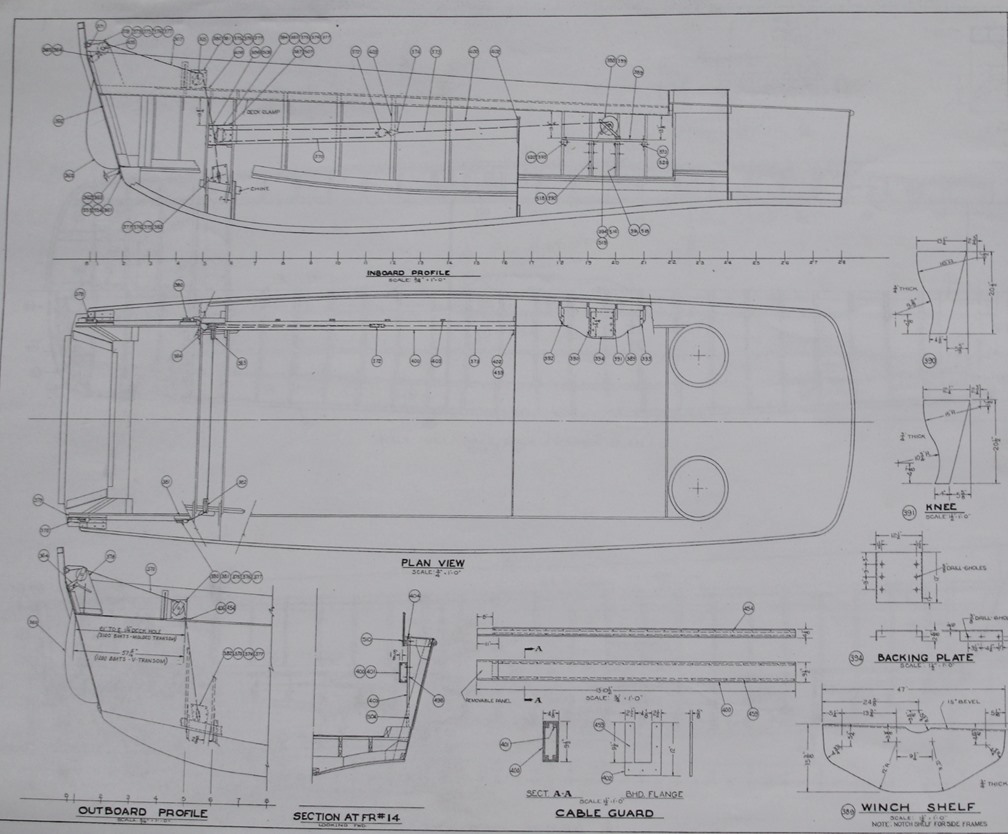

The following engineering drawings are from

the "Operators Manual, 36-foot "Eureka" Landing Motor Boats," Revised

June 1944 by Higgins Industries.

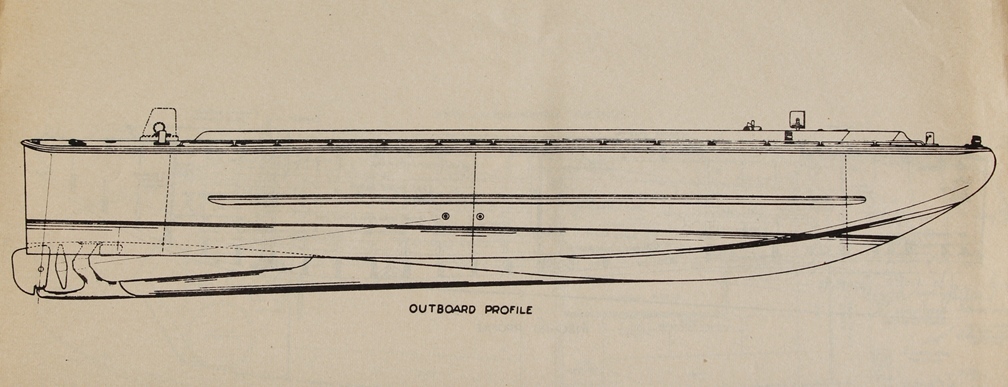

This undated drawing shows the LCP(L) with

the rounded aft chines. The early LCP(L)s and LCVs came with the

rounded chines. At some point in the war Higgins went to the hard

chines. Drawing added 2-15-2020.

Drawing added 2-15-2020.

Drawing added 2-15-2020.

