|

Twin

Disc Clutch Company During World War Two

Racine, WI

1918-Current

This page updated 11-21-2024.

The Landing Craft, Vehicle, Personnel (LCVP) was noted by General

Eisenhower as the boat that won World War Two for the United States.

While that statement can be debated as to how true it actually is, what

is true is that the LCVP was a very important landing boat for the

United States in the war and was the first of several types of landing

craft to land during a seaborne invasion. The LCVP is also known

as the Higgins Boat, named after Andrew Jackson Higgins, who is considered the

inventor of this type of landing craft with a droppable ramp on the bow.

The LCVP was built by Higgins Industries, Chris-Craft, Dodge Boat and

Plane, Matthews Company, Owens Yacht Company, and Richardson Boat.

The six companies built a total of 23,358 LCVPs during World War Two.

Author's photo.

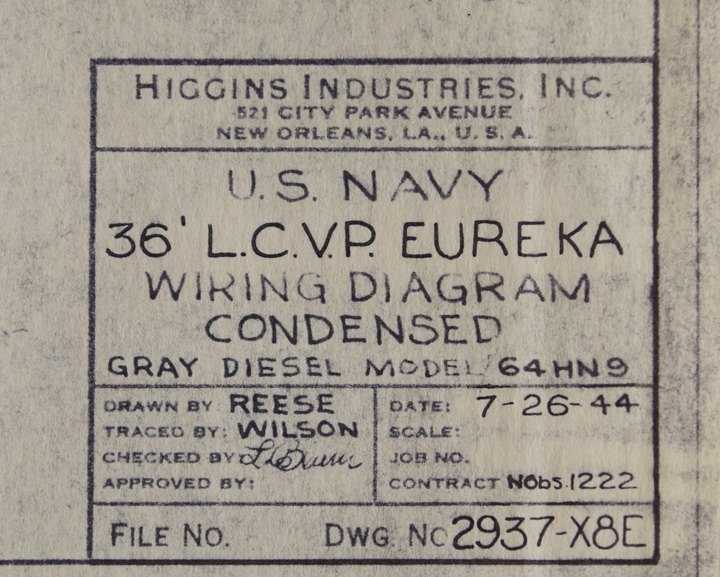

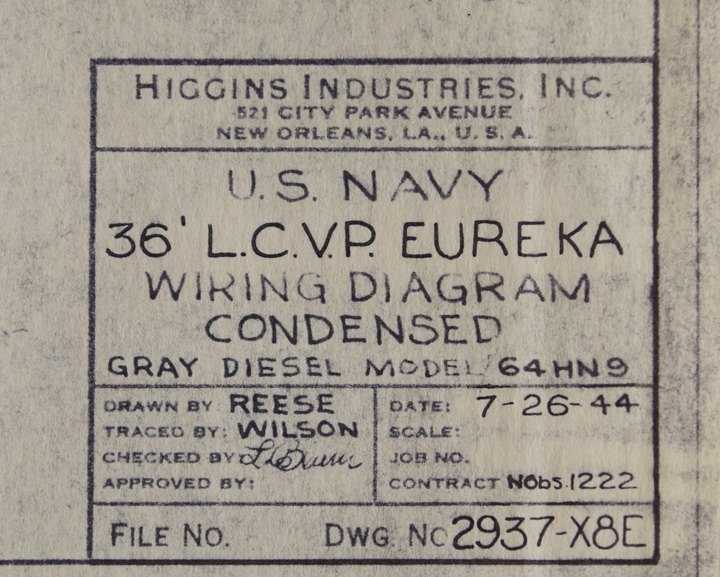

The Gray Marine Motor Company Model 64HN9

diesel engine as shown here, on this Higgins Industries engineering

drawing, was one of several engines that powered the LCVP. The LCVP

and the Gray Model 64HN9 are widely recognized among World War Two

historians and enthusiasts. However, for the Gray 64HN9 engine to

propel the LCVP through the water, it needed a transmission with a

clutch and a

forward and reverse gear. World War Two historians have overlooked

this very important component of the drive train that was manufactured

by the Twin Disc Company of Racine, WI.

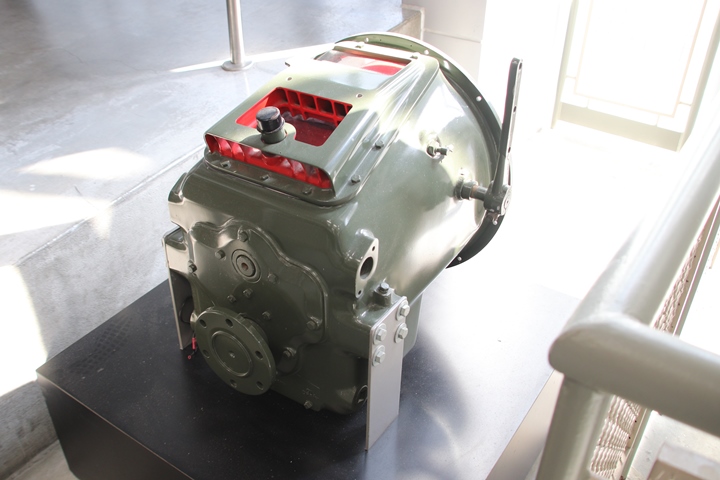

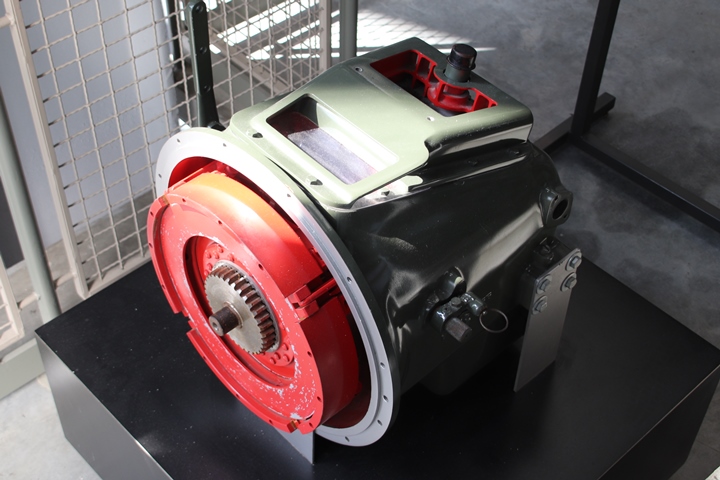

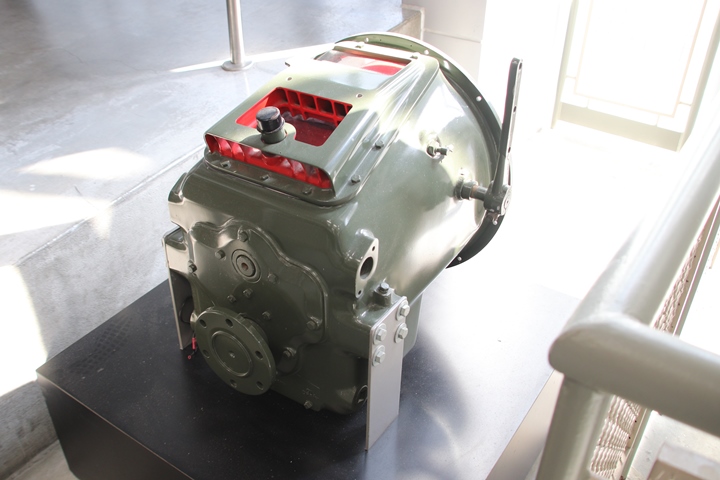

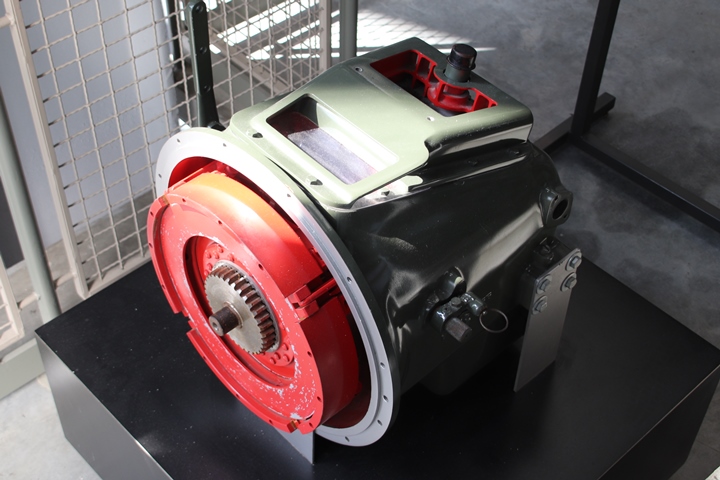

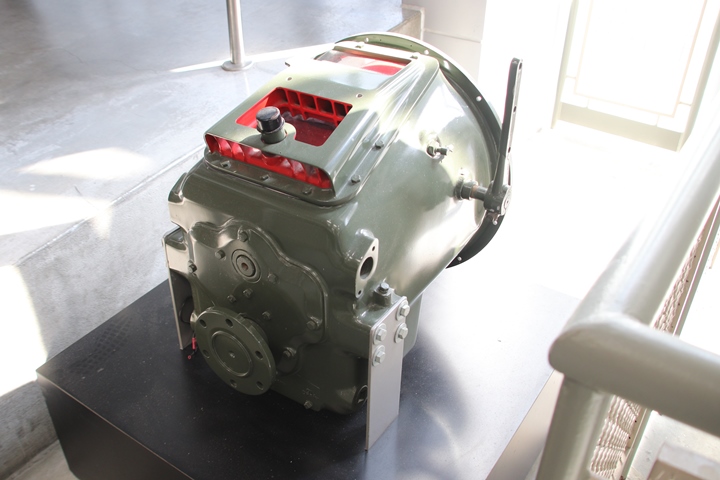

This is an example of a Twin Disc

transmission that was used in many types of landing craft besides the LCVP. This is the device that transferred the power of the engine

to the landing craft's propeller. It is the unknown but very

important part of the drive train for several types of landing craft

that landed on enemy beaches during World War Two. This example is

on display at the National World War II Museum in New Orleans, LA.

