|

Moraine

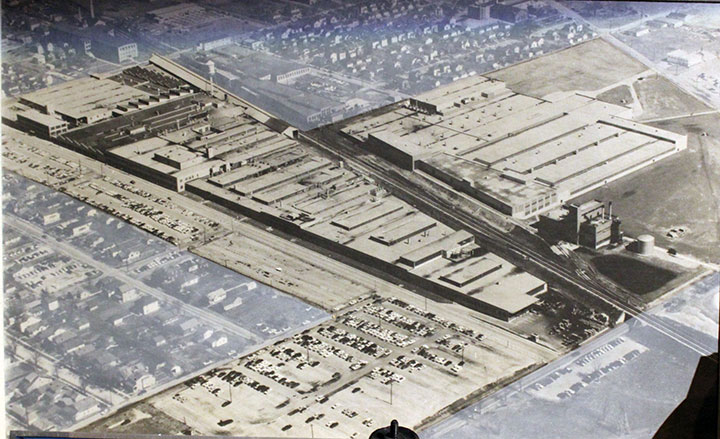

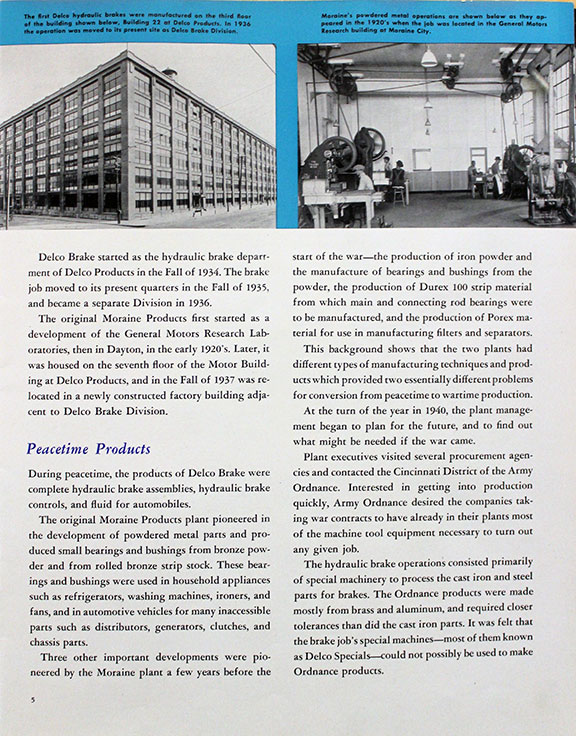

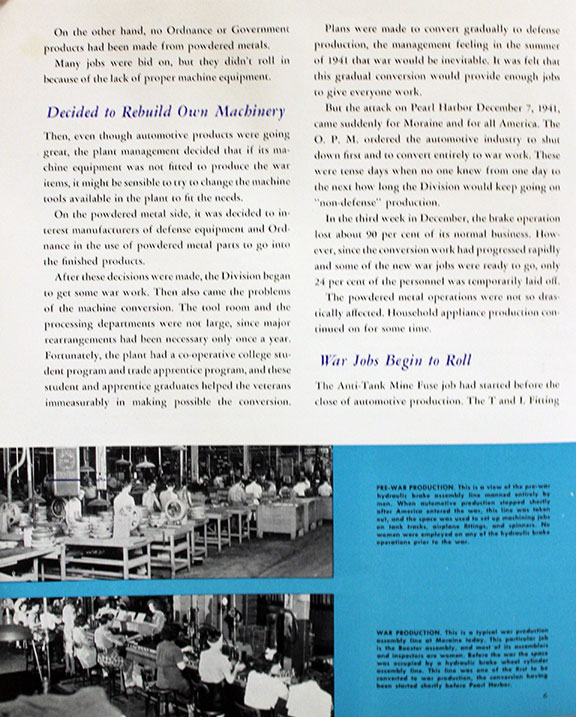

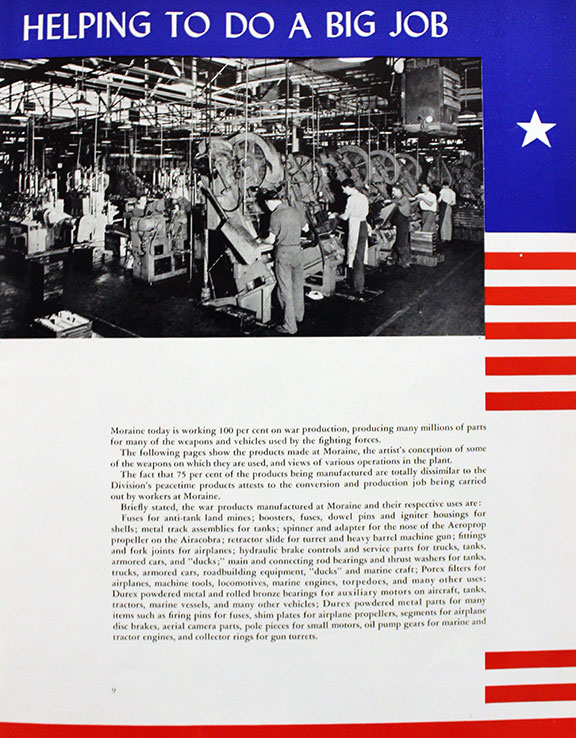

Products Division of General Motors Corporation in World War Two This page updated 10-15-2021. The Delco Brake Division was formed in 1936 as a divestiture from Delco Products, where the hydraulic brake product line had originated. GM decided a stand-alone division was needed to properly market and manufacture hydraulic brake components. The new division moved into an already existing factory complex on Wisconsin Blvd at Miami Chapel Road in South Dayton. In August 1942 Delco Brake Division merged into Moraine Products Division. Moraine Products Division was created by General Motors in 1923 to be the manufacturing division for the GM Research Division, then located in Dayton. Its