|

On Two Fronts

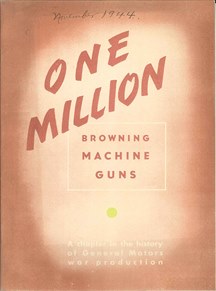

One Million Browning Machine Guns

AC Spark

Plug Division of GMC in World War Two

Flint, MI

1908-1988

Rest in Peace

This page updated

12-10-2024.

This 12x8 foot sign was built into the

overpass at the original AC Spark Plug plant on Industrial Avenue in

1909. Currently it is on display at the Sloan Museum in Flint, MI

after being donated to the museum by General Motors. Author's

photo.

Author's photo.

This is the original Champion spark plug

plant on the southeast corner of Industrial Avenue and Harriet Street in Flint, MI

after the addition of 18,000 square feet in 1915. Champion came to

Flint in 1908 at the request of Billy Durant, to supply spark plugs to

the fledgling local auto industry. Originally, Champion was

located in a Buick building, but then built the one shown above in 1912.

The Industrial Avenue plant as originally

built was 33,000 square feet. The addition of a second building at

the site in 1915 added 18,000 square feet. In 1918 more buildings

were added bringing the total square footage to 88,000 square feet.

This photo shows the AC Spark Plug plant on

Industrial Avenue, at a later date after much expansion. The

original structure is in the center portion on the left-hand side or

west side of the photo. Expansions were built to the north and

south of the original structure, and also on the east side of Industrial

Avenue. During World War Two this was AC Spark Plug's main

manufacturing plant. Many of the products it supplied for the war

effort were built here. In 1975 it was closed and then razed.

This is an early photo of the AC Spark Plug

plant on Dort Highway. J. Dallas Dort originally built the plant

in 1915 to produce automobiles. AC Spark Plug purchased the

plant in 1925 after the Dort Motor Company went out of business in 1924,

and

before becoming part of General Motors in 1929.

The Dort Highway plant, looking northeast from across Dort Highway.

Early Product Development at AC Spark Plug:

The name of the division is AC Spark Plug but it made more than spark plugs. In 1919 AC Spark

Plug added speedometers to its product line. In 1925 it added air

cleaners, and in 1926 oil filters and gas filters started coming off its

assembly lines. These were followed in 1927 by mechanical fuel

pumps, ammeters, oil and temperature gauges, and tachometers. In

1928 the division began the manufacture of complete instrument panels

and crankcase breathers. Fast forward to 1975 and past many other

new products, and AC Spark Plug Division began producing the catalytic

converters that were installed on all General Motors passenger cars and

some light trucks. New products were introduced during its entire

life cycle. AC Spark Plug was just more than a spark plug

manufacturer.

The AC Spark Plug Division of General Motors

Flint, MI won the Army-Navy "E" Award five times.

The original award was presented on September 2, 1942, and the first

star was added in June 1943. The dates of the remaining three

stars are unknown.

The AC Spark Plug Division of General Motors Ionia, MI Plant won the

Army-Navy "E" Award two times. This was a Fisher Body

Plant loaned to AC for the manufacture of spark plugs.

.

The original "E" flag at AC Spark Plug in Flint, MI.

AC

Spark Plug Division of General Motors World War Two Products:

The Flint, MI operation had $270,314,000 in major contracts during World

War Two. Its Ionia, MI plant had $17,203,000 in major contracts

for the war effort.

Air Cleaners, Air Cleaner Replacement Elements, Aircraft Coolant

Pressure Relief Valves, Sperry Automatic Pilots, Bombsights, Cable

Terminal Connectors, Carbon Stack Insulators, Carburetor Intake

Silencers and Air Cleaners, Crankcase Breathers, Crankcase Ventilating

Valves, Die Castings, Diesel Engine Intake Silencers, Electric Pressure

and Vacuum Pumps, Engine Bearings for Aircraft, Tanks, and Trucks,

Firing Pins for Anti-Aircraft Shells (Should this be for Anti-Aircraft

Guns?), Flame Arrestors, Flexible Shafts and Cables, Fuel Pumps

-Electrical and Mechanical, Fuel and Vacuum Pumps, Fuel Pump Repair

Kits, Gas Tank Pressure Caps, Gasoline Strainers, Ignition Cable

Terminals, Instrument Panels for Tanks, Armored Cars, Trucks, and Marine

Craft, (containing: Ammeters, Fuel Gauges, Indicator Lights, Oil

Indicator Switches, Oil Pressure Gauges, Speedometers, Tachometers,

Water Temperature Gauges, Voltmeters), Machine Guns - Browning .50

Caliber, Oil Filters - Lubricating and Fuel, Oil Filter Replacement

Elements, Oil Temperature Gauges, Oxygen Pressure Gauges, Radiator

Pressure Caps, Shell Magazines, Spark Plugs - Automotive and Aircraft,

Spark Plug Cleaners, Spark Plug Gaping Tools, Speedometers Drive

Adaptors, and Torpedo Directors.

Author's Note: The above list

comes from the October 1943 AC Spark Plug publication "On Two Fronts."

There were almost two years left of World War Two. AC Spark

Plug manufactured other products not listed above because they were developed as

the war progressed. One such example is the K-14 Gun Sight documented

below.

The signature product of the AC Spark Plug

Division of General Motors during World War Two was aircraft spark plugs. While

AC Spark Plug made a wide variety of goods for the military during the

war,

it made millions of aircraft spark plugs, as both aircraft production and

air combat missions increased. Demand was so great that AC Spark

Plug set up spark plug manufacturing in a borrowed Fisher Body plant in

Ionia, MI. Author's photo from the Michigan Military Technical and

Historical Society.

Of the 295,959 aircraft built by American

manufacturers during World War Two, 7,546 were TBM torpedo bombers

constructed by the Eastern Aircraft Division of General Motors at

Trenton, NJ. The TBM was powered by a Wright R-2600 radial engine

with fourteen cylinders, each with two spark plugs. After a navy

squadron of twelve TBMs returned from a combat mission, all of the spark

plugs were replaced. Even though there were two sparkplugs per

cylinder, no pilot wanted a cylinder to start missing over the water, or

when full power was needed in combat. This was common practice throughout the war

by all aviation combat units. Aviation spark plugs were consumed

at a prestigious rate during the war! Author's photo from the

Liberty Aviation Museum in Port Clinton, OH.

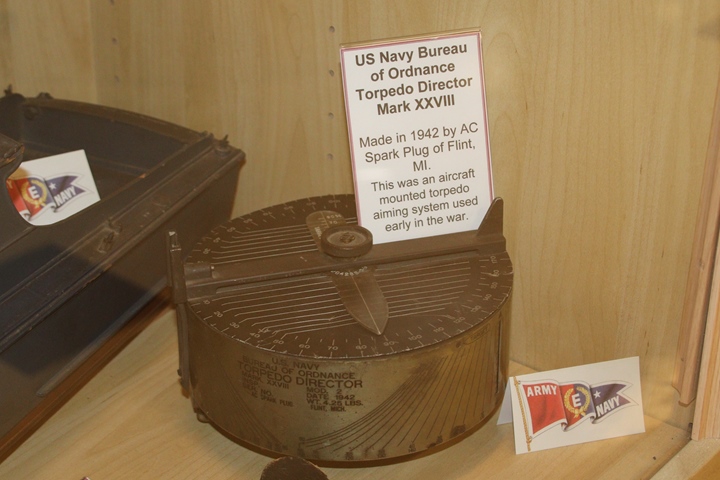

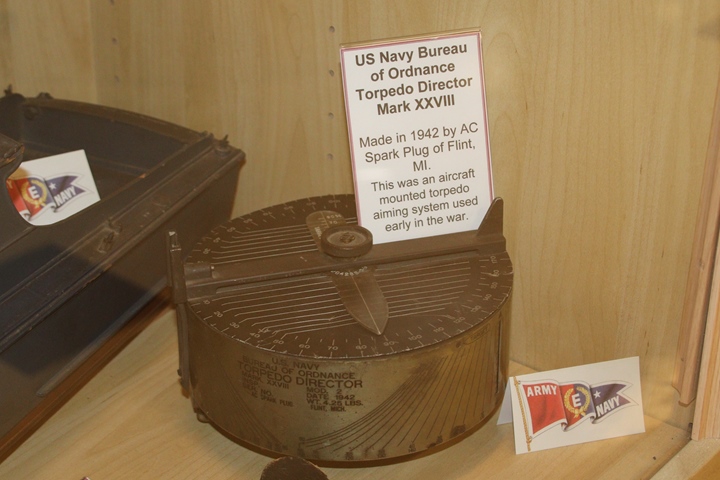

Pages 4 and 16 of "On Two Fronts" note that

AC Spark Plug built torpedo directors which were used in the Battle of

Midway. This very rare example of the AC Spark Plug-built torpedo

director is also on display at the Michigan Military Technical and

Historical Society. Author's photo added 4-19-2021.

Author's photo added 4-19-2021.

Author's photo added 4-19-2021.