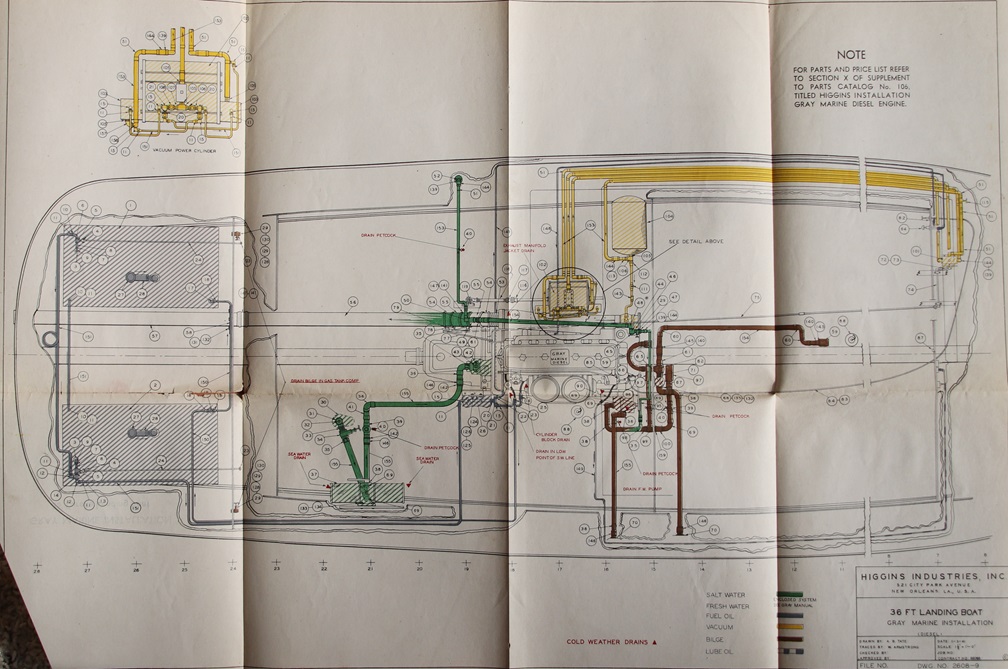

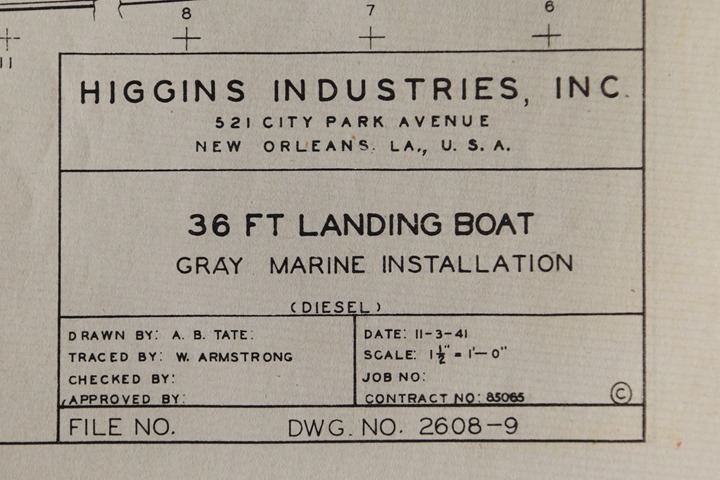

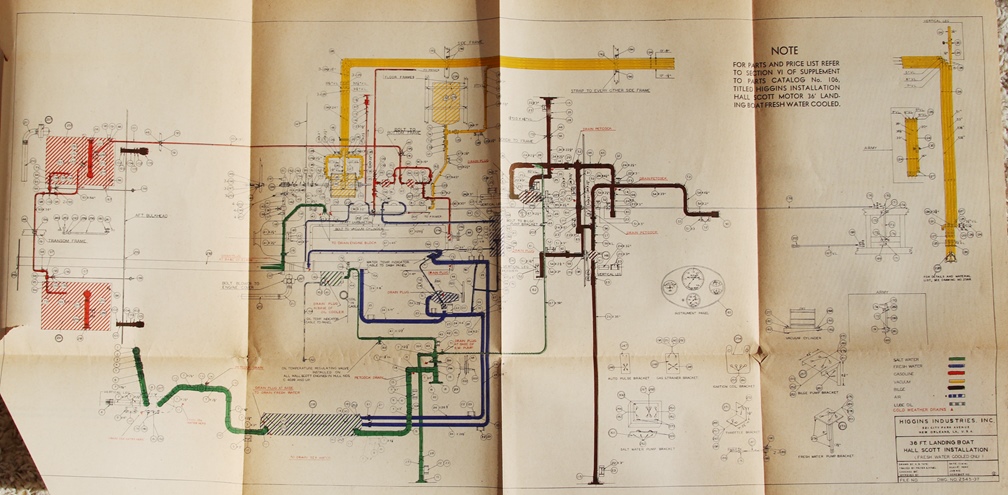

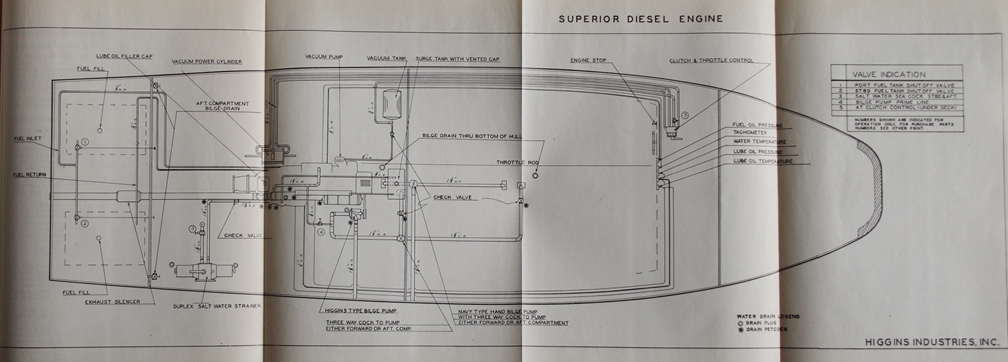

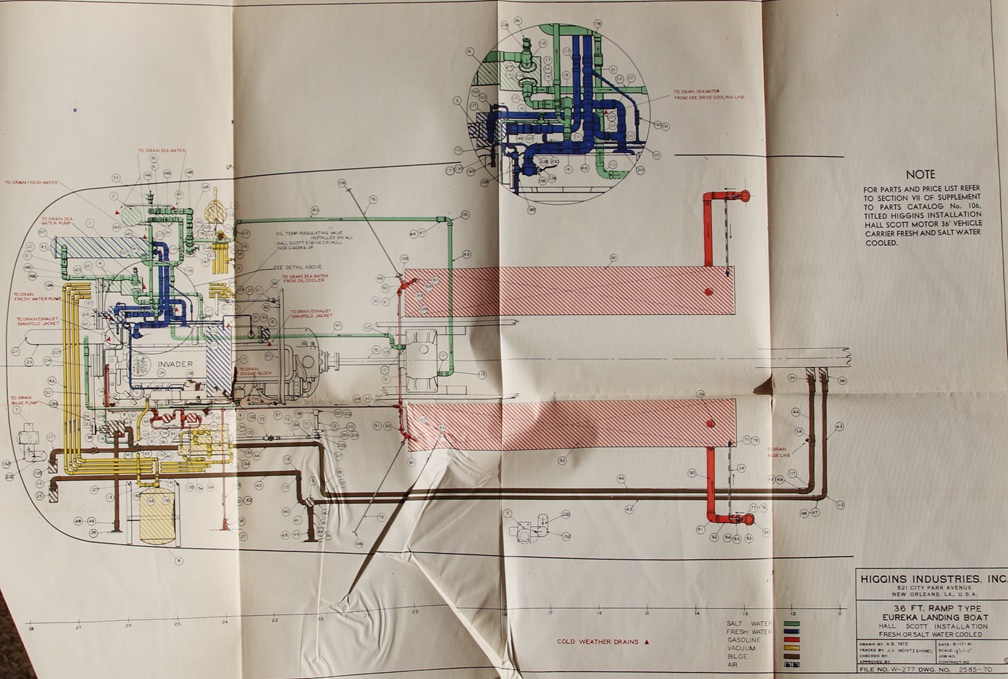

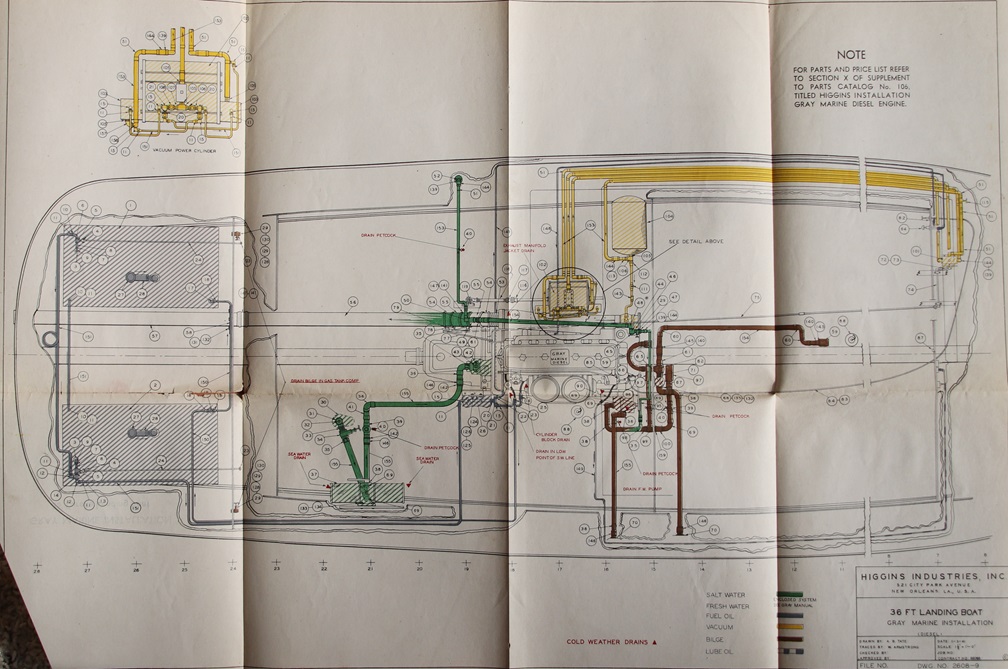

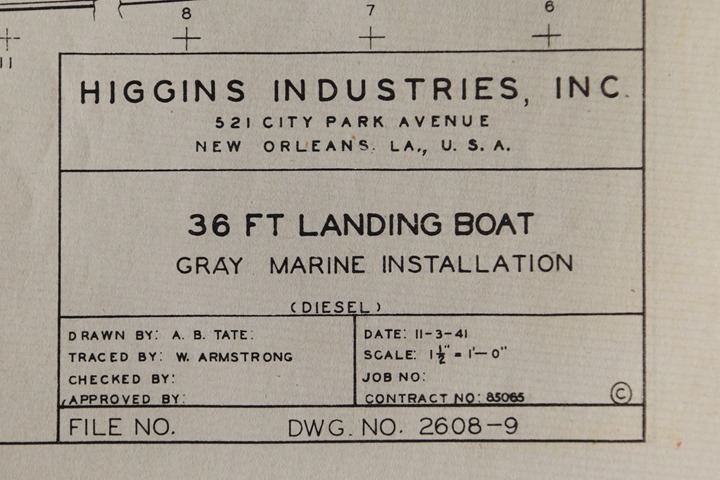

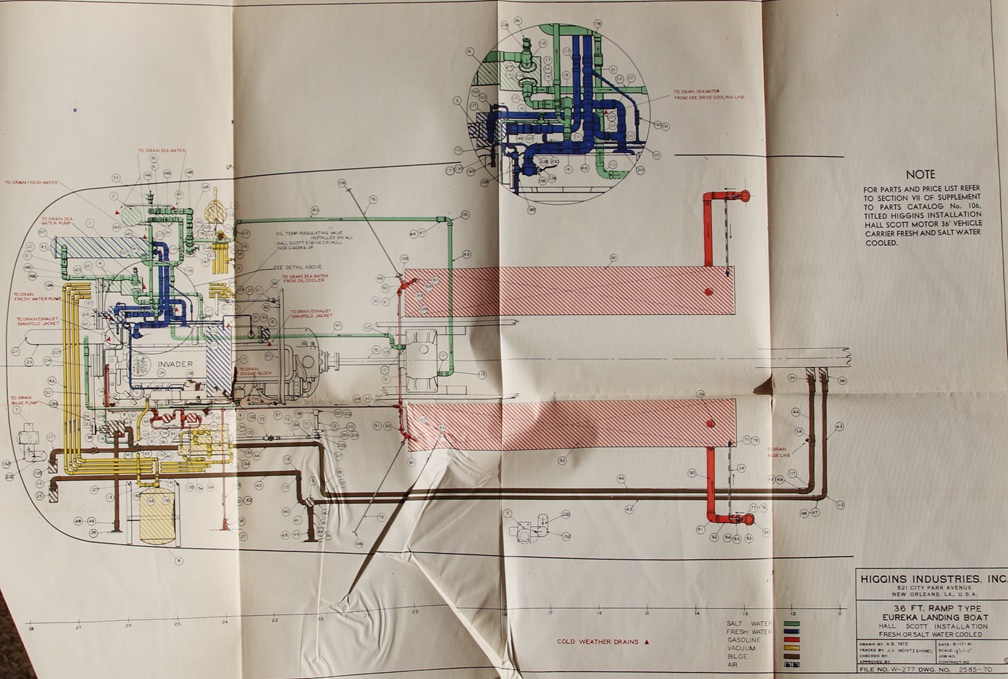

This drawing dated 11-3-1941 shows the

plumbing for a Gray/Detroit Diesel engine installation for the LCP(L).

It has the rounded chines. Drawing added 2-15-2020.

Drawing added 2-15-2020.

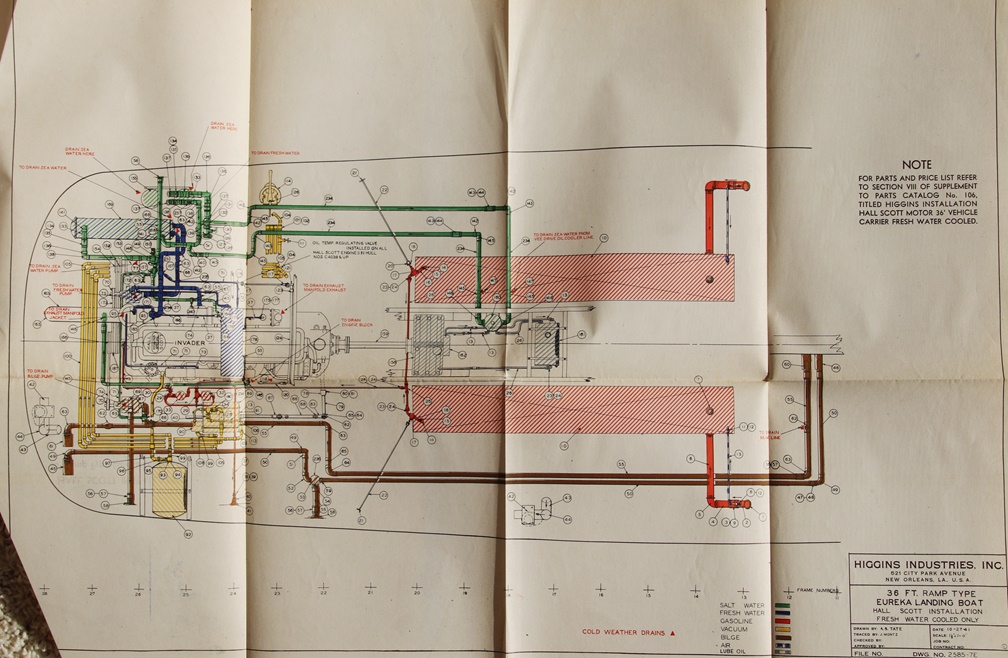

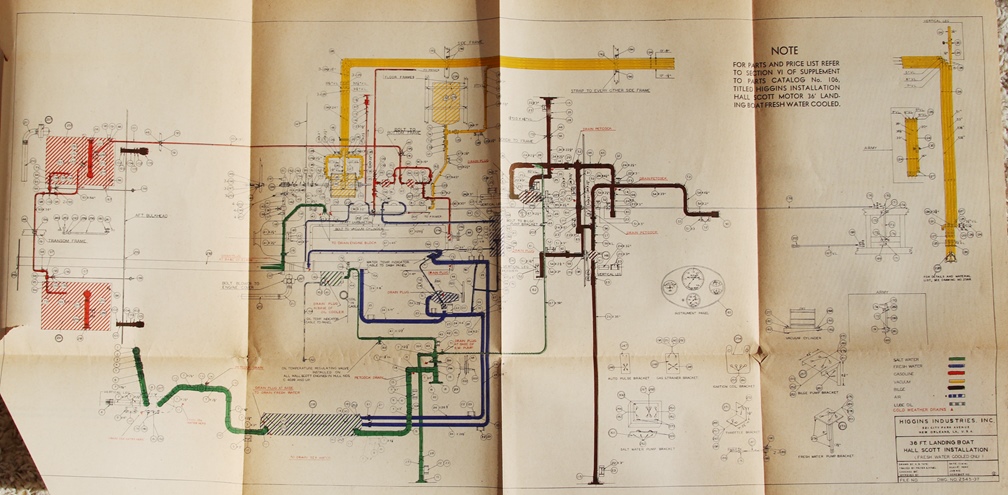

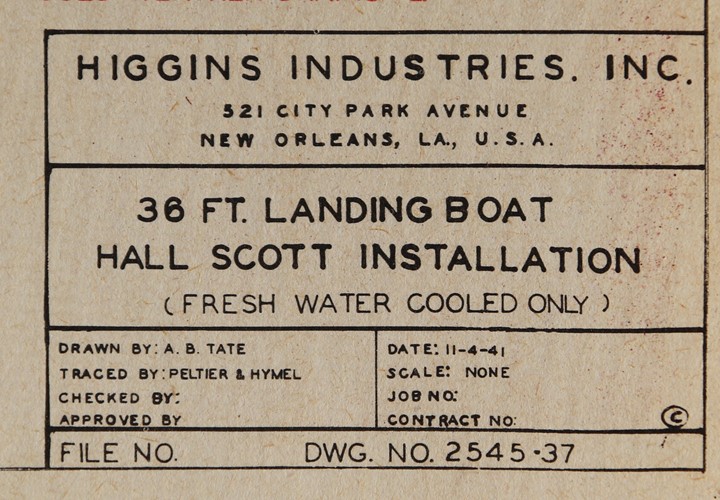

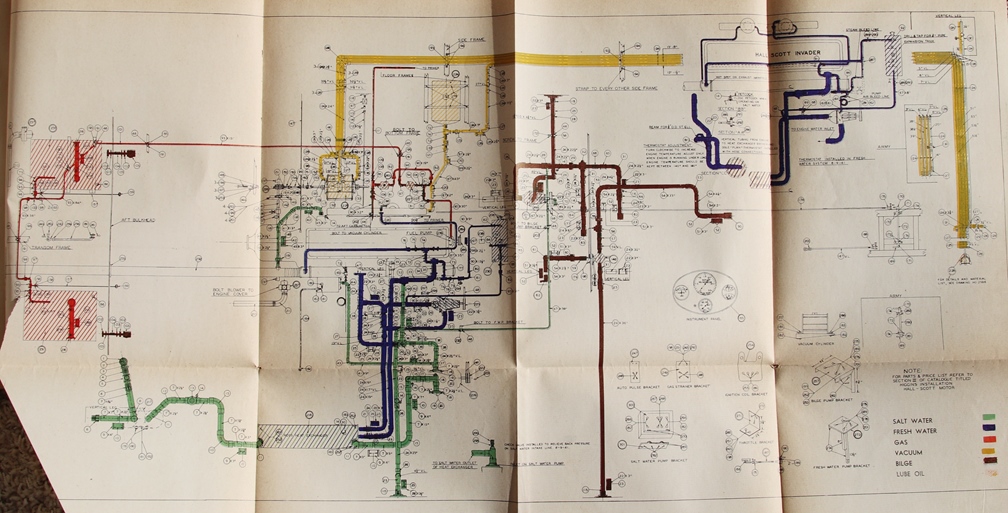

This drawing dated 11-4-1941 shows the

plumbing for a Hall-Scott Invader engine with fresh water cooling for

the LCP(L). Drawing added 2-15-2020.

Drawing added 2-15-2020.

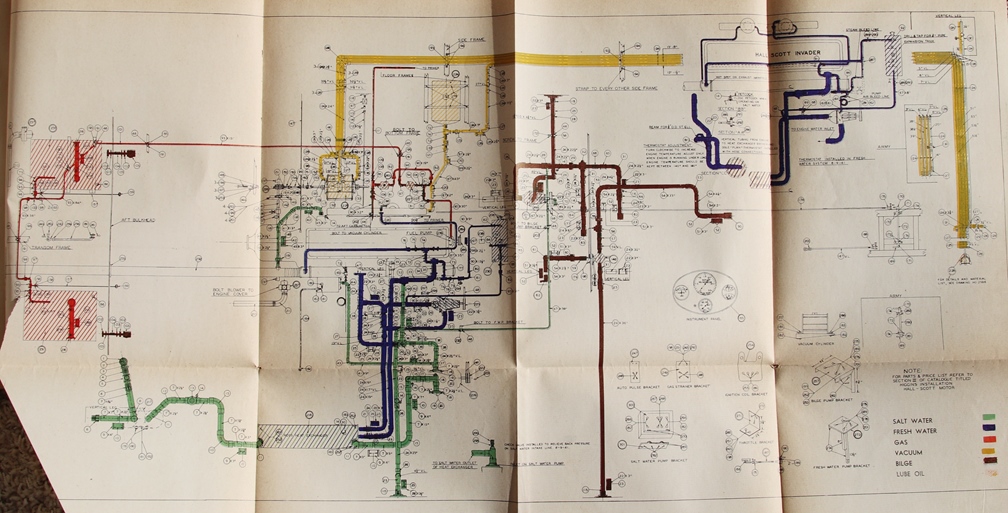

Image added 2-15-2020.

This drawing is undated, but probably from

the same time period as above. This would be early November 1941.

Salt water cooling of boat engines was the norm previous to World War

Two. However, the U.S. Navy in its requirements for the Higgins

designed landing craft called out for fresh water cooling with a heat

exchanger. Drawing added 2-15-2020.

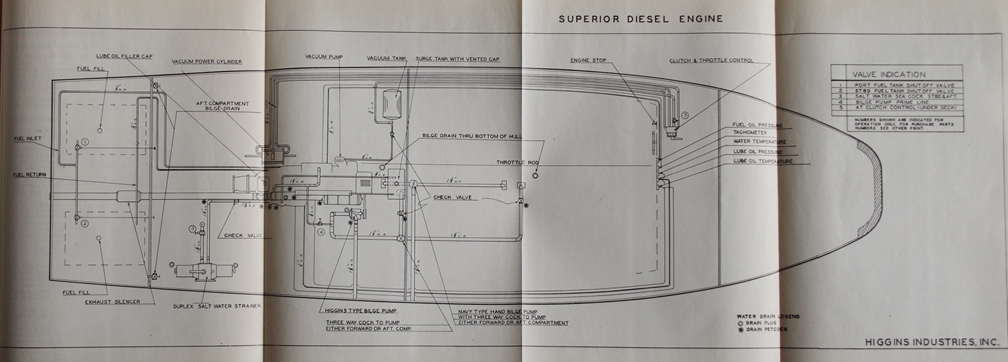

A Superior Gas Engine Company of

Springfield, OH had a diesel that was also specified as an engine for

the LCP(L) as shown in this undated drawing. This was the Superior

Model SMRA-4 four-cylinder, four cycle diesel engine that produced 150

hp @ 2400rpms. Note that this drawing shows the hard chine on the

rear of the boat. Drawing added 2-15-2020.

Landing Craft, Vehicle (LCV) -

In June 1941 Higgins at the request of the Navy designed a Eureka boat

with a ramp. To make the prototype of the ramped Eureka boat,

Andrew Higgins had his workers cut the front end off of an LCP(L) under construction,

and add a ramp to it. While not the most efficient way to

build the prototype, it was expedient. "Higgins Biography"

labels this as an LCVP, but this is what later in the war was

designated as the LCV. In feedback to Higgins, the Navy was

concerned about the location of the engine, the coxswain's location

on top of the stern that left him exposed to hostile fire, and the

lack of provisions for machine guns like the LCP(L) did.

There is an engineering

drawing on page 30 of "The Boat that Won the War - An Illustrated

History of the Higgins LCVP" by Charles C. Roberts, Jr., Published 2017

by the Naval Institute Press. The date of the drawing is 8-22-1942

and it is for a U.S. Navy 36 foot Ramp Type Eureka Surf Landing Boat.

The drawing shows an LCV with rounded chine on the stern. Also, on

the drawing is the Navy contract Number 697 for 600 boats with Registry

Numbers C-10755 to C-11354 Inclusive.

There were 2,633 LCVs built between 1941

and 1943 by Higgins Industries, Chris-Craft, Richardson, and Owens Yacht.

While not built in the

quantities of the LCVP, LCVs saw duty in early American invasions in

World War Two. It continued to be utilized even after the LCVP

became the dominant landing craft later in the war.

There are several key differences

between the original LCV and the later LCVP that can be seen in the

photo above and the outline drawing for the LCV shown below.

The most obvious is the coxswain's station, which on the transom of

the LCV. It was moved into the boat on the LCVP. Note

the ramp winch is also located in an exposed position on the port

side of the LCV. In the LVCP it was moved down into the boat

to protect the crewman operating it from hostile fire.

