|

Lithography in the Pacific War - The

Harris-Seybold-Potter LTE Offset Press in Action

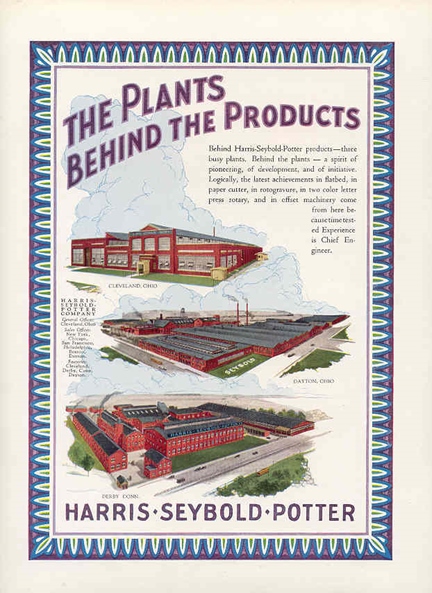

Harris-Seybold-Potter in World War Two

Harris - Cleveland, OH;

Seybold -

Dayton, OH;

Potter - Derby,

CT

1895-1926 - Harris

Automatic Press Company

1926-1946 -

Harris-Seybold-Potter

1946-1957 - Harris-Seybold

1957-1974 - Harris Intertype

1974-2019 - Harris Corporation

2019-Present - L3Harris

This page updated 1-13-2022.

An American Auto

Industry in World War Two Special Edition

During World War Two there were

several top secret American weapons projects. The most

well-known is the Manhattan Project, which produced the atomic bomb.

The story of this former secret project has been well documented since

the end of the war. Another top secret project, at least

until mid-war when it was reduced to confidential, was the Norden

Bombsight. It was reduced to confidential once it was known that

the bombsight had fallen into the possession of German military

authorities from American bombers shot down over Europe. After

World War Two the Norden bombsight was totally de-classified and sold as

military surplus. Many of them can be found in museums today.

NCR built the bombe computers in Dayton,

OH,

which were used to de-code the German Enigma messages. This

project continued its top secret classification for many years after

World War Two due to the technology in the bombes that could be used to

de-code top secret messages from post-war hostile nations. Persons

that worked on the project or operated the bombes were sworn to secrecy.

It wasn't until the several decades later that the project was declassified.

The only surviving bombe is on public display at the National Cryptologic Museum in

Annapolis Junction, Maryland.

However, there was another top secret project

that was developed and produced two miles away from the NCR top secret

project in Dayton, OH. This was the BEA/K-1 bomb computer and

bombsight. The development and production of this top secret

device was at the Seybold plant of Harris-Seybold-Potter at 819 West Washington

Street. The BEA/K-1

computer and bombsight remained in production and as a top secret

project after World War Two. It was not until 1970 when

Harris-Seybold donated two early models of the BEA/K1 to the National

Museum of the United States Air Force that this project became public.

That being said, there is virtually no known

history of the BEA/K1 in wartime use. Unlike the Norden

bombsight it was meant to replace, there is no literature on it nor any

BEA/K1s on display in museums. It is still unknown and by virtue of

this, still secret.

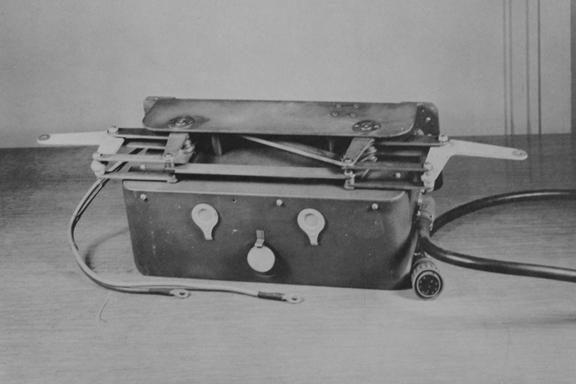

The National Museum of the United States Air

Force has two BEA/K1 bombsight computers in its possession. The

BEA/K1 was an extremely complicated electro-mechanical computer.

Photo courtesy of the National Museum of the United States Air Force.

Most likely, the Seybold facility was chosen

by the Army Air Force Material Command at nearby Wright Field for two

reasons. Firstly, Seybold had demonstrated an ability to take on

diverse and difficult projects and produce them in a timely manner.

Secondly, the close proximity to

Wright Field facilitated communication on the project.

Personal communication on a project of this complexity allowed for

faster development and manufacture. Not only did the Seybold plant

do the development and prototype work, but it then received a

production contract for 250 units.

Photo courtesy of the National Museum of the

United States Air Force.

The Company

All Alfred and Charles Harris wanted to do in 1890 was to be able

to obtain advertising flyers faster for their jewelry business in Niles,

OH. Therefore, they developed an automatic feed mechanism for

printing presses that was ten time faster than manual feed systems of

the era. In 1895 they formed the Harris Automatic Press Company in

Niles, OH. The first factory was in two rooms of the same house in

which President McKinley had been born in 1843.

Today, Alfred and Charles Harris would not recognize the company nor the

company's products that still bear their name, L3Harris of Melbourne,

FL. The company exited the printing press business in 1983 and is

now a premier electronics and defense company. Nor would the

brothers have recognized the BEA/K1 bomb computer that the company

developed during World War Two. However, they would recognize the

printing press shown below. This has direct lineage back to

their products from 1895. But Alfred and Charles would approve of

the changes. Just as they were innovators and changed with the

times, so did the company that still bears their name.