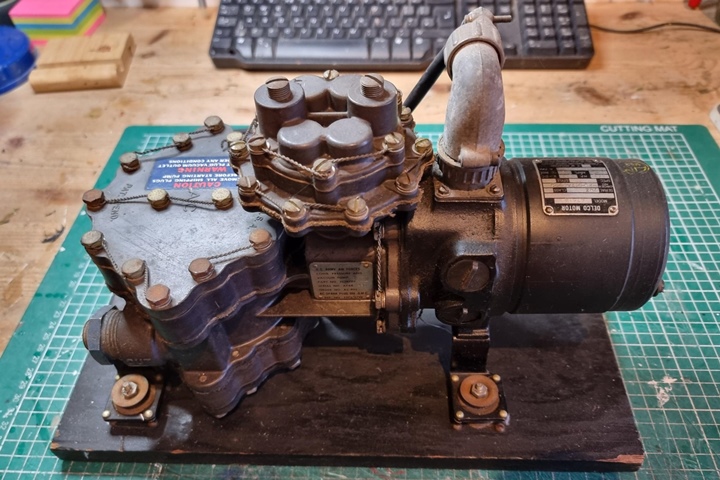

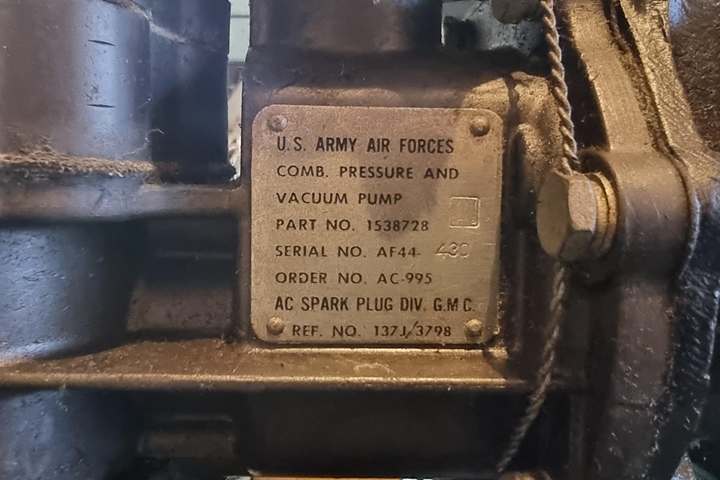

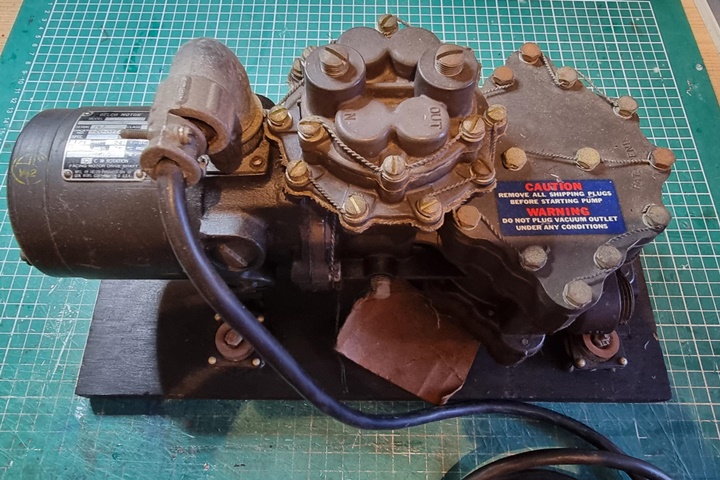

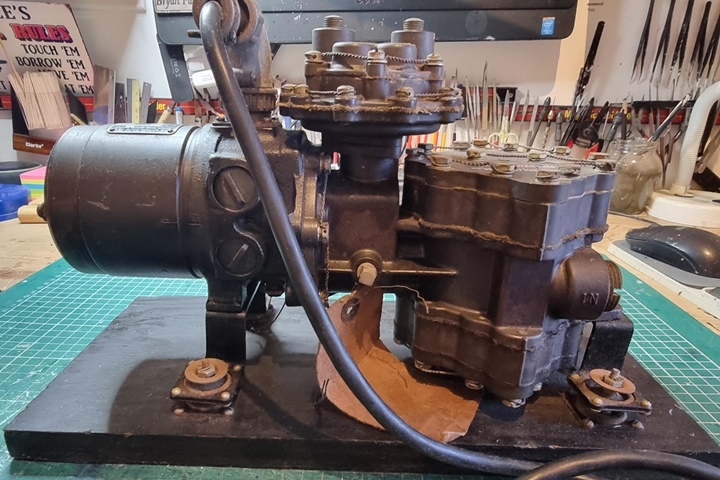

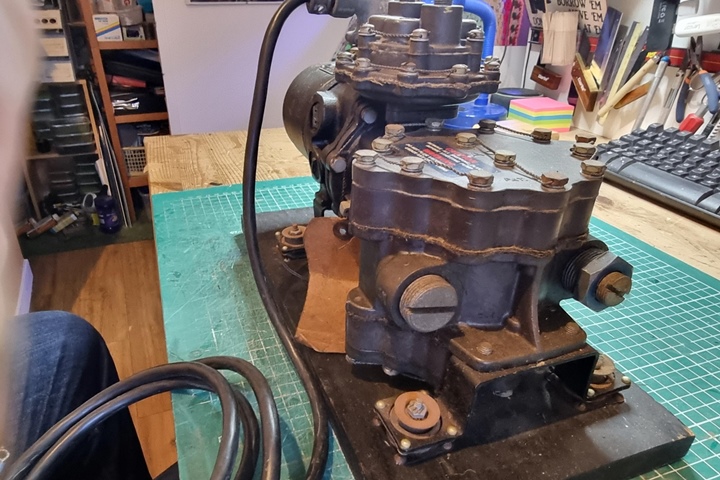

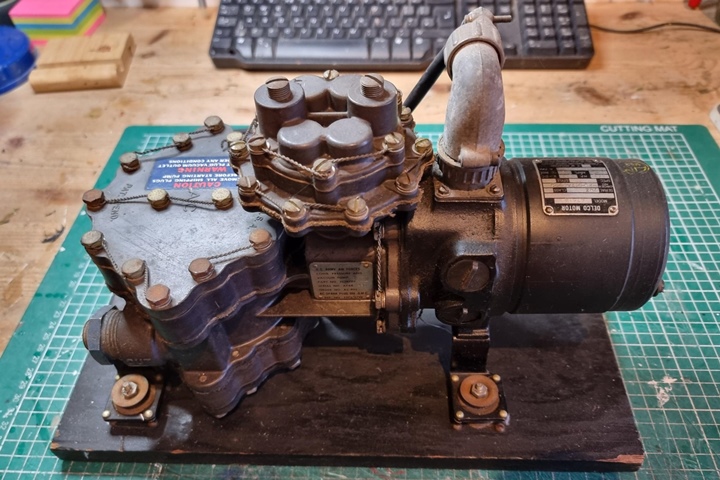

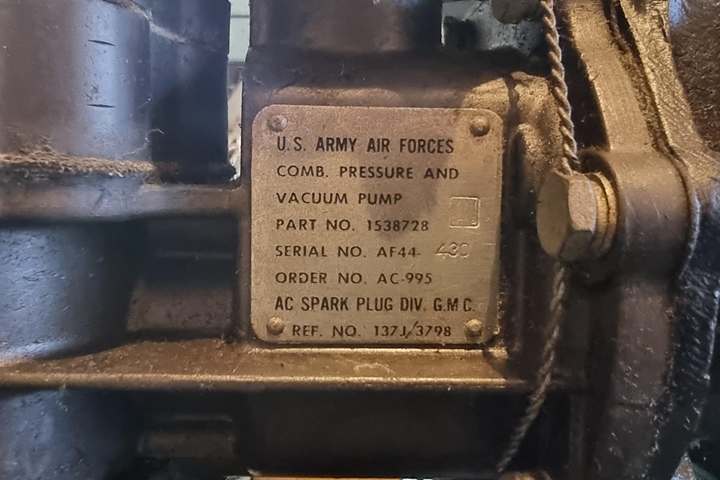

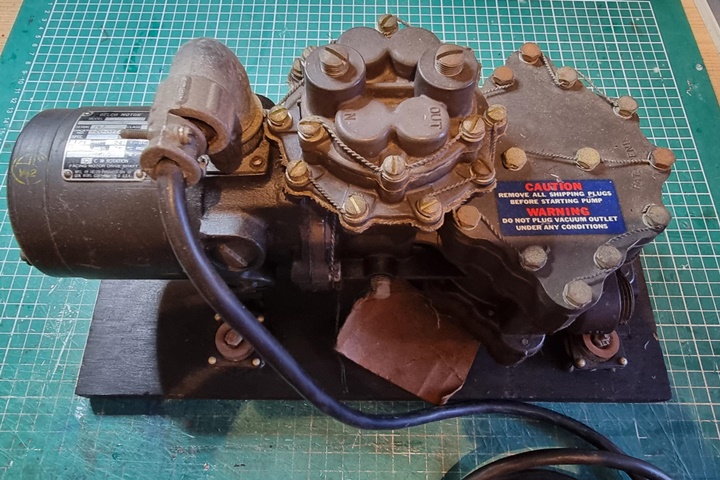

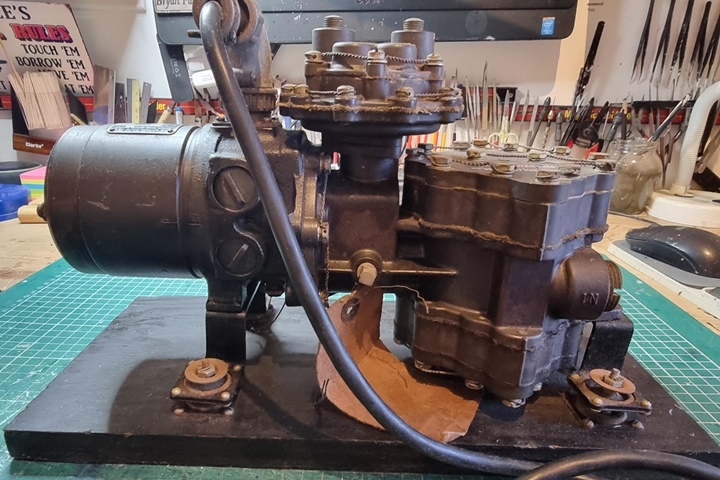

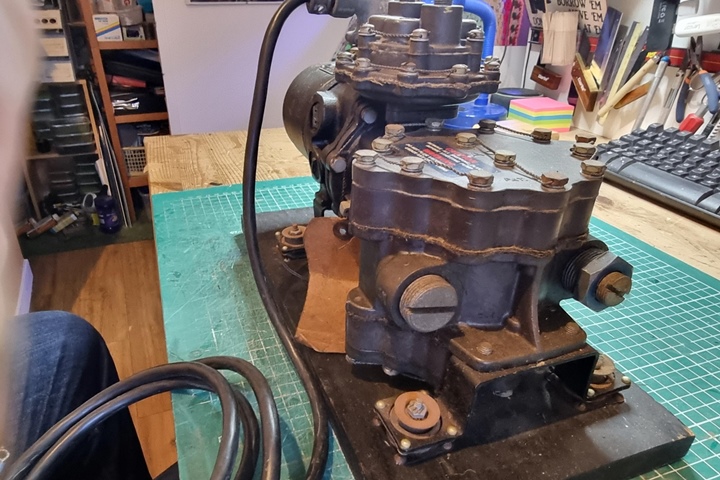

AC Spark Plug had two contracts for pressure

vacuum pumps from the USAAF during World War Two. The first one

was contract number 20017-AC-995 for $198,000. The second was

contract number 33038-AC-5807 for $588,000. This one is part of

the collection of Mr. Lee Smithson. Photo courtesy of Lee Smithson

added 12-10-2024.

Photo courtesy of Lee Smithson added

12-10-2024.

Photo courtesy of Lee Smithson added

12-10-2024.

Photo courtesy of Lee Smithson added

12-10-2024.

Photo courtesy of Lee Smithson added

12-10-2024.

Typical of a General Motors Division, when

AC Spark Plug required a motor for the pressure vacuum pump, it obtained

the motor from another GM Division. This kept the business within

the corporation. Photo courtesy of Lee Smithson added 12-10-2024.

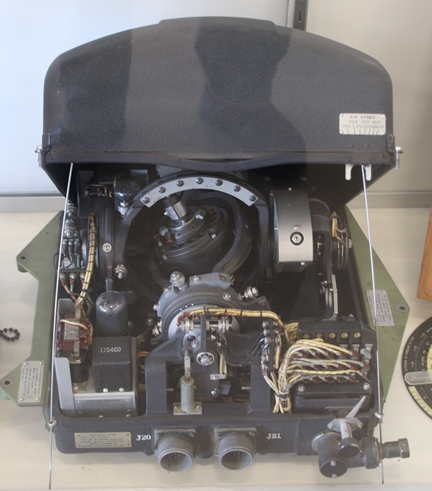

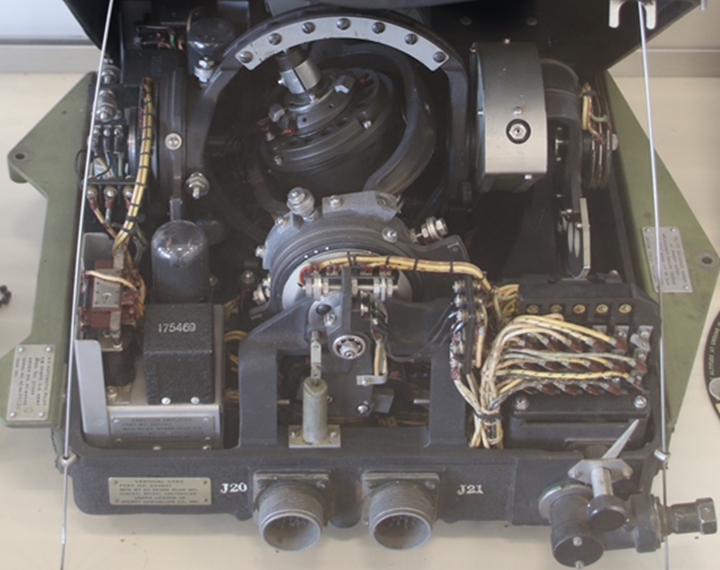

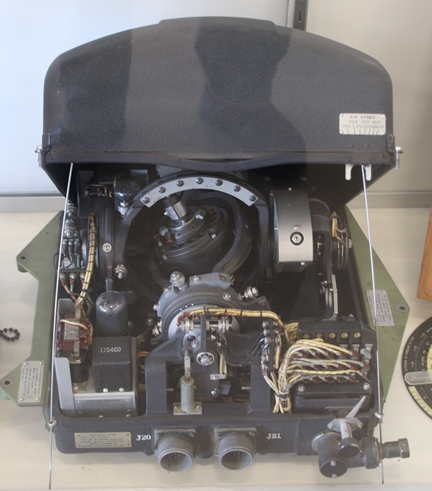

Auto-pilots and Bombsights:

During World War Two, Sperry

Corporation was a producer of bomb sights and auto-pilots for military

