|

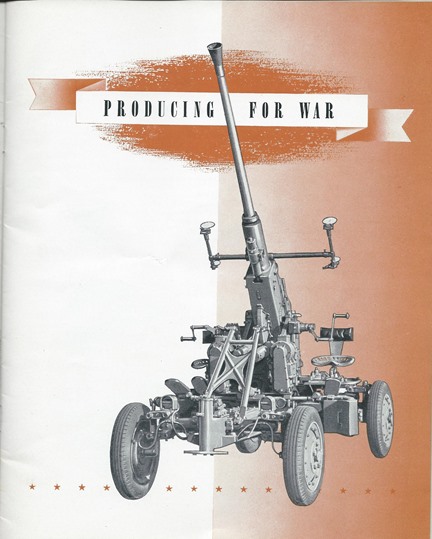

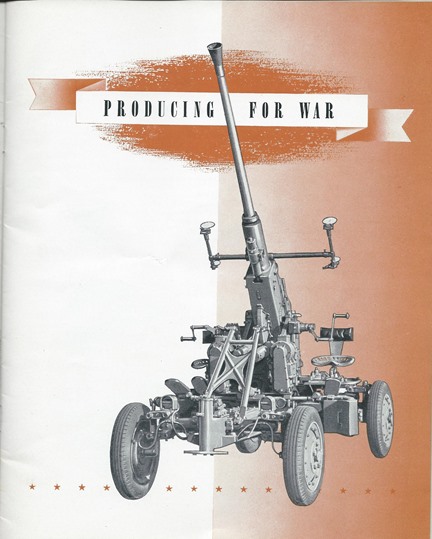

"Producing for War

Preparing for Peace"

Firestone Tire and Rubber Company in World War Two

Akron, OH

1900-Present (Since 1988 as

part of Bridgestone)

Headquarters are now in Nashville, TN

This page updated 11-4-2019.

The Firestone Rubber and Latex plant in Fall

River, MA won the Army-Navy "E" Award three times.

Firestone Textiles, a subsidiary of the Firestone Tire and Rubber

Company in Bennettsville, SC won the Army-Navy "E" Award once.

The Firestone Rubber and Rubber Company, Nebraska Defense Corporation,

Nebraska Defense Plant, Fremont, won the Army-Navy "E" Award once.

Firestone Textiles, a subsidiary of the Firestone Tire and Rubber

Company in Gastonia, NC won the Army-Navy "E" Award three times.

The Firestone Park plants in Akron, OH won the Army-Navy "E" Award three

times.

The original award was presented to the Firestone workers in a ceremony

in front of the plant on March 27, 1944

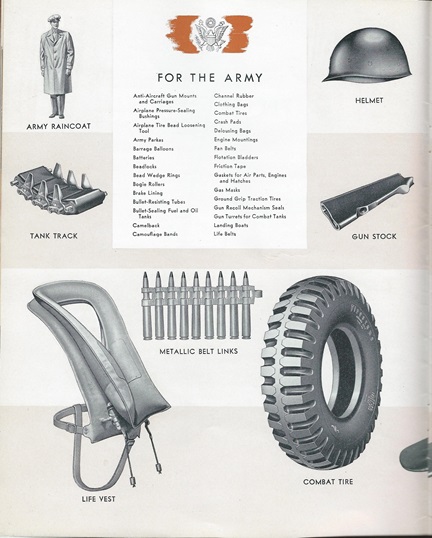

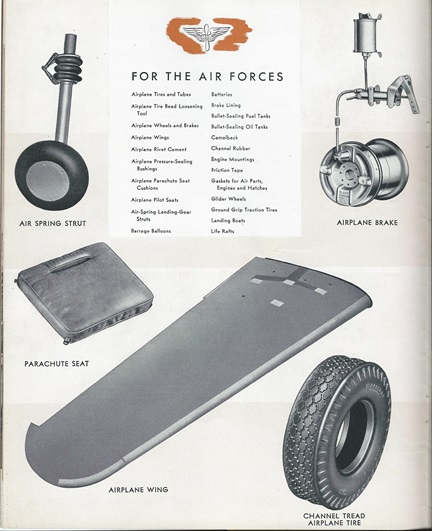

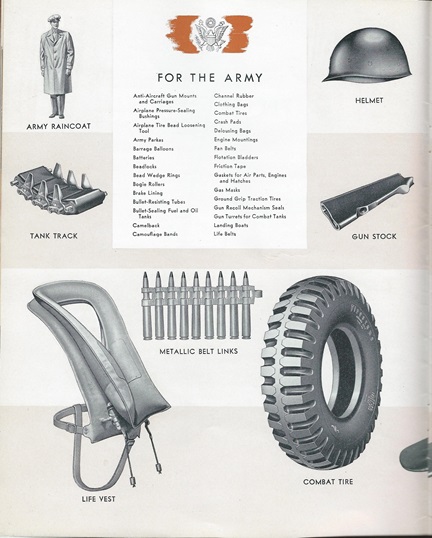

Firestone Tire and Rubber's

World War Two Products: As can be seen below, Firestone

was prolific and varied in the products made for the US Armed Forces

during WWII.

Firestone Tire and Rubber's

World War Two Product Statistics: 7,762 barrage balloons,

600,000 bullet proof fuel and oil cells, 24,500 drop tanks, 2,250 C-46

wing sets (3,198 C-46s built), 1,277,000 aircraft oxygen cylinders,

82,283 tank and half track tracks, 2,320,455 bogie wheels,

2,224,000,000 .50 caliber machine gun links, 7,393,000 gas masks,

1,882,000 M1926 life belts, 429,000 Mae West life vests, 126,500 rafts, 33,500

other types of flotation gear, 20,231 40mm Bofors gun carriages for the

US Army, 10,434 40mm Bofors gun mounts for the US Navy, 765 CG-4A

gliders, 1,550 M5 and M5A1 tank turrets, 3,100 M5 and M5A1 tank tracks,

350 Duplex Drive kits for M4A1 Sherman tanks

Firestone Tire and Rubber's

World War Two Product Statistics:

1944 - 8,877,000 combat tires

1945 - 10,716,000 combat tires

|

Firestone World

War Two Half-Track Tracks

Accepted by Detroit Ordnance, US Army

The information below comes from "Summary Report of

Acceptances, Tank-Automotive Material, 1940-1945."