Of the many military museums that I visited during my research trips, this is

the only Twin Disc transmission I have found on display. Author's

photo.

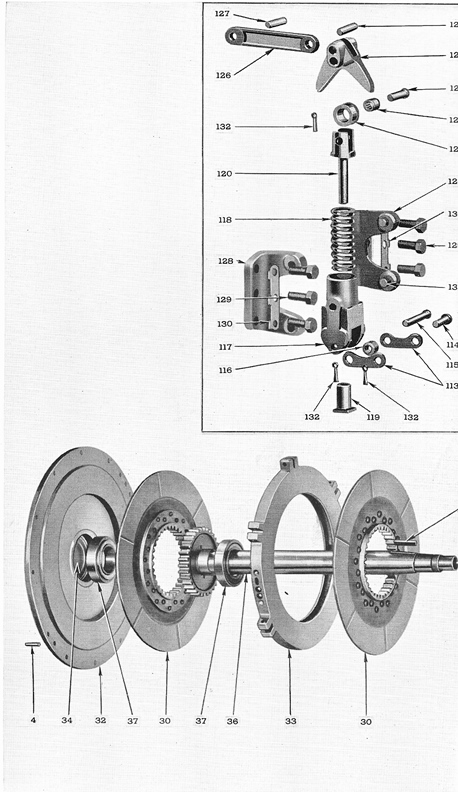

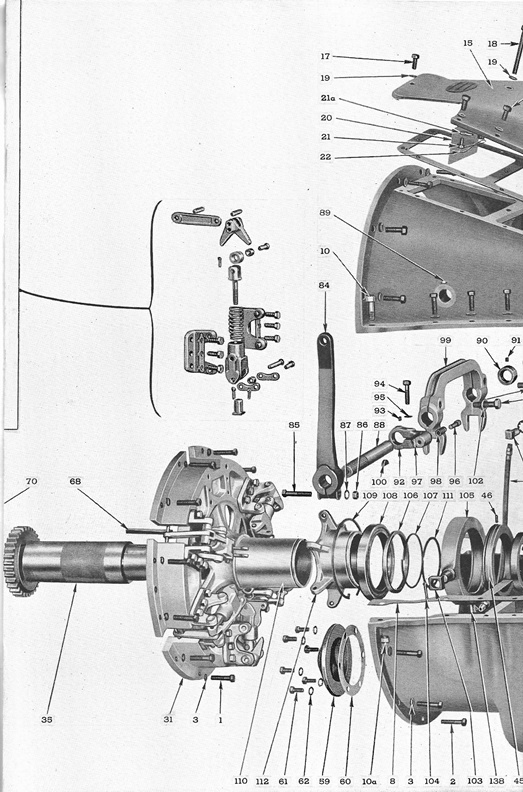

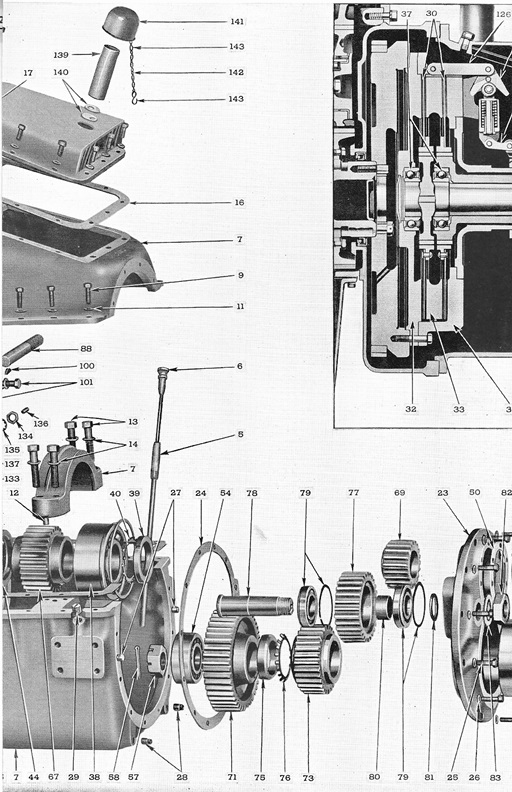

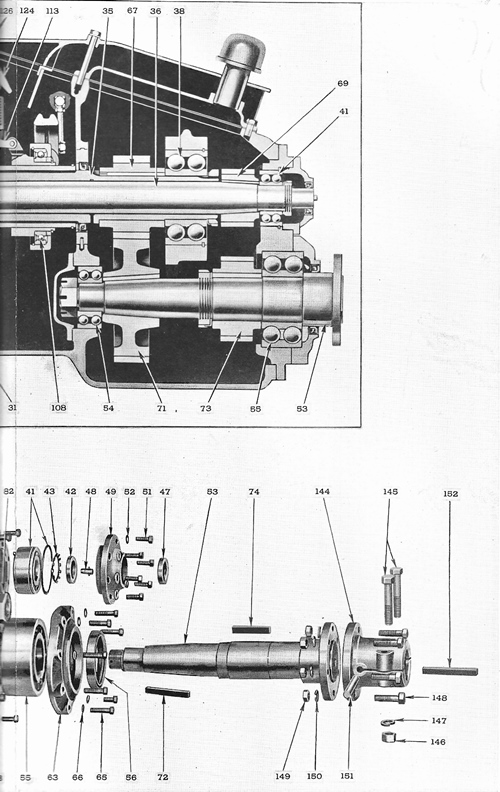

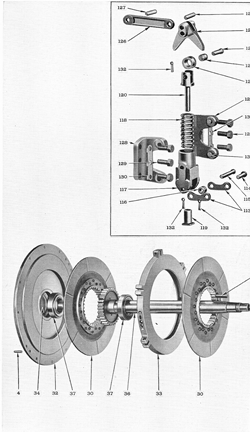

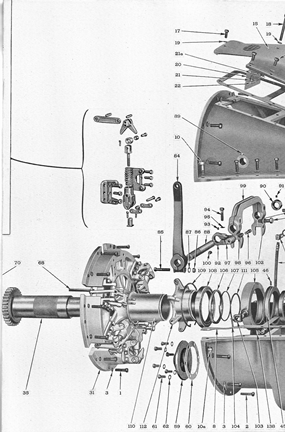

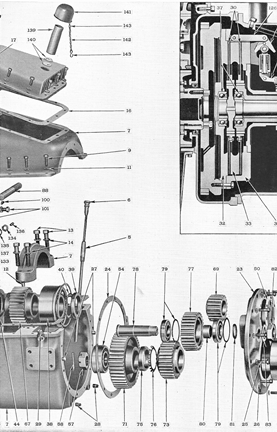

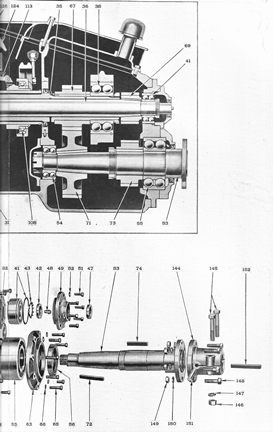

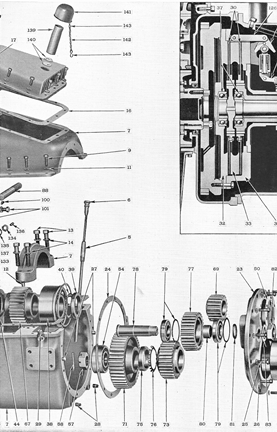

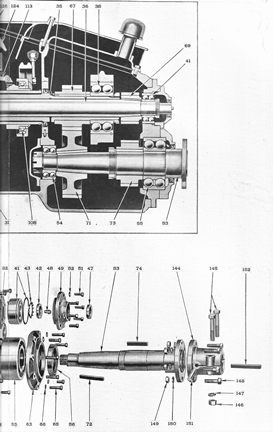

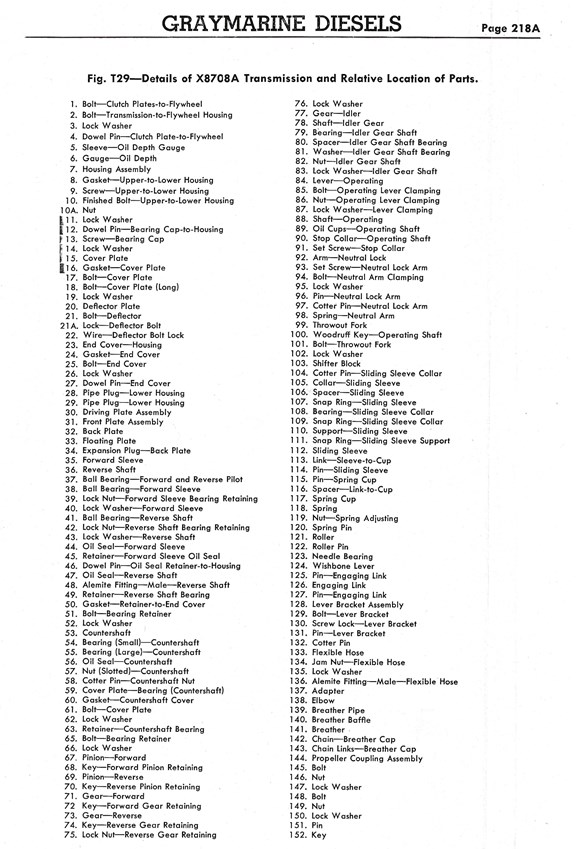

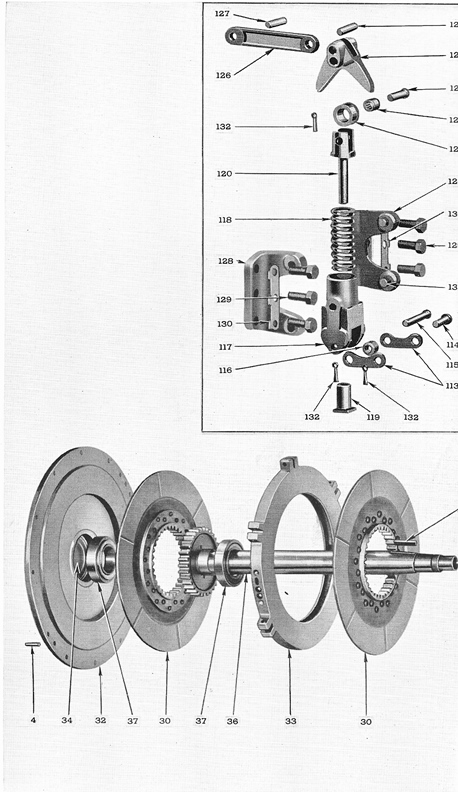