aircraft. With the attack on Pearl Harbor in December 1941, the

demand for these products exceeded the capability of Sperry to provide

them. At the request of the U.S. government, AC Spark Plug took on

the task of also building Sperry auto-pilots and bombsights for American

aircraft. Below are several of the Sperry components AC

Spark Plug built during WWII. More information on these products

can be found in "On Two Fronts" published by AC Spark Plug in October

1943. There are links to this publication at the top and bottom of

this page.

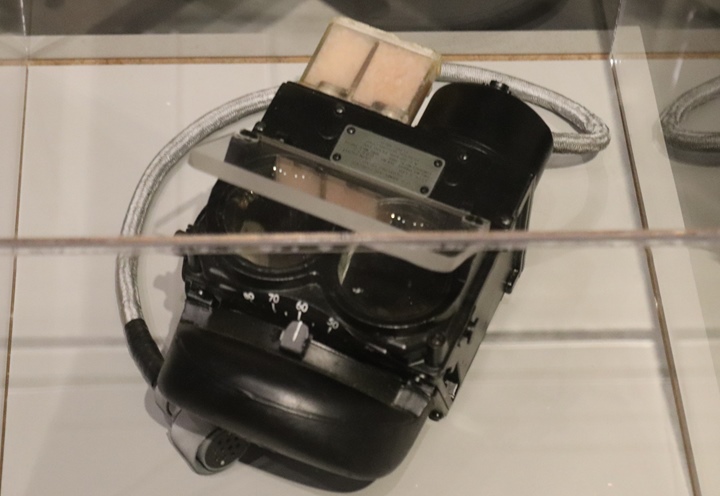

On display at the Sloan Museum in Flint, MI

is an AC Spark Plug built auto-pilot on the left, and a mechanical analog

bombsight computer on the right. Author's photo.

Author's photo.

Author's photo.

The data plate on the bombsight computer

indicates it is the vertical gyro part number 644841, built

under license by AC Spark Plug. Author's photo.

Author's photo.

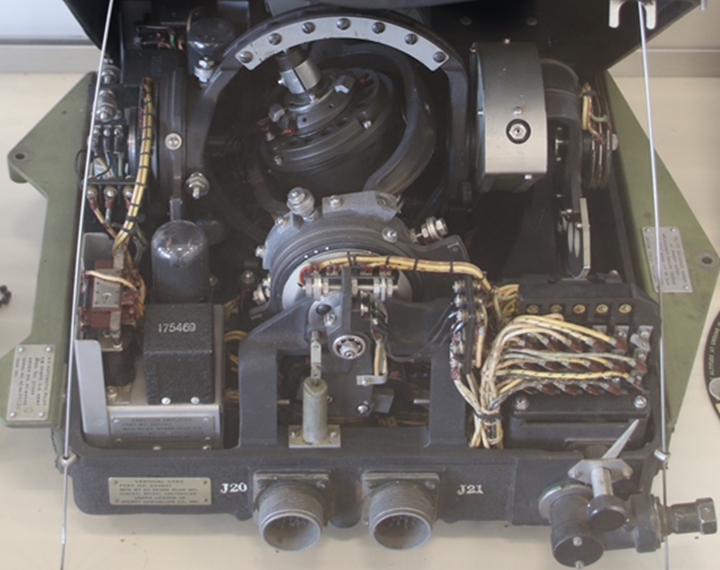

This AC Spark Plug Division-built Sperry

vertical gyro is on display at the Tri-State Warbird Museum in Batavia,

OH. The cover has been lifted to show the internal workings of the

unit. Author's photo.

The gyroscope can be at the rear of the

unit. Author's photo.

Author's photo.

The component on the left of the display is

the vertical gyro for the Sperry auto-pilot. Author's photo.