Published by Army Services Forces, Office, Chief of

Ordnance-Detroit, Production Division, Requirements and

Progress Branch

January 21, 1946. |

|

Type |

Same as |

1940 |

1941 |

1942 |

1943 |

1944 |

1945 |

Total |

| Tracks, 12-inch,

58 pitch band |

B.F. Goodrich,

Goodyear Tire and Rubber |

|

62.5 |

2759.5 |

10,391 |

|

|

13,213 |

Note that Firestone produced a total of

82,823 tank and half-track tracks as shown above. 13,213 were for

half-racks built by Autocar, White, Diamond T, and International

Harvester. Also note that for half-tracks that the numbers in the

table above are for a complete set of two tracks for the vehicle, as in

1941 and 1942 there were half units accepted. It is unknown

whether the 82,823 figure given by Firestone is sets of two, or

individual tracks.

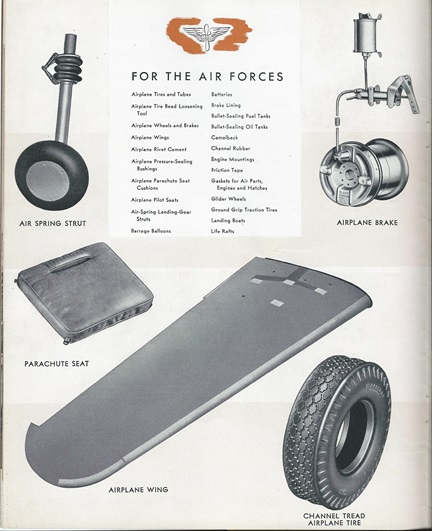

More Firestone Tire and Rubber's

World War Two Products: Artillery shells, aluminum kegs

for food transport, plastic helmet

liners, aircraft rocket launcher tubes, barrage balloons, aircraft drop

tanks, Bakelite stocks for Browning Automatic Rifles, tires, rubber

tires for tank road wheels, Mae West life vests, self-sealing aircraft

fuel and oil tanks, bomb casings, M1926 flotation belts, gas masks, .50

machine gun links, aircraft oxygen tanks, rocket motor boxes, M5 tank

turrets, rockets, C-46 wing panels, aircraft, tires, wheels and brakes, pilot

seats, tank tracks, submarine parts, pontoons, life rafts, crash pads

for tanks, aircraft

pressure-sealing bushings, aircraft tire bead loosening tool, army

parkas, batteries, tire beadlocks, tire bead wedge rings, brake linings,

bullet resistant tubes, camouflage bands, channel rubber, clothing bags,

delousing bags, engine mounts, fan belts, flotation bladders, friction

tape, gaskets, gun recoil mechanism seals, landing boats, masking tape,

molded rubber parts, motorcycle tires and tubes, oxygen nurse bags,

oxygen masks, plastic lenses for gas and oxygen masks, plastic

screening, pontoons for bridges, raincoats, rescue boats, rubber caster

wheels, rubber band tracks for half-tracks, rubber hose, rubber tape,

spark plugs, synthetic foamed latex, tire and tube repair material,

torsion bearings, track link bushings, 60mm mortar base, aircraft rivet

cement, aircraft parachute seat cushions, air-spring landing gear

struts, glider wheels, mooring anchors and buoys, parachute rafts,

pneumatic lifting bags, propeller anti-icers, repair kits for floatation

gear, eye guards for gun sights, marine transmission parts, mine seals,

plane tending barges, seadome contact lighting buoys

Manhattan Project: In 1943-44

Firestone worked with Monsanto in Dayton, OH which was managing the

manufacture of polonium for use as nuclear triggers, or initiators in

nuclear weapons. Polonium is a source of alpha particles.

The alpha particles then bombard beryllium in the initiator which is a

large source of neutrons. These neutrons then bombard uranium in

the Little Boy gun type weapon, or the plutonium in the implosion device

to start the nuclear explosion.

Monsanto explored the Dillon Method that was

being used on Firestone Sparkplugs. It took several chemical

process to produce small amounts of polonium. This process was

only partially successful, and other methods of polonium extraction were

found to be more efficient. The Dillon Method was discarded by the

Dayton Manhattan Project group. But Firestone was a participant in

the Manhattan Project during WWII.

Firestone had nine plants in Akron during

WWII. Products coming out those plants were tires, aircraft wings,

industrial products, steel products, 40mm AA gun mounts and carriages,

barrage balloons, Butaprene N, molds and machinery. and rubber reclaim.

Fuel cells were made at fourteen plants located in

Akron, OH, Los Angeles, CA, Dallas, TX, New Castle, IN, Memphis, TN,

Pasadena, CA, Compton Junior College, CA, Santa Ana, CA, Ferndale, WA,

Coshocton, OH, Zanesville, OH, Patterson, NJ, Bristol, VA and Hamilton,

ONT.

Cotton tire cord for military tires was made

at the Gastonia, NC. In 1942 the plant also manufactured 500,000

pounds of duck material for military tents.

The Atlanta, GA plant also built aircraft

wings, while Memphis also made raincoats, and Indianapolis assembled

tank tracks. The rubber for the tank tracks were produced at the

Noblesville, IN plant.

A complete listing of Firestone's US and international plants during

WWII is included in "Producing for War Preparing for Peace."

See the link at the top or bottom of this page.

40mm Bofors carriages for both the US Army

and Navy:

Firestone's signature war product was the 40mm Bofors

anti-aircraft gun carriage. The actual gun mechanisms were

produced were provided by Chrysler and Pontiac and the the gun tubes

were built by Chrysler, Pontiac, and Otis-Fensom. Firestone mounted them on the

carriages. Firestone was one of three companies that built the

carriages for the US Army during WWII. It built, as of March 31,

1944, 84.5% of the total as shown below. The information provided

below comes from " The History of the Americanization of the Bofors 40mm

Automatic Antiaircraft Gun" written by the Historical Section of the

Ordnance Department in May 1944.

|

Production

of 40mm Gun Carriages for the US Army as of March 1944 (M1,

M2, M2A1) |

|

Company |

Date |

Quantity |

Percentage |

|

Firestone |

3-31-1944 |

20,021 |

84.5% |

|

Koppers |

4-1944 |

2,270 |

9.6% |

|

J.I. Case |

12-1943 |

1,414 |

5.9% |

|

Total |

|

23,705 |

|

What is not known is whether

production continued after March 1944 or ceased at that point.