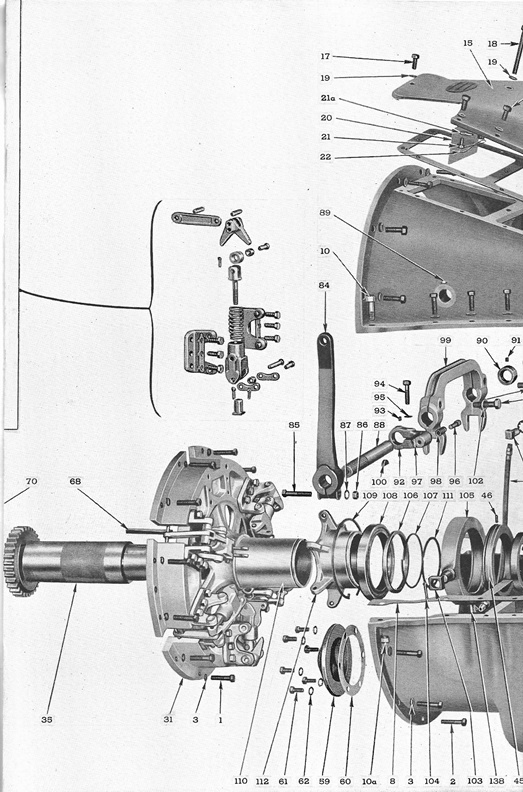

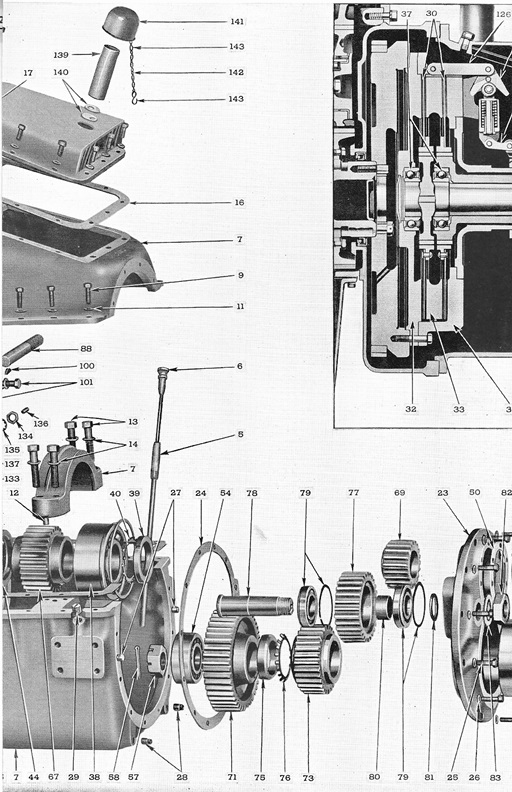

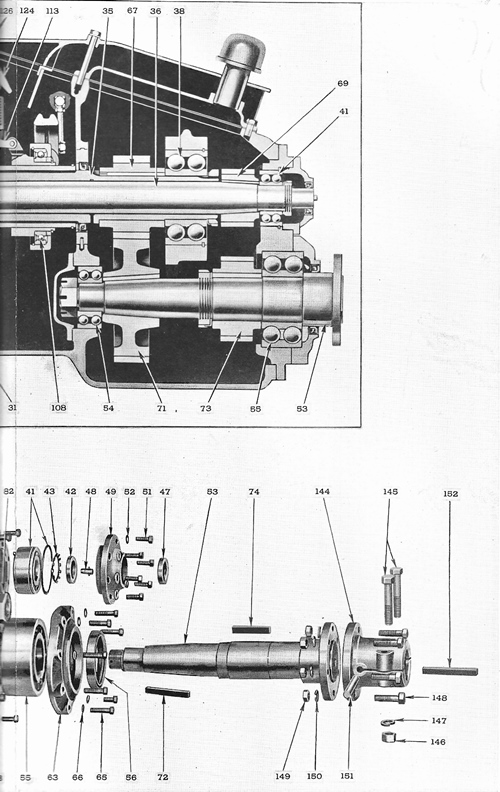

The two castings that make up the case of

the transmission hide the 156 components that make the unit operate. It

is a very complicated piece of mechanical equipment.

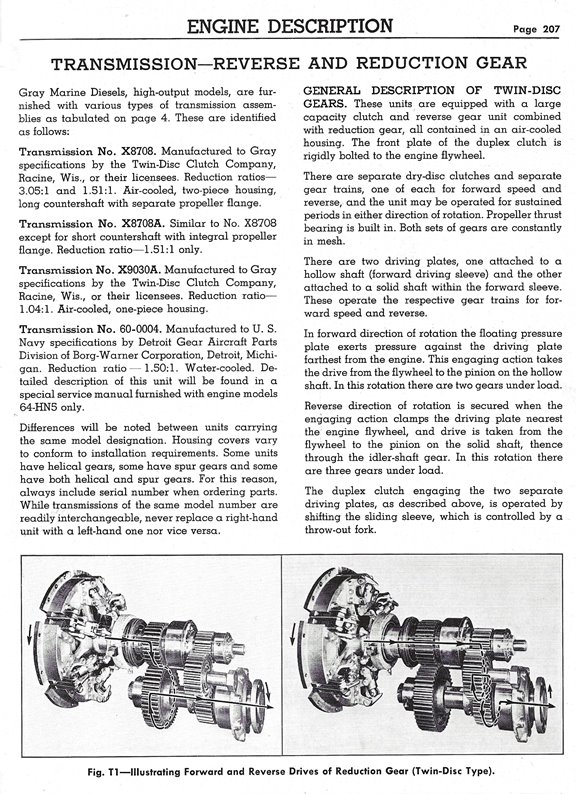

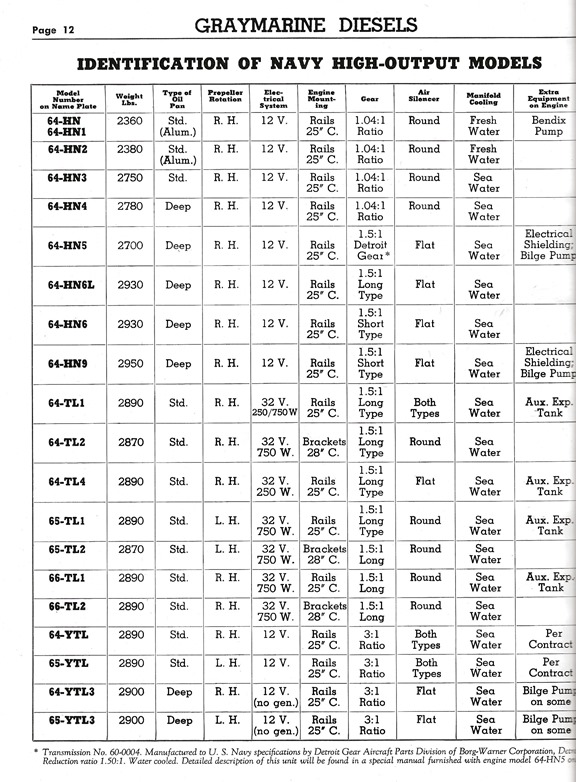

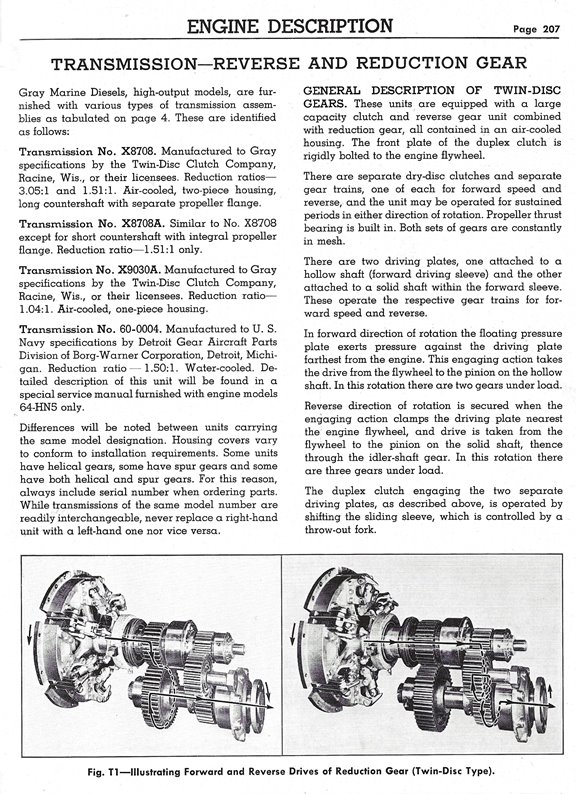

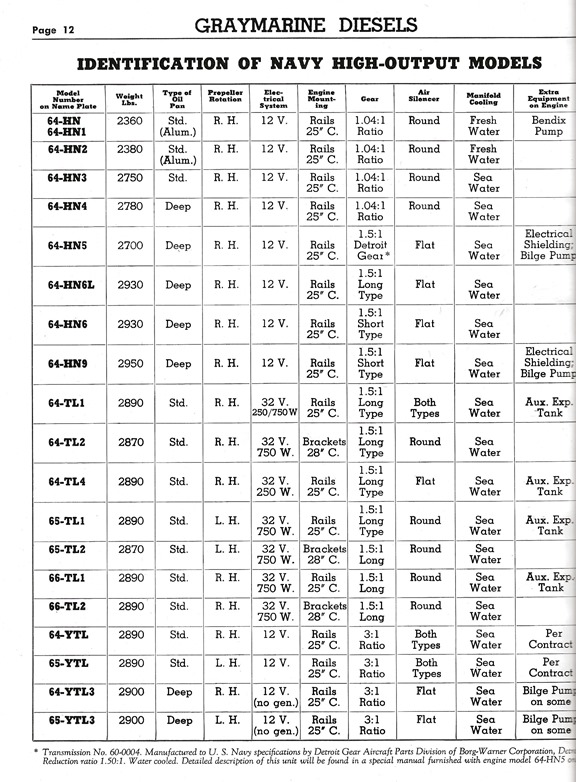

This page from a Gray Marine Motor Company World War Two training manual

shows that all of the different engines the company made, except

for one, were equipped with

three different types of Twin Disc Company transmissions.