first product was an oil impregnated bearing named "Durex" which had its first application in Delco-Remy DC generators. When GM Research moved to Detroit, MI in 1925, the "Durex" product line moved as well. Moraine Division also began manufacturing powder metal bearings and filters in Michigan. In 1937 Moraine returned to Dayton and occupied a newly constructed building just south of Delco Brake in a factory complex that had begun at the turn of the 20th century. In June 1943 the Division employed 1,541 and in April 1945 that number had grown to 2,428

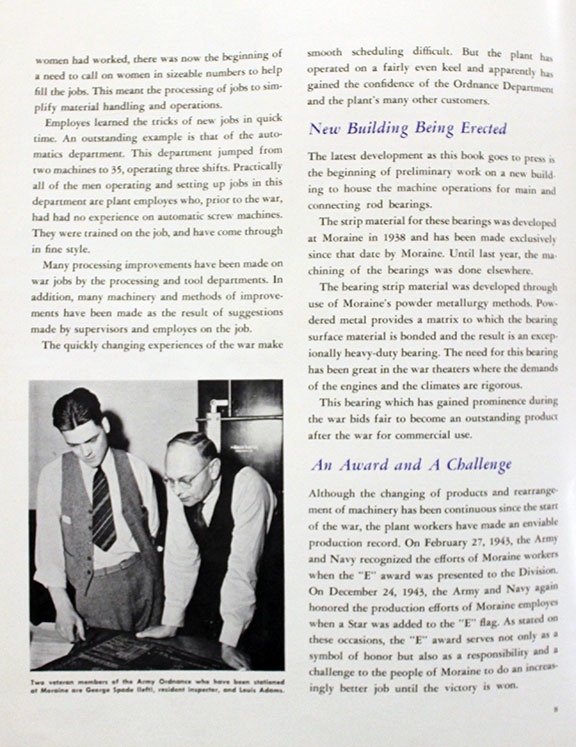

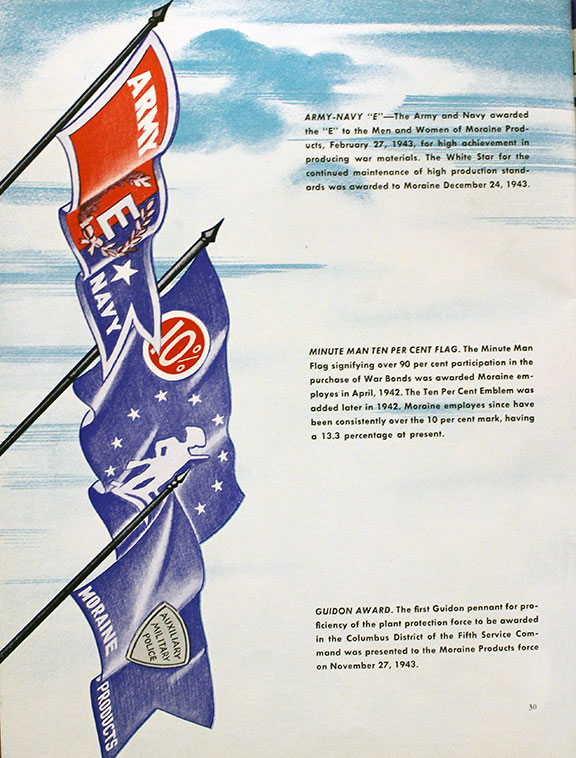

Moraine Products Division won the Army-Navy

"E" flag on 2-27-1943 and a star was added on 12-24-1943.

The Division had a second start added at an undetermined date

approximately six months later for a total of three awards.