The War Effort

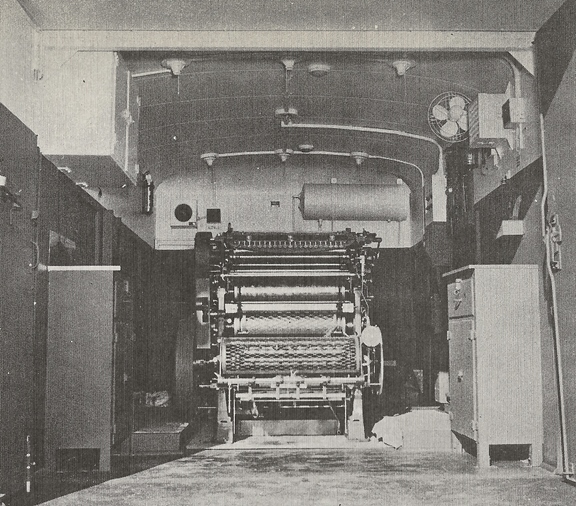

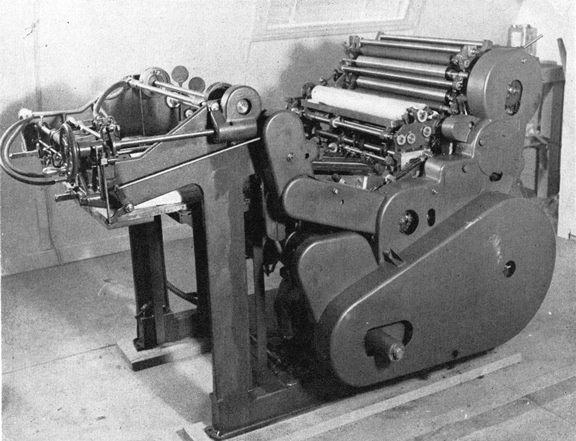

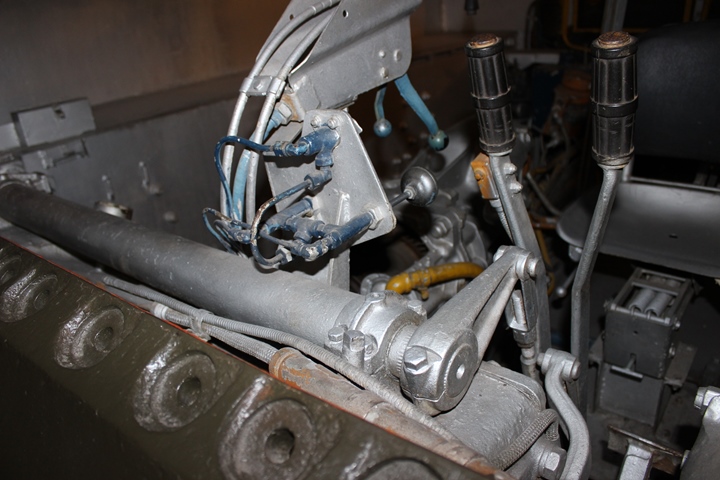

This Harris Cleveland, OH plant-built LTE press is located in the

enclosed body of a 2-1/2-ton 6x6 military truck. This was a mobile

printing press that could keep up with advancing Army units. Local

operating area maps were important to the Army soldiers.

Harris presses printed the needed maps at the location they were needed

for timely distribution to the troops. This was just one of many

applications that the Harris LTE presses performed. There was also

a need for reports and orders to be printed and distributed.

Another possible use for the Harris LTE presses was the printing of the

"Yank" newspaper which kept soldiers informed of what was

happening outside the soldiers' foxholes. Image from the September

1943 Harris Victory Review from the collection of Rich Foley.

In January 2021 I received an email from

Richard Foley of Dayton, OH. In his original and later emails, he

provided information on the company for which he once worked,

Harris-Seybold. This was a company that prior to and after

World War Two primarily manufactured printing presses and paper cutting

machines. I had never heard of Harris-Seybold until Rich's initial

email and had not thought about how a printing press company could

contribute to the winning of World War Two. Over the next few

months, I learned how much Harris-Seybold contributed to the war

effort and the diversity of its products and customers during that era.

Mr. Foley also informed me that as an employee of the Seybold plant in

Dayton, OH, he had been able to save information from the company

pertaining to World War Two. He also informed me that he had

donated this information to the local historical museum, Dayton History

at Carillon Historical Park.

This resulted in several trips for Mr. Foley and me to explore the

historical archives of Dayton History.

Without Mr. Foley's presence of mind to save historical documents and

artifacts from Harris-Seybold, this page would have been very difficult,

if not impossible

to do at all. Mr. Foley has been instrumental in making

this page a reality.

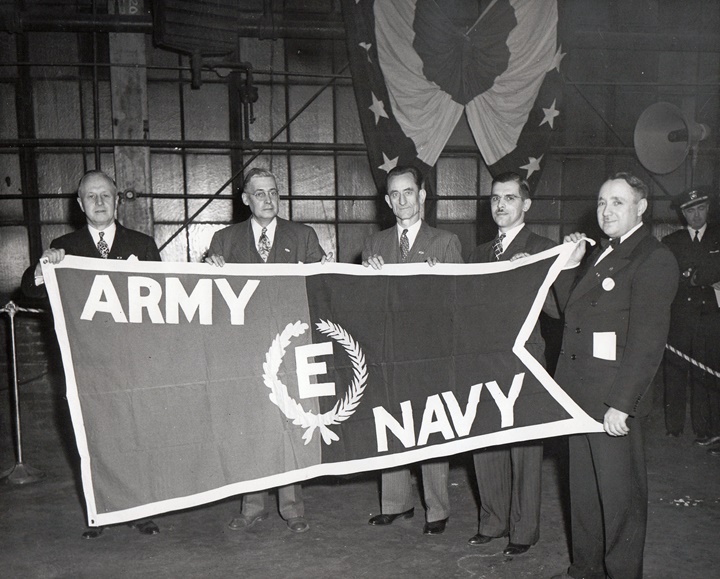

One of the artifacts Mr. Foley saved was

this original Army-Navy "E" flag that

the Seybold plant in

Dayton, OH won on December 12, 1944. He donated this to Dayton

History to be preserved for posterity. I have come across

several cases like this, where an employee is tasked with cleaning out

old documents and artifacts to be trashed, and the employee instead

saves the flag. Seybold won a second award on or about May 25,

1945. From the collections of Dayton History.

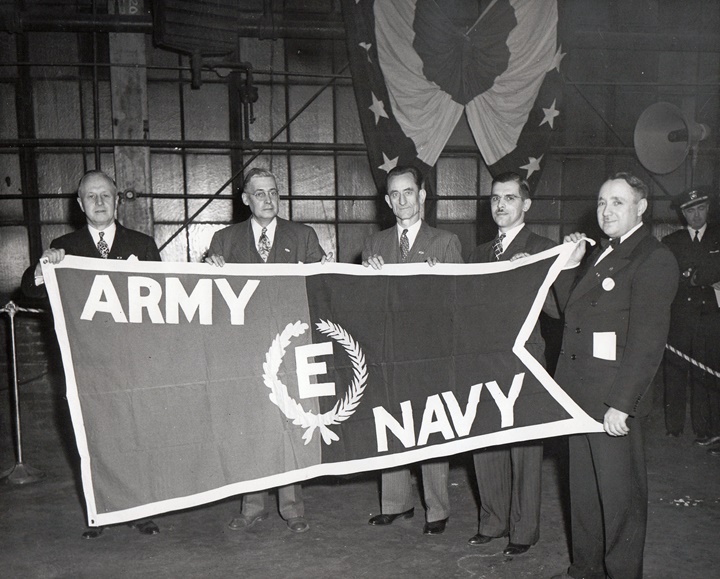

The Harris

Cleveland, OH plant also won the Army-Navy "E" two times. This

photo is from December 11, 1944, when it won the flag for the first time.

It won its second award on May 25, 1945. Photo courtesy of Rich

Foley.

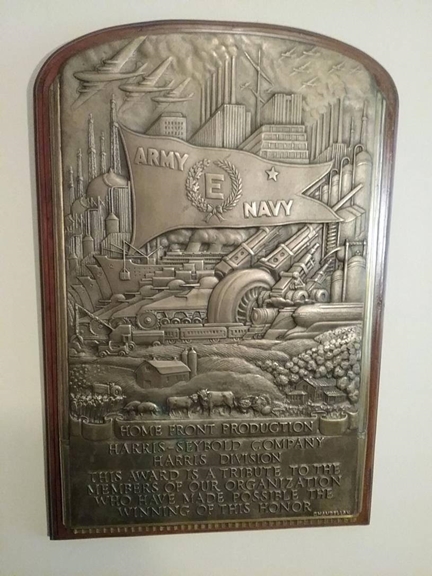

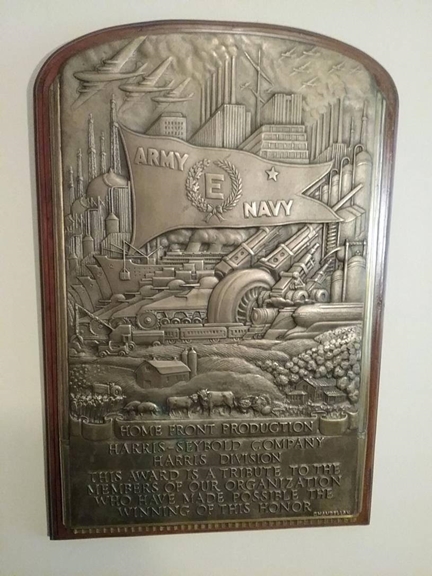

The Harris plant also received this plaque

to honor its winning of the Army-Navy "E" award. Photo courtesy of

Rich Foley.