The record is not clear. Firestone's records indicate the

company built 20,231 40mm carriages during the war which would imply

production ceased for the US Army in early 1944. All of

Firestone's production of carriages did not go entirely to the Army,

as the US Navy took 4,784 mounts minus the wheeled carriage for use

on small ships such as PT boats, submarines, LSTs, and other small

ships. The US Army, which also had its own small ships during

WWII, used 159 of the ship mounts. It is unknown whether the

4,784 and 159 ship mounts are in included in the total totals above.

Records indicate that the US Navy procured up through 3-31-1944

4,784 Firestone built 40mm mounts for many of its smaller ships

including PT boats. PT-305 was built by Higgins Industries in

New Orleans, LA, and is the only WWII combat veteran PT operating in

the world. Author's photo added 4-25-2018.

PT-305 has a 40mm Bofors gun on the

stern with a Firestone M2 mount. Historical literature implies

that Firestone provided all of the 40mm Bofors single mounts for the

US Navy in WWII. The actual gun mechanism and gun tubes were

supplied by either York Safe and Lock Company, or Chrysler

Corporation. This one is a York Safe and Lock gun.

Author's photo added 4-25-2018.

Author's photo added 4-25-2018.

This carriage is serial number 16430

which was built in 1943. Author's photo added 4-25-2018.

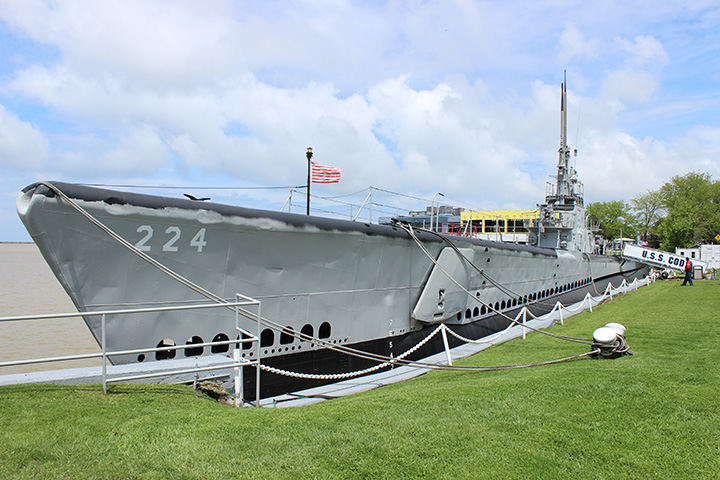

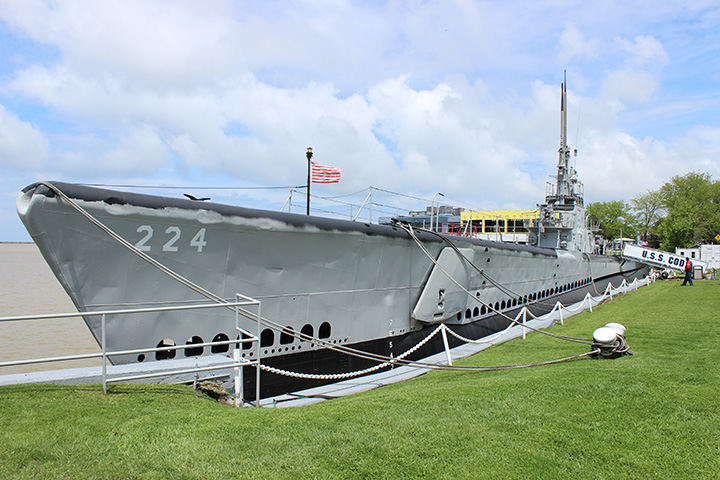

The USS Cod is on display at the Cleveland,

OH waterfront during the summer months. It has a Firestone 40mm

Bofors naval mount. Author's photo.

Author's photo.

The Firestone built 40mm mount on the USS

Cod is 45 miles from where it was built in Akron. Author's photo.

A Firestone built 40mm Bofors mount and

carriage can be

seen at the Indiana Military Museum in Vincennes, IN. Author's

photo.

This is an M3 mount and is serial

number 9899. Author's photo.

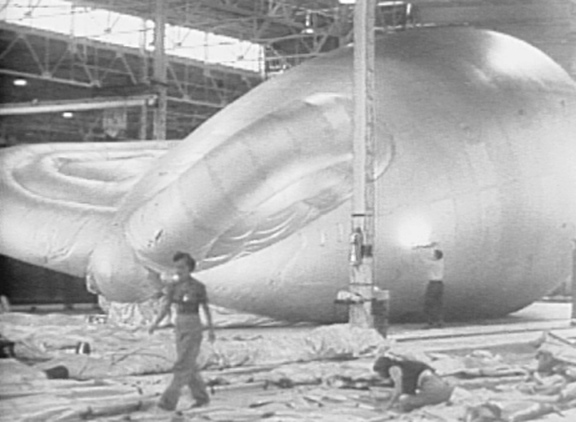

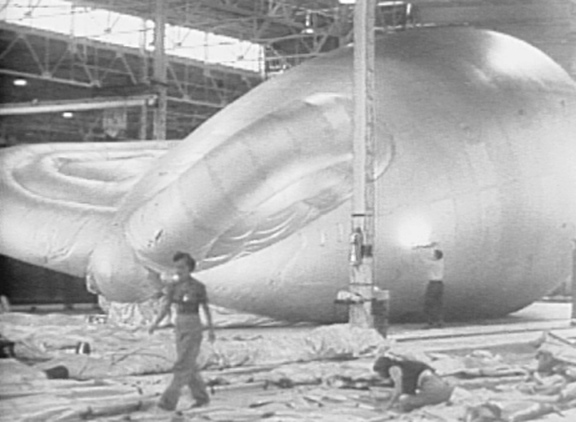

Barrage balloons were also built by

Firestone in Akron.