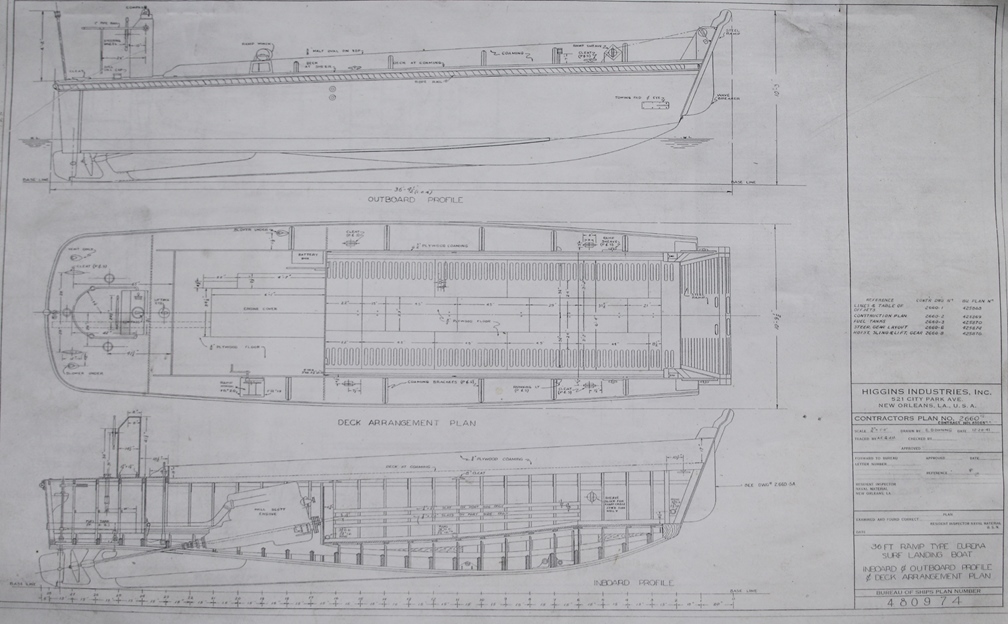

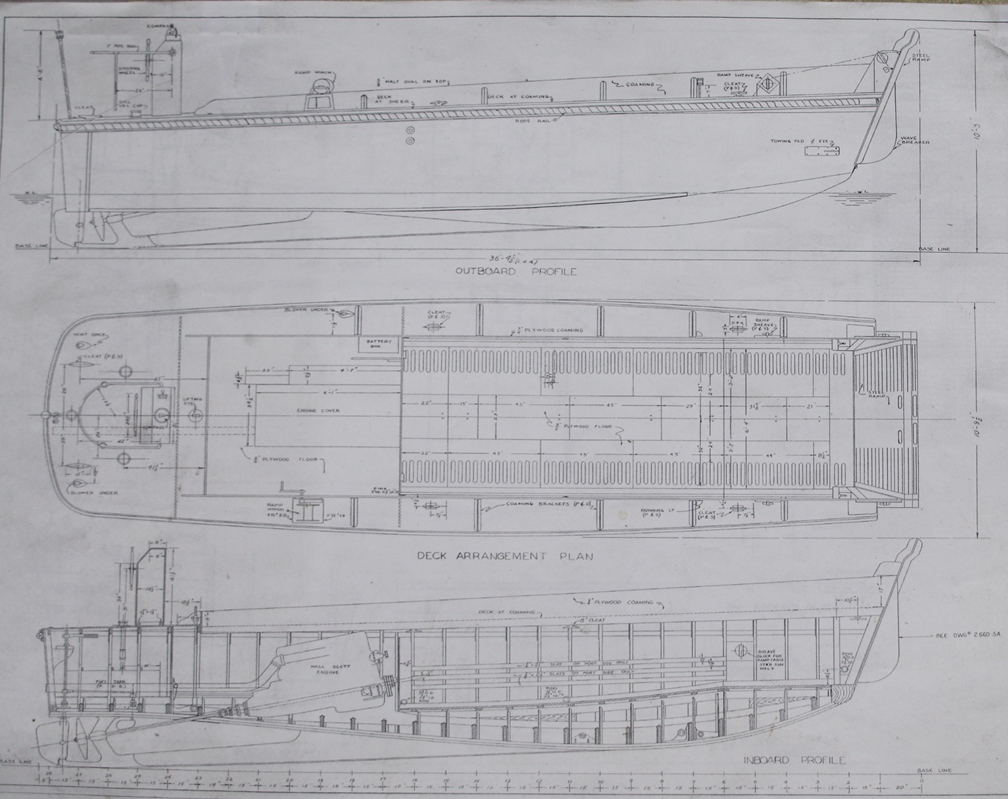

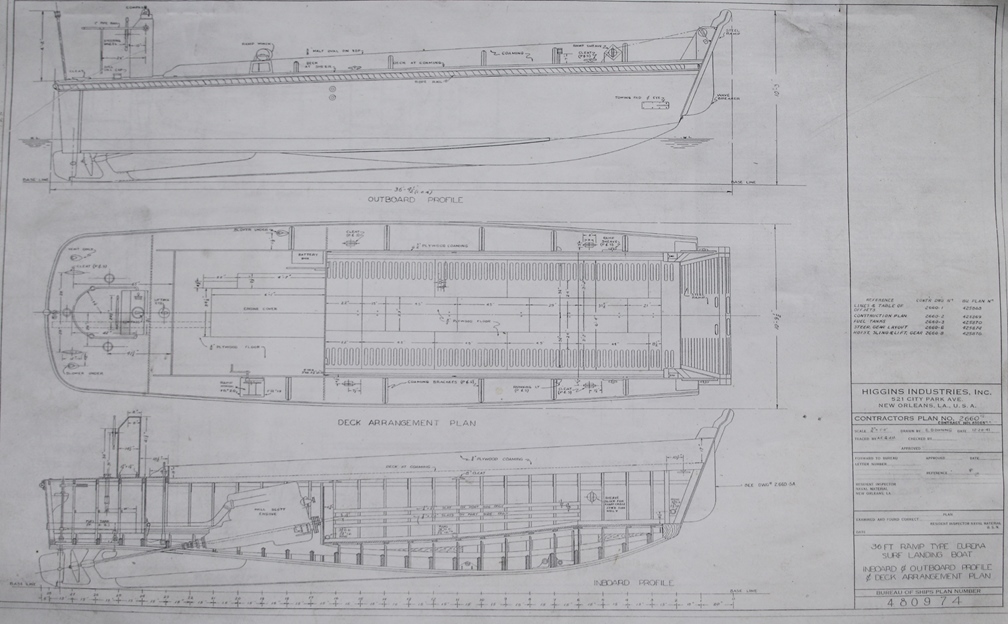

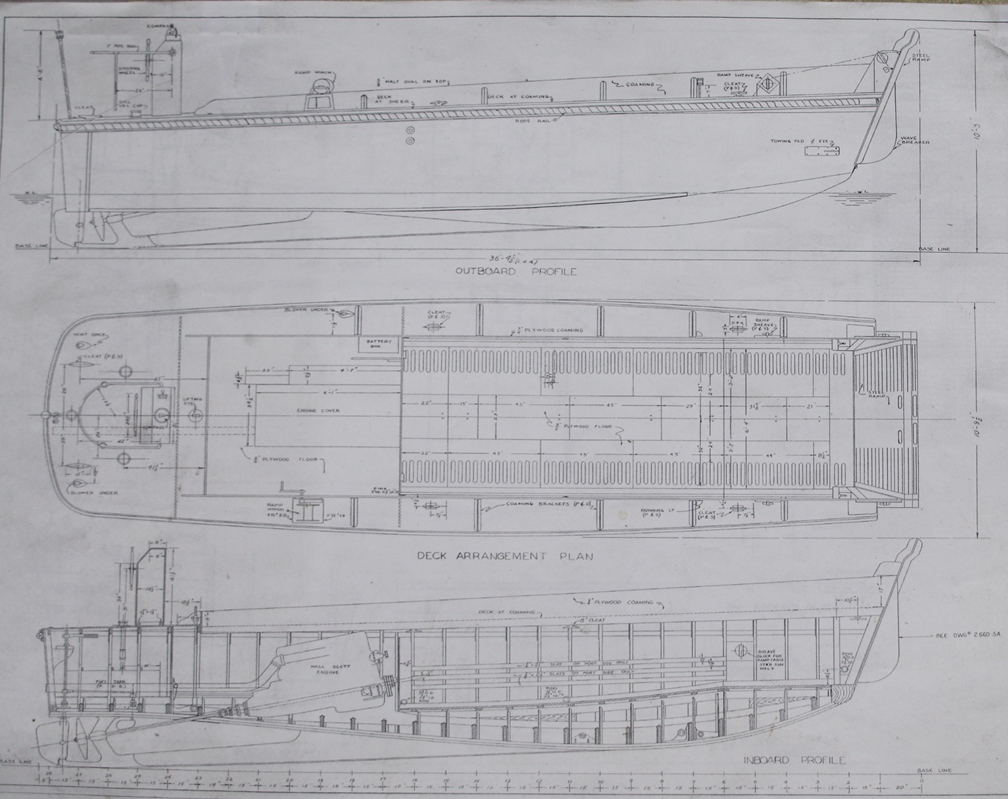

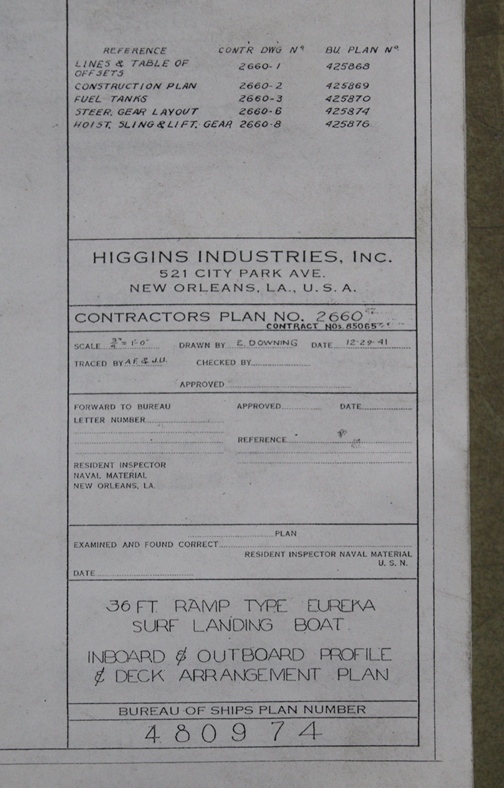

The name given to the LCV at the time of

this drawing on 12-29-1941 was 36 Foot Ramp Type Eureka Surf Landing

Boat. Engineering drawing courtesy of C. Robert Gillmor added

1-9-2020.

The length of the boat was 36 feet and

4-1/2 inches. It was 10 feet and 9 inches in height, and 10

feet and 9-1/2 inches wide. The engine shown is a Hall-Scott

168 Invader six-cylinder gasoline powered engine. Engineering

drawing courtesy of C. Robert Gillmor added 1-9-2020.

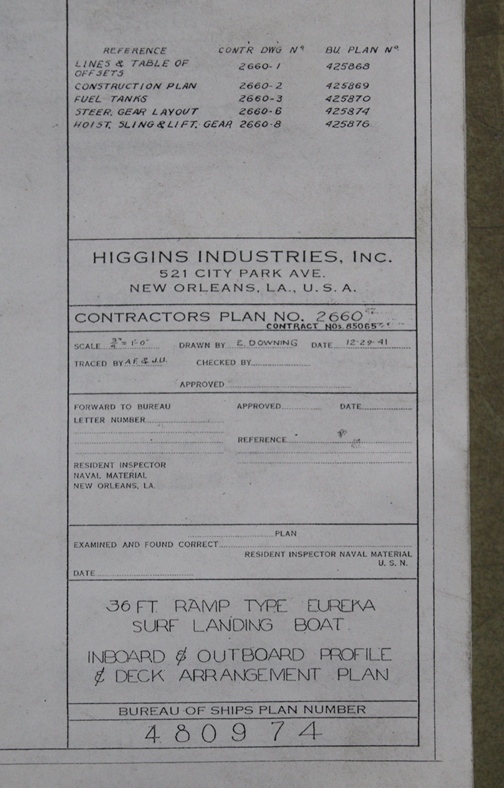

C. Downing drew this engineering drawing

of the 36 Foot Ramp Type Eureka Surf Landing Boat on 12-29-1941.

Note that it was neither checked nor approved. Engineering

drawing courtesy of C. Robert Gillmor added 1-9-2020.

The following engineering drawings are from

the "Operators Manual, 36-foot "Eureka" Landing Motor Boats," Revised

June 1944 by Higgins Industries.

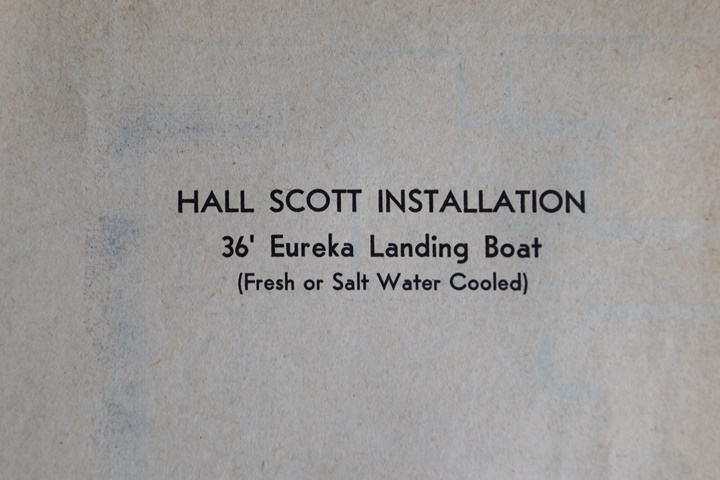

The two drawings below for a Hall-Scott Invader installation for fresh

water cooling and both fresh and salt water cooling are most

interesting. If I am reading the drawings correctly, the

Hall-Scott engine is in the rear of the boat with the drive end of the

engine facing towards the bow of the boat. The driveshaft runs

into what I assume is a transfer case that supplies the power to the

propeller at the stern. These drawings are dated September and

October 1941, 2-3 months before the drawings above that are dated

12-29-1941. It appears that the LCV was originally intended to

have the engine in the stern of the boat and a transfer case to provide

power to the propeller. The drawings of 12-29-1941 above show the

engine amidships with the drive end of the Hall-Scott Invader engine

facing the rear to for direct drive to the propeller. All of the

photos I have seen of the LCV show the engine amidships directly

supplying power directly to the propeller.

There is mention in the literature of the navy being unhappy with the

original location of the engine in the LCV. This may be the reason

for the sudden change. If this is so, then there is the question

of why a 1944 operator's manual has obsolete drawings in it.

This and the drawing below both

have the soft chines on the rear of the boat. Drawing added

2-15-2020.

Drawing added 2-15-2020.

Drawing added 2-15-2020.

Drawing added 2-15-2020.

Landing Craft, Vehicle, Personnel (LCVP):

The LCVP was a great improvement,

allowing for a quicker discharge of the troops onto the beach compared

to the LCP(L) and the LCP(R). In August 1942, tests were

performed by the Amphibious Command of the U.S. Corps of

Engineers to determine how long it took for 36 fully equipped troops

to exit the LCP(L), the LCP(R) and the LCVP.

|

Table 7 -

Results of test for determining how quickly troops can depart a

landing craft |

|

Landing Craft |

Results (Seconds) |

Comments |

| LCP(L) |

57 |

Soldiers had to jump over the gunwales as shown in the photo

above. |

| LCP(R) |

32 |

Soldiers have to exit single file. |

| LCVP |

19 |

|

|

Table 8 - Higgins

Industries built LCVP Registry Information - Partial

The information below comes from "The Boat that Won the War - An

Illustrated History of the Higgins LCVP" by Charles C. Roberts,

Jr., Published 2017 by the Naval Institute Press.