Author's Note: During the World

War Two era, the name of the company was Harris-Seybold-Potter.

However, for all intents and purposes the company was really

Harris-Seybold. The post-war booklet, "Harris-Seybold, Its War

Record," published by Harris-Seybold, makes no mention of the Derby, CT

Potter operation. I was not able to find any other historical

documentation that identified what products Potter built for the war effort.

Therefore, this page is really a Harris-Seybold page. However,

because the company was still called Harris-Seybold-Potter during World

War Two, I will use that nomenclature when referring to the company.

Harris-Seybold-Potter World War Two Products: The information

presented in this section shows the diversity of products

Harris-Seybold-Potter produced to help win World War Two.

Normally, this depth of information is not available. Harris-Seybold-Potter is a great example

of this product diversity that has been lost from many other companies.

Table 1 -

Harris-Seybold

Prime Military Contracts

The information below comes from an

early post-war booklet, "Harris-Seybold, Its War Record."

This was one of the documents saved by Mr. Foley and is now part

in the collection of Dayton History. There is no date of publication in the booklet

but is most likely 1946 or 1947.

On one

hand, the information below is a rare treasure trove of

information on what the company built to help win World War Two.

Product names, quantities, and contract numbers are all included.

On the other hand, many of the product descriptions are vague,

and do not really identify what the product really was. Also, the

booklet shows the contracted and completed amount to be

identical for both quantities. Typically, this was not the

case during World War Two. However, the information below

is invaluable for a look at what this company accomplished during

World War Two. |

|

Quantity |

Product |

Customer |

Contract Number |

Comments |

| ? |

LTE

Presses |

Army

Service Forces, Corps of Engineers |

W-11-114 ENG. (MSP) 790 |

Built

at the Harris Cleveland Plant.

These were an important piece of equipment for the making of

maps in the war zones. |

| 792 |

M4/M4A1 Tank Controls |

Pressed Steel Car Company |

W-271-ORD-717 |

These

were for the Pressed Steel-built M4/M4A1 Sherman tanks. The

M4/M4A1 was the preferred version of Sherman tank for the first

2.5 years of the war. |

| 60 |

Radar

Units |

Navy

Department |

NXso-21252 |

Harris-Seybold-Potter built the mechanical geared systems that

allowed the shipboard radar units to rotate and elevate to track

enemy ships and aircraft. |

| 100 |

Radar

Units |

Navy

Department |

NOrd-3971 |

Harris-Seybold-Potter built the mechanical geared systems that

allowed the shipboard radar units to rotate and elevate to track

enemy ships and aircraft. |

| 538 |

Spindles, elevating arcs, covers, and associated equipment for

827 radar antenna mounts |

Navy

Department |

NOrd-5879 |

Built

at the Harris Cleveland Plant.

Harris-Seybold-Potter built the mechanical geared systems that

allowed the shipboard radar units to rotate and elevate to track

enemy ships and aircraft. |

| 185 |

Radar

Units |

Navy

Department |

NOrd-6026 |

Harris-Seybold-Potter built the mechanical geared systems that

allowed the shipboard radar units to rotate and elevate to track

enemy ships and aircraft. |

| 1,000 |

M-10

Recoil Mechanisms |

War

Department, Cleveland Ordnance District |

W-303-ORD-1209 |

Built at the Harris Cleveland Plant.

These were the recoil mechanisms for the M10 Wolverine tank

destroyer. |

| 100 |

57mm

Anti-Tank Gun M-12 Recoil Mechanisms |

War

Department, Cleveland Ordnance District |

W-303-ORD-1658 |

This

was a small number of recoil mechanisms compared to the 16,637

57mm anti-tank guns that were built. |

| 50 |

Servo

Units |

Navy

Department |

NOrd-7062 |

Harris-Seybold-Potter built the mechanical geared systems that

allowed the shipboard radar units to rotate and elevate to track

enemy ships and aircraft. |

| 3,950 |

Servo

Units |

Navy

Department |

NOrd-8130 |

Harris-Seybold-Potter built the mechanical geared systems that

allowed the shipboard radar units to rotate and elevate to track

enemy ships and aircraft. |

| 3,000 |

Control Units for Project Pelican |

Navy

Department |

NOrd-4813 |

The

Pelican was a 1,000 pound guided bomb that never got out of the

development program and was cancelled in 1944 after two years of

limited testing. Only a few were built. It is

unlikely 3,000 units were actually built. |

| 900 |

Control Units for Project Bat |

Navy

Department |

NOrd-6412 |

This

weapon was the operational guided bomb for the U.S. Navy during World War Two

and was derived from the early Project Pelican. However,

it only saw limited use with 33 launched during the war.

It is unknown whether the 900 originally contracted control

units were actually built. |

|

120,000 |

Stereoscopic Relief Prints |

Navy

Department |

NXsa-20687 |

|

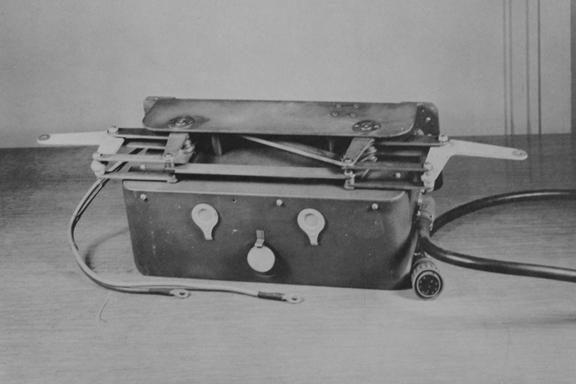

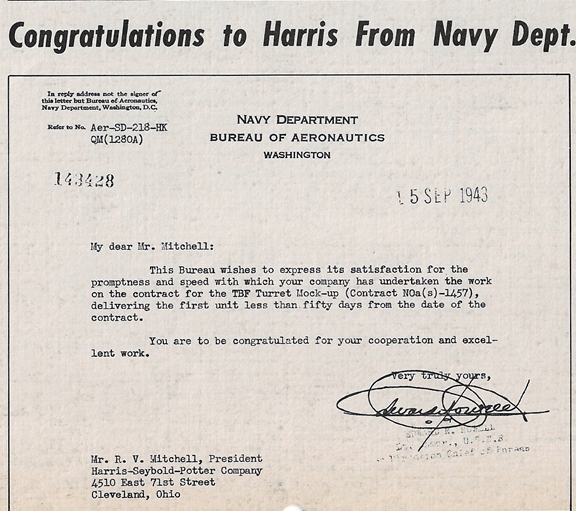

| 1 |

TBF

Avenger Turret Mock-up Model |

Navy

- Bureau of Aeronautics |

NOa(s)-1457 |

Built

at the Harris Cleveland Plant.

The Navy must have needed this for a special display. |

| 201 |

Five-Inch/25 Caliber Wet Gun Mounts for Submarine Use |

Navy

Department |

NOrd-4461 |

Built at the Harris Dayton Plant. |

| 100 |

Propeller Stands |

Wright Field, USAAF |

W-535-ac-22871 |

Built at the Harris Dayton Plant.

These

were actually propeller blade stands and looked like a picnic

table benches. |

| 600 |

Propeller Stands |

Wright Field, USAAF |

W-535-ac-27733 |

Built at the Harris Dayton Plant.