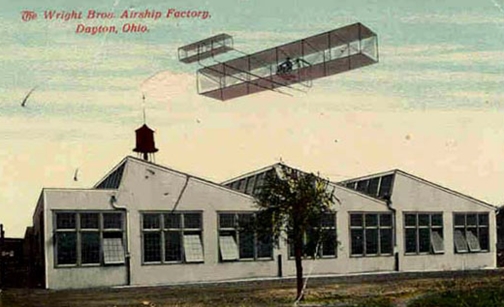

The separate building to the south was built specifically for Moraine Products to move into in 1937 when it returned to Dayton from Detroit. With the consolidation of the two divisions into one in August 1942, both complexes could be used to run war production in the most efficient manner. Photo courtesy of Susan Crusey. There is a lot of industrial history in the north factory complex. It originally started as the single story brick building on the corner, which was part of a four acre plot occupied by the Dayton Machine Tool Company before 1907. It is unknown when the building was originally built. It is documented that the Speedwell Motor Car Company moved into the one story building in 1907, and then two years later expanded the complex to nine buildings. Including the water tower, the complex occupied a total of six acres. From the expansion of the complex in 1909 until 1936, several tenants occupied the factory complex. Speedwell went out of business after the Great Dayton Flood of 1913. The most well-known occupants were the Wright Brothers, who leased space in the facility from February to November 1910 while waiting for the completion of their new plant on Home Avenue. The Wright Brothers' plant on Home Avenue later became part of the Inland Division of GM. The Wright buildings still exists today, awaiting restoration to become a museum. (See the photo on my Inland page.)