Mr. Roberts obtained several original Higgins 36 Foot Landing

Craft LCVP engineering drawings from the National World War II

Museum in New Orleans, LA for use in his book. Also, the

first line of data comes from Mr. Robert's Website; http://www.robertsarmory.com/Higgins-Boat.htm.

These drawings have provided the information below. The

data is incomplete, but does provide more than was known before. |

|

Date of Drawing |

Title of Drawing |

U.S. Navy Contract Number |

Registry Numbers |

Number of LCVPs |

Type of Stern Chines |

Page No. in Book |

Comments |

|

Before July 1943 |

N/A |

Unknown |

C-32238 |

3,600 |

Round |

N/A |

From

the website. Mr. Roberts has Higgins LCVP Registry C-32238

which was one of 3,600 boats built between February-April 1943.

It came with rounded chines on the stern, but was later changed

to a sharp chine. |

| July

9,1943 |

General Arrangement and Profiles |

None |

None |

|

Sharp |

31 |

|

| May

17, 1944 |

Ramp,

Hoisting Gear Layout |

1222 |

C-39071 thru C-41670 Inclusive |

2,600 |

Round |

57 |

|

| " |

" |

" |

C-54847 thru C-55046 Inclusive |

200 |

Round |

" |

|

| " |

" |

" |

C-69664 thru -70663 Inclusive |

1,000 |

Round |

" |

|

| " |

" |

" |

C-70999 thru C-71598 Inclusive |

600 |

Round |

" |

|

|

February 13,1945 |

Framing |

None |

None |

|

Sharp |

41 |

|

| April

17, 1945 |

General Arrangement and Profiles |

1950 |

C-77944 thru C-78678 Inclusive |

750 |

Sharp |

31 |

This

same information is on a drawing dated March 31. 1945, for

a 36 FT. Landing Craft LCVP Lines and Table of Offsets. |

| " |

" |

2009 |

C-81554 thru

C-82528 inclusive |

975 |

Sharp |

" |

|

|

Total |

|

|

|

9,725 |

|

|

|

Analysis: While

not complete, the information above does give some insights into Higgins

LCVP production. Three US Navy contract numbers are listed, along

with the 6,125 Registry numbers built under the contracts, although not

all boats on contracts 1950 and 2009 may have been built by the end of

hostilities. Also, it shows that Higgins apparently changed back

and forth on the type of chines it installed on the stern of the LCVPs.

The original LCVPs were built with the round chines, but Higgins later

changed to the sharp chines when other manufacturers began production.

This was apparently because the other companies could not do the rounded

version. This may or may not be true. The other companies

may have requested this because it was easier and cheaper to build.

This would have also made for faster LCVP production. The

data shows that in 1943 Higgins had sharp chines on the prints, then in

1944 rounded chines, and then in 1945 it returned to the sharp chines.

It is unknown why the company was switching back and forth. The

LCVP below is a rounded chine version, one of 4,400 built under US

Navy contract 1222. The LCVP, like several of

other World War Two weapons, continued to be built after World War Two.

It was a good solid design, and 1,465 36-foot wooden LCVPs were built

for the U.S. Navy from 1950 through 1962. Between 1965 and 1969

452 fiberglass versions were built from 1950 to 1969. This,

along with the Jeep. may have very well been the longest lasting design built into the Vietnam

War era. Higgins did not build any of the

post-World War Two LCVPs.

That raises the question

of why were there new LCVPs built. No doubt because they those

that were kept in service after World War Two were wearing and

rotting out. Replacements were needed. This then casts

doubts on museums and individuals that have LCVPs and do not have

any C- number to identify who or when it was made. Many of the

LCVPs in museums being identified as World War Two-built are more

likely to be the newer post-war built boats.

Known Surviving Higgins-built LCVPs:

This is not a surviving Higgins-built LCVP.

It is a replica that the National World War Two Museum in New Orleans,

LA had built and is now on display at the entrance to the museum.

What is interesting about this replica is that it is not like any of the

known LCVPs I have looked at or the known Higgins boats shown below.

See the photo below for more details. Photo added 2-15-2020.

Note that towards the bow the side of the

boat is not flat and there is a sharp angle were it changes. All

of the LCVPs I have looked to date in several different museums all have

flat sides. This one does not have any armor plate and the molding

along the edge of the side of the boat and the gunwale is a lot

different than on those that I have seen. Photo added 2-15-2020.

In looking at the LCVPs below, note they all

have flat sides.

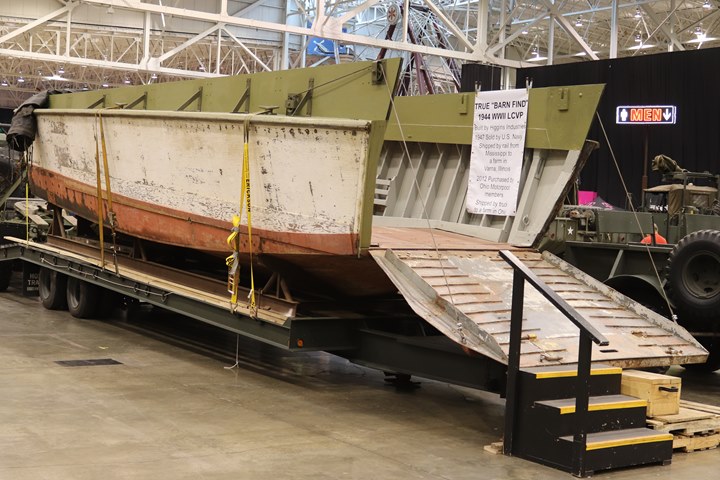

Theoretically, there are around twelve known original World War Two LCVPs left in the

world. Assuming for a moment they are, and that is doubtful

based on lack of documentation or C-numbers, Higgins did not built them

all. Based on the fact that Higgins built approximately 60%

of the LCVPs during World War Two, seven should be Higgins built. To date, only two have been verified

as World War Two era, and both are Higgins-built LCVPs. The one shown below

is owned by three members of the Ohio Motorpool in OH. The photos below were

taken at the 2017 Military

Vehicle Preservation Association National Convention, Cleveland, OH.

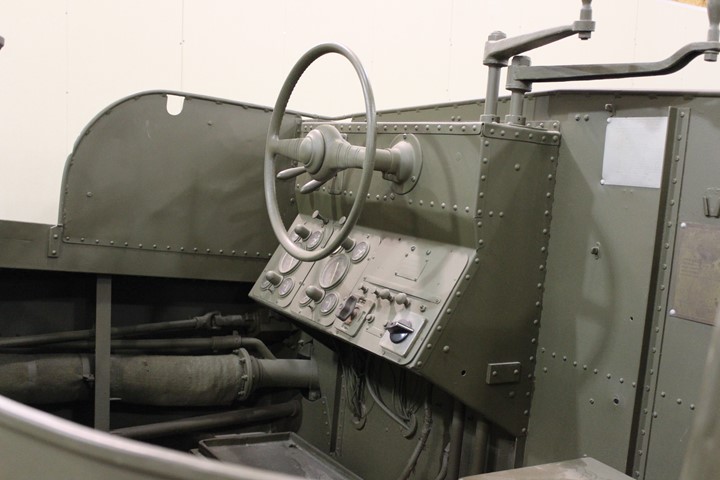

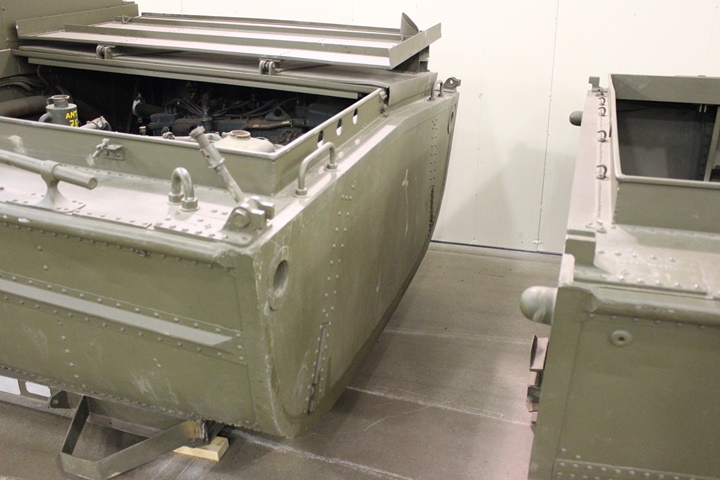

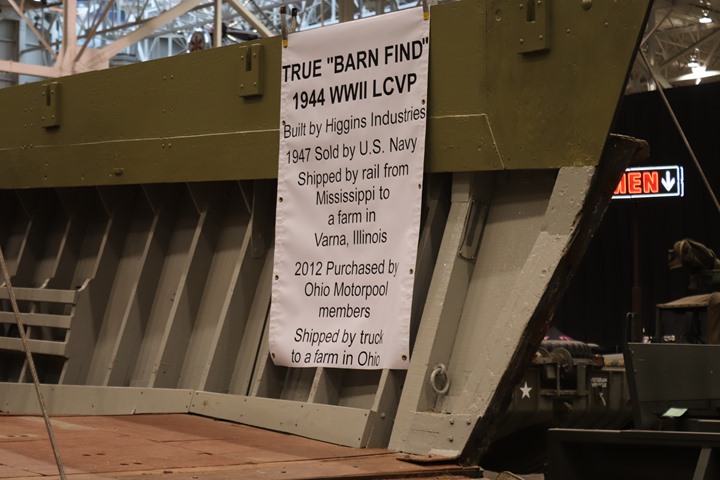

This LCVP sat in a barn from 1948 to 2012.

Because it was put in storage, and never used as a tourist or fishing

boat, unlike many others on display, it is original. Nor was it

kept by the Navy and then modified. The first set of photos below

show it in its original condition before restoration.

This is a real 1944 Higgins Industries built

LCVP looking no doubt very much like it did in 1947 when it was shipped

from Mississippi to a farmer in Illinois. There is no need for

extensive restoration, as it was in a barn for 65 years. Author's

photo.

The boat's registry number of 70032 is imbedded in the wooden structure.

Unless other LCVP owners can produce registry numbers like this, there

is no direct way to discern whether their boats are World War Two or

post-World War Two-built. Author's

photo.

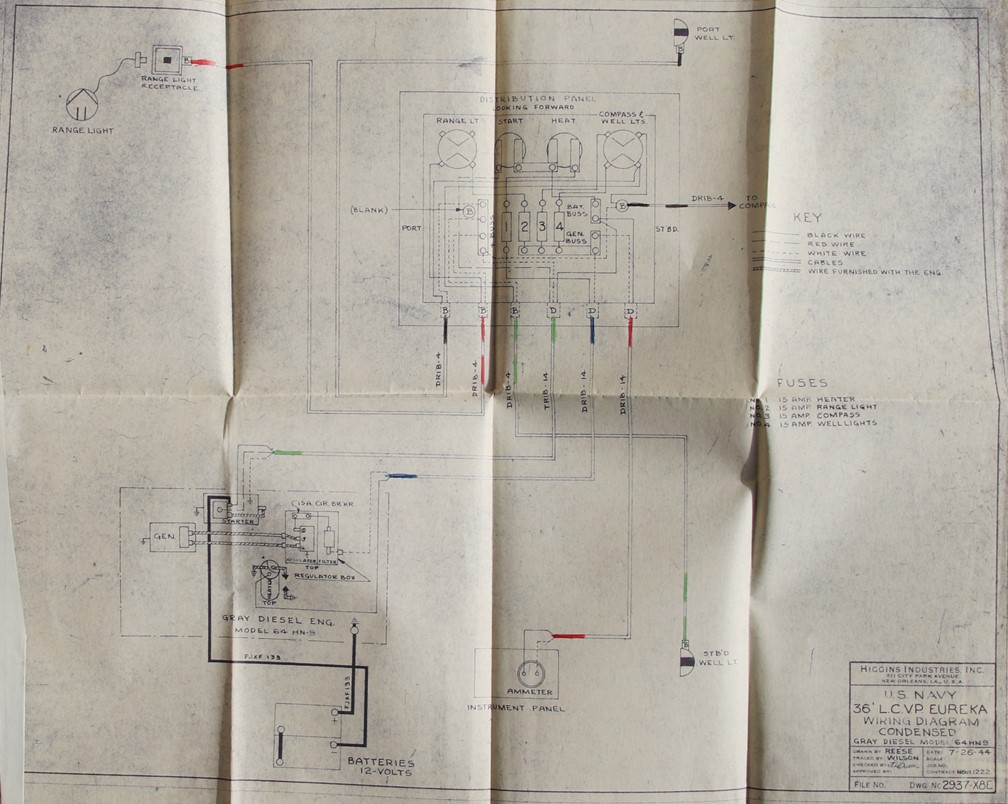

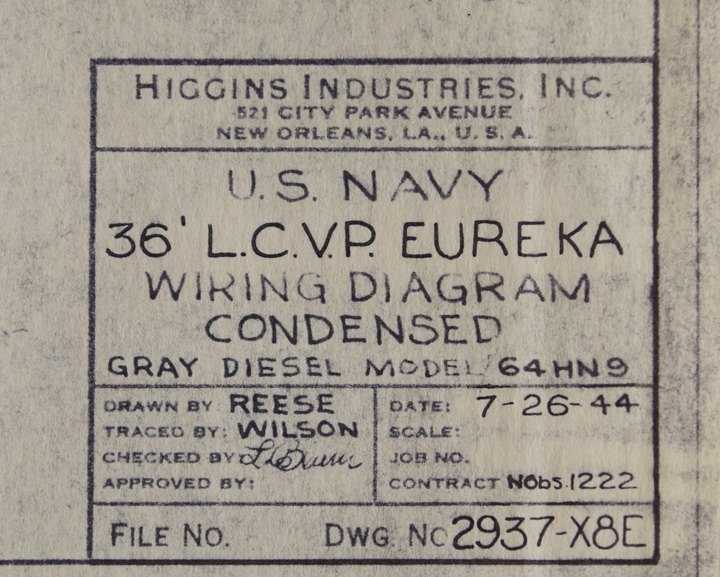

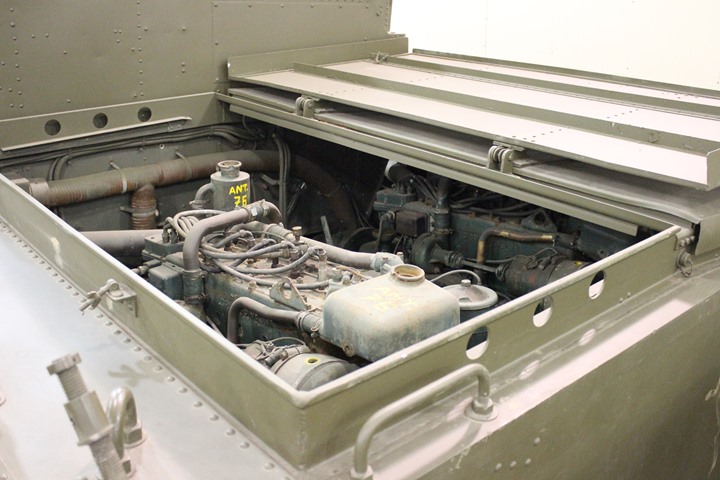

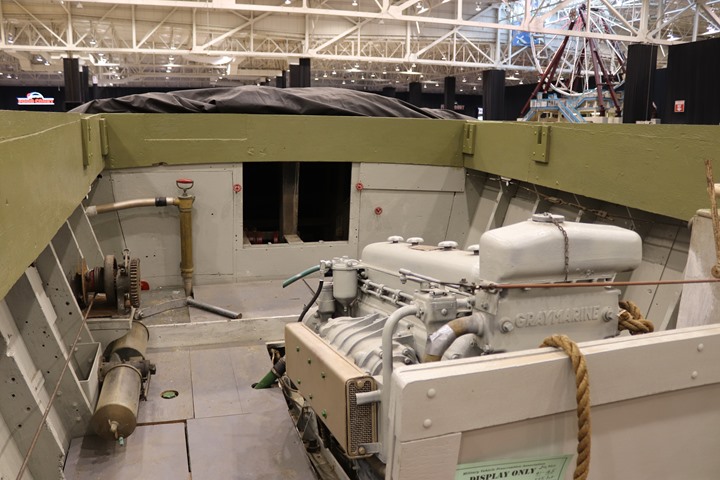

The Gray Marine name can be seen on the heat

exchanger in front of the Detroit Diesel 6-71 engine. This is the

connection between the American Automobile Industry in Detroit, MI, and

the largest manufacturer of small boats during World War Two in New

Orleans, LA. The preferred engine for the LCVP and other small

landing craft during the war was the Gray/Detroit Diesel 6-71 engine.