The Borg-Warner transmission was only used with the 64-HN5 engine.

This page from a Gray Marine Motor Company

World War Two training manual shows that all of the different engines the

company made were equipped with Twin Disc Company transmissions.

The one exception is the 64-HN5 engine.

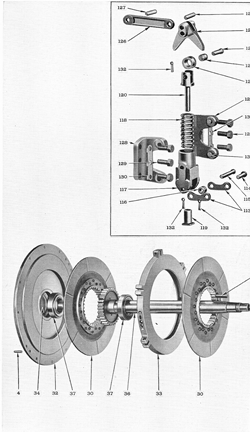

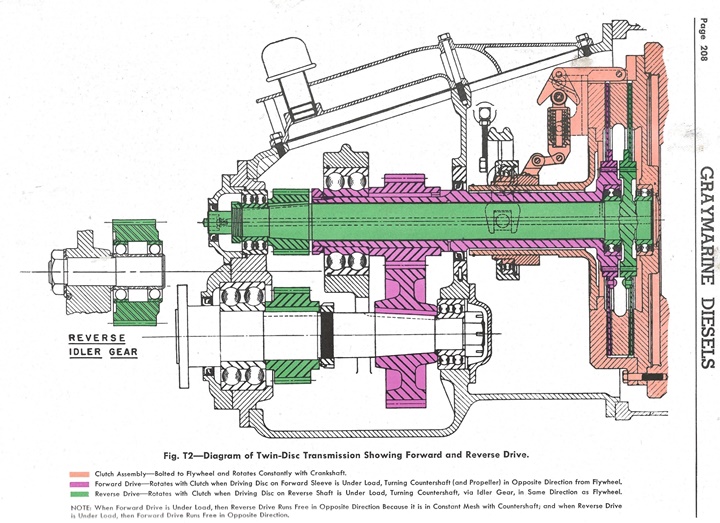

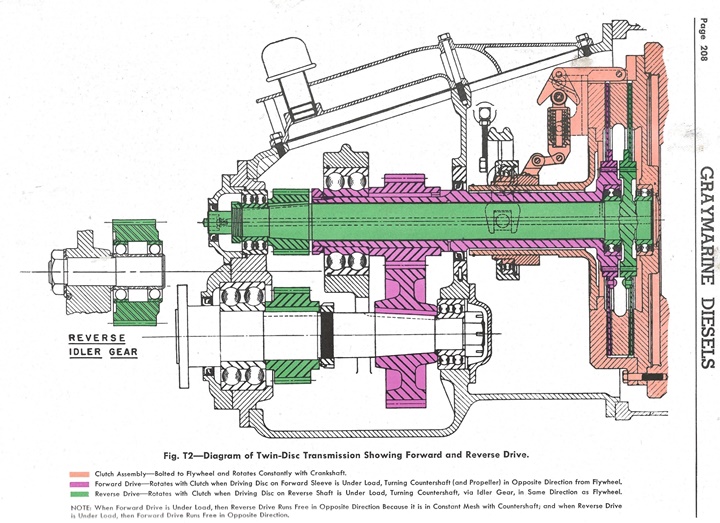

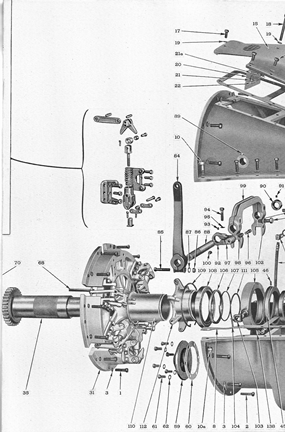

This color image gives another internal view

of the Twin Disc transmission used on most small landing craft of World

War Two.

The LCVP was not the only type of

36-foot landing craft during World War Two, although it was the most

prominent as shown in Table 1. Table 1 also shows that there were

other types of engines used to power the landing craft when Gray-built

engines were not available. But all of the engines and landing

craft shown in Table 1 required Twin Disc transmissions.

|

Table 1 - Twin

Disc and Gray Marine

Motor Company

Engine World War Two Landing Craft Applications

|

| Type

Landing Craft |

Number

built |

Type

Engine |

Engines per Landing Craft |

Total Twin Disc Transmissions and Gray Marine Engines per

Landing Craft |

| LCP(L) |

2,193 |

Gray Marine 64HN9/Detroit Diesel 6-71,

Hall-Scott Invader, and Superior Diesel |

1 |

2,193 |

| LCP(R) |

2,572 |

Various including

Gray Marine 64HN9/Detroit Diesel 6-71 |

1 |

2,572 |

| LCV |

2,366 |

Various including

Gray Marine 64HN9/Detroit Diesel 6-71 |

1 |

2,366 |

| LCVP |

23,353 |

Gray Marine

64HN9/Detroit Diesel 6-71 or Hudson built Hall-Scott 210 hp

gasoline powered Invader |

1 |

23,353 |

| LCM(3) |

8,631 |

Gray Marine

64HN9/Detroit Diesel 6-71 or

Kermanth 100 hp six cylinder gasoline engines |

2 |

17,262 |

| LCM(4) |

2,718 |

Gray Marine

64HN9/Detroit Diesel 6-71 or

Kermanth 100 hp six cylinder gasoline engines |

2 |

5,436 |

| LCM(6) |

2513 |

Gray Marine

64HN9/Detroit Diesel 6-71 or

Kermanth 100 hp six cylinder gasoline engines |

2 |

5,026 |

| LCT(5) |

470 |

Gray Marine 64HN9/Detroit Diesel 6-71 |

2 |

940 |

| LCT(6) |

960 |

Gray Marine

64HN9/Detroit Diesel 6-71 |

2 |

1,920 |

| Totals |

45,776 |

|

|

61,068 |

This 1944 Landing Craft, Personnel, Large (LCP(L))

was the first type of landing craft that Andrew Higgins designed.

It was this type of boat that Higgins Industries first built with a Twin

Disc transmission.

This particular boat was built by Higgins

Industries in New Orleans in October 1944 and is currently on display at the National WWII Museum in New Orleans.

It has been returned home for museum visitors to see. It is the

only one on display left in the world. Hall-Scott Invader engines

were one of three types of engines Higgins Industries specified for this

landing craft. They were the Gray/Detroit Diesel, Superior

Diesel, and Hall-Scott Invader engines. Each required a Twin

Disc transmission. Author's photo.

Note the location of the coxswain's steering

station, the two gun tubs for mounting self-defense machine guns, and the

engine housing in the middle of the boat.

Note also that the 25 armed troops carried in the craft were in two

different sections of the LCP(L). Author's Photo.

The LCP(R) was an LCP(L) with the bow

modified for a three foot wide ramp. The U.S. Navy had Chris-Craft

modify one of the LCP(L)s it was building and install a three-foot wide

landing ramp. This was the U.S. Navy's attempt to build a landing

craft with a ramp. The engines in this type of boat had Twin Disc

transmissions. Photo courtesy of the

Algonac-Clay Township Historical Society.

The LCV was Andrew Higgins' first attempt to build a landing craft

with a ten-foot wide landing ramp. There were 2,633 LCVs built between 1941

and 1943 by Higgins Industries, Chris-Craft, Richardson, and Owens Yacht.

While not built in the

quantities of the LCVP, LCVs saw duty during early American invasions in

World War Two. It continued to be utilized even after the LCVP

became the dominant landing craft later in the war. There are several key differences

between the original LCV and the later LCVP that can be seen in the

photo above.

The most obvious is the coxswain's station, which is on the transom of

the LCV. It was moved into the boat on the LCVP. Note

the ramp winch is also located in an exposed position on the port

side of the LCV. In the LVCP, it was moved down into the boat

to protect the crewman operating it from hostile fire. The LCV

engine required a Twin Disc transmission.

This is one of 960 LCM-6s that were produced

during World War Two and powered by two Gray Marine

64HN9/Detroit Diesel 6-71 engines equipped with Twin Disc

transmissions. Author's photo taken at the U.S. Army

Transportation Museum at Fort Eustis.

Author's photo taken at the U.S. Army

Transportation Museum at Fort Eustis.

Author's photo taken at the U.S. Army

Transportation Museum at Fort Eustis.