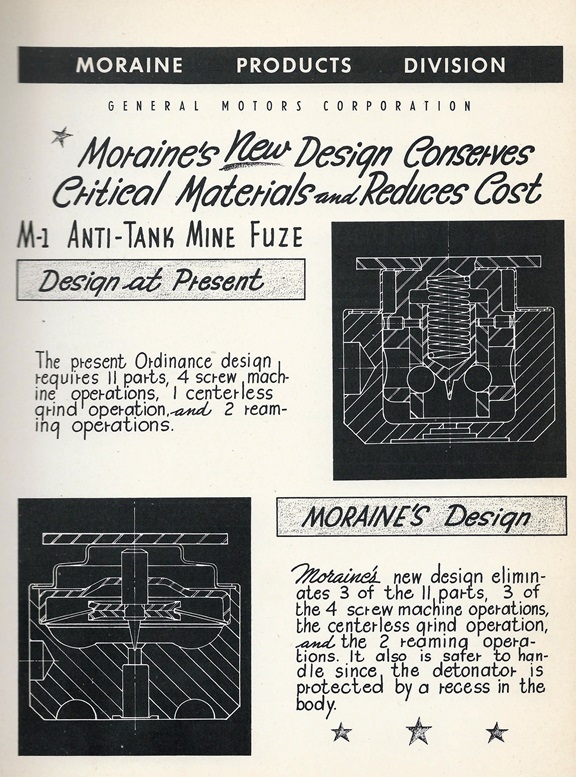

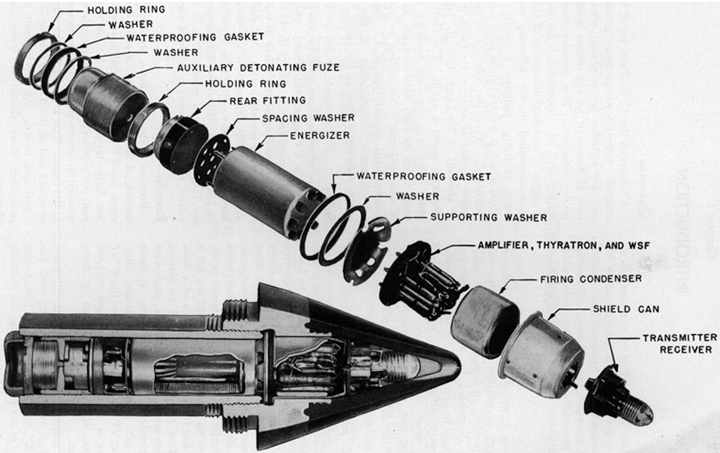

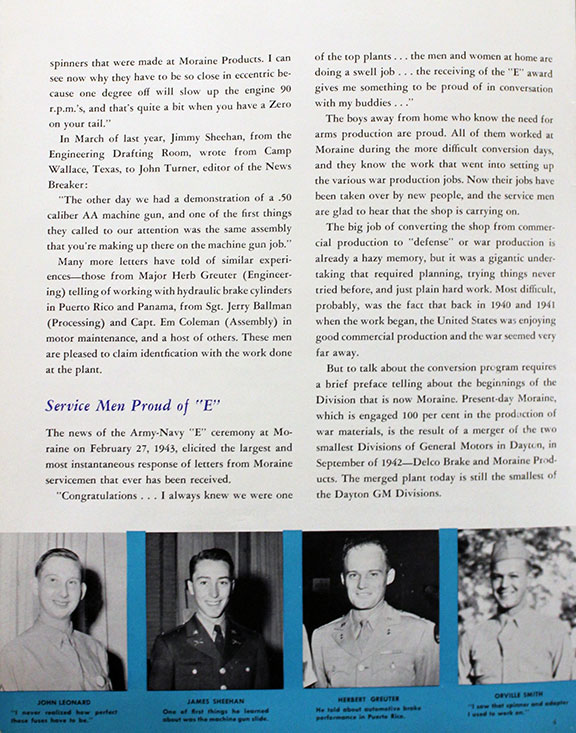

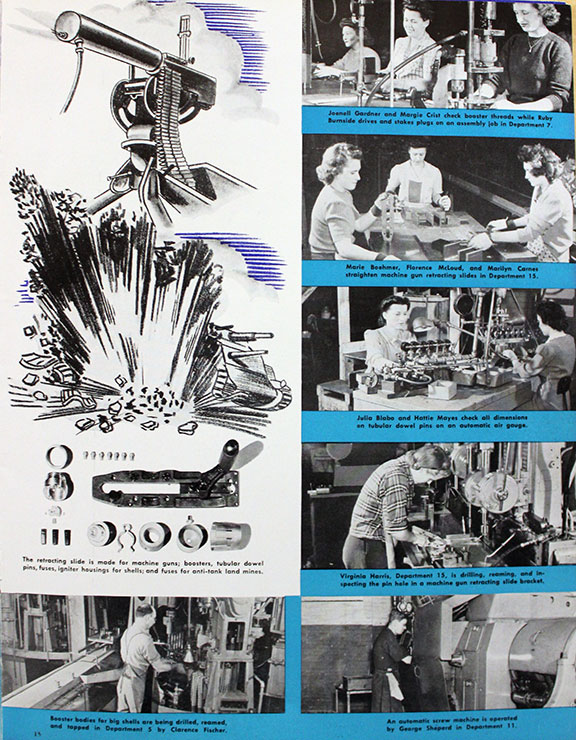

M-1 Anti-Tank Mine Fuse: This was placed in the top of the land mine and then detonated the explosives in the mine when a tank or heavy vehicle drove over it. Through the end of June 1943, Moraine had produced 5.5 million for the war effort, having started production in November of 1941. Moraine Products also supplied the M-1 tank mine fuse bodies and striker assemblies to other manufacturers.

M-54 Relay Igniter Housing: This is described as "a small housing for which a powder charge which is ignited from a tracer charge in the rear of certain high explosive anti-aircraft shells." I am not quite sure if this then sets off the main charge or not, but this is how it was described in "Moraine's Participation in the War". But 4 million were produced between November 1941 and February 1943. M-20 Booster: This device contained a booster powder charge to detonate the high explosive powder in 60mm, 75mm, 90mm, 105mm, and 155mm artillery shells. In July 1943 Moraine Products had contracts running until October 1943. At that point in time, it would have produced 8.5 million of the M-20s.

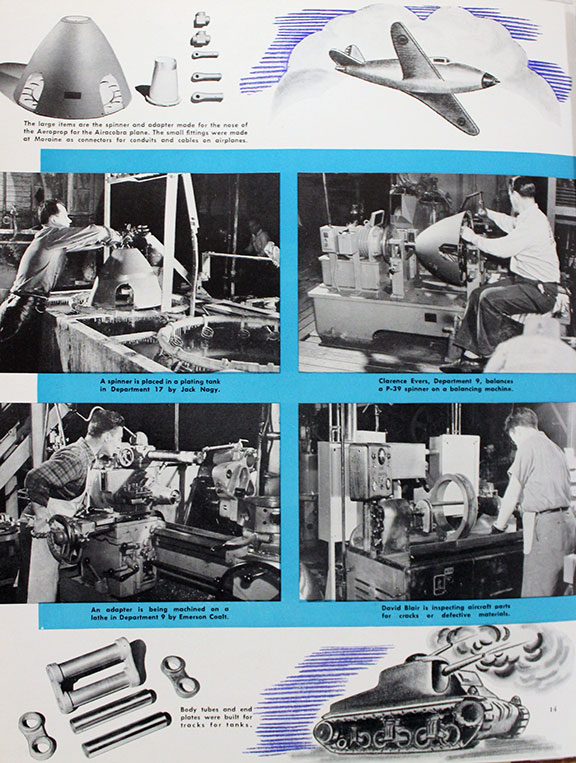

Tank Track Parts: Starting in May 1942, an order for 4 million light tank track parts started with no end date as of July 1943. The Moraine-manufactured body tubes and end plates were then sent to Inland Division. Inland added rubber treads and then shipped the final tank track to Cadillac, for the M5 Stuart and M24 Chaffee. 138,000 of the same type parts, but for the M4 Sherman tank, were built by Moraine between January and September 1942.