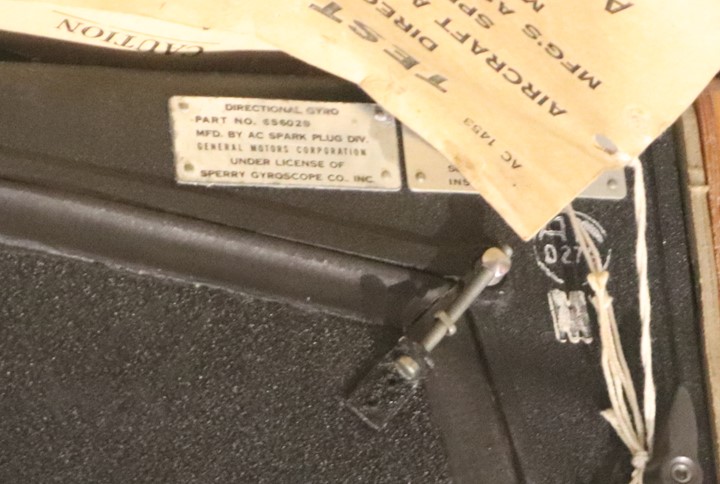

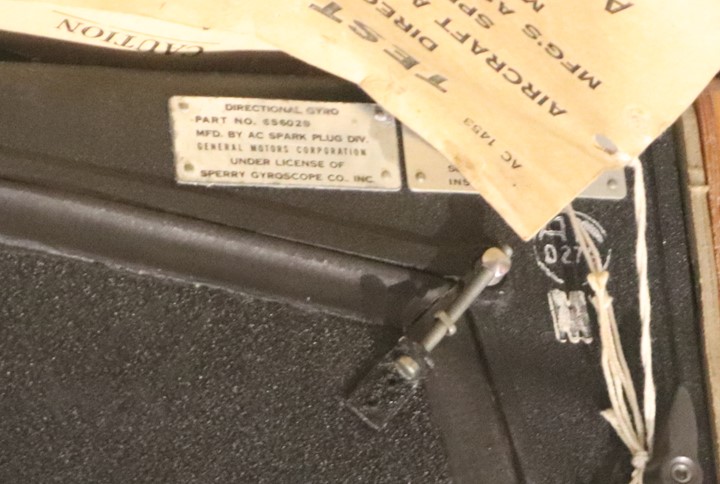

The direction gyro is part number 656029.

Author's photo.

A-C Spark Plug built this Sperry T-1-A

bombsight computer which was also used with the sighting head shown.

It was photographed as part of the special International Radio

Corporation/Argus display at the Yankee Air Museum in Belleview, MI.

Author's photo added 2-10-2019.

Author's photo added 2-10-2019.

Author's photo added 2-10-2019.

This T-1-A Bombsight Computer was built in

1943 and is Serial Number 43-19718. Author's photo added

2-10-2019.

Author's photo added 2-10-2019.

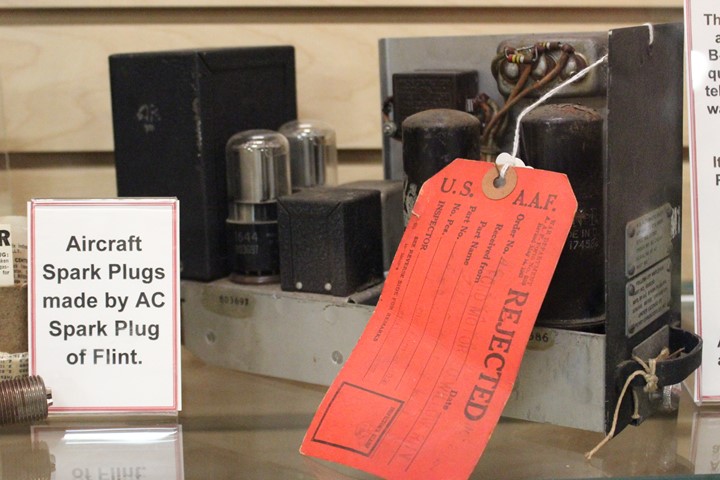

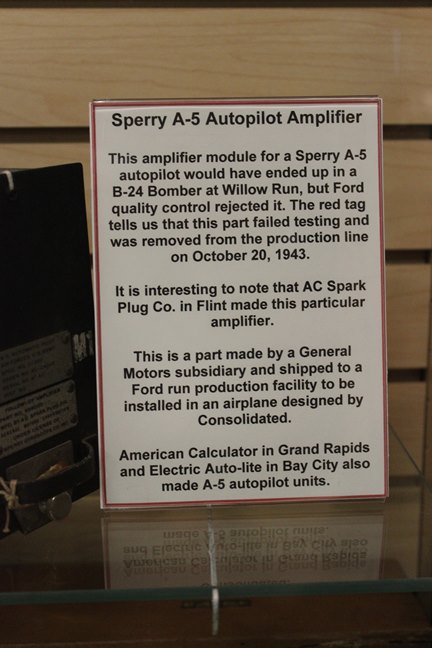

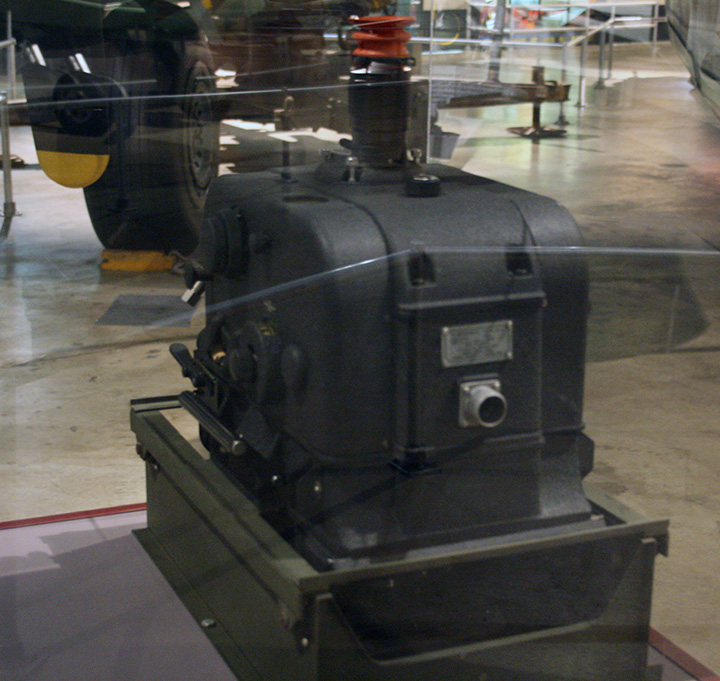

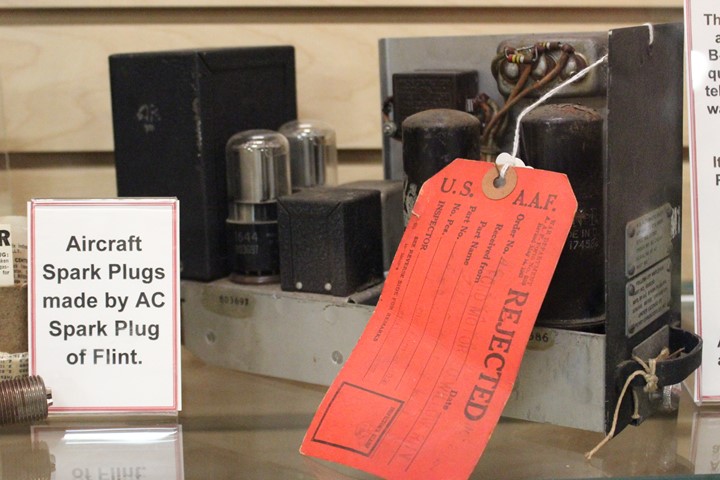

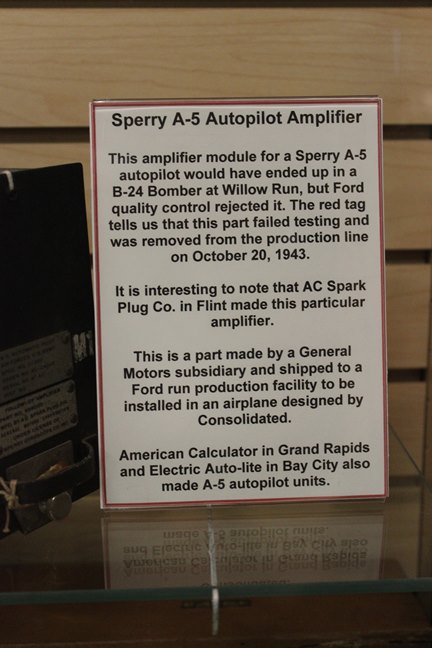

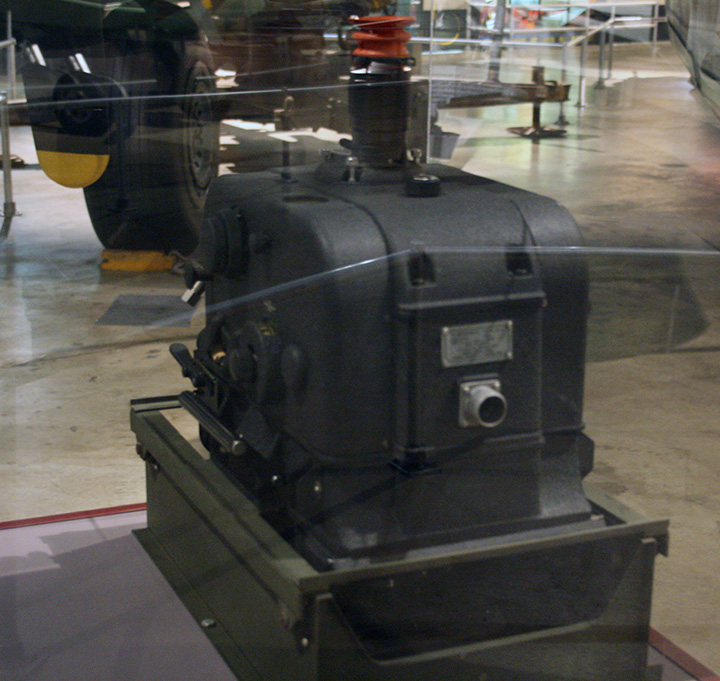

On display at the Michigan Military

Technical and Historical Society is this Sperry A-5 auto-pilot amplifier

that was supposed to be installed in Ford built B-24.

Unfortunately it did not meet the requirements of the Ford incoming

inspection and was rejected. On the positive side, if it had not

been rejected, it would not have been saved for eventual display at the

museum. Author's photo

AC Spark Plug was not a subsidiary of

General Motors. It was a Division of GM.