Twin Disk Company History: The

Twin Disc Company was formed in 1918 for the manufacture of farm tractor

clutches. Co-founders were Percy H. Batten, Arthur B. Modine, and

Thomas Fawick, inventor of the Twin Disc Clutch. Early investors

included local business leaders Henry Wallis Jr. of the Wallis Tractor

Co. and H.F. Johnson of S.C. Johnson & Son. From the further development

of farm tractor clutches

by company founder, P.H. Batten, Twin Disc developed durable marine

transmissions for Great Lakes fishing boats in the 1930ís, manufacturing

countershaft reduction gears with 100 percent reverse power.

World War Two was a significant turning point

for the company. With it being the main supplier of the

transmissions that were used in nine types of landing craft

used around the world, Twin Disc became a recognized name in the marine

propulsion industry.

How cool is this?

John H. Batten, the current President and Chief Executive Officer of the

Twin Disc Company, is the great grandson of P.H. Batten, who founded the

company. This is extremely rare and may be the only case where a

fourth generation member of the family is still involved, let alone the

President and CEO of a company. Normally, by the third generation,

the grandchildren have no interest in the family business, or are not properly

able to manage it, resulting in the companies going out of

business.

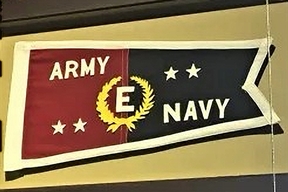

The Twin Disc Company won the Army-Navy "E"

Award five times during World War Two.

The "E" flag shown here shows the four stars on the flag. Twin

Disc Company had this flag on display at its former Heritage Center.

The company won its first award in September 1943.

Twin Disc Company World War Two Products:

As noted above, the company produced over 61,000 marine

transmissions for various small landing craft. Table 1 shows that the Racine plant had $306,000 in major contracts with both

the Army Corps of Engineers and the U.S. Navy. Table 2 shows that

its Rockford, IL plant had $123,000 for torque converter parts for the

Navy. From the large number of landing craft transmissions built, companies such as Gray Marine Motor Company ordered

the required transmissions directly from Twin Disc.

Table 1 - Twin Disc Clutch Company's

Major World War Two Contracts - Racine, WI Plant

The information below

comes from the "Alphabetical Listing of Major War Supply

Contracts, June 1940 through September 1945." This was

published by the Civilian Production Administration,

Industrial Statistics Division. |

|

Product |

Contract Amount |

Contract Awarded

|

Completion

Date |

| Clutch Parts -

Army Corps of Engineers |

$60,000 |

2-1943 |

5-1943 |

| Machine Parts -

Army Corps of Engineers |

$70,000 |

7-1943 |

9-1943 |

| Twin Disc Clutch

Parts - Army Corps of Engineers |

$57,000 |

12-1943 |

8-1944 |

| Marine Engine

Gears - Navy |

$119,000 |

2-1945 |

11-1945 |

| Total |

$306,000 |

|

|

Table 2 - Twin Disc Clutch Company's

Major World War Two Contracts - Rockford, IL Plant

The information below

comes from the "Alphabetical Listing of Major War Supply

Contracts, June 1940 through September 1945." This was

published by the Civilian Production Administration,

Industrial Statistics Division. |

|

Product |

Contract Amount |

Contract Awarded

|

Completion

Date |

| Torque Converter

Parts - Navy |

$123,000 |

6-1944 |

12-1944 |

| Total |

$123,000 |

|

|

More Photos of the Twin Disc Transmission

at the National World War II Museum in New Orleans, LA:

Author's Photo.

Author's Photo.

Author's Photo.

Author's Photo.

Author's Photo.