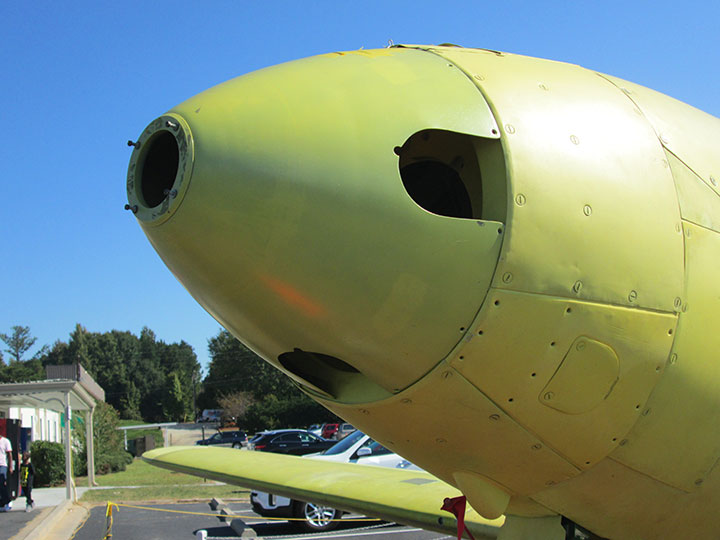

Spinner Assembly and Adaptor: Moraine was contracted to build 7,574 of these parts for the three bladed Bell P-39 Aircobra produced by the Aeroproducts Division of GM in nearby Vandalia, OH. Production started in February 1942 and was completed in June 1943. Moraine also was awarded the contract for 5,000 of the four bladed versions of these parts for the Bell P-63 in April 1943. Most of these parts ended up in the Soviet Union, as both the P-39 and P-63 were sent extensively to that country under Lend-Lease. The Guide Lamp Division of GM also built the same parts for the P-39.

Tubular Dowel Pin: This was actually the core for .50 caliber incendiary and tracer bullets. Four million of them were manufactured by Moraine as an iron Powder Metal part staring in October 1942. M-57 Fuse: Moraine was contracted to build one half million of these point denoting fuses starting in May 1942. All contracts for this device to all manufacturers were cancelled in May 1943. Retractor Slide Assembly for the .50 caliber machine gun: Moraine had one contract for 147,169 Assemblies for AC Sparkplug Division of GM in Flint, MI and another for 40,800 from Army Ordnance. All of the parts were produced on equipment provided by AC Sparkplug Division.

T and L Fittings and Fork Joints: This was a Lend-Lease contract for aircraft "T" and "L" shaped fittings for aircraft oil and hydraulic lines. The fork joints were for electrical wiring in the aircraft. Tube and Strap: There were 730,826 of these parts made for a "secret project" between June and August 1942. The historical information indicates that several other GM Divisions were involved. This leads me to believe that these parts were for the "Top Secret" FP-45 Liberator Pistol assembled by the Guide Lamp Division for three months of 1942. The FP-45 fits into the category of "it sounded like a good idea at the time". The pistols were to be given to partisans in German occupied territory to attack German soldiers. Cooler heads prevailed, as firing a .45 caliber pistol is an acquired skill as it creates significant recoil. The light weight of the FP-45 would not have been able to absorb the amount of recoil. Firing the weapon would probably have been more dangerous to the shooter than the target. There was also the issue of what happened to the shooter if the shooter missed with the first shot, which was highly likely, and then killed by return fire from the German soldier. The pistols were never used as intended and most were subsequently scrapped. In the end, it took massive well-trained armies to end the war.