Same

as above. |

| 5,000 |

Cam

Limit Stops |

Navy

Department |

NOrd-7096 |

This

is very well defined. |

| 8,000 |

Cam

Limit Stops |

Navy

Department |

NOrd-5554 |

This

is very well defined. |

| 10,000 |

Cam

Limit Stops |

Navy

Department |

NOrd-5364 |

This

is very well defined. |

| 200 |

Computer Assemblies |

Army

Air Forces |

W-33-038 ac-627 |

Built at the Harris Dayton Plant. |

| 2 |

Experimental Models of BEA-AN/APN-3 |

Army

Air Forces |

W-535

ac-33682 |

Built at the Harris Dayton Plant.

This was the top secret bomb release computer. The

AN/APN-3 was a Shoran based system. |

| 250 |

Computer Assemblies |

Army

Air Forces |

W-33-038 ac-7701 |

Built at the Harris Dayton Plant.

This was the top secret tK1 bomb release computer. The

AN/APN-3 was a Shoran based system. |

| 1000 |

Elevating Arcs |

Navy

Department |

NOrd-7069 |

Elevating arcs were used in the three-inch dual purpose gun that

was used in destroyer escorts, LSTs, and Merchant Marine ships.

Elevating arcs were also used in

the Navy's five-inch dual purpose gun that was used on all

fighting ships larger than a destroyer escort. These were

the main guns and destroyers. Cruisers, battleships, and

aircraft carriers were all armed with five-inch guns.

Harris-Seybold-Potter probably

made elevating arcs for both types of weapons. |

| 600 |

Elevating Arcs |

Navy

Department |

NOrd-7946 |

Same

as above. |

| 1000 |

Elevating Arcs |

Navy

Department |

NOrd-4473 |

Same

as above. |

| 200 |

Elevating Arcs |

Navy

Department |

NOrd-9194 |

Same

as above. |

| 2,500 |

3-Inch Fuze Setters and Spare Parts |

Navy

Department |

NOrd-939 |

The three-inch dual purpose gun that

was used in destroyer escorts, LSTs, and Merchant Marine ships.

|

| 1,750 |

3-Inch Fuze Setters and Spare Parts |

Navy

Department |

NOrd-4858 |

Same

as above. |

|

Table 2 -

Machine Tools built for Other Companies |

|

Quantity |

Type |

Location |

| Over

250 |

Bullard Vertical Boring Machines |

Built

at the Harris Cleveland Plant. |

| |

Wickman Screw Machine Lathes |

Built at the Harris Dayton Plant. |

| |

Hartinge Precision Lathes |

Built at the Harris Dayton Plant. |

| |

Morrison Metal Stitching Machines |

Built at the Harris Dayton Plant. |

Companies Harris-Seybold had sub-contracts

with:

Akron Standard Mold, Allen Bradley Company,

Allen Tool & Mfg. Company, Babcock Wilson Company, Bell Industries, Bell

Sound System, Bendix Corporation, Briggs Manufacturing Company, Broat

Pattern & Casting Company, Cincinnati Gear Company, Cort Engineering and

Manufacturing Company, Crucible Steel Company, Cutler Hammer, Inc.,

Dayton Aircraft, Inc., Dayton Rubber Company, Diamond Machine Company,

Eclipse Pioneer Division of Bendix Corporation, Emerson Electric

Company, Fafair Bearings, Inc, Fawick Airflex Company, Federal Gear

Company, General Aluminum Company, Goodyear Aircraft Corporation,

Hoffman Sheet Metal Company, Hooper Transmission Company, Joseph T.

Ryerson & Sons, Kin-E-matic Machine Company, Lear, Inc., Leece-Neville

Company, New Departure Division of General Motors, Option Laboratories,

P.R. Mallory Company, Piqua Engineering, R.C. Allen Company Strong,

Carlisle & Hammond, Reynolds Metal Company, Rocket Machine Company,

Scientiae, Struthers Wells Company, Veeder-Root Company, Westinghouse

Electric Corporation.

Harris-Seybold Machine Tools: The reason that

Harris-Seybold-Potter was able to make a variety of products for many

different customers during World War Two was that the manufacture of

printing presses required well equipped tool rooms. So, when the

war came, the Harris plant in Cleveland and the Seybold plant in Dayton

were able to manufacture a variety of products.

Both the Cleveland and Dayton factories also

had their own gray metal cast iron foundries and pattern shops.

This allowed both locations to make the castings and then do the final

machining at one location.

|

Table 3 -

Harris-Seybold Machine Tools |

| Tool

Type |

Quantity

at Harris Plant, Cleveland, OH |

Quantity at Seybold Plant, Dayton, OH |

|

Single Spindle Drill Press |

15 |

9 |

|

Multi-Spindle Drill Press |

10 |

|

|

Radial Drills |

10 |

12 |

|

Sensitive Drills |

|

10 |

| Fixed

Bed Milling Machines |

5 |

|

| Jig

Borers |

3 |

|

|

Horizontal Boring Mills |

3 |

5 |

|

Verticlal Milling Machines |

10 |

|

|

Horizontal Milling Machines |

13 |

16 |

|

Miscellaneous Milling Machines |

5 |

6 |

|

Hydrotel Type Milling Machines |

|

2 |

|

Engine Lathes |

|

10 |

|

Horizontal, Bar Type Turret Lathes |

12 |

|

|

Horizontal, Chuck Type Turret Lathes |

10 |

|

|

Bullard Lathes |

|

4 |

|

Vertical Turret Lathes |

4 |

9 |

|

Cylindrical Grinders |

7 |

4 |

|

Internal Grinders |

1 |

|

|

Surface Grinders |

1 |

5 |

|

Centerline Grinders |

|

1 |

| Disk

Grinders |

|

3 |

|

Polishers |

8 |

|

| Gear

Cutters |

9 |

3 |

| Gear

Hobbers |

|

4 |

| Gear

Shapers |

|

2 |

| Gear

Shavers |

|

1 |

| Large

Planers |

|

7 |

| Small

Planers |

|

8 |

| Small

Hand Screw Machines |

|

4 |

| Small

Hand Feed Screw Machines |

|

2 |

|

Automatic Screw Machines |

|

1 |

| Large

Head Screw Machines |

|

5 |

| Broaches |

|

2 |

|

Shapers |

|

2 |

Product Photos:

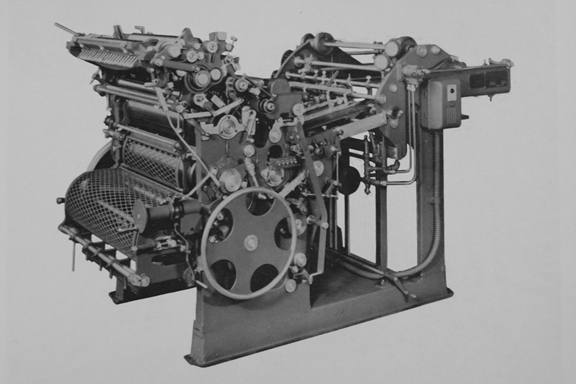

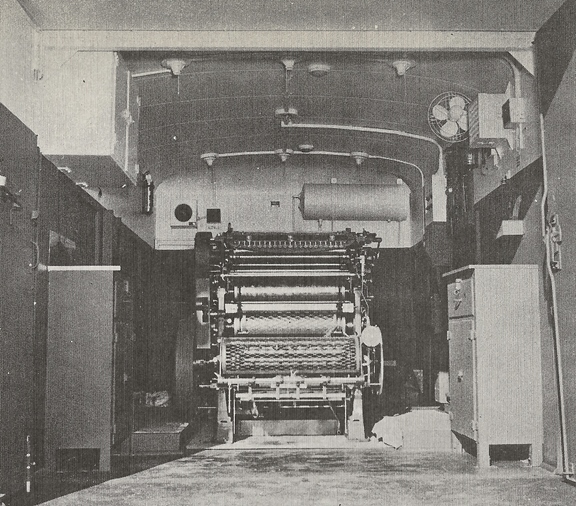

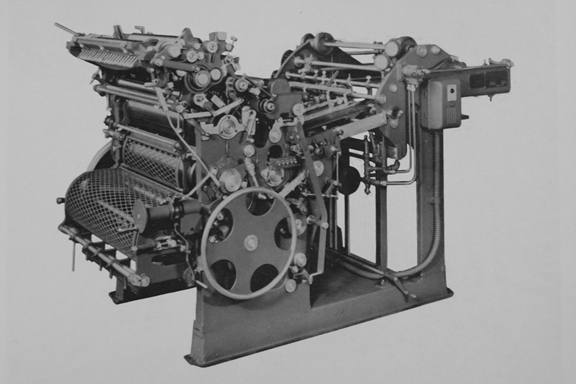

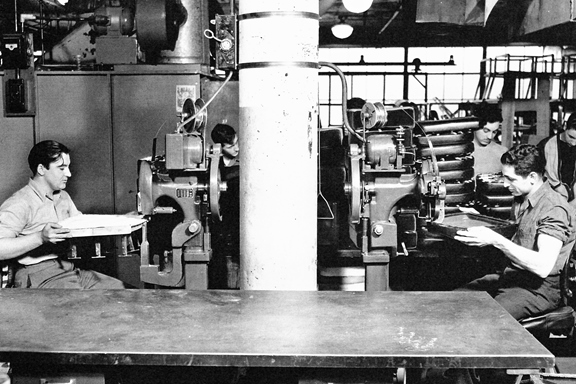

The Cleveland plant built 750 LTE 20x22

single color offset printing presses for the Army Corps of Engineers

during World War Two. From the collections of Dayton History.

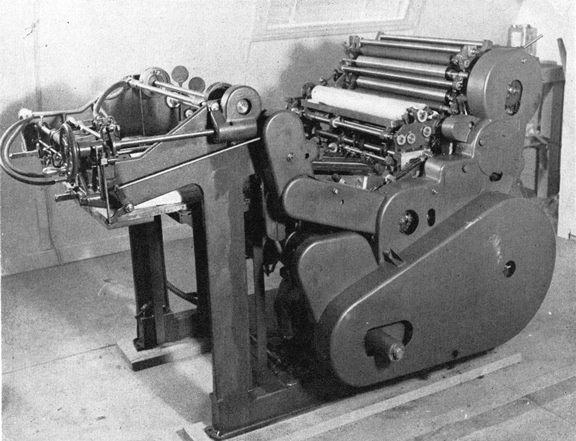

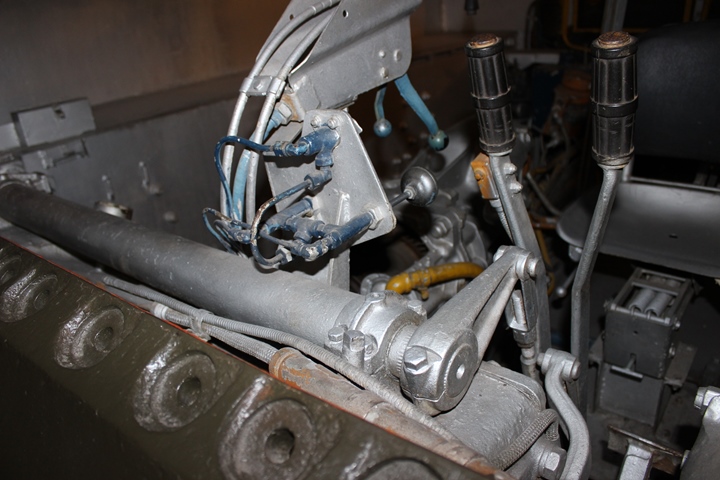

This shows the reverse side of the LTE.

Photo courtesy of Richard Foley added 1-8-2022.

This is the USS Slater on the Hudson River in

Albany, NY. This is the most well restored World War Two warship

on display in the United States. Author's photo.

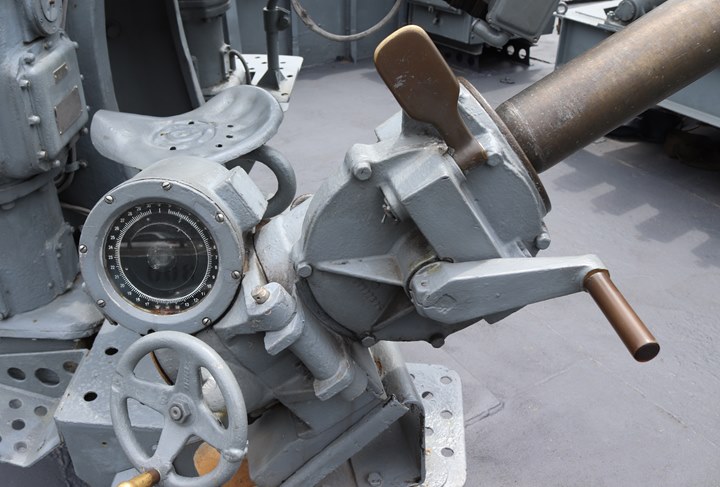

This is the number one three-inch gun on the

USS Slater. Part of the geared elevating arc is visible under the

weapon's recoil mechanism. The fuze setter is on the opposite side

of the weapon. Author's photo.

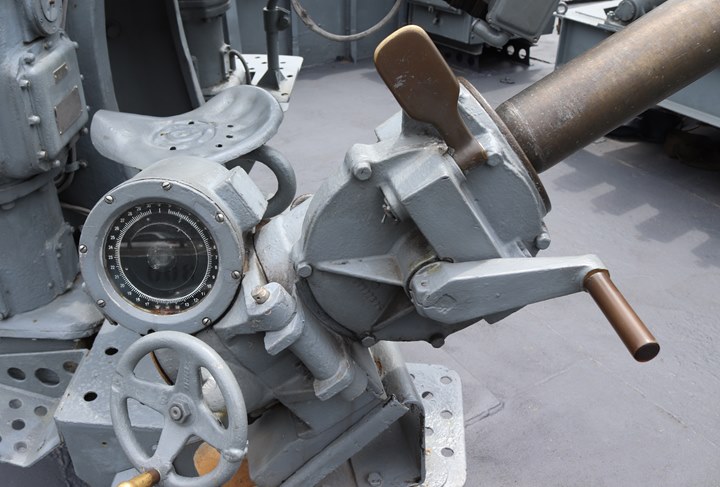

A fuze

setter for the three-inch shell is On the left side of the weapon. Author's photo.

Harris-Seybold made 4,250 of the three-inch

fuze setters for the U.S. Navy during World War Two. With that

many made, this could very well be a Harris-Seybold unit. The fuze

setter is an assembly of castings with internal parts. Both the

Cleveland and Dayton plants had the capability to make the patterns,

cast the parts, and then machine them to final tolerances and assemble them. Author's photo.

The dial pointer could designate the

range of the projectile before exploding to the nearest two hundred

feet. Author's photo.