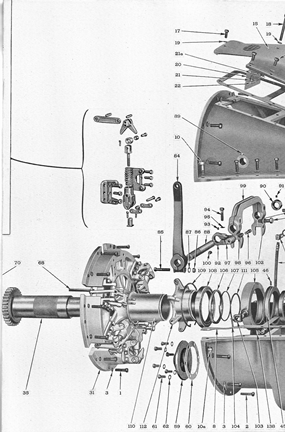

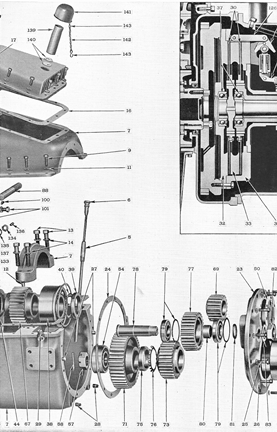

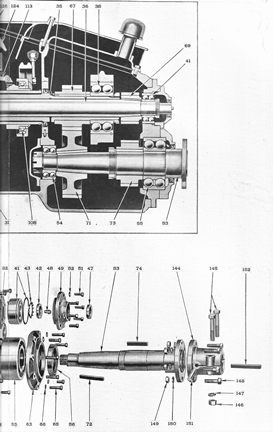

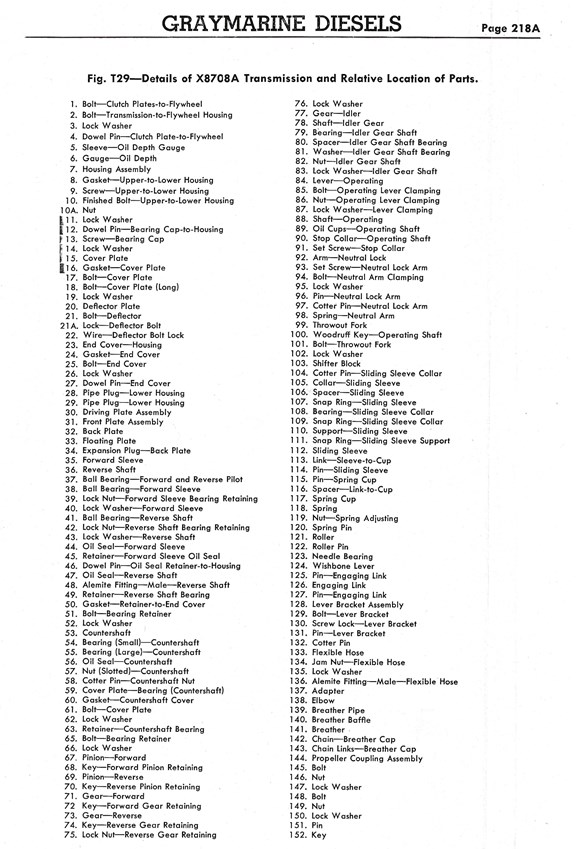

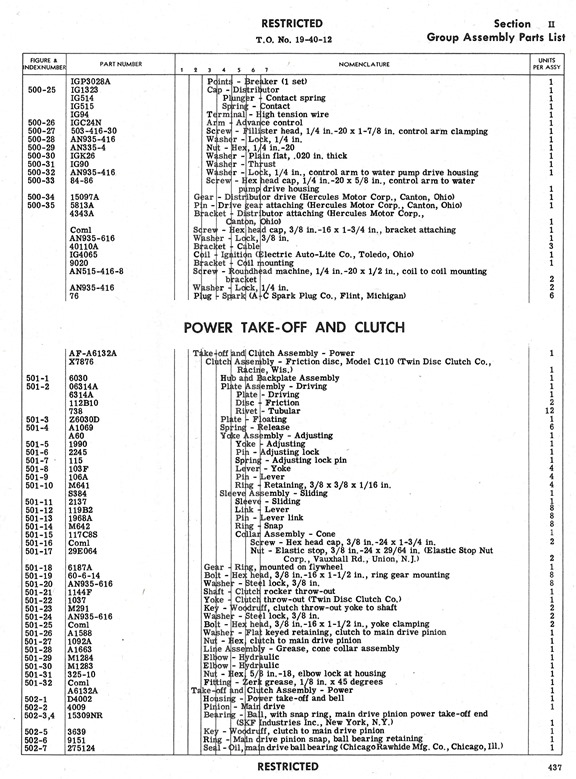

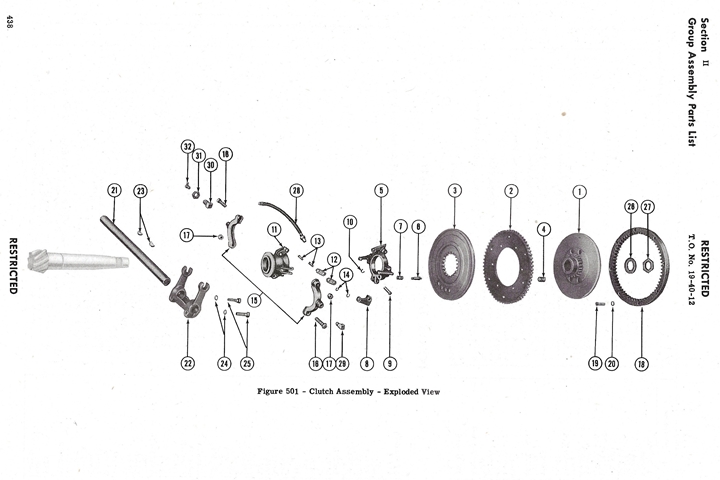

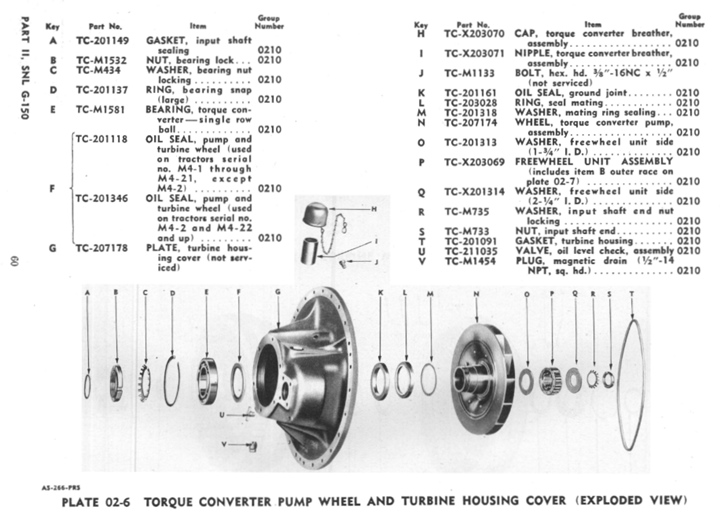

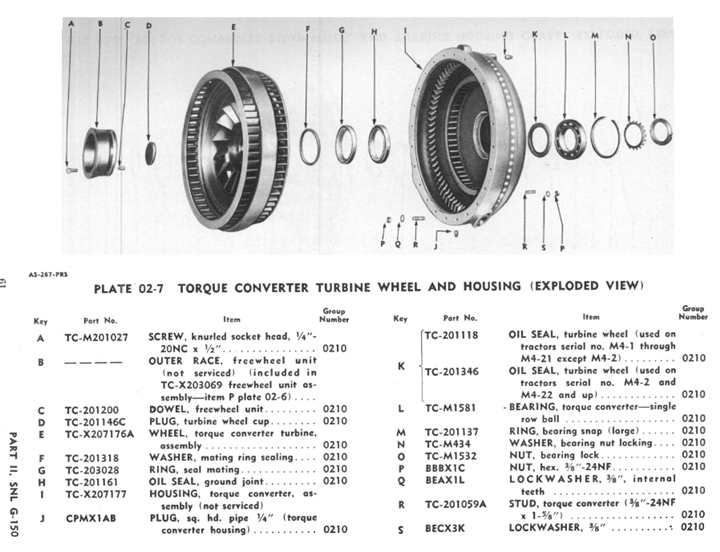

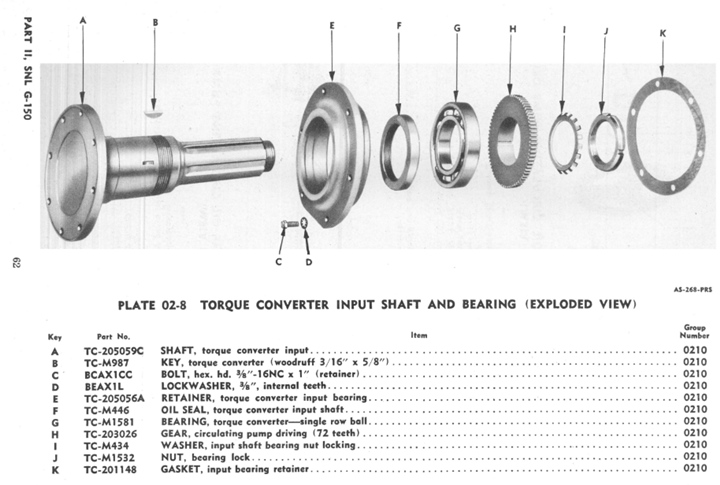

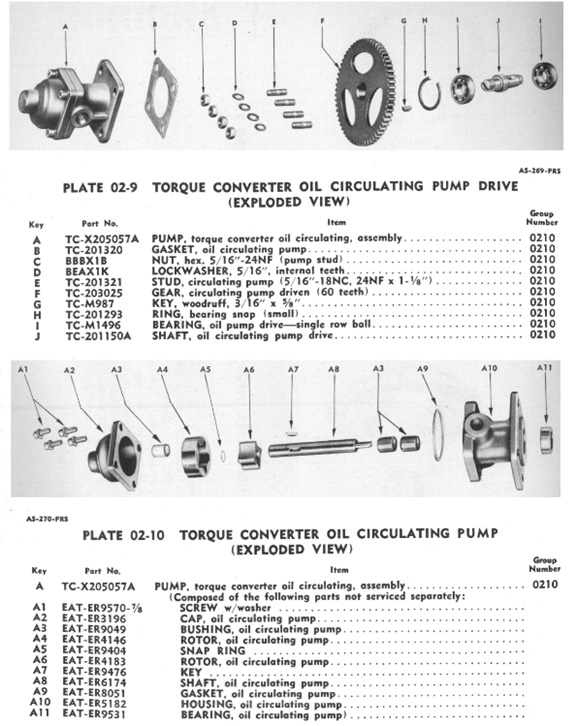

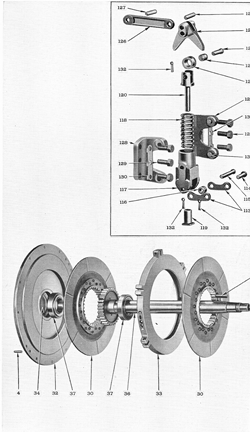

Exploded View and Parts Listing for the

Twin Disc Model X8708A Transmission:

Muncie Gear Works-Built Model X8708A

Transmission: As noted on page 207 of the Engine Description

above,

authorized licensees also built the

transmission. Apparently, the Twin Disc Clutch Company was not

able to keep up with production during World War Two, and other

companies became involved. One of the authorized licensees was the

Muncie Gear Works in Muncie, IN.

This Gray Marine Motor Company engine with a

transmission is part of the collection at the Indiana Military Museum in

Vincennes, IN. Author's Photo.

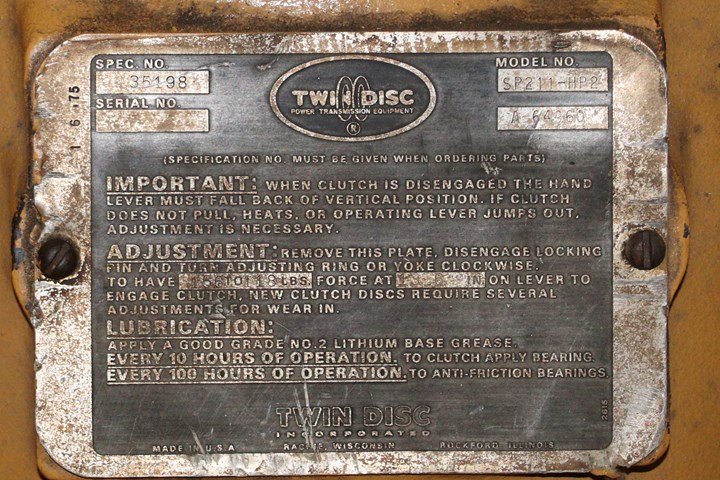

Of the several landing boat transmissions I

have found, this is the only one that has a legible data plate on it.

In this particular case, it was built by the Muncie Gear Works and not

Twin Disc.

Other Twin Disc World War Two Products and

Applications:

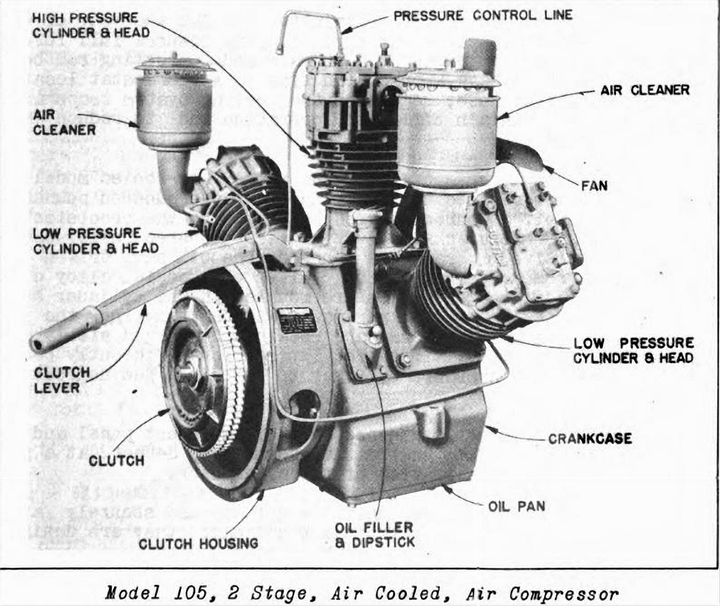

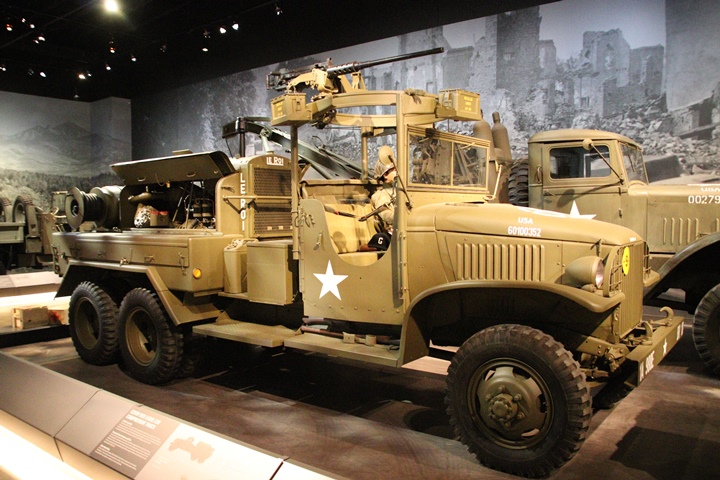

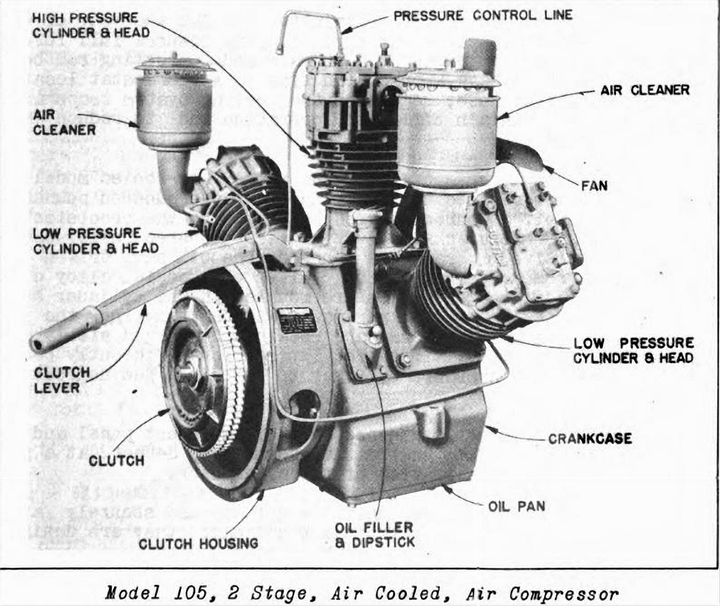

Le Roi Company Compressor Trucks:

Twin Disc supplied over 10,000

clutches for Le Roi G-105 air compressors mounted on GMC CCKW 2-1/2 -ton

6x6 and GMC AFK-352 1-1/2-ton 4x4 trucks during World War Two.