When it was not available, in many cases the replacement was a gasoline

marine engine from a manufacturer in Detroit. Author's

photo.

Author's photo.

Author's photo.

Author's photo.

The National World War Two Museum in New

Orleans missed out on this. I asked the Ohio Motorpool person at

the show what the WWII Museum thought when they found out about this

LCVP. He told me that they visited it before the Ohio Motorpool,

and couldn't figure out how to get it out the front of the barn, as

there were interferences. So, they left. The Ohio Motorpool

went to Illinois and determined if they took the back of the barn off,

they could take it out that way. It would have to go across the

neighbor's property and some trees on that property would have to be cut

down. The neighbor agreed, and the Ohio Motorpool ended up with,

in my estimation, the most important original LCVP in existence because

it was built by the same company that designed it. Author's photo.

The rounded soft chines on the stern

indicate this is a Higgins-built boat. But there is confusion

and mystery in reference to this type stern. Supposedly other

manufacturers could not build the rounded corners, and a design change

was made to build the LCVP with squared corners. Author's photo.

This is Higgins-built LCVP 70032 after

restoration. This was photographed at D-Day Conneaut, OH in August

2019. Author's photo added 1-9-2019.

This is the second known Higgins-built LCVP, owned by Roberts Armory in Rochelle, IL. It is

registry

number 32238. This had several post-WWII modifications to it.

Author's photo.

Drawing added 2-15-2020.

Drawing added 2-15-2020.

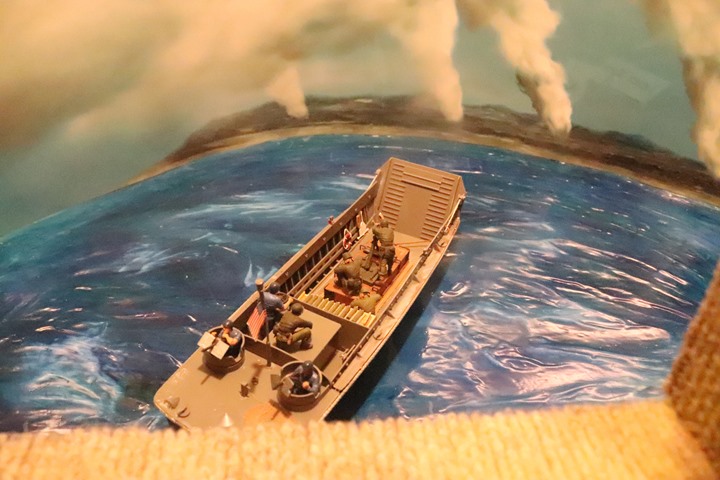

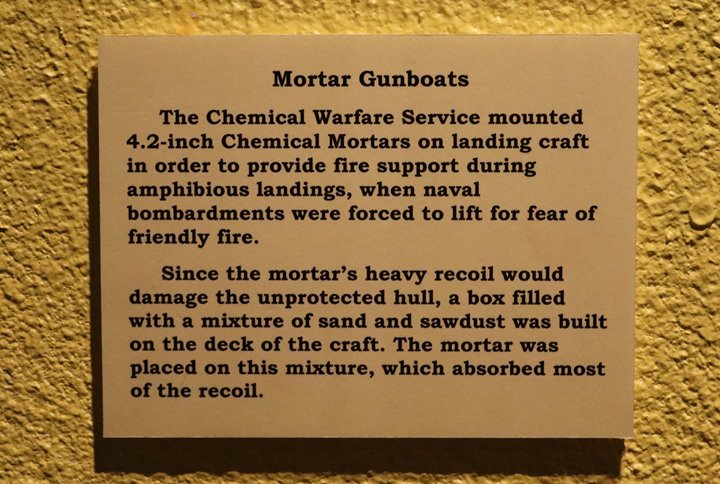

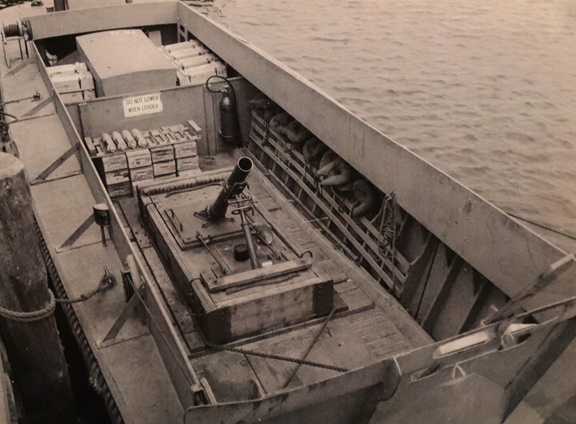

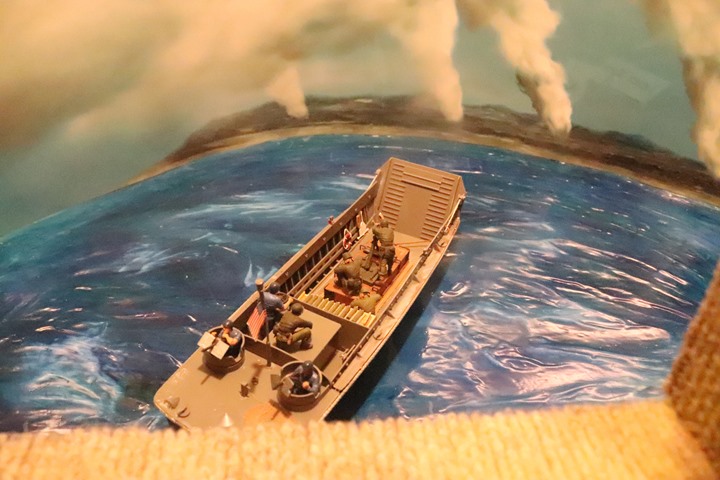

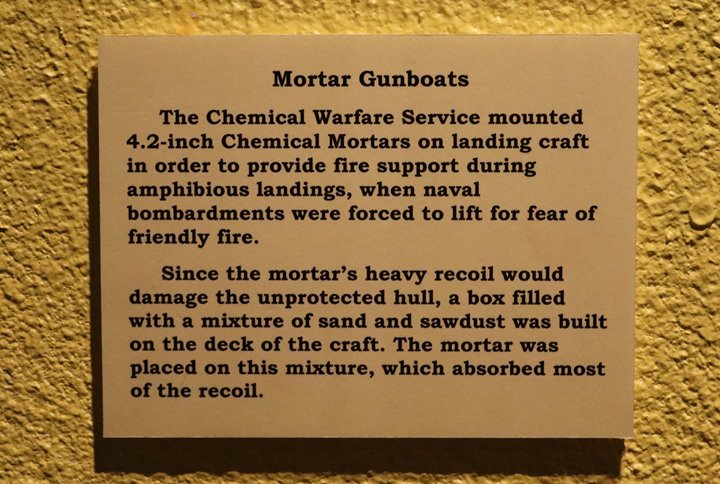

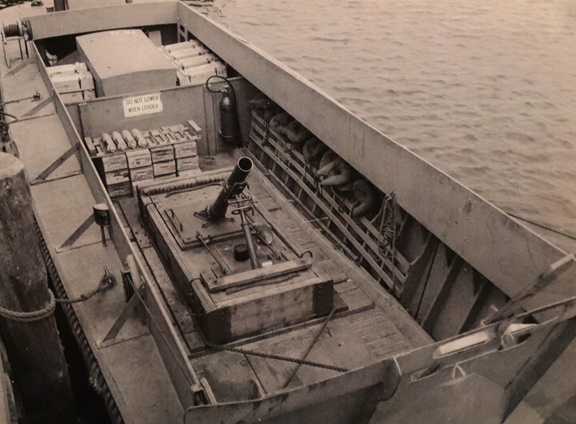

This model LCVP and diorama is at the US

Army Chemical Corps Museum at Fort Leonard Wood, MO. It shows how

the Army Chemical Corps used the LCVP to fire smoke from 4.2 inch

mortars during beach invasions. Author's photo.

Author's photo.

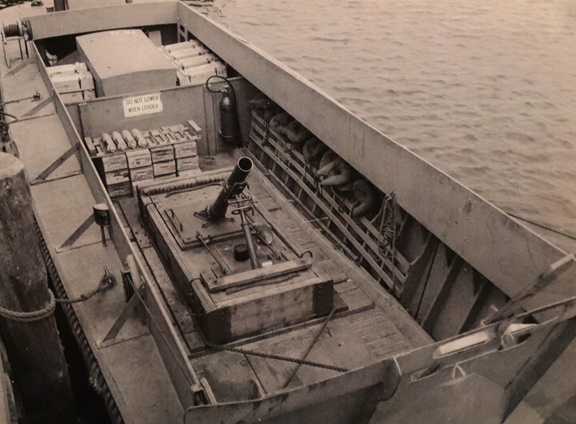

This is an LCV with a mortar in it.

This photo shows an LCVP being used as a

rocket launcher.

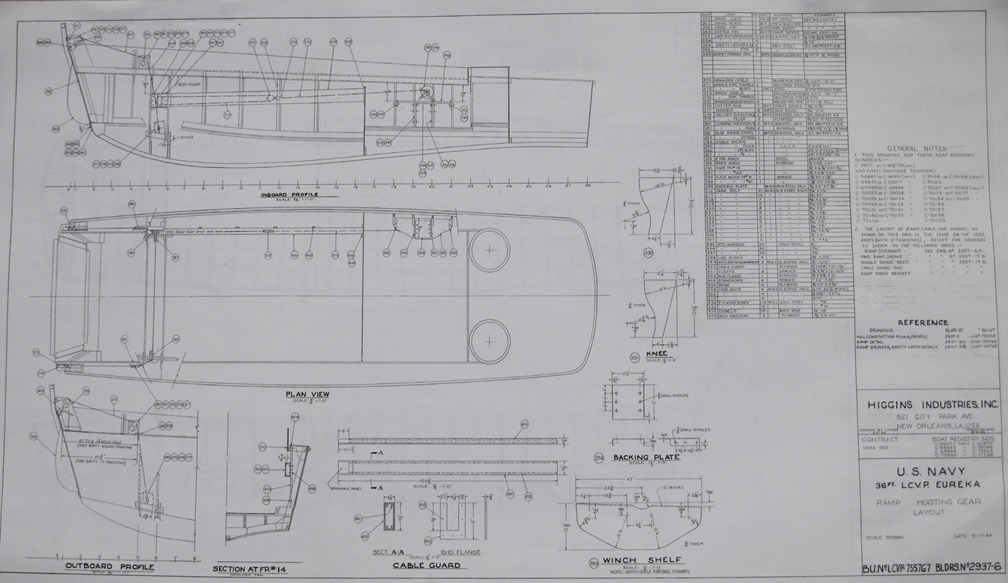

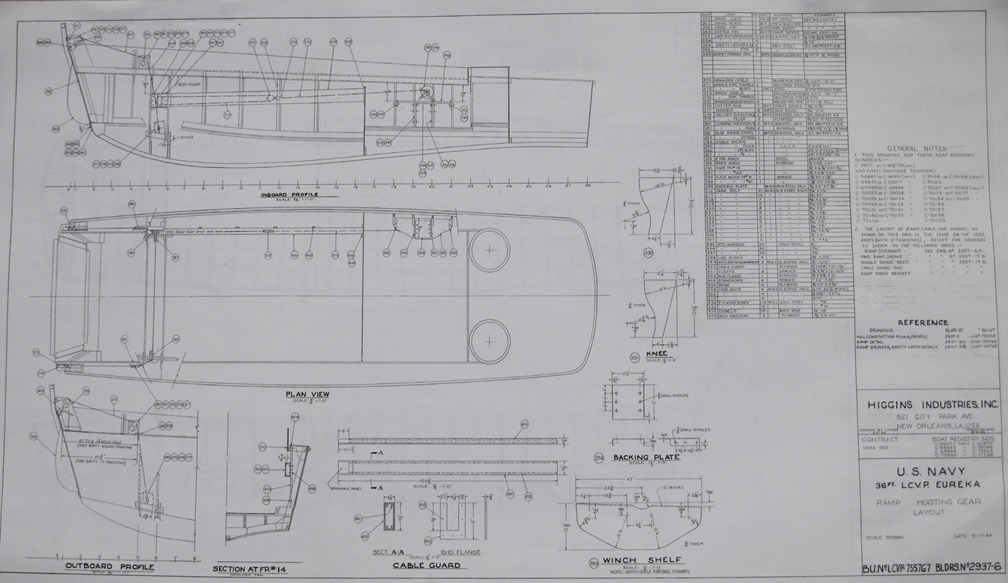

LCVP Landing Ramp Hoisting Gear Layout: There were several

ways cables ran to drop and lift the ramp at the front of the LCVP. Some may have been design changes made by Higgins. Othierwise, one of the

other manufacturers of the LCVP may have run the cables differently than

the drawings called for. The original method was a carryover from

the LCV which had the winch located on the starboard side gunwale.

One cable ran forward from the winch along the inside of the boat and

then connected to two cables. One cable ran to the starboard side

of the ramp while the other cable ran under the floor of the boat.

It then came back up and attached to the port side of the ramp. A

latter version moved the winch to the deck on the inside of the boat, as seen in the

drawings below. The only difference between this latter version

below and the original is the location of the winch. The routing

of the cables was the same.

Engineering drawing courtesy of C. Robert

Gillmor added 1-9-2020.

Engineering drawing courtesy of C. Robert

Gillmor added 1-9-2020.

This photo of an LCV shows the winch

located on the rear starboard side gunwale. The cables then run as

shown in the drawing above. The port side cable can be seen

running out from under the deck as shown in the drawing above.

This shows the ramp winch relocated to the

floor of this LCVP. Author's photo.