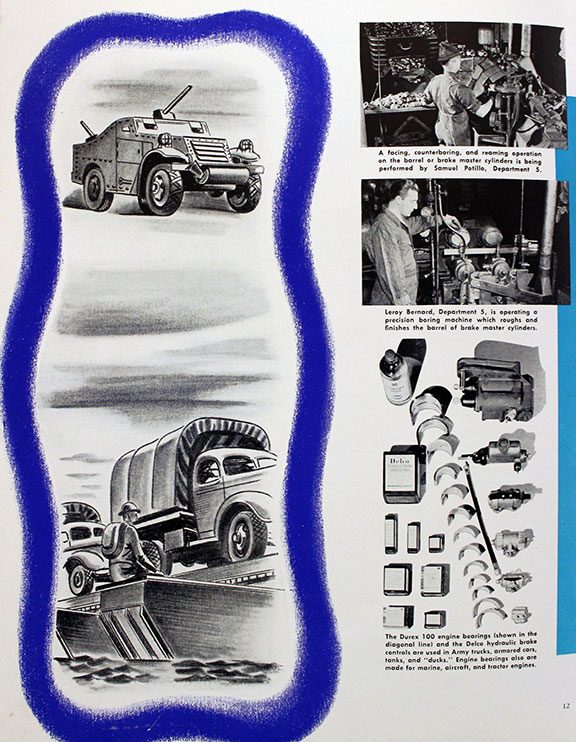

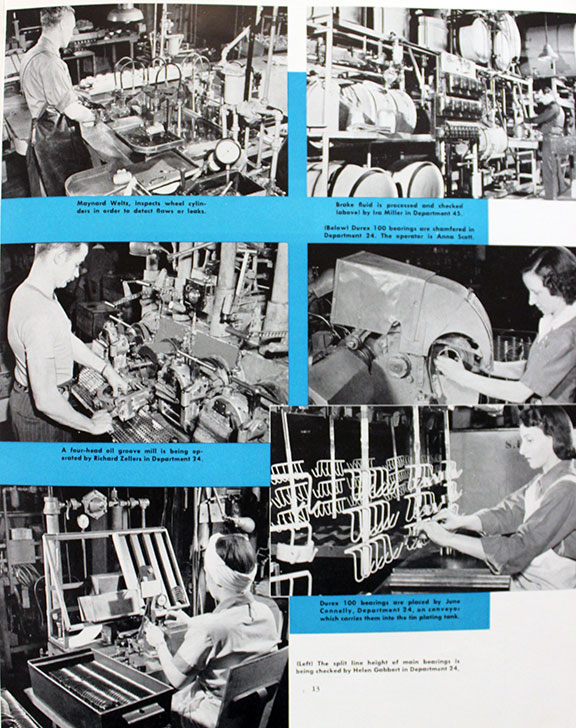

Hydraulic Brake Controls: These were brake master cylinders, wheel cylinders, hoses, and brake fluid that were supplied for Chevrolet 1-1/2 ton trucks and GMC 2-1/2 ton trucks. They were larger versions of what the old Delco Brake Division had built for passenger cars.