This is a WWI observation balloon on display

at the National Museum of the USAF. To date the author has not

been able locate a WWII barrage balloon. This WWI balloon is

similar to the WWII balloons. Author's photo added 12-8-2017.

Firestone, Aircraft Fuel Cells, and the

B-29 "Enola Gay:"

Firestone Tire and Rubber built a plethora of

products in support of the effort during WWII. One of the many

products were fuel cells for military aircraft. Nine Firestone

plants produced aircraft fuel cells during the war. Coshocton, OH

built fuel cells for the B-24, B-29 and P-38.

The B-29 "Enola Gay" was the first aircraft

to drop an atomic bomb, and hastened the end of WWII. Author's

photo added 2-20-2017.

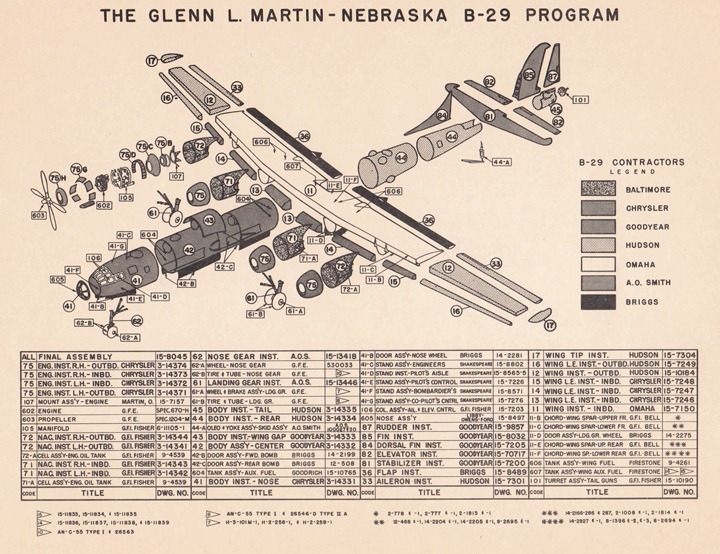

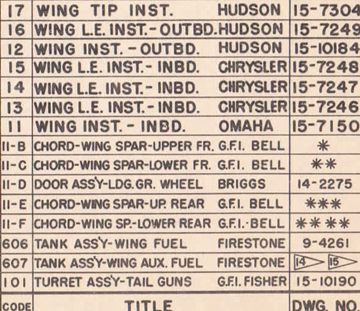

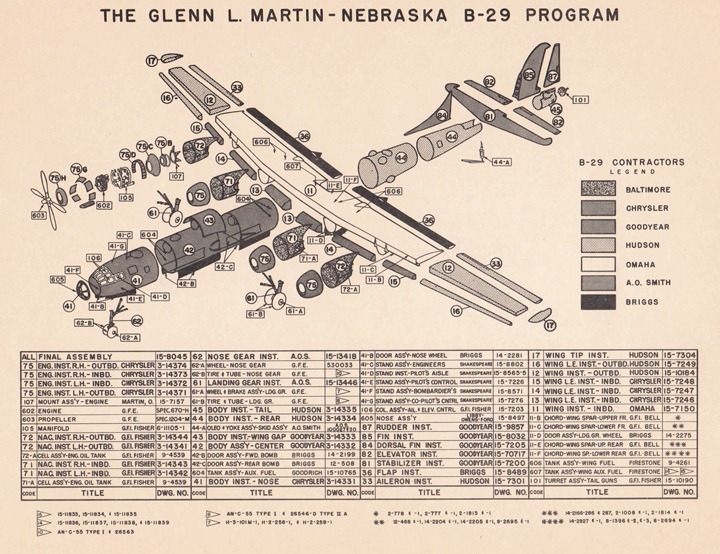

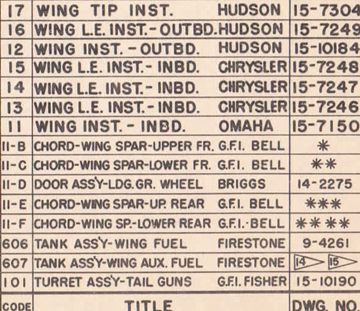

The Glenn Martin Aircraft Company at its

Omaha, NE plant built the B-29 "Enola Gay" along with the rest of the

Silverplate nuclear bombers. Part number 606 is a Firestone built

1,387.5 gallon main wing fuel tank. Part number 607 is a

Firestone Coshocton, OH built 1,436.5 gallon auxiliary wing fuel tank.

There were two of each in the B-29. Photo added 2-20-2017.

Photo added 2-20-2017.

Inside the wings on the "Enola Gay" are four

Firestone built fuel cells. They are located between the outboard

engines and the fuselage. Author's photo added 2-20-2017.

The first Firestone fuel cell was for the

North American P-51A. Author's photo added 3-16-2017.

Firestone Tire and Rubber produced over

600,000 fuel cells for the P-51, B-25, P-39, P-38, P-47, SB2C, B-24,

B-17, and B-29. The Firestone plant making the fuel cells included

Akron, OH, Los Angeles, CA, Dallas, TX, New Castle, IN, Memphis, TN,

Pasadena, CA, Compton Junior College, CA, Santa Ana, CA, Ferndale, WA,

Coshocton, OH, Zanesville, OH, Patterson, NJ, Bristol, VA and Hamilton,

ONT.