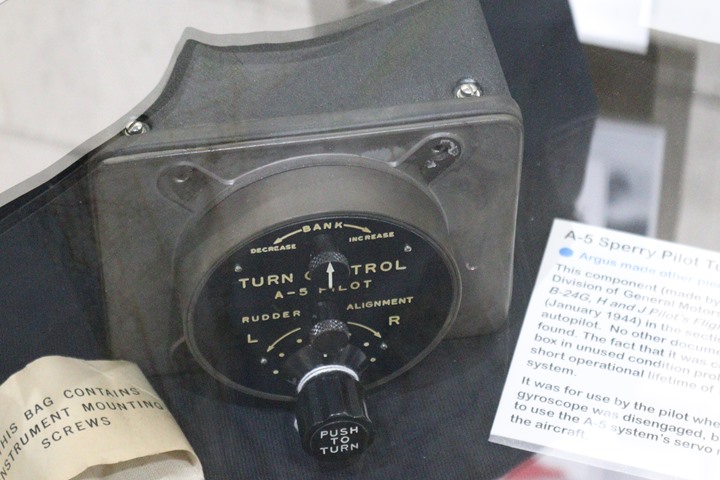

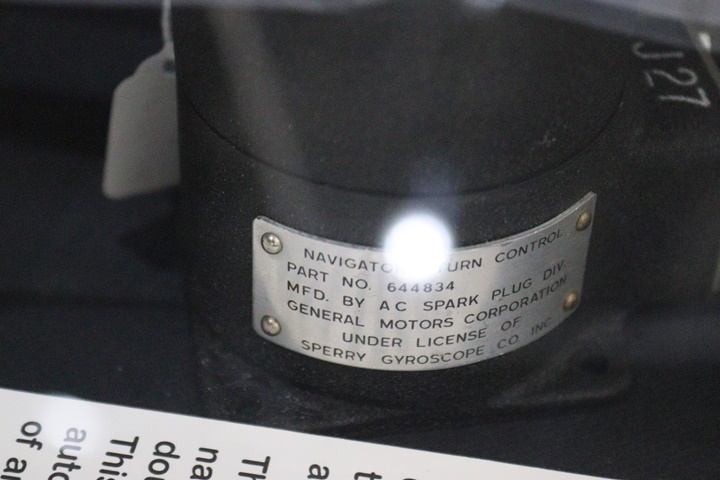

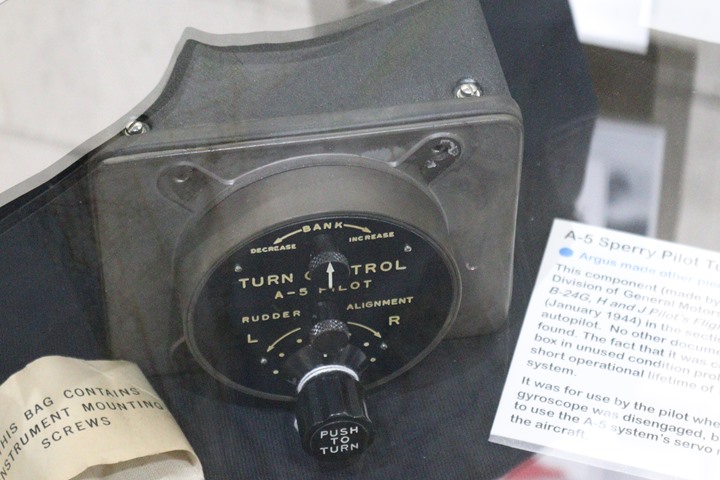

This Sperry A-5 Pilot's Turn Control was

also built by A-C Spark Plug. It was photographed as part of the

special International Radio Corporation/Argus display at the Yankee Air

Museum in Belleview, MI. Author's photo added 2-10-2019.

Author's photo added 2-10-2019.

Author's photo added 2-10-2019.

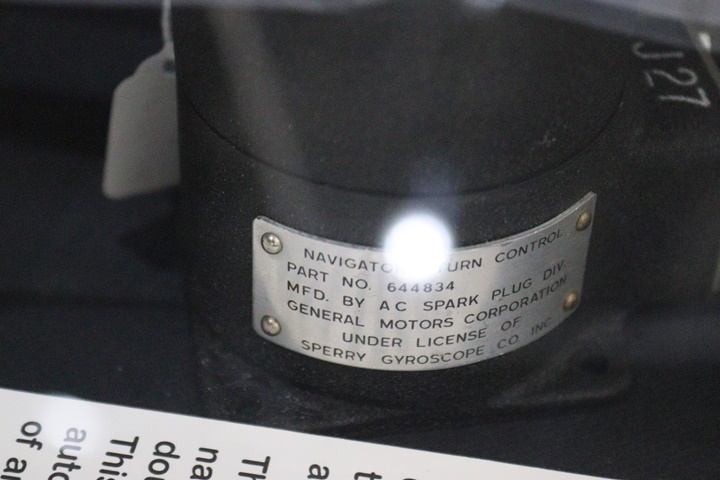

This Sperry A-5 Navigator's Turn Control was

also on display as part of the special International Radio

Corporation/Argus display at the Yankee Air Museum in Belleview, MI.

Author's photo added 2-10-2019.

Author's photo added 2-10-2019.

This is a B-24 like the ones Ford built at Willow Run, MI. The B-24 was

also built in California, Oklahoma, and Texas. AC Spark Plug-built

Sperry components may have also been shipped to these locations.

Author's photo.

"On Two Fronts" discusses AC Spark Plug

building a bombsight. But it is very generic and does not state

much else because bombsights during World War Two were top secret

devices. There were two advanced bombsights used by the United

States military; the Norden and the Sperry. While the Norden

was the most famous, and the better of the two bombsights, the Sperry

was also used in many bombers during the war. From what "On Two

Fronts" says, it was also given to American allies during the war.

The Norden was only used by American bombers. AC Spark Plug no

doubt built the Sperry version, due to its relationship with the company.

This one was photographed by the author at the National Museum of the

United States Air Force in Dayton, OH.

Author's photo.