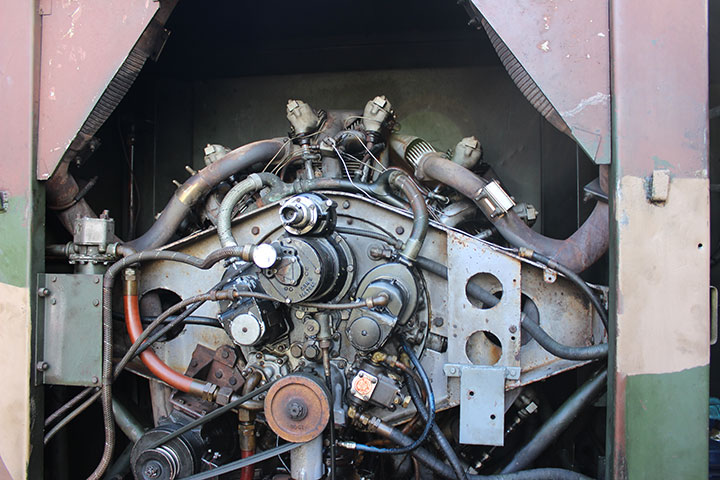

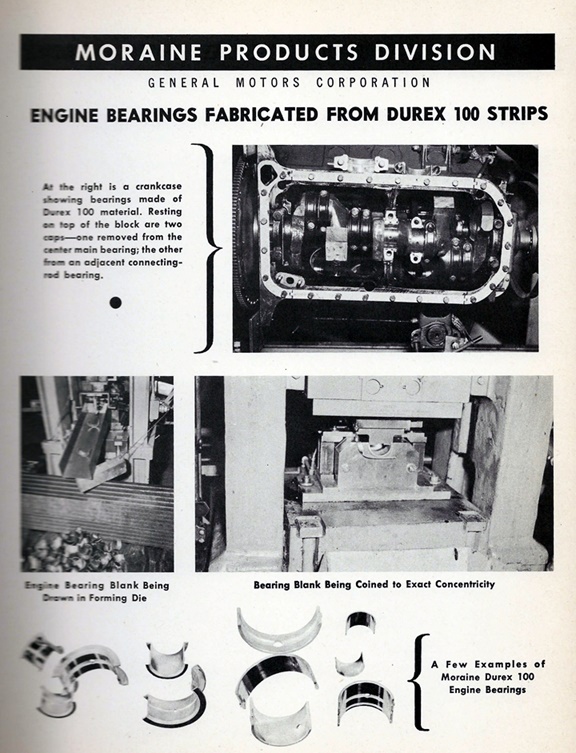

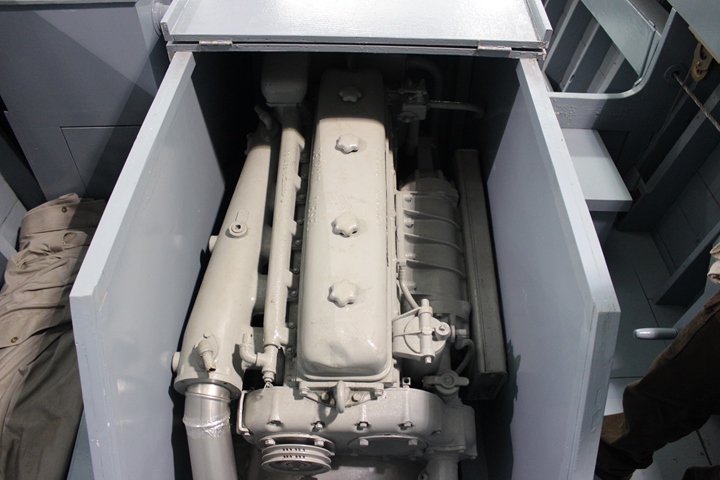

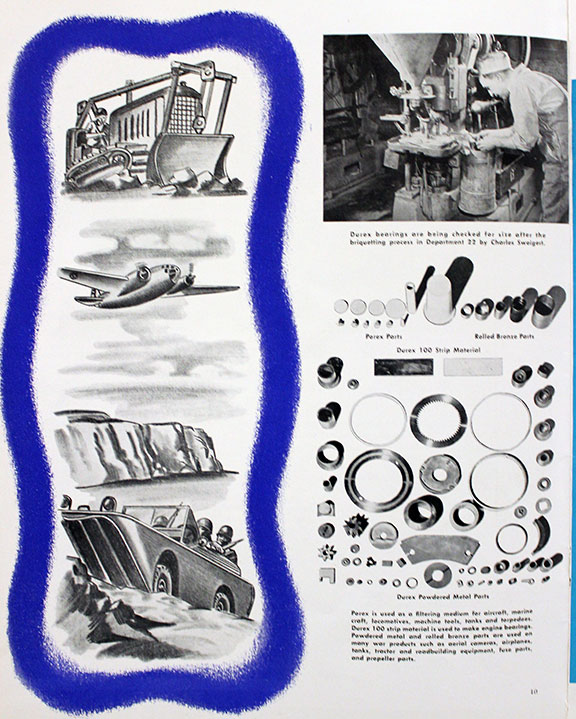

Main and Rod Connector Bearings: This was a huge product line for Moraine during the war. The bearing material was made out of its Durex 100, which was Powder Metal manufactured in continuous strip form. The process was developed just before the start of World War Two and introduced in Buick engines. The World War Two customer base included Cadillac for tank M5 and M24 tank engines, Continental for radial aircraft engines that were also used in M4 Sherman tanks and Landing Vehicle Tanks (LVT) or Amtracs, GMC and Chevrolet for trucks, and Detroit Diesel and Electro-Motive for diesel engines for tanks, tank destroyers, stationary engines, and landing craft.