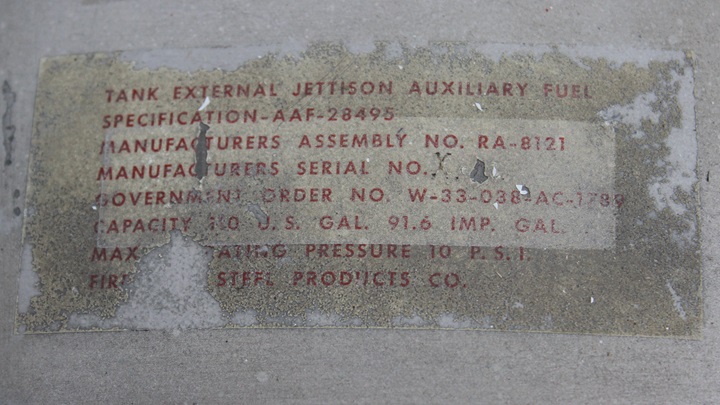

The Coshocton, OH Firestone plant also built

450 gallon auxiliary fuel tanks for the B-24 Liberator bomber. The

plant employed 1,200 persons during WWII. Author's photo

added 2-20-2017.

Firestone Coshocton also built the auxiliary

fuel tanks for the P-38. Author's photo added 2-20-2017.

This is a fuel cell in a B-17 wing under

restoration at the Museum of the United States Air Force. Author's

photo added 3-16-2017.

Firestone also built fuel cells for the

Convair B-36. Author's photo added 3-16-2017.

Firestone in its Atlanta plant built wings

for the PB4Y Navy patrol bomber. Author's photo added 3-16-2017.

Author's photo added 3-16-2017.

Of interest in the photo are the three

tubes. These were the initial rocket launchers used by the US Army

Air Forces during WWII. This one was built by Firestone, and is on

display at the MAPS air museum at the Akron-Canton Airport.

Author's photo.

In period photos of WWII, the three tubes

are normally seen mounted under the wings of P-47 Thunderbolts.

Later the tubes were replaced by zero launch rails, as the technology

progressed. Author's photo.

Author's photo.

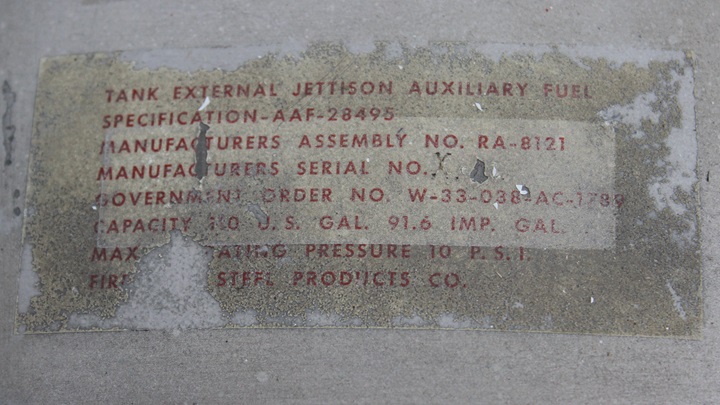

Firestone built drop tanks for US fighters.

Author's photo from the MAPS Museum.

These are 110 gallon tanks.

Author's photo.

Firestone Steel Products was located in

Akron, OH; and in peacetime, built tire rims. Author's photo.

The Browning Automatic Rifle (BAR) brought

portable automatic fire down to the squad level during WWII.

Originally the stocks were made of black walnut like the handgrip.

Shortages of black walnut lead Firestone to make them out of a combination of Bakelite, Resinox, and shredded fabric. They were

then sandblasted to reduce glare. Author's photo.

The stocks were made at the Firestone Rubber and Latex plant in Fall River, MA. The plant

won the Army-Navy "E" award three times during WWII. Author's

photo.

On March 21, 1942 the US Army approved the

Firestone produced plastic stock for use in the BAR. This

particular weapon is on display at Fort Macon State Park in Atlantic

Beach, NC. Author's photo.

Author's photo.

This M24 Chaffee is one of several tanks on

display at the First Division Museum in Wheaton, IL. Author's

photo.

Like many of the tanks of WWII, this one has

Firestone built bogie wheels. Author's photo.

Firestone Tire and Rubber plants in Akron,

OH and Wyandotte, MI produced 2,320,455 tank bogie wheels like this one

for various American tanks during WWII. Author's photo.

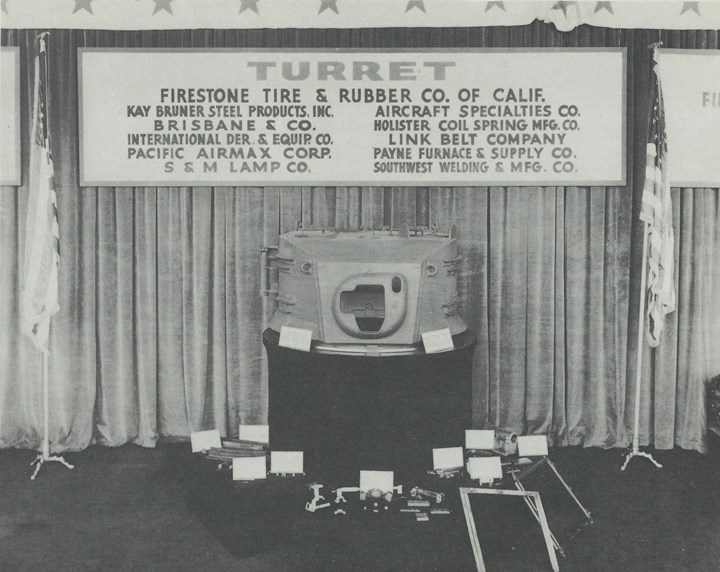

Firestone Tire and Rubber in Los Angeles, CA

also produced 1,550 turrets used M5 and M5A1 Stuart tank built by the

Southern California Division of General Motors in South Gate, CA.

It also provided the 3,100 tank tracks required. This Southern

California Division built M5 with a Firestone built turret is ironically

located at an automotive salvage yard in Akron, OH. M5 serial number

2295 came off the assembly line in September 1942. Author's photo added

2-15-2018.

This M5A1 on display at the Virginia

Military Museum in Newport News, VA is the tenth M5A1 built by the

Southern California Division. It is serial number 2632 and was

built in December 1942. It also has a Firestone built turret. Author's photo added

2-15-2018.