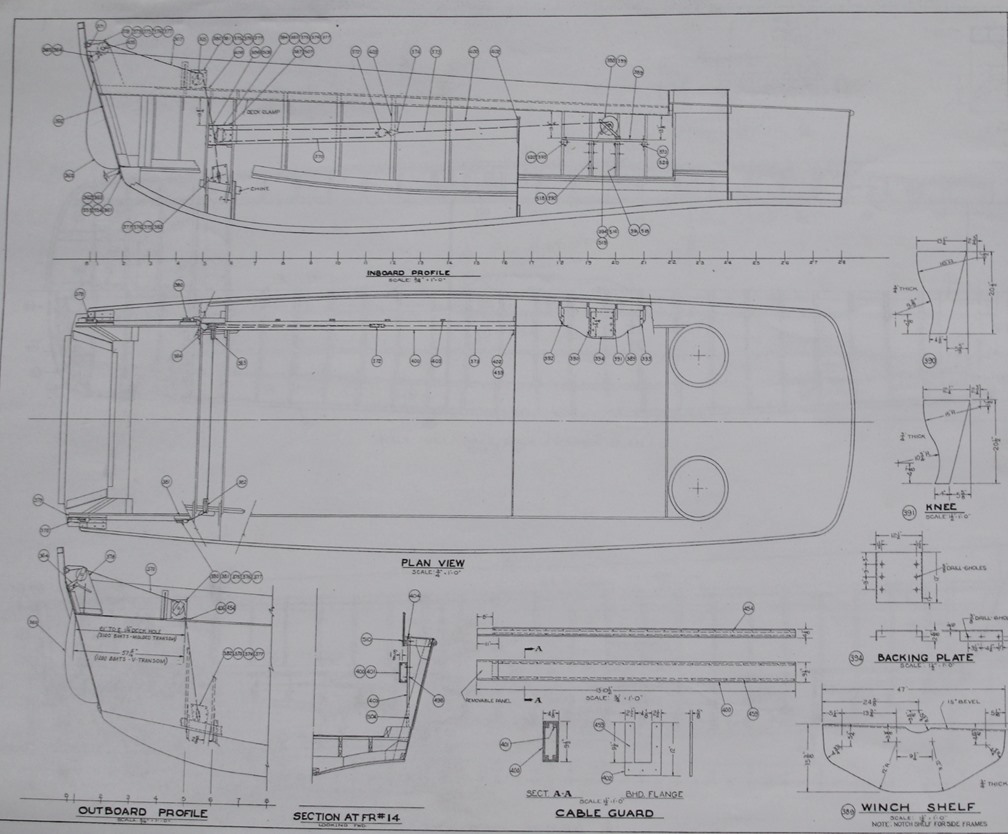

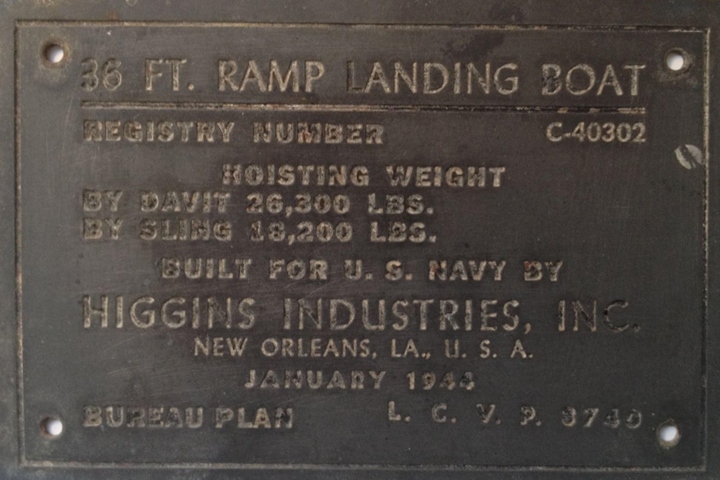

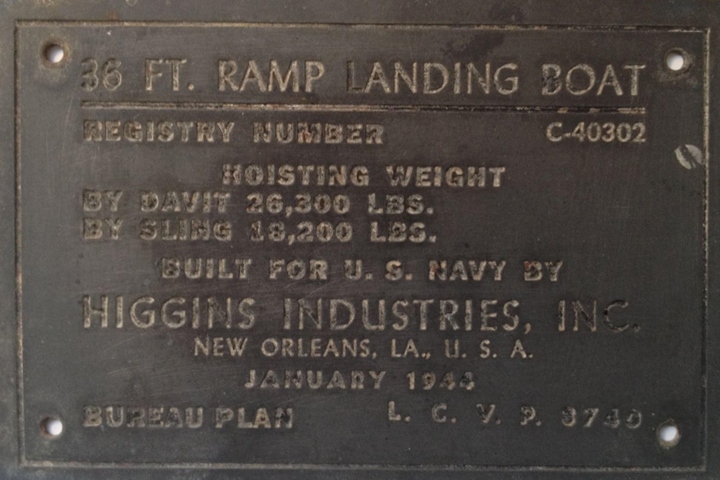

Registry Plate for LCVP C-40302:

This item is part of the collection of Mr.

John Posusta and tells us that LCVP C-40302 was built in January 1944.

Image courtesy of Mr. John Posusta added 6-15-2024.

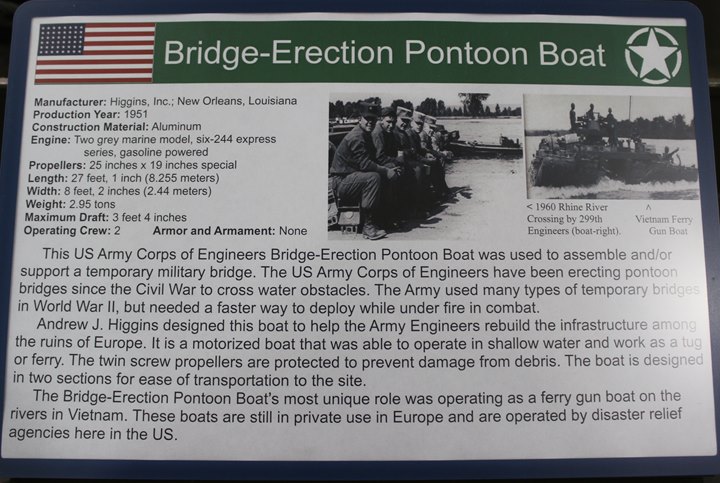

Landing Craft, Mechanized (LCM) - On

December 8, 1941 Andrew Higgins applied for a patent for a "Lighter for

Mechanized Equipment." US Patent Number 2,341,866 was granted on February 15, 1944. This became the Landing Craft, Mechanized

in the US Navy nomenclature. It was more commonly known as a Tank

Lighter to the sailors and coastguardsmen who operated it. This term

became the generic term for this type landing craft. Both the

LCM(3) and LCM(6) could deliver one Sherman medium tank directly to the

landing beaches. While the LCVP has gained all of the publicity since World War Two, the LCM

series of tank lighters were just as important and have been

overlooked. Being able to land a Sherman tank on hostile beaches

to provide heavy fire support for the infantry could

make the difference in how quickly the invasion beach could be secured.

Like the Higgins's designed LCVP, the LCM

series was a robust design that continued to be built after World War

Two. Between 1950 and 1987, 1,164 LCMs were built. Ten were

still in service in 2018. This is a strong testament to the

soundness of the original design in Andrew Higgins's patent issued February

15, 1944.

Patent Number

2,341,866 This is the Higgins patent for a ramped LCM.

PT Boats: The 137 PT boats

delivered to the U.S. Navy served in the Aleutians, the Mediterranean,

Normandy, the Southwest Pacific, South Pacific and Central Pacific.

Higgins-built PT boats PT-450 through PT-461 served along the English Channel

from June 1944 to July 1945.

PT-305 - PT-305 had its keel laid down

on March 30, 1943, was launched on May 27, 1943, and was completed

December 8, 1943. On December 22, 1943 it was assigned to Motor

Torpedo Boat Squadron 22, and was based at Bastia, Corsica in the

Mediterranean Theater of Operations. After the invasion of

southern France in August 1944, PT-305 moved to St. Tropez, France.

During her time in the Mediterranean, she was credited with sinking five

enemy vessels. When the war ended in Europe, PT-305 returned to the

United States for deployment in the Pacific. When the war with

Japan ended, she was in New York. PT-305 was struck from the Naval

Register on November 25, 1945. On June 18, 1948, PT-305 was transferred

to the War Assets Administration and was sold in 1948 to the first of

twelve private owners through 2001. During that time period, the

former PT-305 operated as a tour boat and a fishing vessel.

Currently, after 17,000 hours of work by

volunteers at the National World War Two Museum in New Orleans, PT-305

has been restored to her original World War Two configuration. She is the

world's only Higgins-built PT boat combat veteran in operating condition.

PT-305 is in her boathouse at Lake Pontchartrain on the morning of

3-17-2018. She carries the name USS Sudden Jerk. During

World War Two, she also was named Higgins Mortuary, Half Hitch, and Bar

Fly. Author's Photo.

Author's Photo.

Author's Photo.

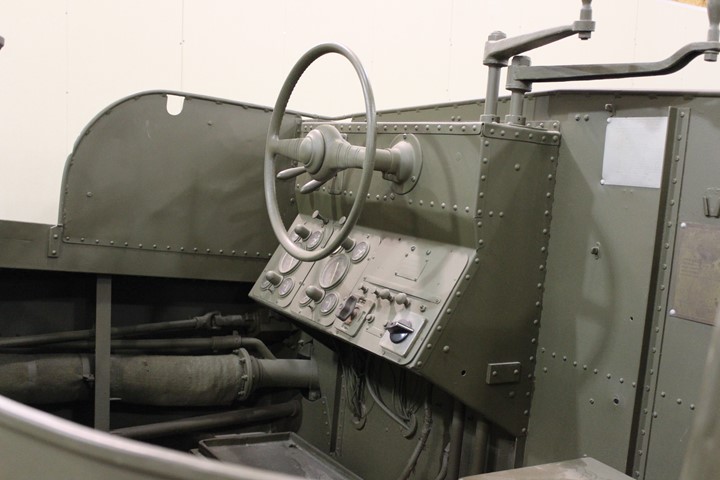

The door to the right leads down into the

chart house and radio room. Author's Photo.

Author's Photo.

Author's Photo.

The chart house is on the port side of the

compartment. Author's Photo.

The radio room is on the starboard side of

the compartment. Author's Photo.

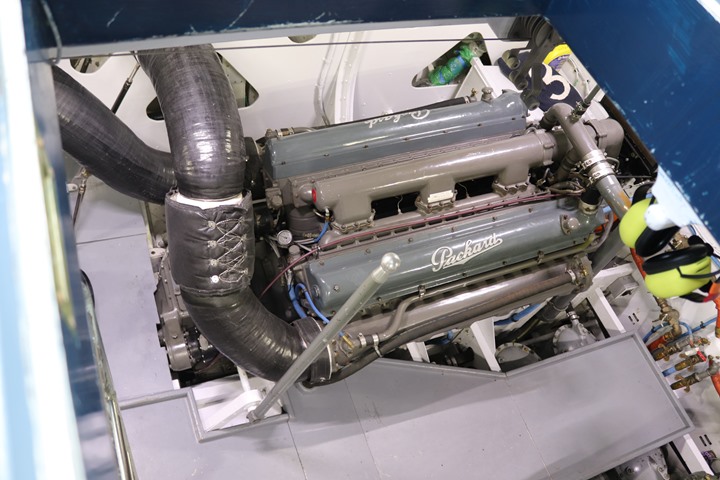

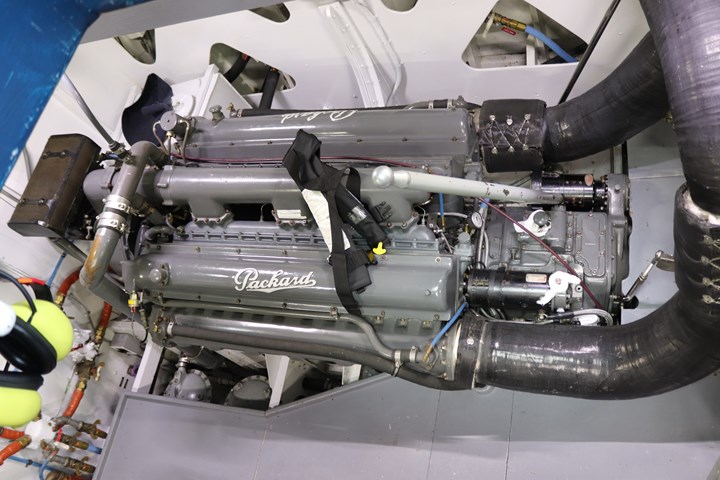

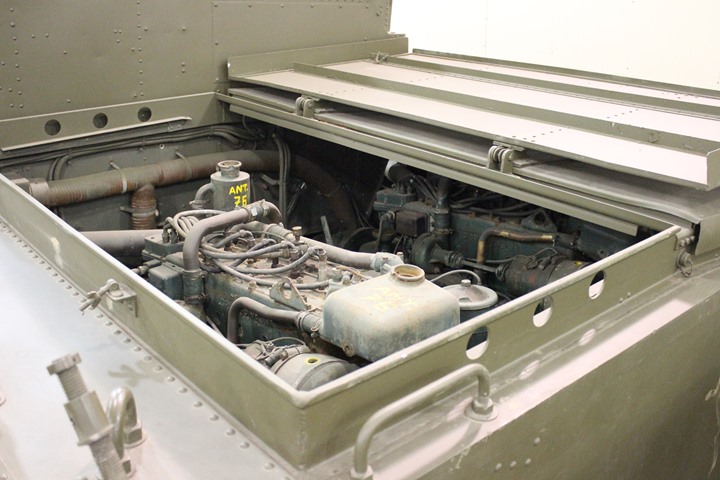

The American Automobile Industry connection

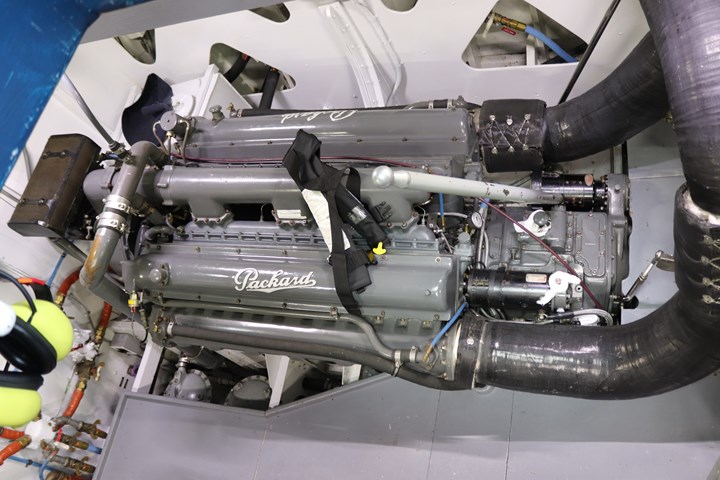

to PT-305 was her three Packard-built 4M2500 marine engines. This is the

port engine. Author's Photo.

This is the starboard engine with Delco-Remy

Division of General Motors starter and DC generator visible at the rear

of the engine. The Harrison Division of General Motors furnished

the heat exchangers for the engines. Author's Photo.