Table 3 shows that the Le Roi Company built at least 9,606 compressors

for mounting on the GMC CCKW truck. Le Roi also supplied 819

compressors for the GMC AFK-352. There were also several U.S. Navy

contracts for the Le Roi G-105 compressor with the Twin Disc clutch.

The Twin Disk part number was SL-2-11-1/2.

Table 3 - Le Roi Company's Army Corps of Engineers Engine

and Compressor Serial Numbers with Twin Disc Clutches

The contract numbers and the associated engine and

compressor serial numbers were obtained from TM 5-5060, Le

Roi Air Compressor 105GA Technical Manual dated November 30,

1942. However, interior pages show a Le Roi copyright

of 1944. Note that the engine serial numbers are even

numbers and the compressor serial numbers are the

corresponding odd numbers.

Not all of the contracts for

air compressors are comprehended in this table. There

are two Army Corps of Engineering contracts that were not

listed in TM 5-5060, Le Roi Motorized Air Compressor, Model

105GA : Technical Manual : Includes Independent Pneumatic

"Thor" Air Tools, 1942.

|

|

Contract Number |

Engine Serial Numbers |

Compressor Serial Numbers

|

Quantity |

Contract Amount |

Unit Cost |

|

978-ENG-3969 |

157000-158998, inclusive |

157001-158999, inclusive |

1,000 |

$2,543,000 |

$2,450 |

|

160200-160274, inclusive |

160201-160275, inclusive |

38 |

|

978-ENG-5371 |

171500-172508, inclusive |

171501-172509, inclusive |

505 |

$1,324,000 |

$2,622 |

|

1122-ENG-969 |

172510-177250, inclusive |

172511-177251, inclusive |

2,370 |

$7,553,000 |

$3,187 |

|

1122-ENG-972 |

177262-177488, inclusive |

177263-177489, inclusive |

114 |

$422,000 |

$3,702 |

|

1088-ENG-2067 |

177490-178888, inclusive |

177491-178889, inclusive |

700 |

$2,063,000 |

$2,947 |

|

1088-ENG-2332 |

183900-184010, inclusive |

183901-184011, inclusive |

56 |

$139,000 |

$2,482 |

|

1088-ENG-2751 |

189000-190212, inclusive |

189001-190213, inclusive |

607 |

$2,131,000 |

$3,510 |

|

1088-ENG-2929 |

190214-192030, inclusive |

190215-192031, inclusive |

909 |

$3,605,000 |

$3,606 |

|

32-ENG-28 |

194000-195556, inclusive |

194001-195557, inclusive |

779 |

$3,002,000 |

$3,854 |

|

47013-ENG-460 |

201004-204620, inclusive |

201005-204621, inclusive |

1,809 |

$6,934,000 |

$3,803 |

|

11114-ENG-134 |

200560-202002, inclusive |

200561-202003, inclusive |

722 |

? |

? |

| |

|

Total |

9,609 |

|

|

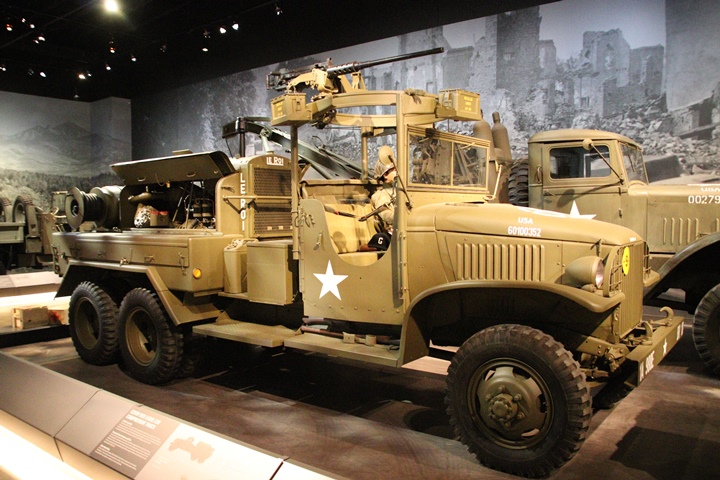

This Le Roi compressor truck is on display

at the National Museum of Military Vehicles in Dubois, WY.

Author's photo added 11-21-2024.

Author's photo added 11-21-2024.

This image shows the Twin Disc clutch handle

above the Delco-Remy DC generator. Author's photo added 11-21-2024.

Author's photo added 11-21-2024.

Michigan Power Shovel Company TM-16 Crane:

Twin Disc Company Model X7876 clutch is for the crane. An

estimated 756 TM-16s were built by both the Michigan Power Shovel Company

and International Detrola during World War Two.

This U.S. Navy

Michigan Power Shovel truck crane is being used by navy stevedores. Palm

trees in the background suggest this is in the South Pacific. Image

courtesy of Andre Margage via Jeff Lakaszcyck.

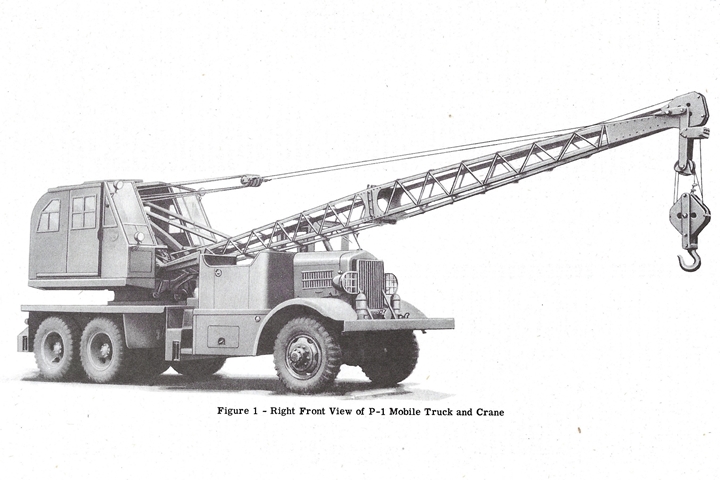

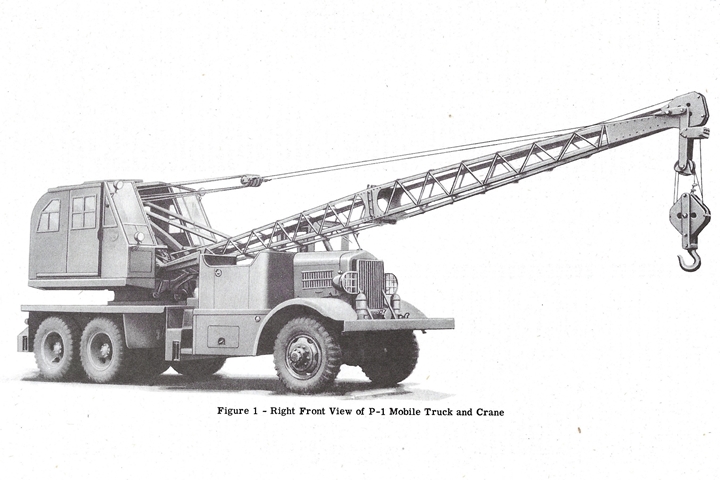

An estimated 455 Biederman Motors

Corporation P-1 crane trucks with Twin Disc Company Model X7876 clutches

were built during World War Two.

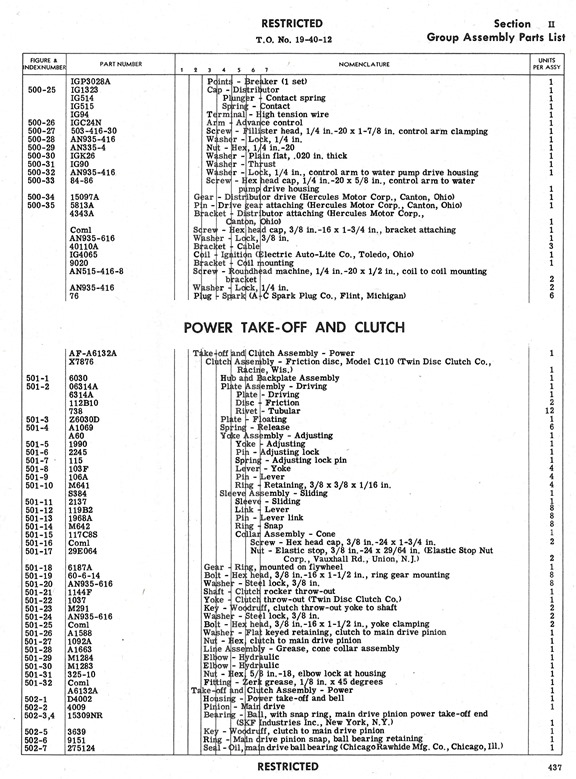

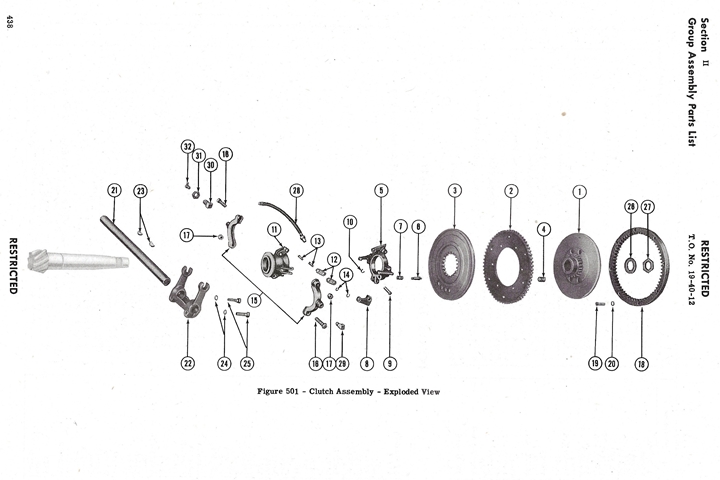

This image and the one below show the parts

listing and exploded view of the Model X7876 clutch used in the crane.