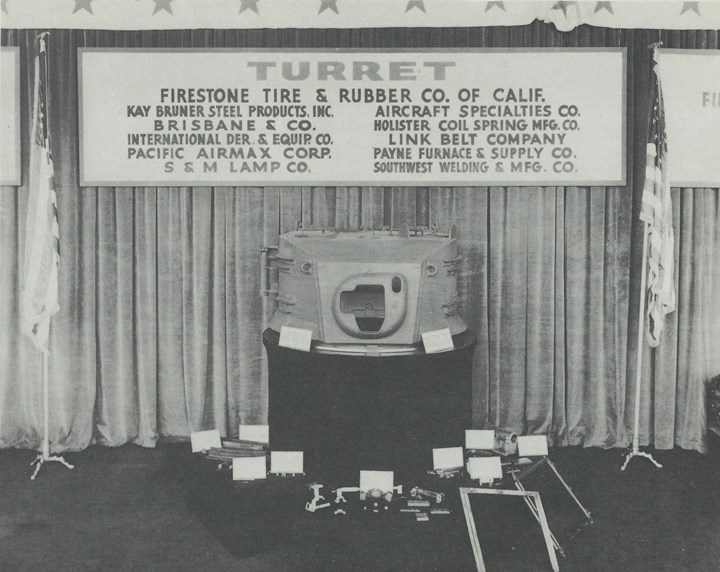

A Firestone produced turret on display at

the South Gate General Motors Tank Arsenal in 1942. Photo added

3-16-2017.

Firestone tank tracks. Photo added

3-16-2017.

Halftracks were one of the many recipients

of heavy duty military

truck tires produced by Firestone in Memphis, TN.

Firestone also bonded rubber pads to steel halftrack and tracks.

Author's photo.

Bomb casings were another product of

Firestone. Author's photo.

Bomb casings ready for shipment at

Firestone.

Firestone Tire and Rubber Company

produced many oxygen tanks for aircraft. These can be seen inside

the B-29 "Command Decision" at the National Museum of the US Air Force.

Author's photo.

2,250 Curtiss C-46 Commandos had Firestone

built wings. Author's photo.

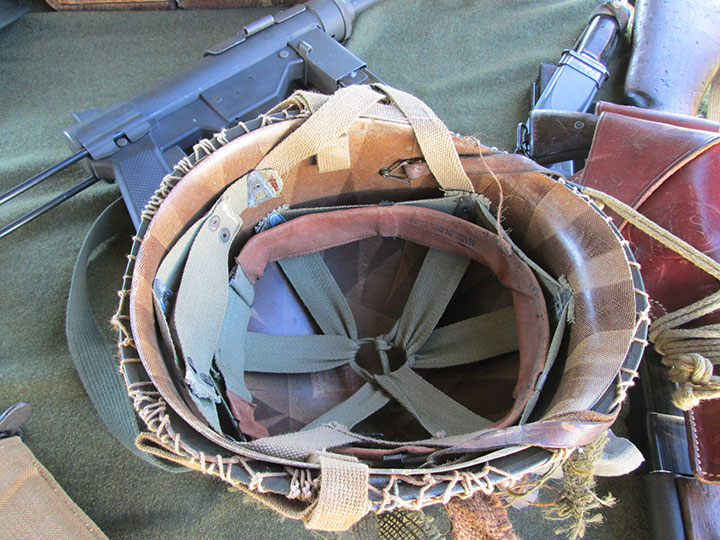

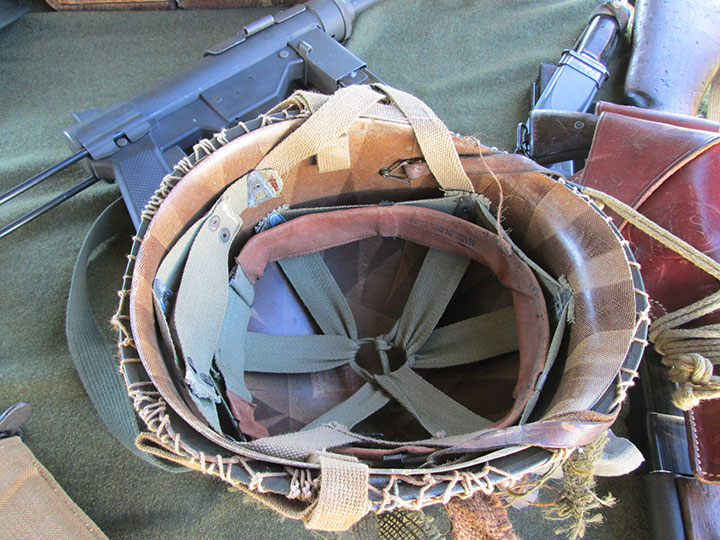

Plastic helmet liners were molded by

Firestone. Author's photo.

Helmet liners went into the M1 steel

helmet. The helmets, sometimes called "steel pots," and

their Firestone liners

were still used through the end of the Vietnam War.

Author's photo.