Cruising at 30 knots, the sweet spot for a

Higgins-built PT boat. The flag, the pennants, and the crew member's

pants were whipping around in the wind. This was a nice 70-degree

day on Lake Pontchartrain, so the 30-knot wind over the deck was not too

uncomfortable. Higgins PT boats were used extensively in the

Mediterranean and Aleutians Theaters of Operation during WWII.

Imagine being on deck of a PT boat going 30 knots in the Aleutian

winters. The crewmen suffered many hardships in these small boats.

Author's photo.

The wake of PT-305 at 30 knots.

Author's photo.

PT-796- PT-796 had its keel laid down

on May 3, 1945, was launched on June 23, 1943, and was commissioned on

July 17, 1945. It was decommissioned on July 7, 1970 and is now on

display at Battleship Cove in Fall River, MA. It is owned by PT

Boats, Inc.

Author's photo added 2-15-2020.

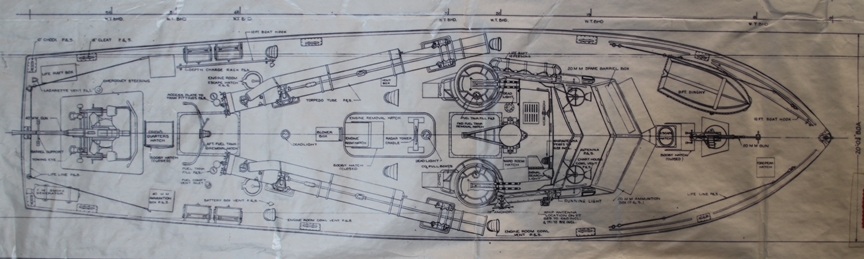

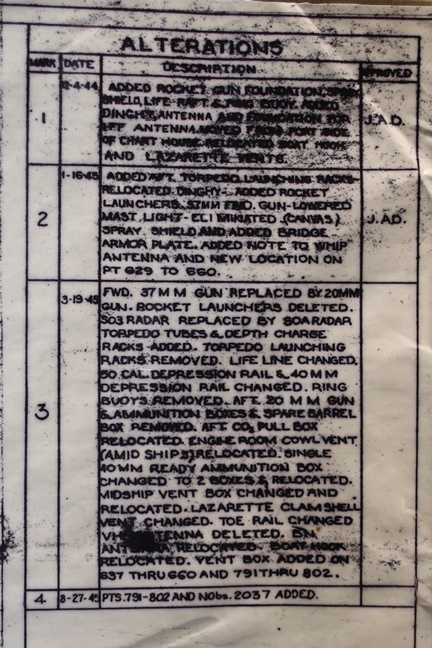

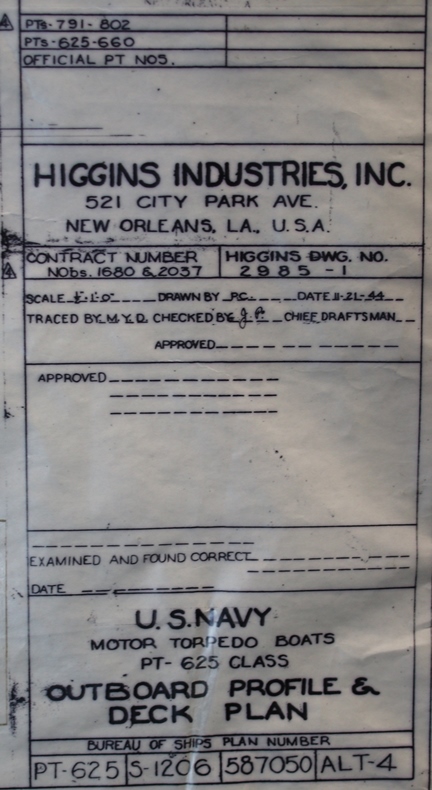

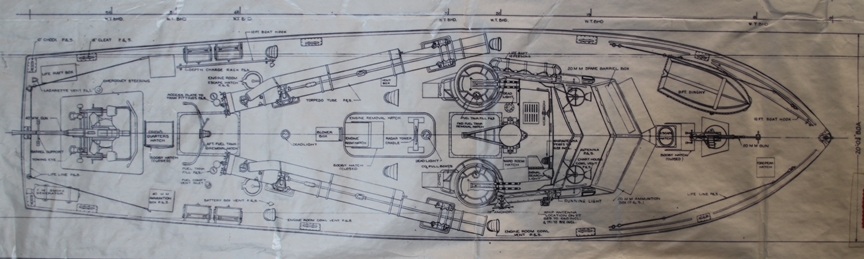

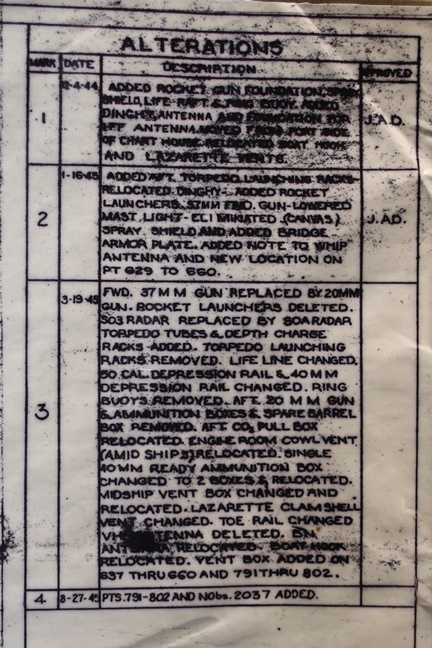

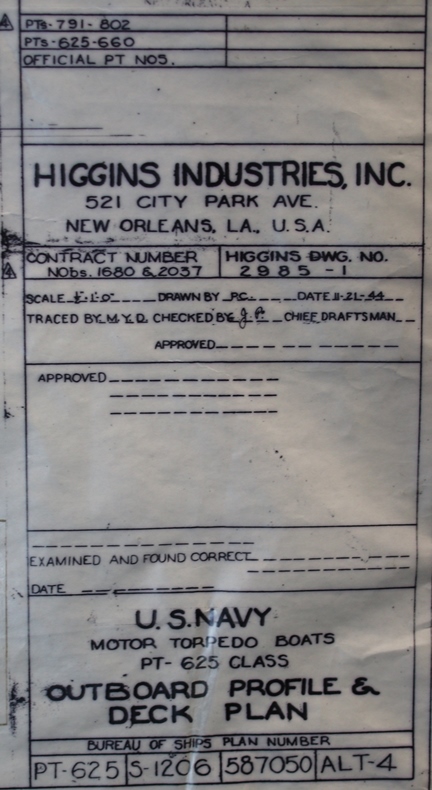

PT-625 Series PT Boat Engineering Drawings:

Two major changes are the replacement of the

bow 37mm cannon with a 20mm Oerlikon and the replacement of the aft

torpedo tubes with depth charge racks. Image added

5-10-2024.

Image added 5-10-2024.

Image added 5-10-2024.

This image shows all of the changes that

went into the last two contracts of Higgins-built PT boats.

Image added 5-10-2024.

Image added 5-10-2024.

Table 9 - Higgins Industries'

Major World War Two PT Boat Contracts

The information below

comes from the "Alphabetical Listing of Major War Supply

Contracts, June 1940 through September 1945." This was

published by the Civilian Production Administration,

Industrial Statistics Division, Requirements and Progress

Branch January 21, 1946. Table added 5-10-2024. |

|

Product-Customer |

Contract Number |

Contract Amount |

Contract Awarded

|

Completion

Date |

| Motor Torpedo

Boats - Navy |

Nos - 94729 |

$15,941,000 |

11-1941 |

9-1943 |

| Motor Torpedo

Boats - Navy |

Obs -1053 |

$4,714,000 |

4-1943 |

8-1944 |

| Motor Torpedo

Boats - Navy |

Obs -1284 |

$100,000 |

8-1943 |

7-1944 |

| Torpedo Boats PT

- Navy |

Obs -1680 |

$4,899,000 |

5-1944 |

8-1945 |

| Torpedo Boats PT

- Navy |

Obs -2037 |

$1,623,000 |

1-1945 |

11-1945 |

| Total |

|

$27,277,000 |

|

|

From the information above we have cost and

the number of PT boats ordered under contracts Obs-1680 and Obs-2037.

The cost of PT 625-660 built under contract

Obs-1680 was $136,083. This was 36 boats.

The cost of PT 791-802 built under contract

Obs-2037 was $135,250. This was 12 boats.

The information above indicates the average

cost of a Higgins-built PT boat during World War Two was at least

$135,000.

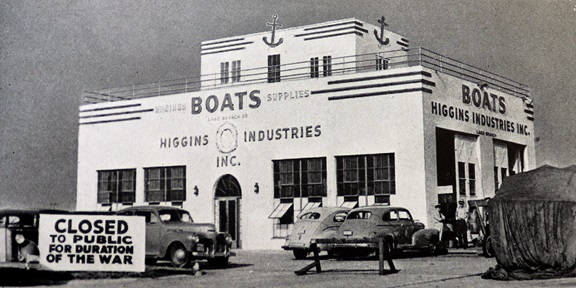

Manufacturing Plants:

Higgins

conducted its boat manufacturing in five different plants during World

War Two. Four were in New Orleans and one was in Houma, LA.

The four plants in New Orleans were the St. Charles Avenue Plant, City Park Plant, the Industrial

Canal Plant and the Michoud Plant. The five of them covered 1,486

acres and employed 20,000 workers. When the boats were completed

at the St. Charles Avenue Plant or the City Park Plant, they were

transported by truck or rail to St. John Bayou, a small river on the

north side of New Orleans. The St. John Bayou was one mile east of

the City Park Plant by road. The boats were then taken out on Lake

Pontchartrain for testing. When the testing was complete, the

boats were loaded onto railway cars to be shipped to their final

destination. The boats built at the Industrial Canal Plant would

be launched on the Industrial Canal, tested, and then delivered to the

St. John Bayou for shipment.

St. Charles Avenue Plant:

This was Higgins Industries' original plant

It built the early landing craft and PT boats. All of

the boats were trucked to the Bayou St. John for testing and delivery.

On May 30, 1941 the USMC ordered 50 LCMS from Higgins Industries.

Ten had to be delivered to Norfolk, VA by June 30, 1941. The first

ten LCMS were built at the St. Charles Ave. plant. Due to the size and time

frame of the project, some of the work was done outside on Polymnia

Street at the end of the block northeast of the plant. Tarps were

placed over the buildings on either side of the street to

protect the workers from the elements. Vehicles were not able to

use the street during the work, which was an inconvenience for the

residents. They accepted the inconvenience as necessary to get the boats built. Final

assembly was done in a nearby vacant stable.

St. Charles Avenue was closed as a

production facility in March 1942. LCM work shifted to the City

Park

Plant temporarily until the Industrial Canal Plant opened. Higgins headquarters moved from St. Charles Avenue to the City

Park Plant in September 1942.

The Plant was located at 1755 St. Charles

Avenue in New Orleans. Today Houston's Restaurant is at this location. It does not appear to be the same building as this one. Apparently

this one was torn down, and a new one built in its place.

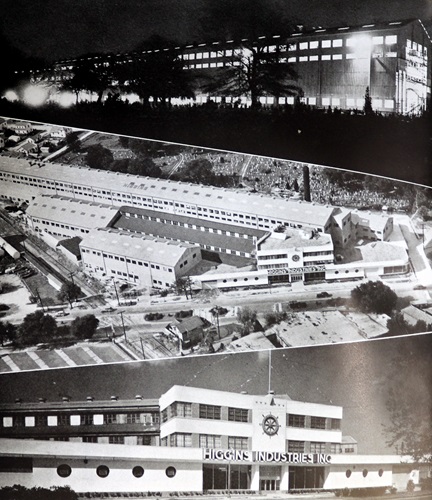

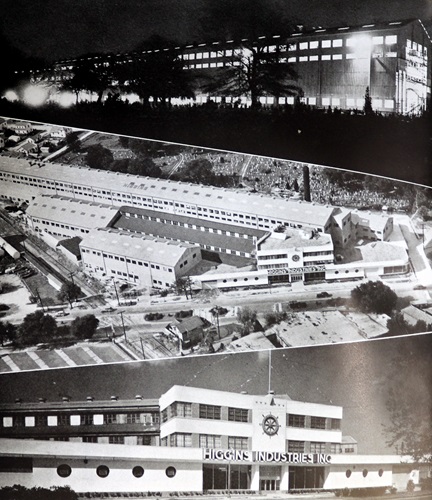

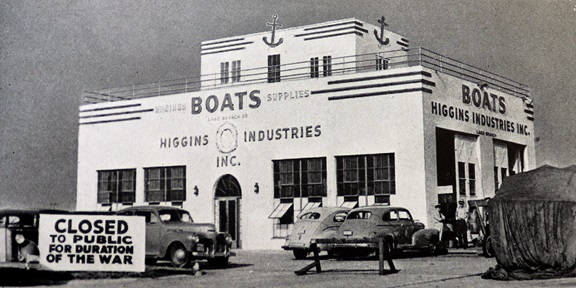

City Park, New Orleans,

LA Plant: Higgins purchased the former Albert Weiblen Marble

and Granite Works plant at 521 City Park Avenue in July 1940, and converted it to the world's

largest boat manufacturing plant under one roof. The construction

of the PT boats and landing craft was done on the second floor, with the

completed boats lowered to ground level by an elevator. Because

the plant was not near water, the boats were then moved by rail or truck

to Bayou St. John for testing and shipment. Today the plant is the

location of Delgado Community College Administration building and

adjacent parking lot. Only a historical marker at

the college indicates that this was once the location of a thriving

plant that built thousands of boats for the winning of World War Two.

Higgins implemented assembly line techniques developed by

the American Auto Industry, allowing the facility to turn out thousands

of landing craft and 216 PT boats.

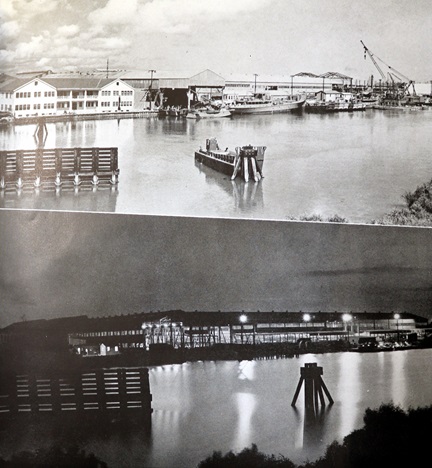

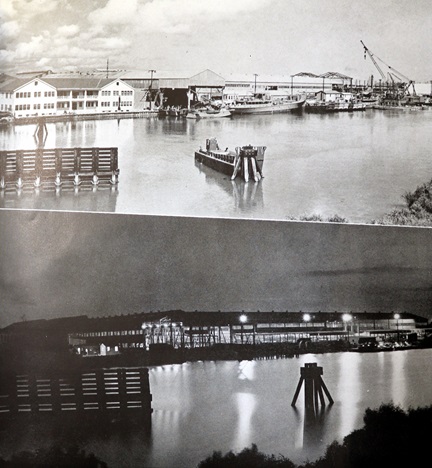

The top photo is City Park Plant at night. Apparently, there

was no black-out in New Orleans. The middle photo looking

northwest, the City Park Plant is bounded by City Park Avenue on the

south side, the railroad tracks on the west side, and the Holt Cemetery

to the north. The bottom photo shows the main entrance to the

plant along City Park Avenue.