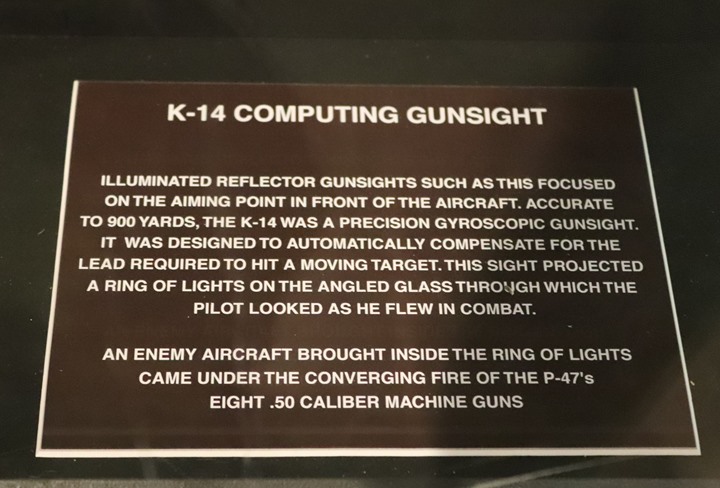

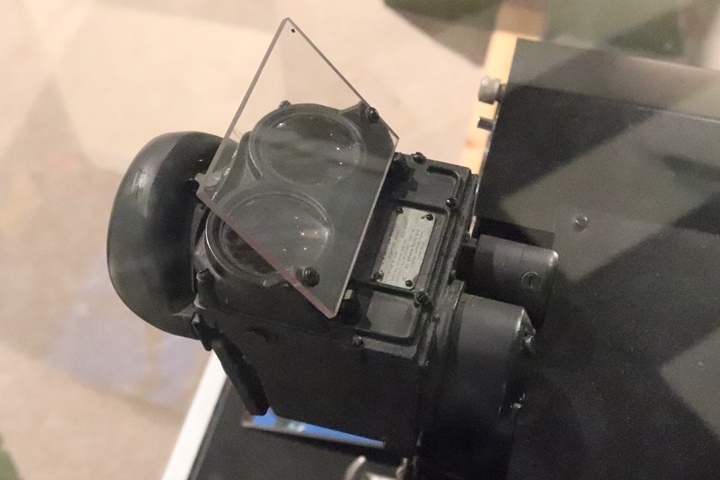

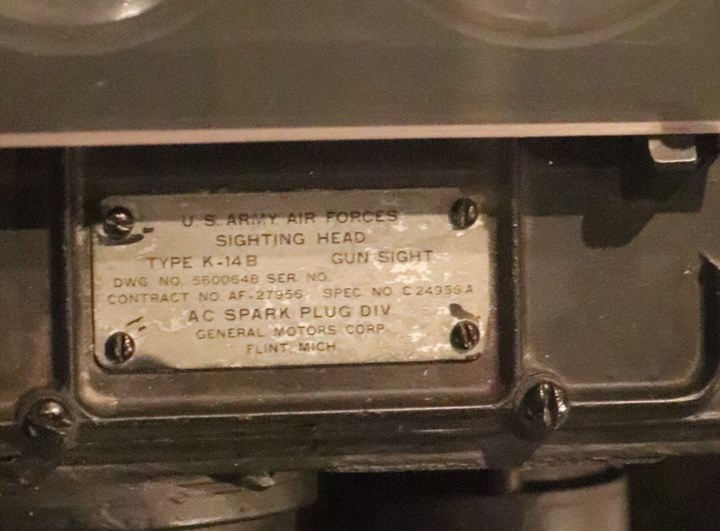

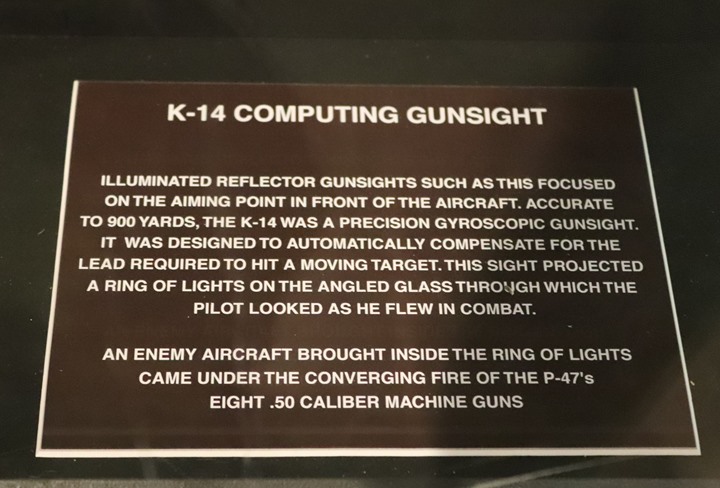

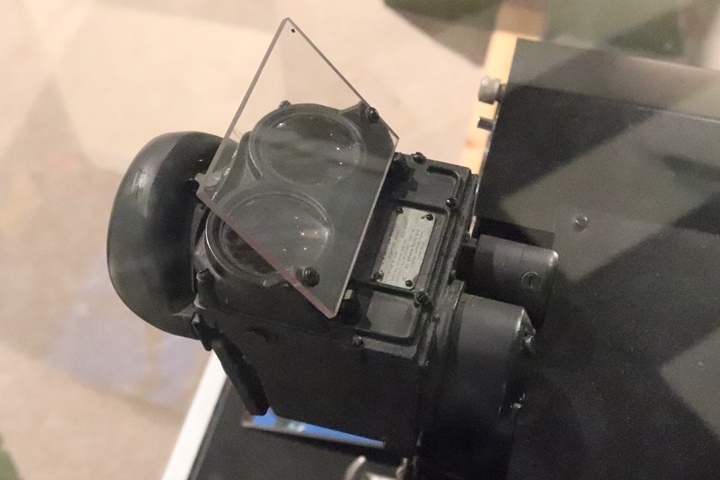

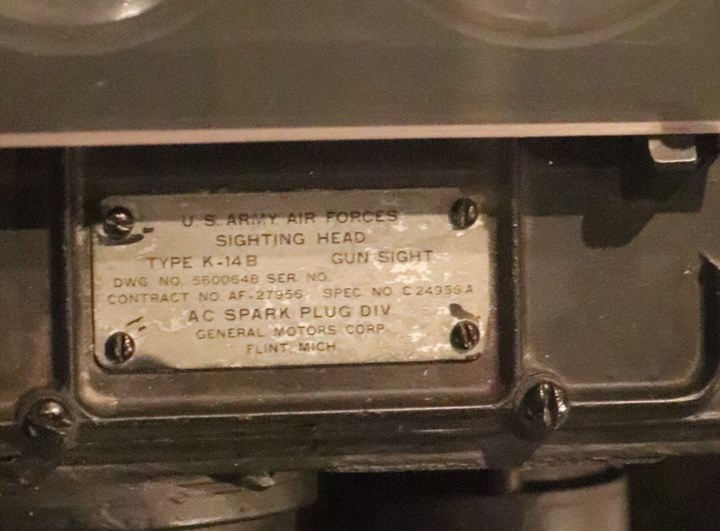

K-14 Series Gun Sights: AC Spark

Plug Division was the sole supplier of K-14s gyro-computing gun sights

during World War Two. These sights were a post-1943 development, and not included in the

October 1943 "On Two Fronts." The Division produced the A, B, and C

models of the K-14. The K-14B series gun sights were introduced in

September 1944 for P-51D Mustang fighters, making K-14B the most modern of the

gun sights utilized by the US Army Air Forces in World War Two. K-14B gun

sights were used on American fighters up through the 1950s, even on some

early jet aircraft. It was the ultimate in World War Two American

gun sights.

Bendix made the naval version of the K-14

during World War Two. After the war A-C Spark Plug and Bendix

stopped making the K-14. Eastman Kodak in Rochester, NY took over

the business of both companies and

continued the production or remanufactured the K-14 series for the early

post war period.

|

Information Found on AC Spark Plug

K-14 Series Gun Sight Data Plates via Internet Images |

|

Type Gun Sight |

Drawing Number |

Serial Numbers of Examples Found |

Contract Number |

Spec. Number |

Manufacturer |

|

K-14A |

5581001 |

2405 |

AC 1898 |

C-24955 |

AC Spark Plug Division, General Motors Corp, Flint Mich. |

|

K-14B |

5581622 |

0043 |

AC-541 |

R-24977 |

AC Spark Plug Division, General Motors Corp, Flint Mich. |

|

K-14C |

5600108 |

AF858 |

33(038)27956 |

Mil-S-6147 |

AC Spark Plug Division, General Motors Corp, Flint Mich. |

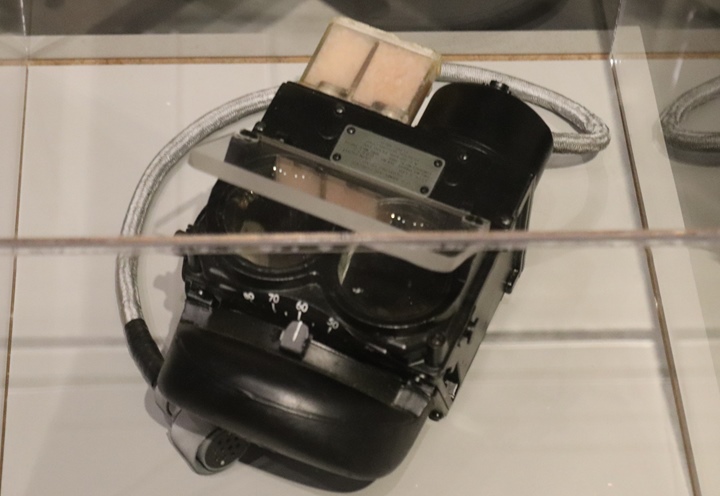

Below is an AC Spark Plug-manufactured K-14B

on display at the Sloan Museum in Flint, MI.

Author's photo.

Author's photo.

Author's photo.

K-14B Gun Sight at the Cradle of Aviation

Museum on Long Island, NY, May 2018:

Walking up to this display at the Cradle of

Aviation Museum and understanding immediately that I had found a

precious piece of AC Spark Plug history in New York, would not have been

possible without my trip to the Sloan Museum two months earlier in

March. Previously, I was totally unaware that AC Spark Plug

made gun sights for fighter aircraft in World War Two. Without the

knowledge gained in March, I would have walked right by this display,

not knowing that the K-14B Gun Sight was used on late model P-47s.

This P-47 instrument panel on display at the

Cradle of Aviation Museum on Long Island, NY has an AC Spark Plug built

K-14B Gun Sight on it.

Author's photo added 8-4-2018.

Author's photo added 8-4-2018.

Author's photo added 8-4-2018.

Author's photo added 8-4-2018.

Author's photo added 8-4-2018.

Author's photo added 8-4-2018.

Author's photo added 8-4-2018.

The Republic P-47 Thunderbolt utilized the

K-14B gun sight after September 1944.

Author's photo added 8-4-2018.

The P-51D also utilized the K-14B gun sight

after September 1944. Author's photo.