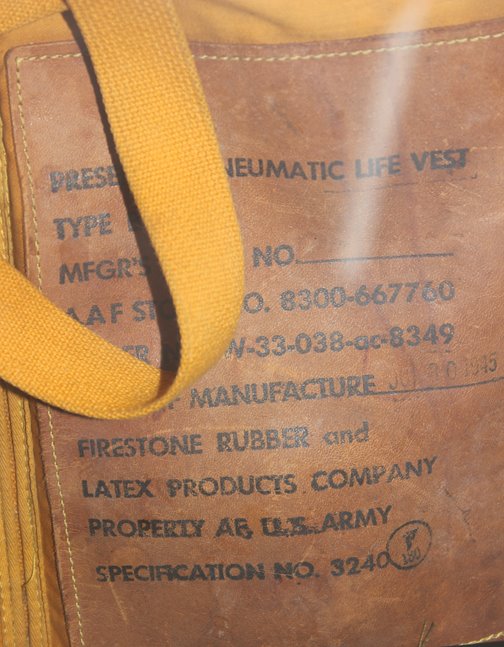

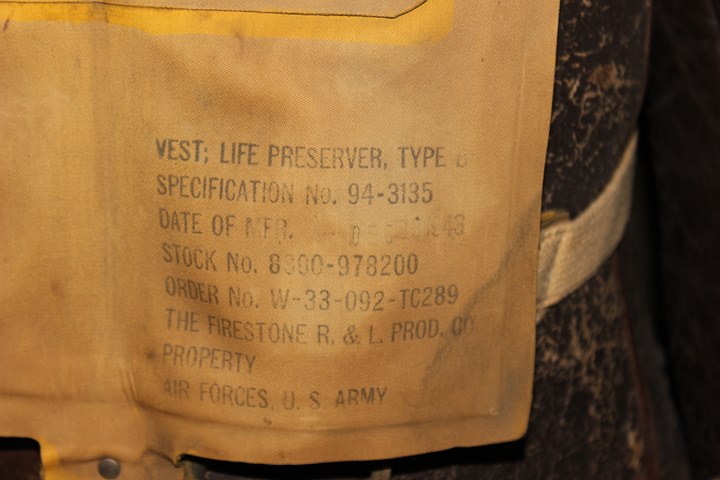

In a display case at the Champaign Aviation Museum in Urbana, OH is this

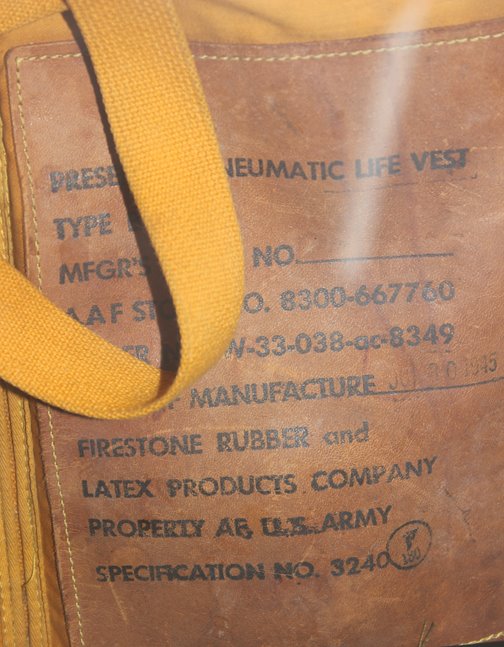

Mae West life preserver made by the Firestone Rubber and Latex Products

Company. Firestone made 429,000 of these life preservers. Author's photo added 4-19-2017.

According to US Army nomenclature, this is a

Preserver, Pneumatic Life Vest. In the vernacular it was known as

a Mae West. Date of manufacture was June 30, 1945.

Author's photo added 4-19-2017.

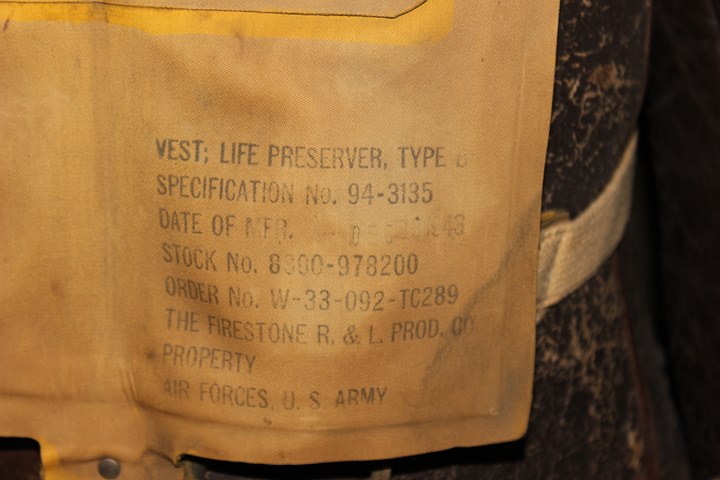

This Firestone Mae West is on display

at the Military Honor Museum in South Bend, IN. Author's photo

added 12-8-2017.

Firestone continued to make life preservers

after WWII. This one was built on December 18, 1948.

Author's photo added 12-8-2017.

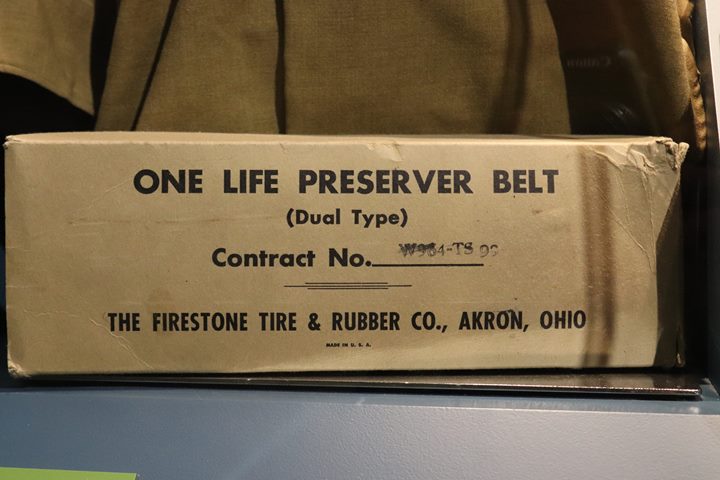

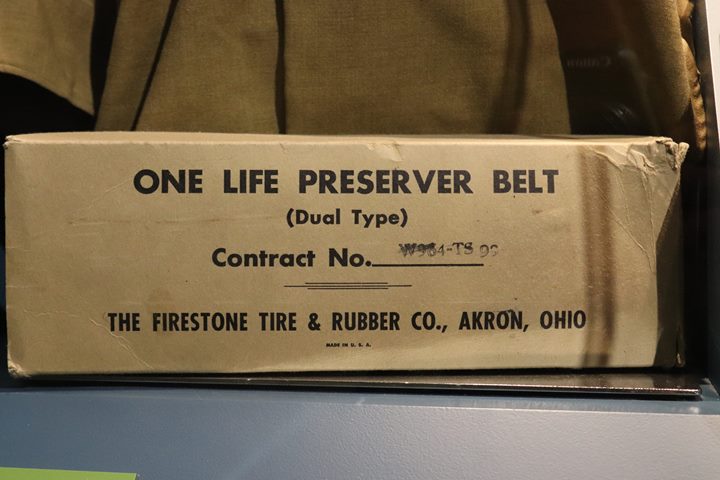

On display at the 4th Infantry Division and

Fort Carson History Museum in Colorado Springs, CO is one of

1,882,000 M1926 life belts that Firestone produced during WWII.