This view of City Park Plant is looking

north to northeast, while the Isaac Delgado Hall of the Delgado Community

College is to the northeast of the plant.

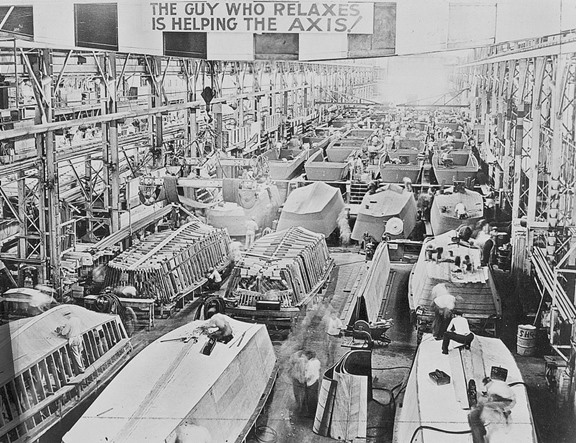

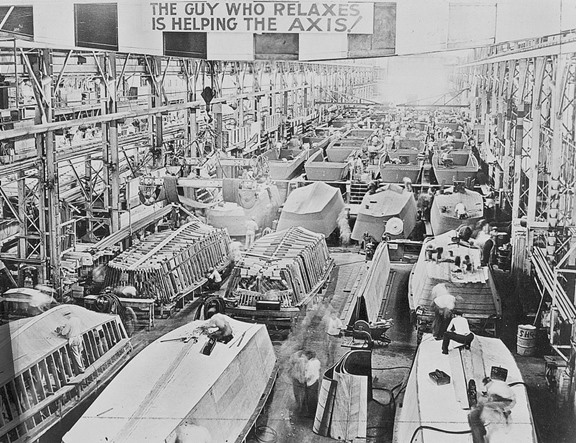

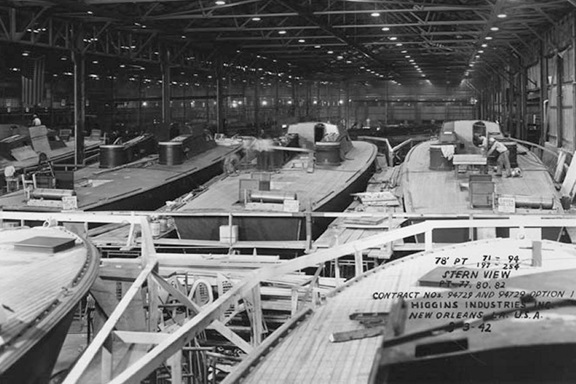

The final assembly line on the second floor

of the City Street Plant building LCVP landing craft. Assembly of

PT boats took place in the next bay.

The 7,000th LCVP built by Higgins in October

1944 is in front of the City Park Plant for a photo shoot. From

here, the LCVP went to Bayou St. John for testing and final delivery to

the U.S. Navy.

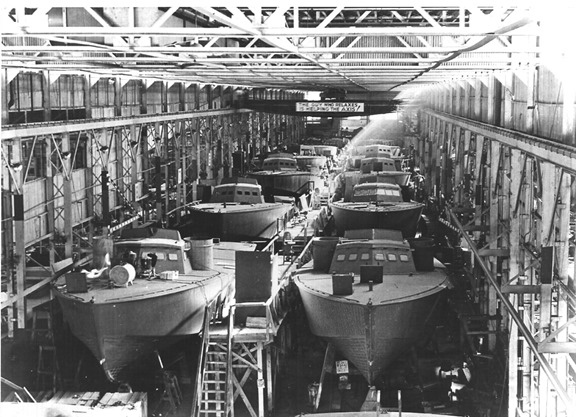

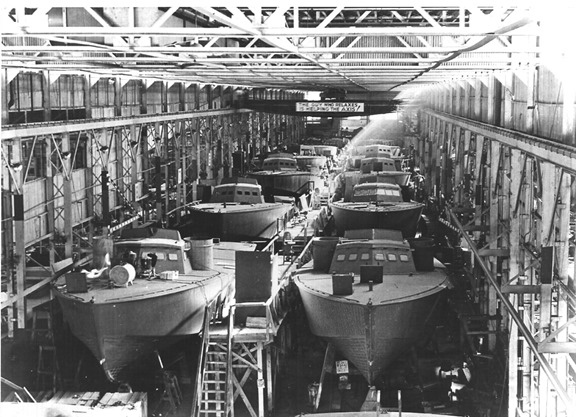

The PT boat assembly line at the City Park

plant. Note the overhead crane that runs the length of the

building to deliver large components to the assembly area.

PT-77, PT-80 and PT-82 are shown in this

stern view from 8-3-1942. This photo is significant in that it

shows the PT boats being built at least four abreast. Photo added

3-4-2019.

The stern view of PT-75 and PT-76 are seen

in this photo from 8-3-1942. Photo added 3-4-2019.

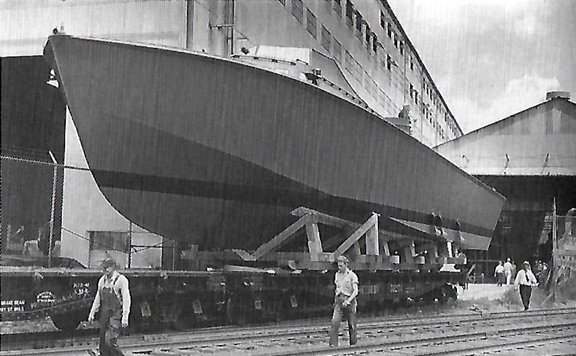

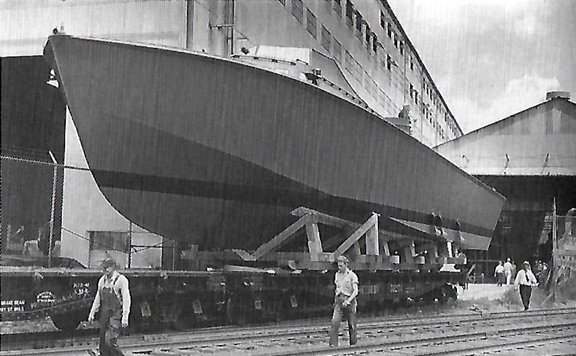

A PT boat exits Park City via railroad

transport to nearby Bayou St. Johns northeast of the plant.

Industrial Canal, New Orleans,

LA Plant: Land was purchased along the Industrial Canal for

a new plant. While Higgins and his staff drove to the negotiations for the purchase of the land for the plant, they were

listening to the car radio broadcast of news of the attack on Pearl

Harbor. The land was purchased, and workers started clearing the

land for construction the same day. Construction began on

the plant in January 1942 and it was dedicated on September 13, 1942.

First construction was for 150 50-foot LCM Tank Lighters that the British

had ordered in late 1941. The plant built at least 1,400 LCMs by the end of the war, most of them for the U.S. Navy. The

plant also built the 100 170-foot FS ships for the US Army.

Higgins built torpedo tubes at the plant that were activated by compressed air for

its PT boats. This product did not last to the end of the war

because the U.S. Navy went to a simpler roll-off torpedo launcher.

The plant also built the J-boats, tugs barges and other small boats for

the U.S. Army and Coast Guard. It was a busy place during World

War Two.

Two views of the Industrial Canal plant from

World War Two.

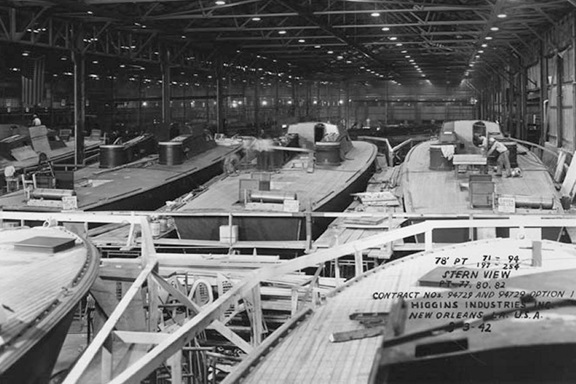

Inside the long assembly bay of the

Industrial Canal Plant, six LCM Tank Lighters are under construction in

the foreground with many others towards the rear of the plant. The

LCM(6) was fifty feet long and fourteen feet across the beam. In

October 1944, the Industrial Canal Plant produced its 1,000th LCM, having

started in September 1942 with a run rate of 450-500 per year. By

the end of the war, Higgins produced at least 1,400 of the LCMs for both

the U.S. Navy, the U.S. Army and the British. The British ordered 150 of the 50-foot tank lighters in early 1942. Production of the LCM commenced

in early June 1941 at City Park Plant. It then moved to Industrial Canal when

it opened.

A contemporary view of the former Higgins

Industrial Canal Plant. This was the primary ship and boat building

plant for Higgins Incorporated after World War Two. However, the

plant was too big to compete with the smaller boat manufacturers, and

too small to compete with the larger ship manufacturers. In the

end this led to the final demise of the Higgins' operations in 1959.

This Google Earth image shows the current

state of the former Higgins Industrial Canal plant complex. While

the factory buildings seem to be in relatively good shape, the covered

monorail structure is in poor condition. It was the monorail that

carried the completed LCMs from the building on the left out out the the

canal for launching. Image added 5-10-2024.

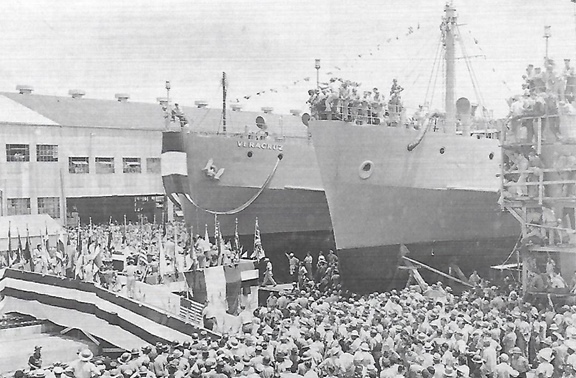

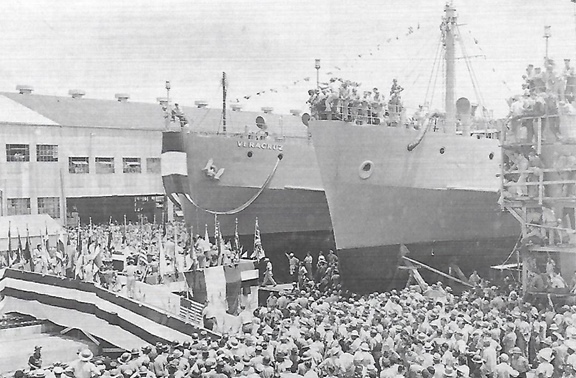

FS ship the Veracruz is launched at the

Industrial Canal Plant. Industrial Canal had the only moving

assembly line for cargo ships in the country.

Bayou St. Johns, New Orleans, LA: This

is where all of the boats came for testing and final shipping.

Sometimes the boats would be finished without engines and stored here

until they could be installed. The PT boats after initial work was

completed at the City Park plant were delivered to Bayou St. Johns by

railcar. Here they would be finished out, which took normally about

five months of work.

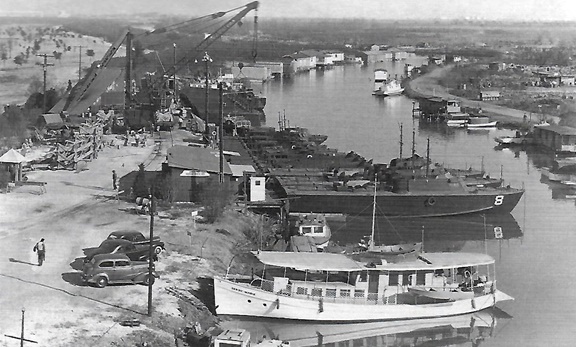

There are around 135 boats in this photo,

most of them landing craft. The majority of the landing craft

appear to be the fifty-foot LCM Tank Lighter. Near the bottom of

the left side of the photo are three 78-foot PT boats. Just above

them are about twelve smaller boats which are the 36-foot LCS(S) boats.

There are another seven LCS(S)s near the top of the photo.

An unfinished PT boat from the City Park

plant is lowered into the water for the average five-month finishing out

process.

LCVPs are being loaded on to railroad cars

at Bayou St. John for shipment to the U.S. Navy. Note that they

have the rounded chines on the stern.

Higgins Engine Company Plant, New Orleans,

LA: In March 1942, Higgins purchased the Tucker Aviation

Company of Ypsilanti, MI, and formed the Higgins-Tucker Engine Company to

build marine engines for his boats, as there were engine shortages during

the war. The company was renamed Higgins Engine Company after

Preston Tucker, CEO of Higgins-Tucker Engine resigned in December 1943.

The engine shortage went away, and only 100 engines were produced to fulfill a government

contract near the end of World War Two. Afterwards Higgins Engine

was dissolved.

Victory Plant, New Orleans, LA:

During World War Two Higgins Industry cut

LCMs into several pieces with torches. The components were then

boxed at the Victory Plant where they could be more easily shipped in

the hold of a transport. U.S. Army engineers near the war fronts then re-welded the

parts back into the final LCM. This process was an Andrew Higgins

invention.

West End Plant, New Orleans, LA:

This was located on the New Basin

Canal. Military boat operator and maintenance

training was conducted in this plant for a good portion of the war.

The training moved to another location when the numbers of trainees

exceeded the capacity of the building. By the end of the war

300,000 military personnel were trained by Higgins Industries in New

Orleans.

Industries Building,

New Orleans, LA: Occupied

by Higgins in September 1943. The first four floors of this

eight-story building at Gravier and South Saratoga Streets in New

Orleans were the employment offices for Higgins Industries, Higgins

Aircraft, Higgins Engine Company, and Higgins Plastic Corporation.

The fifth and sixth floor were leased out.

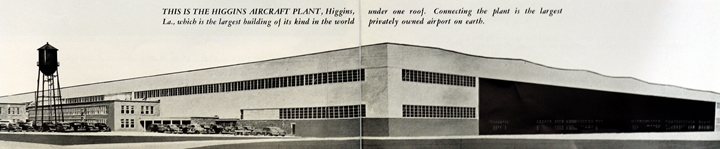

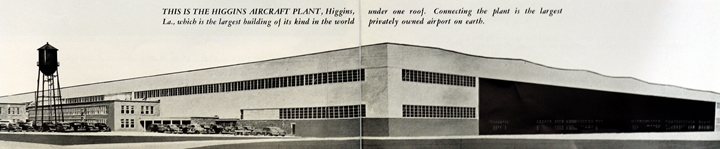

Higgins Aircraft Plant, Michoud District,

New Orleans, LA: Construction on this plant

started in April 1942, to build

100-200 Liberty Ships on four parallel production lines. Work stopped on July 18, 1942, when the Liberty Ship

contract was cancelled for lack of steel. Work resumed on the

plant to convert it from a ship building facility to an aircraft plant.

This transpired when Higgins received a contract to build 1,200 Curtiss

C-76 all wooden twin engine transport aircraft. This contract was

then cancelled on August 3, 1943. The same day it was

announced that Higgins Michoud would build C-46 Commando transport

aircraft. Only one C-46 was produced at Michoud as the contract for C-46s was