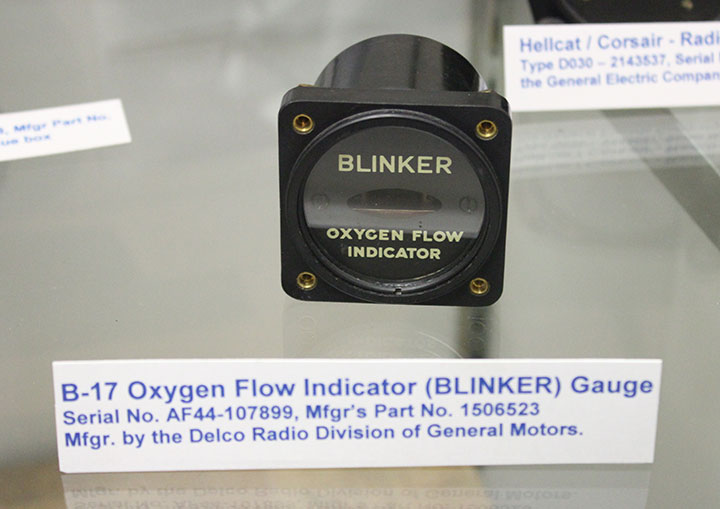

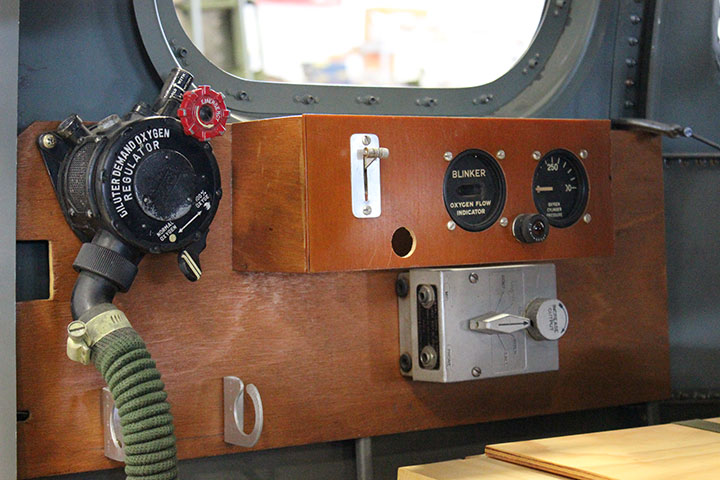

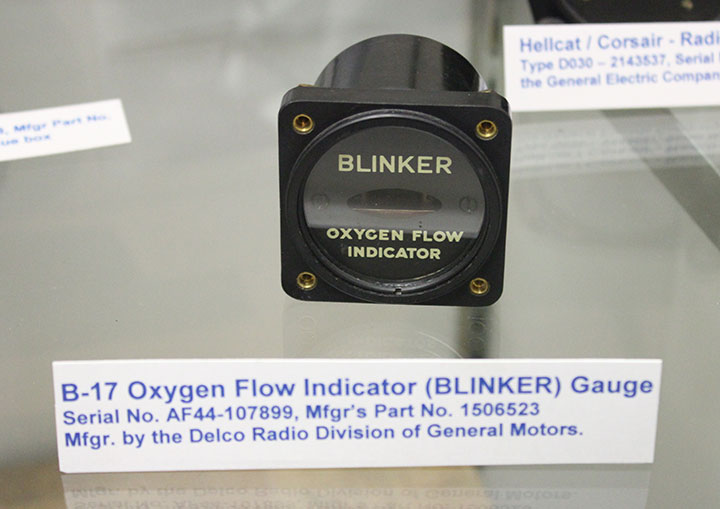

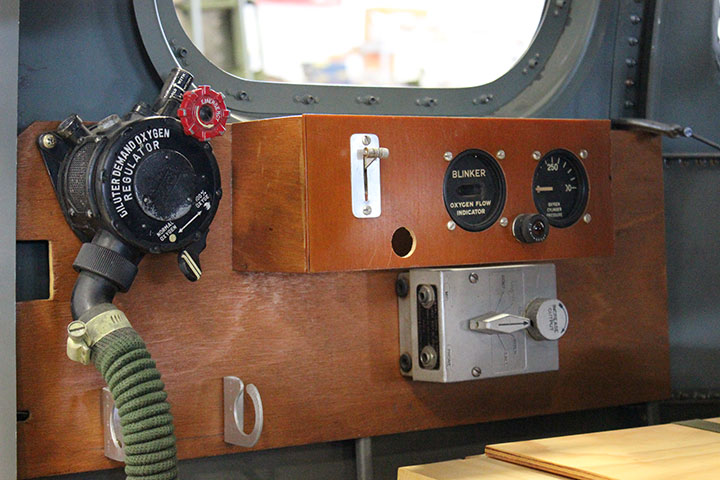

Oxygen Flow Indicator (Blinker):

"On Two Fronts" describes how AC Spark Plug developed the Oxygen Blinker;

and shows the engineering capability of AC Spark Plug during World War

Two to develop products beyond the normal automotive product line.

This was a very important instrument for bomber crews to verify that

oxygen was flowing at high altitudes. AC Spark Plug did not have

the manufacturing capacity to make the Blinker, so Delco Radio built

the instruments during the war.

At altitudes above 10,000 feet, aircrews in World War Two needed

supplemental

oxygen to stay alive, as the oxygen content thinned out. Each crew

member on an aircraft would have one of these indicators which blinked

when oxygen was flowing. It was an important visual aide, allowing

a crewman to quickly verify

that his all-important oxygen was flowing. Author's photo.

This view, from the bombardier's position on

a B-17 undergoing restoration, shows how the AC Spark Plug-designed

Blinker was part of the crew member's entire oxygen system. AC

Spark Plug produced oxygen pressure gauges, like the one to the right of

the Blinker, and were used in many of the American military aircraft of

World War Two. Author's photo from the Champaign Aviation Museum

in Urbana, OH.

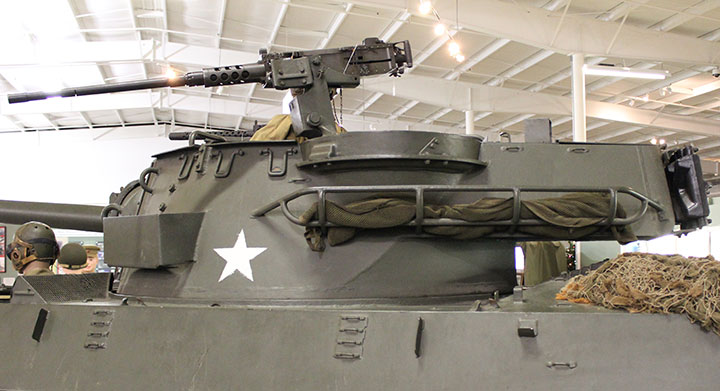

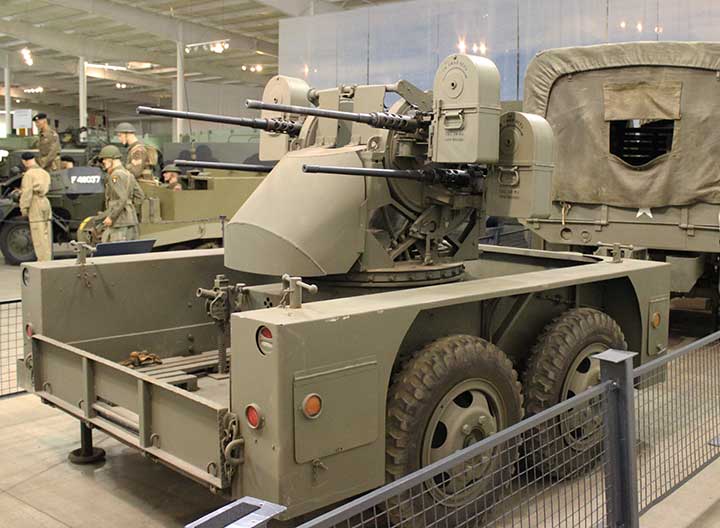

.50 Caliber Machine Gun:

The .50 caliber heavy machine gun was AC Spark Plugs' signature World

War Two product. On September 30, 1940, AC Spark Plug received an

order for 14,741 aircraft flexible and 7,385 heavy barrel .50 caliber

machine guns. By November 1944, AC and three other GM divisions

produced one million machine guns. Between Saginaw Steering Gear

and Frigidaire Divisions of GM, they produced 775,384 Browning machine

guns by war's end. The amount that Brown-Lipe-Chapin built is

unknown but estimated at 100,000. An estimate for the number of .50 caliber Browning machine guns built by AC Spark Plug is 250,000.

The complete story of AC Spark Plug's

manufacture of .50 caliber machine guns is explained in detail in both

"On Two Fronts" and "One Million Browning Machine Guns." There are

links to these two documents at the top and bottom of this page.

This cut-away of .50 caliber Browning

machine gun was found in the maintenance shop of the National Armor and

Cavalry Museum at Fort Benning, GA. Author's photo added

10-7-2018.

Author's photo added 10-7-2018.

Author's photo added 10-7-2018.

The .50 caliber heavy barrel machine gun was

used by all of the services in WWII. Author's photo.

Author's photo.

Author's photo.

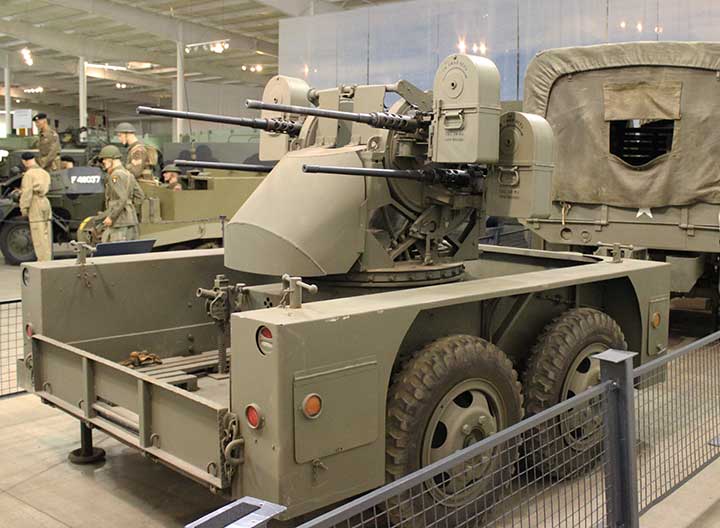

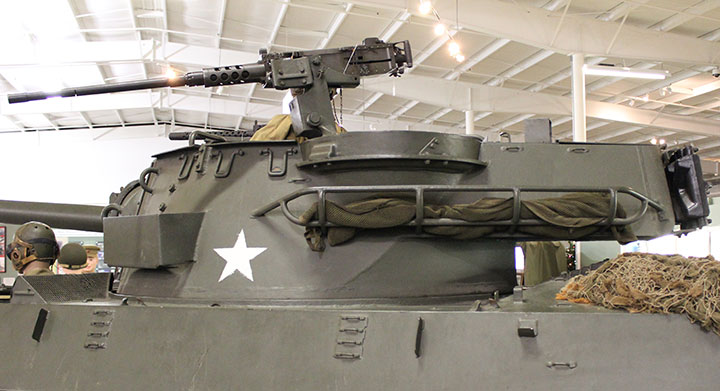

Instrument Panels: According

to page 26 of "On Two Fronts," written in October 1943, AC Spark Plug

had 15 different types of instrument panels that were used in tanks,

trucks, submarines, jeeps, and small boats. As the war progressed,

new weapons were introduced that required more and different instrument

panels. This was especially true for armored vehicles, which

included the Buick built M18 Hellcat tank destroyer, Cadillac built M26

Chaffee light tank, and the Fisher Body M26 Pershing heavy tank.