Author's photo added 10-4-2017.

The original box was even on display at the

museum. Author's photo added 10-4-2017.

Firestone made 2,224,000,000 .50 caliber machine gun links.

The .50 machine gun was used by all services during WWII. They

were used on bombers and fighters, tanks, trucks, ships, and as

stand-alone weapons. Author's photo.

Firestone built base plates for the 60mm mortar. Author's photo

added 11-4-2019.

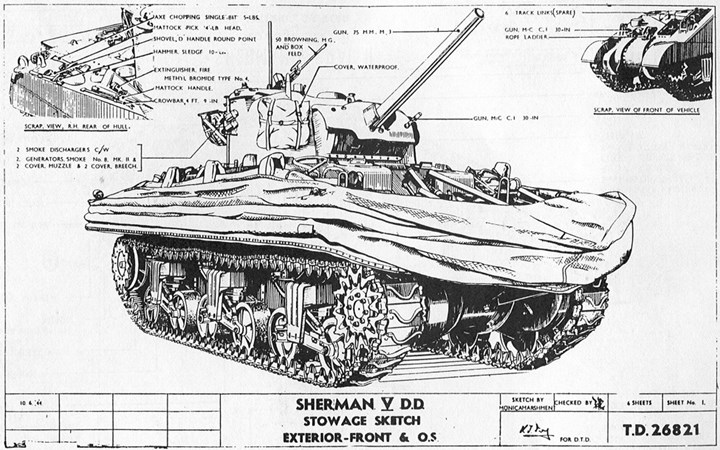

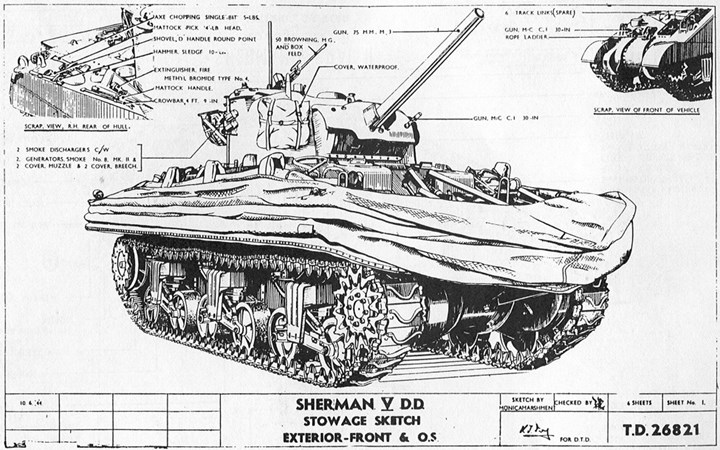

This engineering drawing shows how the

floation screen rested on the tank when not in use. This British

drawing shows the installation for a M4A4 Sherman tank. Drawing

courtesy of the Sherman Minutia website. Photo added 11-4-2019.

This is the only existing Duplex Drive

floatation screen still in existence, and is on a M4A2 Sherman tank

located at the Tank Museum in Bovington, UK. This is not a

Firestone built floatation screen as this one was built by the British

during World War Two for its Duplex Drive tanks. The 350 Firestone

floatation screens would have been very similar to this one.

American M4A1(75) tanks used the Firestone-built units at Normandy.

Photo courtesy of "Megashorts" via the Sherman Minutia website.

Photo added 11-4-2019.

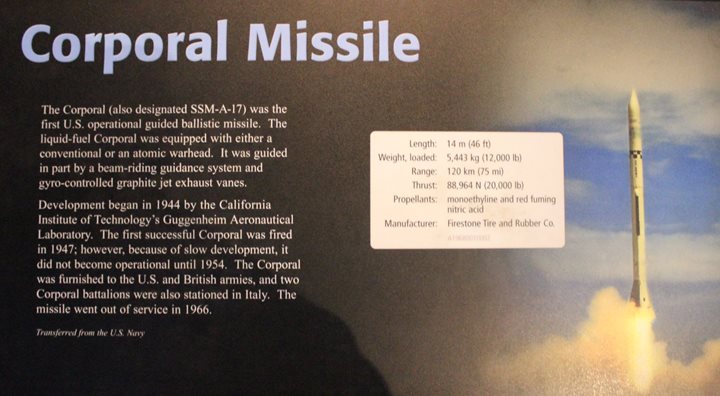

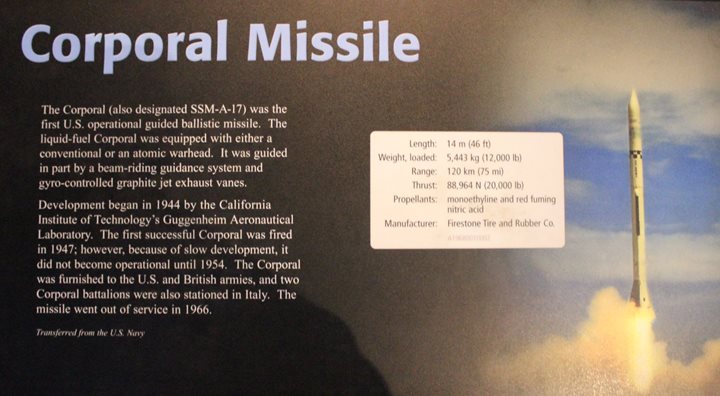

Post WWII Military Products

Firestone built 1,100 Corporal Missiles after World War Two. This

one is one display at the Udvar-Hazy Center of the National Air and

Space Museum in Chantilly, VA. Author's photo.

Author's photo.

This section added 2-7-2017.

"Producing for War, Preparing for Peace"

Below are the seven pages from

this 34 page booklet pertaining to the products Firestone made during

WWII. See the link at the bottom of this page to view the full 34

pages.

The

full 34 page version of "Producing for War Preparing for Peace"

|