The fuze setter was used when the weapon was

used as an anti-aircraft gun. The distance to target was estimated

and the fuze was set for that amount of distance. This information

was furnished to the gun crew from the sailors operating the range finders.

Author's photo.

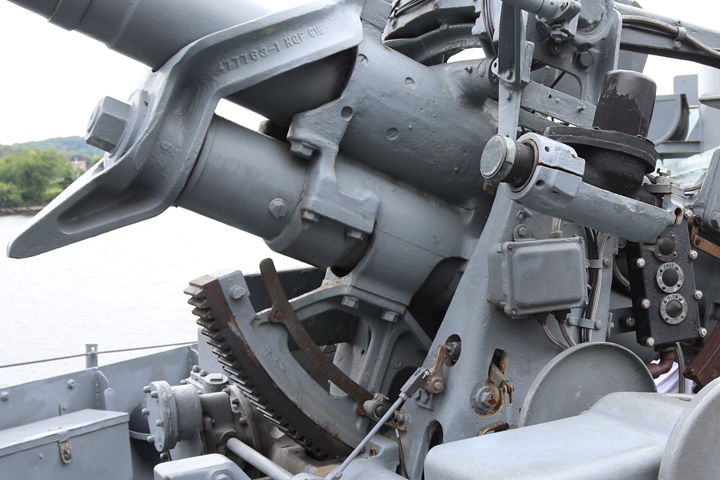

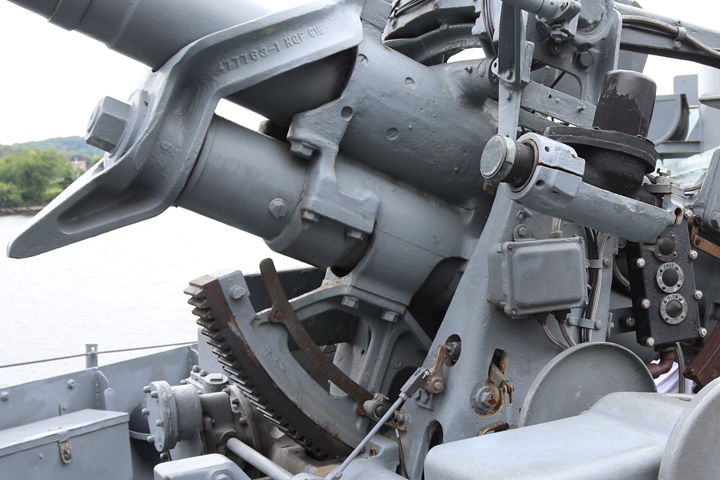

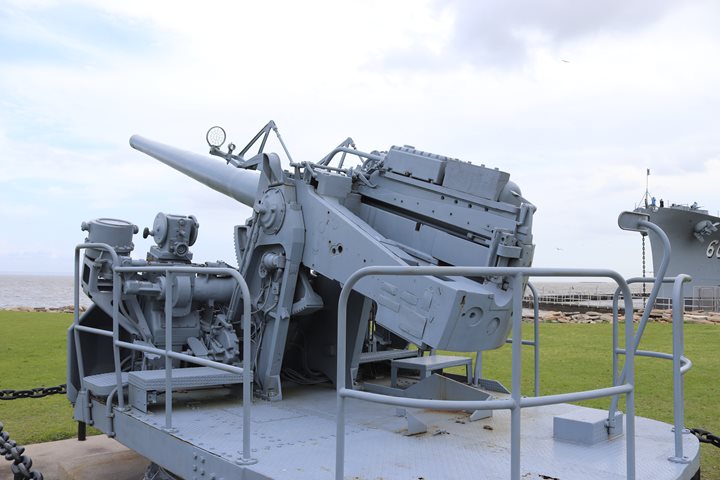

Harris-Seybold-Potter had four contracts from the U.S. Navy totaling 2,800

elevating arcs. The elevating arc on the three-inch gun was

attached to a large casting by four bolts that encased the barrel and

recoil mechanism. Author's photo.

This three-inch gun on LST 393 in Muskegon,

MI reveals the Harris-Seybold-Potter-built elevating arc underneath the

barrel of the weapon. Author's photo.

The elevating arc for the three-inch

gun consisted of several castings and a stamped part assembled together.

This photo gives a good view of the rear of the elevating arc and how it

connects to the rear of the weapon. Author's photo.

This three-inch dual purpose gun is on

display at the American Legion in Shelburne, IN and shows the front of

the elevating arc. Author's photo.

This view of the elevating arc shows the

gears cut into two castings and the markings on the stamped part.

The entire elevating arc consists of at least four castings. Both

the Cleveland and Dayton plants had the ability to cut the gears for this

device. Author's photo.

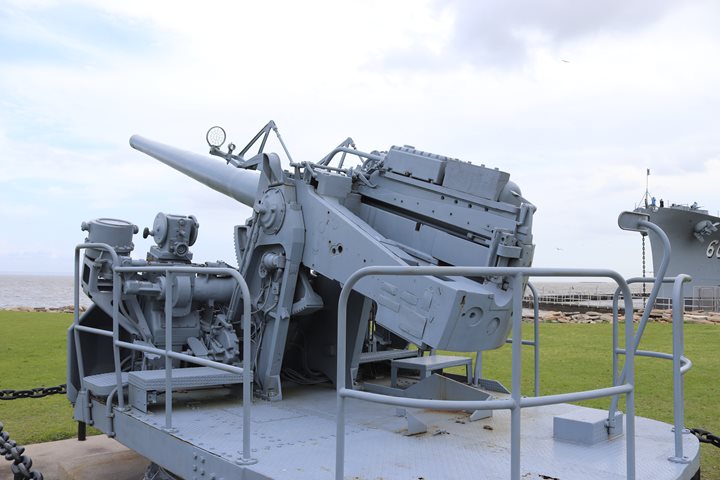

This five-inch, 38 caliber gun is on display

at the USS Alabama in Mobile, AL. Both ends of the elevating arc

on the weapon can be seen. This is a much larger unit than the

ones utilized for the smaller three-inch gun. The U.S. Navy had

larger guns that had elevating arcs up to sixteen inches, which would

have been extremely large units. These may have been beyond

Harris-Seybold-Potter's capability to produce. Author's photo.

This five-inch, 38 caliber gun can be

seen at the USS Sullivans at the Buffalo and Erie County Naval and

Military Park in Buffalo, NY. This is the more familiar form of a

five-inch naval gun from World War Two. Author's photo.

The U.S. Navy was a big customer of

Harris-Seybold-Potter during World War Two. The company produced

201 wet mounts for the five-inch deck guns on U.S. Navy submarines.

These mounts were required to function properly after being immersed in salt

water for long periods of time.

Harris-Seybold-Potter built control units

for both the U.S. Navy's Pelican and Bat guided glide bombs. The

Pelican program was terminated while still in the testing phase.

However, the ASM-N-2 Bat did go into production and was used in very

limited combat late in the war. Between April and July 1945, 33

Bats were launched at targets. Four were hits, one of which

severely damaged the bow of a Japanese escort ship. The ASM-N-2

Bat carried a 1,000 pound warhead and had a range of fifteen miles.

It was guided to its target by a radar seeker in its nose.

As the Bat approached the target, the radar

seeker in the nose of the weapon sent correction signals to the

Harris-Seybold-Potter-built control unit. While the use of guided

bombs was in its infancy during World War Two, it was high-tech for the

era. Harris-Seybold-Potter was a part of this high tech

revolution. From the collections of Dayton History.