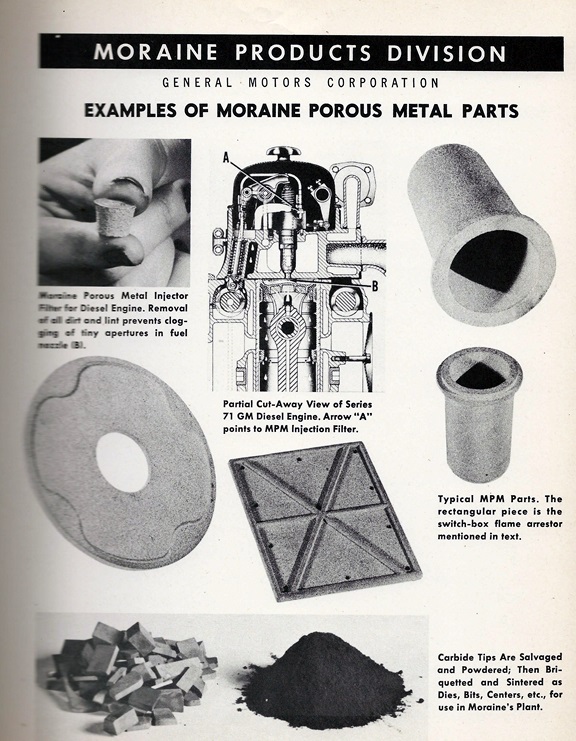

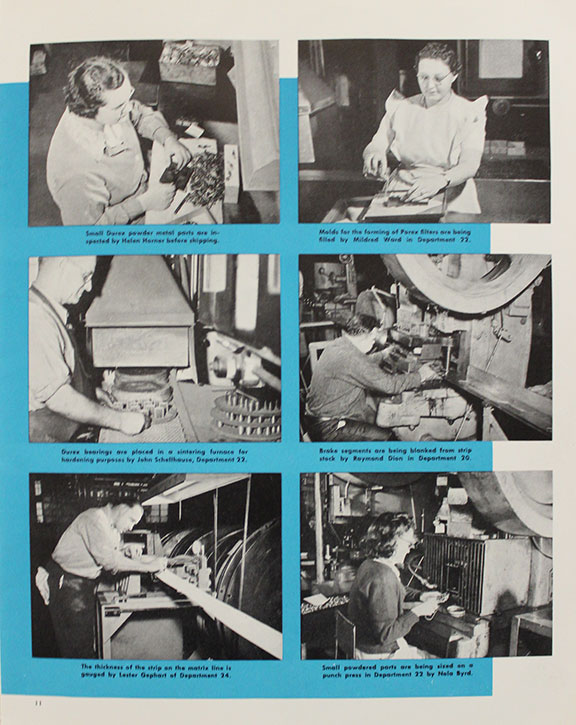

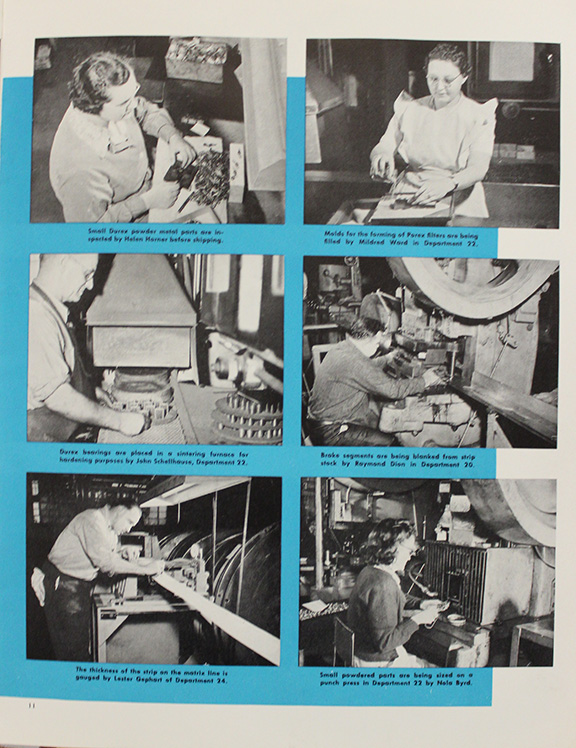

Porex Parts/Moraine Porous Metal or MPM: Originally identified as Porex by Moraine, the name was changed by 1945 to MPM. This was a three dimensional filtering material of tiny brass particles sintered together and developed by Moraine Products before the war. Porex or MPM filters were used in aircraft carburetors and fuel pumps, in diesel injectors as shown below, and as desiccant retainers for bomb sight lenses, among other uses. Customers included Chandler-Evans, Detroit Diesel and Electro-Motive as shown below, Bendix, and Delco-Products, among others.

What was Moraine's contribution to the LCVP? Of the 23,353 built, 19,353 were built with Detroit Diesel Division of GM 6-71 engines. They came equipped with filters made of Moraine Porous Metal (MPM), assuring no fuel contaminants got into the injectors, which would prevent them from operating. So, while the fuel filter may have been a small part of the whole boat, the filter's function was extremely significant compared to its size. The soldiers, marines, and coast guardsmen operating the LCVPs did not need to have their engines fail due to dirty fuel while making the dangerous run in to the landing beaches. Also, the engines had Moraine-built Durex 100 main bearings which prevented the engine from spinning a bearing.

In between the small LCVP and the large LST were various types of landing ships powered by engines built by Detroit Diesel, which supplied 54,033 6-71 engines with Moraine Porous Metal Filters and Durex 100 engine bearings.

Powder Metal Parts (PM): Iron, copper, and bronze Powder Metal technology is known as "near net shape forming" as the part is molded close to if not to its final dimensions, saving both material and machine over traditional machined components. While not suitable for all applications, it can be used as a more cost effective solution to producing metal parts. Powder Metal components included but were not limited to aerial camera parts for Eastman Kodak, shim plates for Hamilton Standard propellers, collector rings used as electrical contacts on aircraft gun turrets manufactured by Bendix, magnetic pole pieces for Bendix, Westinghouse and Globe Industries small aircraft motors, firing pins made out of copper PM for firing pins that Lionel needed, oil pump gears for Continental built engines and aircraft disc brake segments for Bendix.

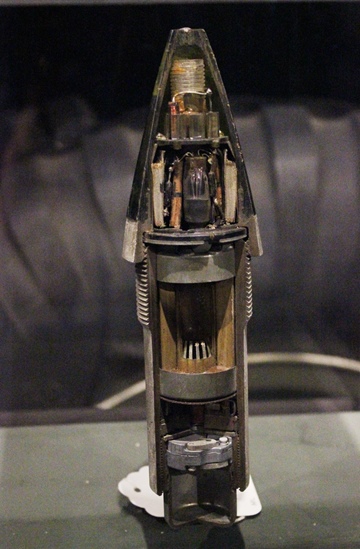

Small Bearings and Bushings: These were small parts. Many of them self-lubricating, due to their porosity made out of powdered iron and rolled and powdered bronze. They were used in small auxiliary motors for use in tanks, aircraft, and marine vehicles. The customer base for these parts was diverse; with the bearings and bushings going to such companies as Pratt & Whitney, North American Aviation, Douglas Aviation, Cessna, Lord Manufacturing, Wico Electric, Bendix Aviation, Thompson Products, Detroit Transmission, J. I. Case, John Deere, Eclipse Aviation, and Sun Shipbuilding among others. VT Proximity Fuze: This was one of the most top secret projects of World War Two. Historical records show that Moraine furnished powder metal parts for the fuze early in the development program. It is unknown which parts and how many the division produced.

The story of the people in

a small plant doing their part in a big job...

|