Allis-Chalmers M4 and M6 High Speed Tractor

Torque Converters: The devices were produced by the company's

Rockford, IL factory.

M4 High Speed Tractor: Allis-Chalmers

built a total of 5,811 M4 high speed tractors in three different versions.

This totally restored and operational M4 is

owned by the Museum of American Armor in New Bethpage, NY.

Author's photo.

WW2 Armor Allis-Chambers M4 High Speed

Tractor Restoration: The next set of photos starts with photos

I took of the WW2 Armor M4 High Speed Tractor while undergoing

restoration in March 2019 at the organization's facility in Osteen, FL.

Next is a photo of the restored M4 at the 2019 Conneaut D-Day event in

August 2019 in Conneaut, OH.

Author's photo.

A Ford V-8 has replaced the original

Waukesha inline six-cylinder engine. Author's photo.

With the body of the tractor off, one can

see the layout of the chassis and the drive train. The fuel tank

is at the top of the photo. Author's photo.

Author's photo.

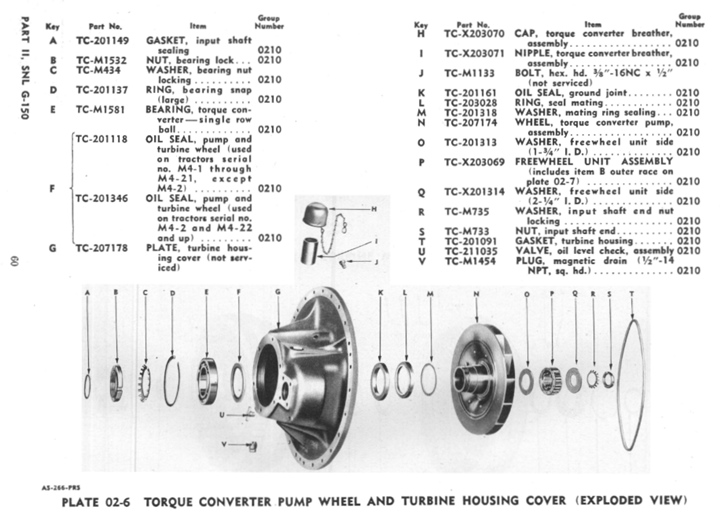

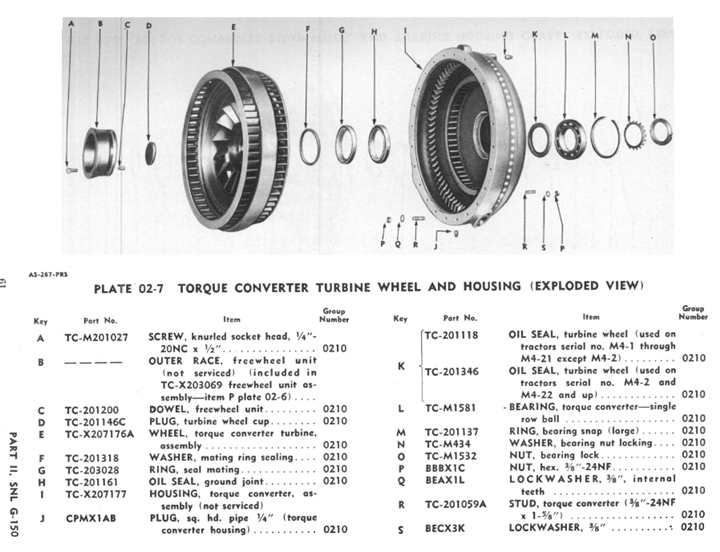

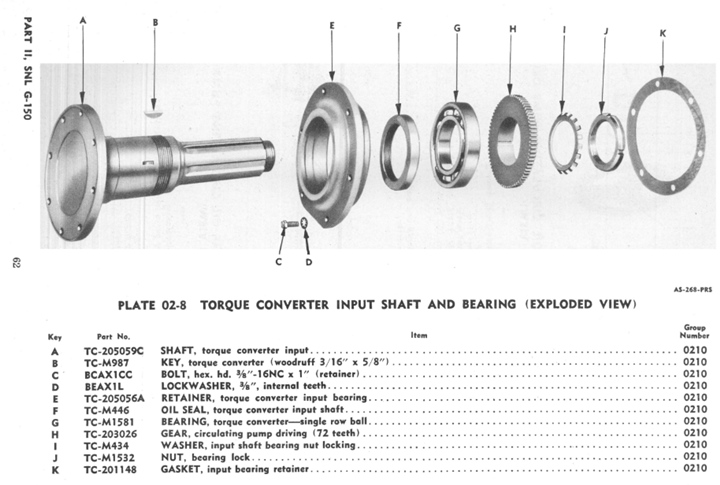

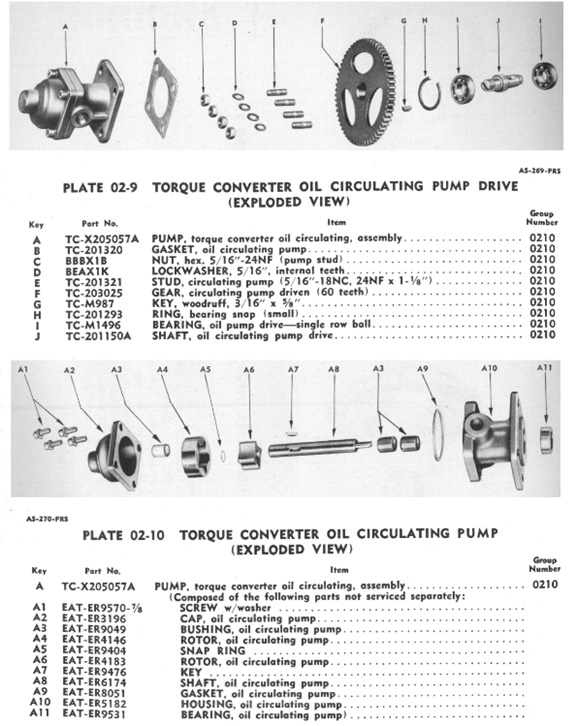

This and the following three images are from

the M4's parts manual and show the exploded views and part numbers for

the torque converter. TC is the designation for the Twin Disc

parts.

M6 High Speed Tractor: 1,235 of

these 38-ton tractors were built in 1944-45 at the Allis-Chalmers La

Porte, IN Works. There are only two known to still exist; one in The

Netherlands, and one at the Indiana Military Museum in Vincennes,

IN, 250 miles from where it was originally built. It is in need of

extensive restoration, as can be seen below. It is the one that is

shown below.

The Indiana-built M6 is located outside with

a lot of other equipment the museum has purchased. Hopefully, it

is waiting for restoration when time and funding becomes available.

Author's photo.

The M6 was powered by two Waukesha 145GZ

six-cylinder gasoline engines each producing 190 h.p. The M6 would

therefore have required two Twin Disc-built torque converters.

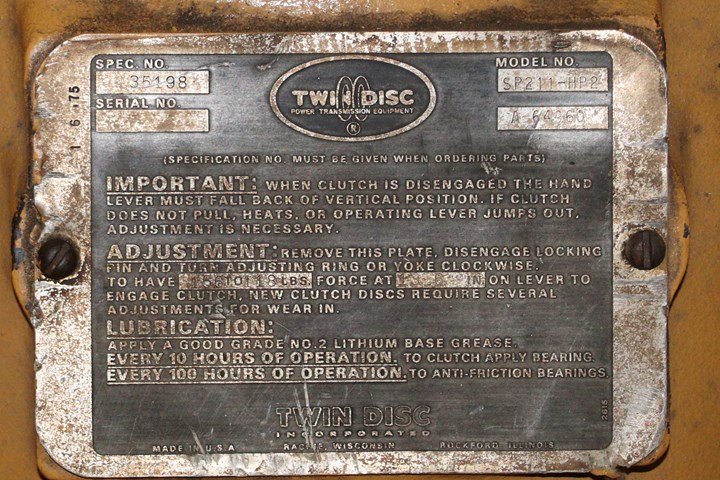

Cummins

HB150 Stationary Diesel Engine:

This 1945 Cummins HB150 has a Twin Disc Model SP211-HPP clutch.

Author's Photo.

Author's Photo.

Author's Photo.

Author's Photo.

The Twin Disc World War Two Factory:

The factory in Racine was located on what is now 32nd Division

Memorial Highway, previously Racine Street, between 13th and 14th

Streets.

Image courtesy of Google Maps.

The company's address was 1328 Racine Street in Racine, WI. Twin

Disc moved out of this facility in 2022. The Heritage Center that

was located in this building may no longer exist. The transmission

that is at the National World War II Museum in New Orleans, LA appears

to have previously been on display at the Heritage Center. Image

courtesy of Google Maps.

This is the northeast corner of the building at the intersection of

Racine Street and 13th Street. Image courtesy of Google Maps.

This is the west side of the plant. The

original plant was yellow brick. The red brick sections are later additions

to the structure. This view is from 13th Street. Image

courtesy of Google Maps.

This view is from 14th Street.

Image courtesy of Google Maps.

This image shows the plant at Racine and 14th

Streets. Image courtesy of Google Maps.

|