This photo from "On Two Fronts" shows an

instrument panel that would go into either an M4A2 Sherman tank or an M10

Wolverine tank destroyer. Both were powered by twin Detroit Diesel

engines requiring two sets of instruments and switches to operate the

vehicles.

"On Two Fronts" states that AC Spark Plug

instrument panels were used in all Sherman tanks. If so, the GM

Division supplied 49,234 instrument panels for five different types of

Sherman tanks built by ten different companies from the State of

Washington to Pennsylvania.

One thing is certain. AC Spark Plug

supplied instrument panels and other components to other General Motors

Divisions that were building tanks, tank destroyers, and armored cars.

The Fisher Body Tank Arsenal in Grand Blanc, MI was just 5.5 miles south

of the main AC Spark Plug plant on Industrial Ave. in Flint.

During WWII the Grand Blanc Tank Arsenal turned out 19,034 tanks and

tank destroyers with AC Spark Plug components in them.

This M4A2 is the oldest Fisher Body built

tank on display in North America. It is located at Victoria Park in London,

Ontario. It came off the Grand Blanc assembly line in September

1942 equipped with AC Spark Plug parts. It landed with the Canadian Army at

Normandy, and then fought its way across Europe until the end of the

war. It survived its many battles, and then came back to Canada.

Fisher Body Grand Blanc produced 7,508 M4A2 Sherman tanks. Author's

Photo.

This is a cutaway of a Fisher Body Grand

Blanc M4A2 on display at the Canadian War Museum in Ottawa, ONT.

Author's Photo.

The AC Spark Plug instrument panel.

Author's Photo.

Author's Photo.

The M4A2 was powered by two Detroit Diesel

6-71 engines. Author's Photo.

Four of the six AC Spark Plug air filters

can be seen in this photo along with a cutaway of one oil filter.

Author's Photo.

The Grand Blanc-built M10 Wolverine tank

destroyer had the same power train as the M4A2. 4,993 were built

at Grand Blanc. Author's Photo.

Of all of the Sherman Tanks built during World

War Two,

it is noteworthy that a Fisher Body M4A3(75) tank built in Grand Blanc,

MI has the honor of representing all of the M4s that participated in

the Battle of the Bulge. Registration Number 3081532 was one

of 339 M4A3 Sherman tanks built in the Fisher Body Tank Arsenal in Grand

Blanc, MI in March 1944. It has an AC Spark Plug instrument panel.

The engine is a Ford built 500 hp V-8 which would have Ford components

in the engine bay. Author's photo.

Buick was located near AC's main plant on

Industrial Avenue. Buick built 2,507 M18 Hellcats with AC Spark

Plug instrument panels installed. Author's photo.

"On Two Fronts" states that AC Spark Plug

instrument panels were used in all M5 and M5A1 Stuart light tanks.

If so, then, AC Spark Plug supplied instrument panels for 6,810 M5

series tanks built by the Cadillac and Southern California Divisions of

GM, and Massey Harris. Each tank had two Cadillac V-8 engines that

would have AC air, fuel, and oil filters.

This Cadillac-built M5 came off the assembly

line in September 1942. Author's photo from the First Division

Museum in Wheaton, IL.

After M5 production halted, Cadillac and

Massy Harris built 4,731 M24 Chaffee light tanks powered by twin

Cadillac V-8 engines equipped with AC Spark Plug components.

Author's photo from the First Division Museum in Wheaton, IL.

Fisher Body and Chrysler built 2,202 M26

Pershing heavy tanks from 1944 through 1945. Each one had an instrument

panel built by AC Spark Plug. This particular Fisher Body M26 was

at the Battle for the Remagen Bridge on the Rhine River in March 1945.

Author's photo from the Wright Museum of WWII in Wolfeboro, NH.

Chevrolet was also located near AC's main

plant on Industrial Avenue. Chevrolet built 3,844 Staghound

armored cars for the United Kingdom. Along with the AC instrument

panels, the division also supplied the fuel, air and oil filters for the

two GMC 6-cylinder engines that powered the Staghound. Author's

photo from the Canadian War Museum in Ottawa, ONT.

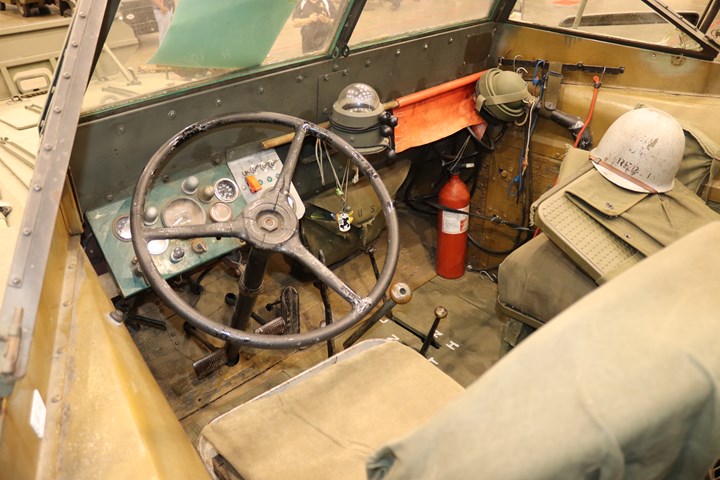

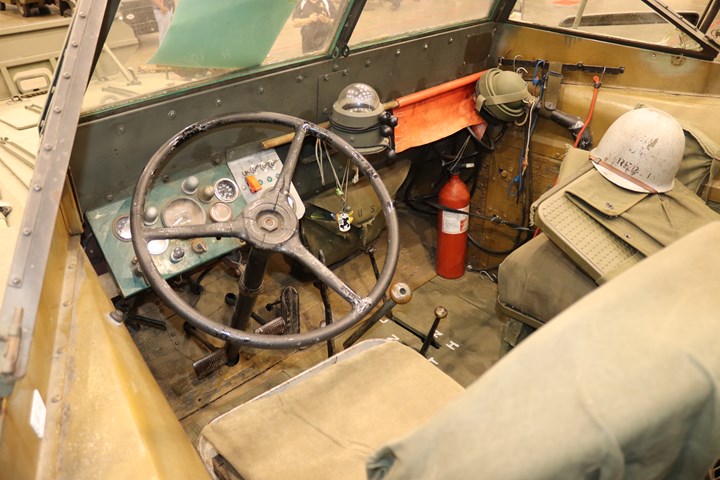

GMC and Chevrolet built 528,829 2-1/2 ton

6x6 trucks with the GMC nameplate on it. Author's photo.

Seen here is one of the 528,829 AC Spark

Plug instrument panels that were installed in the GMC trucks. AC

Spark Plug also supplied 528,829 oil, air, and fuel filters for the GMC

inline six engines. Author's photo.

GMC and Chevrolet built

21,147 2-1/2 ton 6x6 amphibious trucks DUKWs with the GMC nameplate on

them. Author's photo.

It was built with AC instrument panels, and

oil, air, and fuel filters. Author's photo.

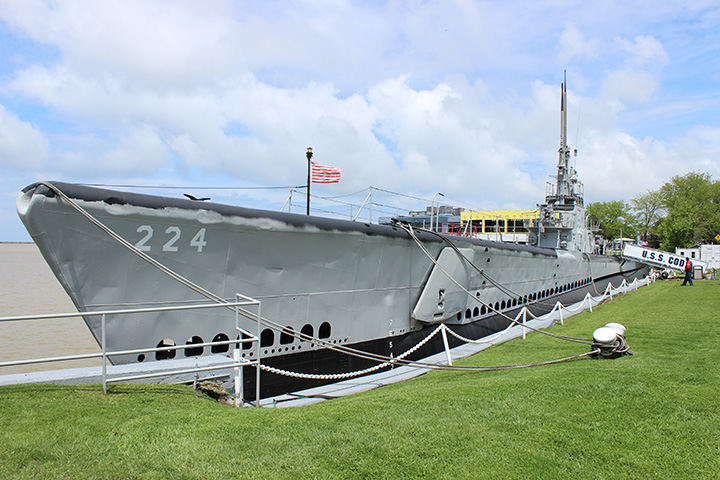

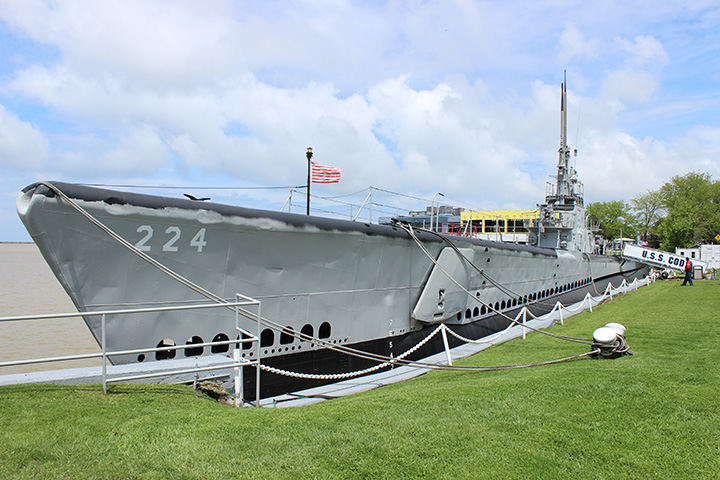

"On Two Fronts" mentions instrument panels

used in submarines. This panel was for the four engines built by

Cleveland Diesel Division of GM, which powered 136 American submarines

during WWII. This is the USS Cod in Cleveland, OH. Author's

photo.

Below are links to "On Two Fronts" and "One

Million Browning Machine Guns." Both give excellent detail on

operations at AC Spark Plug during WWII.

On Two

Fronts

One

Million Browning Machine Guns

|