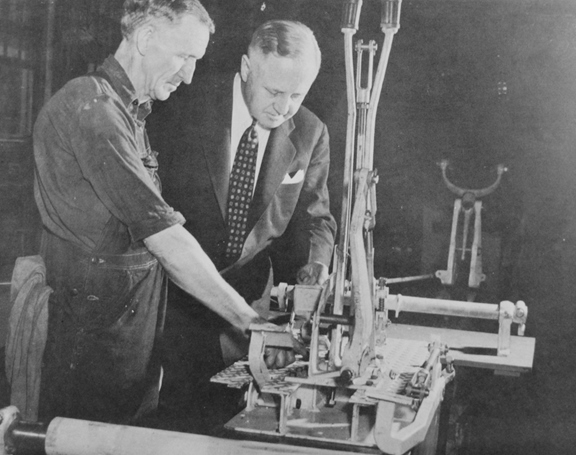

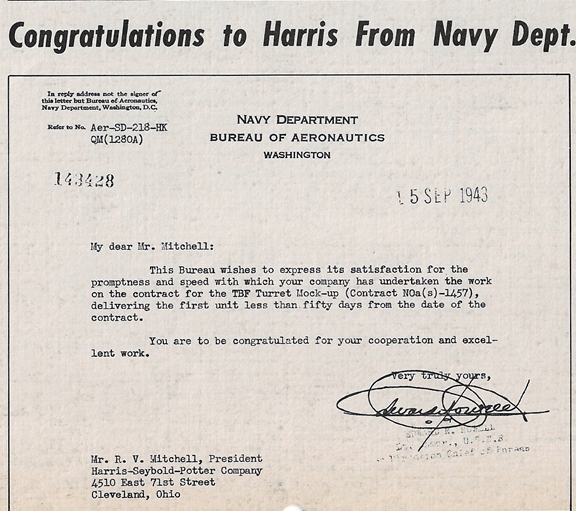

In 1943 Harris-Seybold-Potter built one TBF

turret mock-up. Company records indicate only this one was built.

However, this letter implies that this was the first of several.

Production of the actual turret had been in production since before

Pearl Harbor. In 1943 the General Motors Eastern Aircraft Division

was producing the license-built TBM in volume and Emerson Electric was

building the turrets. It is unknown why a mock-up was needed when

the actual turrets were in production. Image from the September

1943 Harris Victory Review from the collection of Rich Foley.

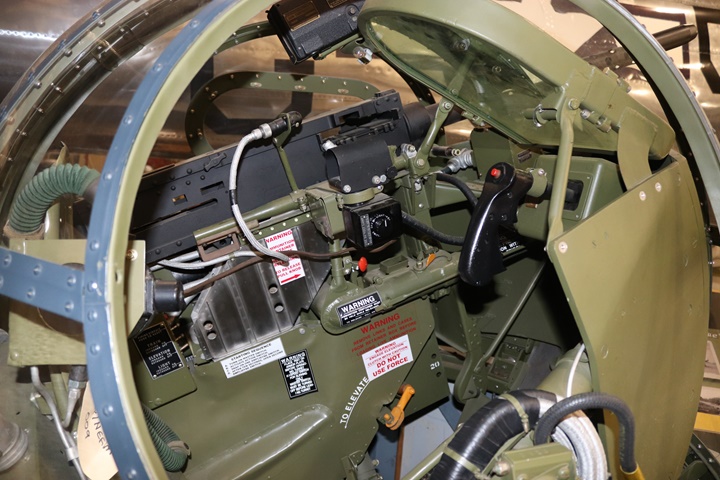

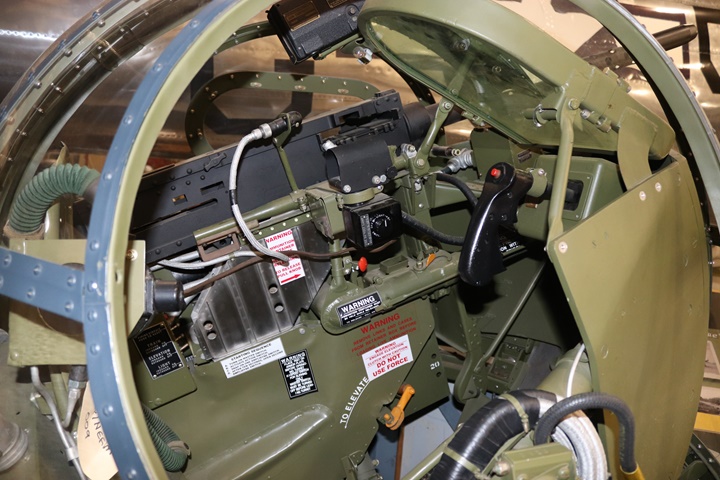

This and the next three photos show an

actual TBM turret. It is unknown how much detail and functionality

the mock-up contained. Its purpose is unknown. Author's

photo from the

New England Air Museum.

Author's photo from the

New England Air Museum.

Author's photo from the

New England Air Museum.

Author's photo from the

New England Air Museum.

This un-restored TBM turret at the Liberty

Aviation Museum in Port Clinton, OH shows that the framework of the

turret was formed steel pipe. Author's photo

This Fisher Body-built M10 Wolverine is

armed with a three-inch main gun. The Harris Cleveland plant built 1,000

recoil mechanisms for this weapon. The M10 was the main

self-propelled anti-tank gun used by the U.S. Army during World War Two.

It began its combat service in North Africa and served in Sicily, Italy,

northeast Europe, and the Philippines. There were a total of 6,406

M10 and M10A1s built during World War Two. Author's photo.

Harris-Seybold-Potter built 792 tank

controls for the Pressed Steel Company of Chicago, IL which built the M4, M4A1, and M4A2

Sherman medium tank. The two long levers are the

steering brakes. The driver pulled back on the one for the

direction he wished to steer the tank. This applied the brakes to

the drive mechanism for that side of the tank. To slow down or

stop, both levers were pulled to the rear. This was not easy work

for the driver. I have seen videos of restored Sherman tanks

showing the driver pulling back on the brakes. Many times, they used both arms to pull one of them back and turn the tank. Good

upper arm and shoulder strength in a driver was a big plus.

The tank control shown here also includes the

gas clutch pedals. It was a true control assembly. From the

collections of Dayton History.

Here are the two upper ends and hand grips

on the steering brakes in an M4A2 Sherman tank at the Canada War Museum.

Author's photo.

The 792 tank controls built by Harris-Seybold-Potter could have gone into

any of several of the Sherman tanks built by Pressed Steel. This Pressed Steel-built small hatch

M4A1(75) is serial number 192, built in July 1942. It

is USA number 3014948. It is the oldest Pressed Steel

M4A1(75) known to exist and is owned by the Virginia Military Museum of

Military Vehicles. The tank controls could have been used

in a tank like this. Author's photo.

This

M4E9(75) was built by Pressed Steel and is on display at the USS Alabama

in Mobile, AL. This was the welded version of the Sherman. Harris-Seybold-Potter-built tank controls were in

tanks that were used in all the campaigns and many important battles.

Author's photo.

Harris-Seybold-Potter built 100 recoil

mechanisms for the 57mm anti-tank gun. Author's photo.

Harris-Seybold-Potter machined several of

the small parts used in the Allison V-1710 aircraft engine. The

engine was used in the both the P-40 and P-38 fighters of World War Two.

Author's photo.

Morrison Stitchers developed by the Dayton

Seybold plant were not shown in any of the contracts in Table 1. In

the background, workers can be seen assembling these machines. Aviation companies

used these to replace rivets in many

applications. The Morrison Stitcher was a faster and more

efficient way to fasten two parts together. Photo courtesy of Rich

Foley.

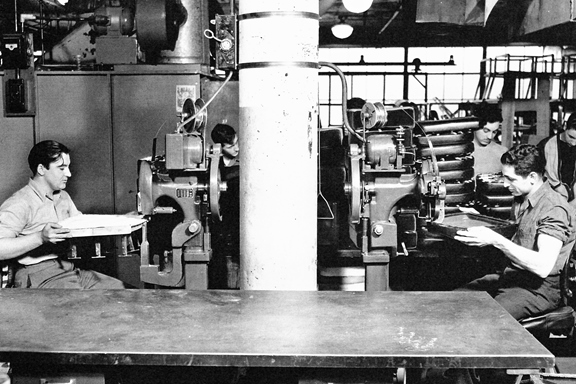

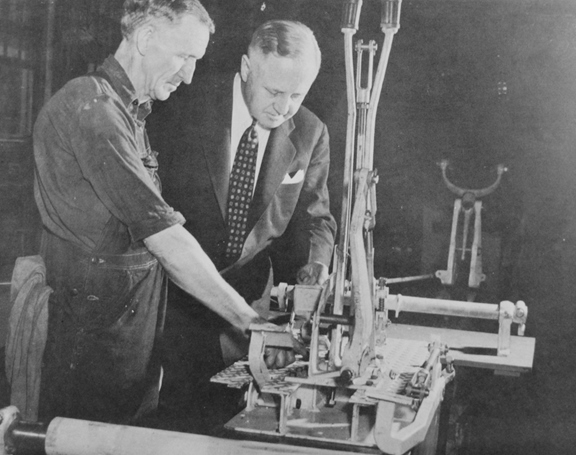

Two Seybold workers in the Dayton plant are

using Morrison stitchers to fasten different components together.

Photo courtesy of Rich Foley.

The Plants:

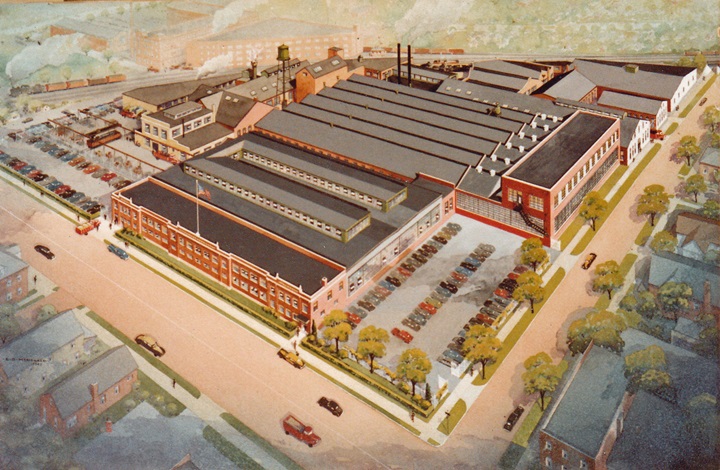

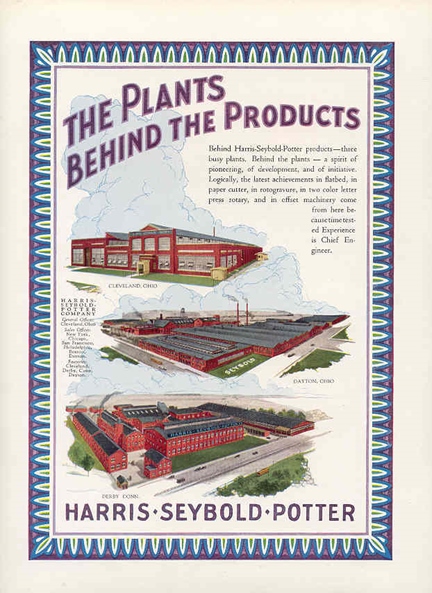

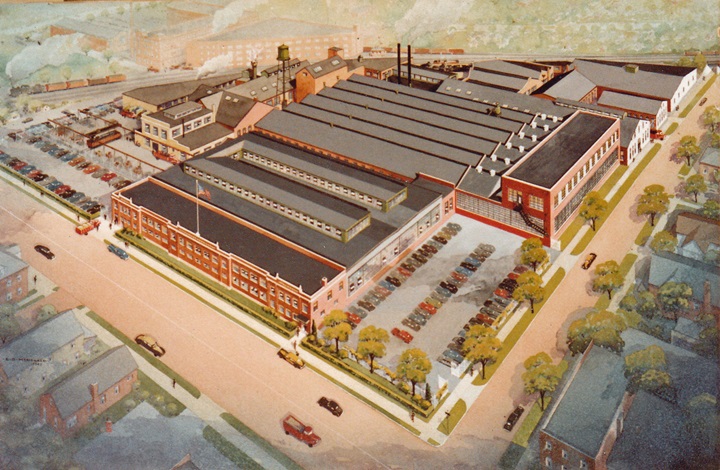

This artist's water color rendering shows the

factory's red brick construction. It shows how large the Seybold plant was. Photo

courtesy of Rich Foley.

This beautiful water color rendering of the Dayton plant is looking

northwest with Washington Street at the bottom of the picture.

This plant had its beginnings in 1893 as the Seybold Machine Company.

This image added 1-13-2022 is courtesy of Richard Foley.

This is the former Dayton Seybold plant at

819 West Washington Street looking east. The plant was razed and today

the Ponitz Career Technology

Center occupies the property.

This plant employed

between 600-1,500 workers, depending on the work load. The plant had a

cast iron foundry with pattern making capabilities. Its primary

products were for the book binding industry to include guillotine paper

cutters, stitchers, and trimmers. Photo courtesy of Rich Foley.

Photo courtesy of Rich Foley.

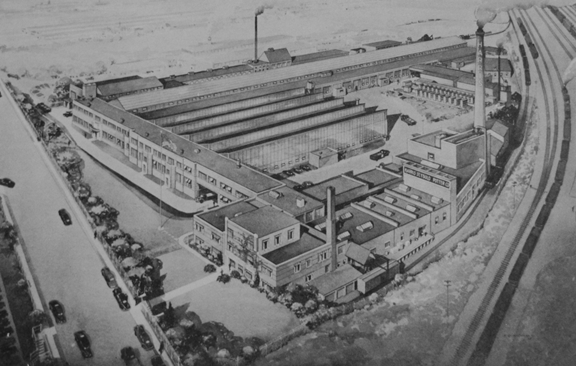

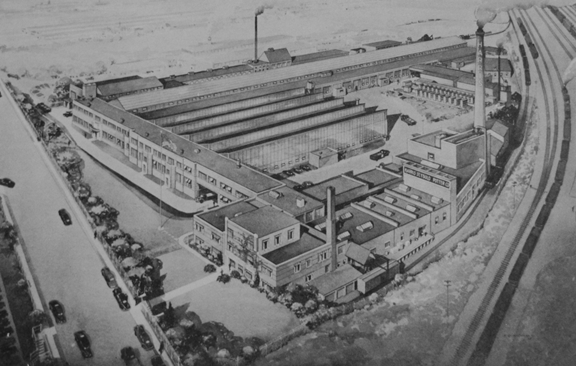

This is an artist's rendering of the Cleveland plant of

Harris-Seybold-Potter. It specialized in offset printing presses

and employed between 600-1,500 workers. From the collections of

Dayton History.

|