|

S.F. Bowser

& Co. During World War Two

Fort Wayne, IN

1885-1990

This page updated 10-30-2024.

An impromptu visit to the Fort Wayne

Historical Society on the day after Thanksgiving 2022, took me in an

unexpected direction. On display was an early 20th Century Bowser

"Long Distance" pump. Author's photo.

The Bowser pump was located along with an

early Tokheim gas pump on the left in this photo and a Wayne

pump in the center. Earlier in 2022, I had researched both Tokheim

and Wayne Pump companies and released a page for each company on its

World War Two contributions. However, until I visited the Fort

Wayne Historical Society, I was unaware that there was a third company

in Fort Wayne producing gasoline pumps. Author's photo.

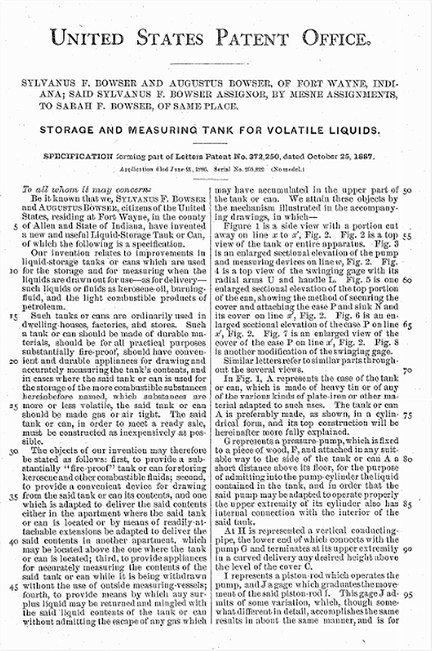

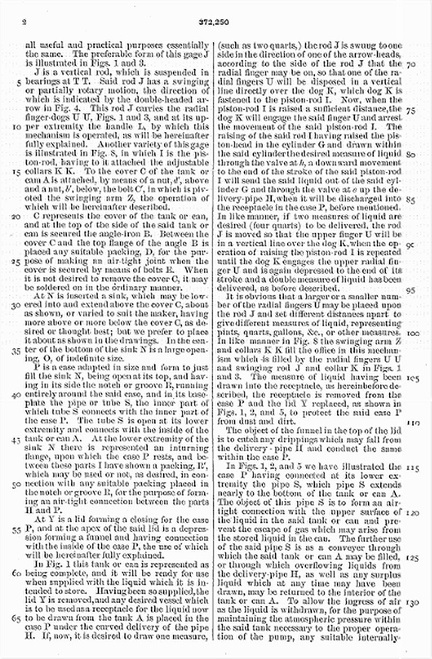

Once I returned home and was able to

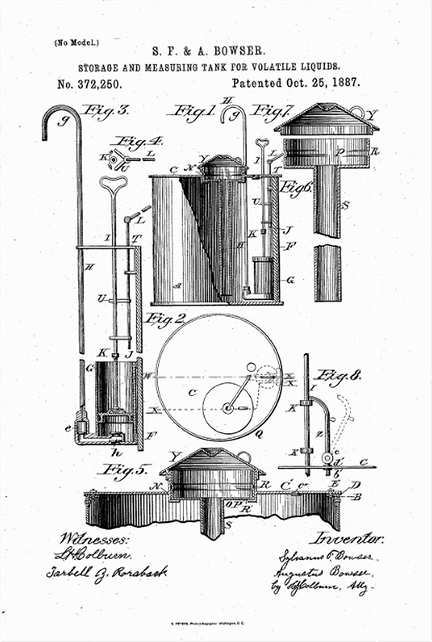

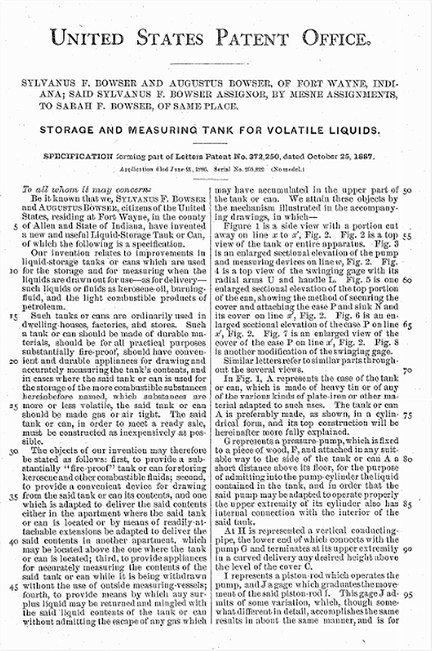

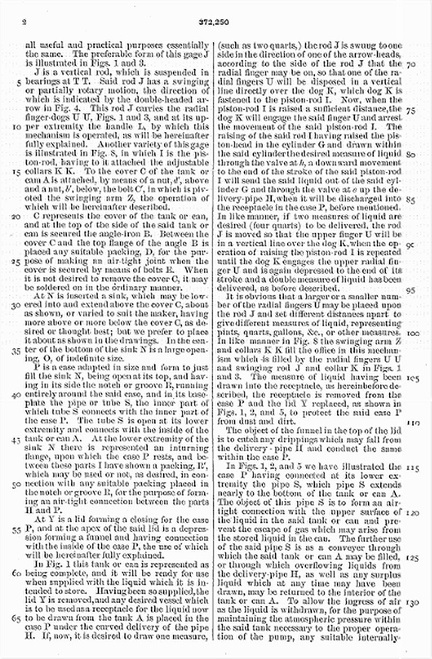

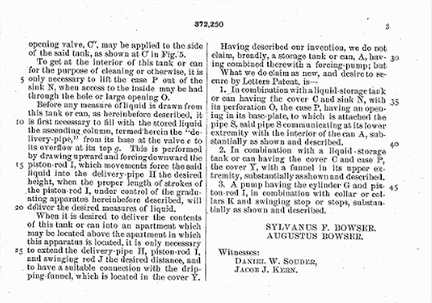

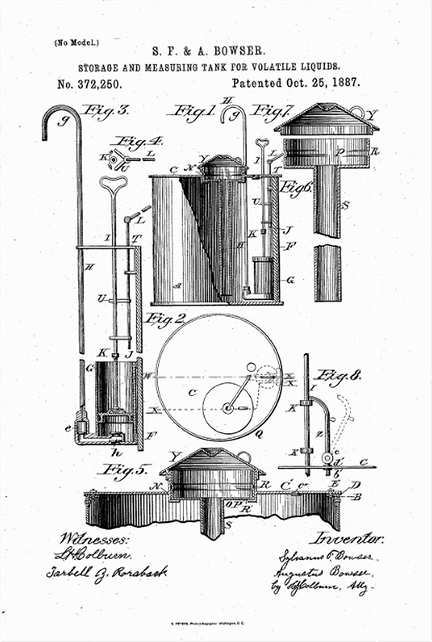

research Bowser, I learned that Sylvanus F. Bowser is credited with the

invention of the first pump that metered the amount of fluid dispensed.

Shown here is his patent 272,250 dated October 25, 1867, for a "Storage

and Measuring Tank for Volatile Liquids." It should be noted that

while Sylvanus is recognized as the inventor of the gasoline pump, a

relative, Augustus Bowser, also signed the patent application.

The volatile liquid that the Bowsers were

referring to in their patent was kerosene, which was expensively used

for both heating and lighting at the time. Hardware stores sold

kerosene and typically poured it out of a barrel or ladled it into the

customer's container, resulting in spills. This patent included a

method of storing the liquid and then pumping and measuring the amount

dispensed. It was a closed system.

In 1867, Sylvanus Bowser then began to

manufacture kerosene pumps in Fort Wayne, IN. His company was

the first to produce this type of product in the city.

When the automobile began to replace horses

as transportation in the early twentieth century, the Bowser pump was able to dispense

either the gasoline or the oil required in the vehicles.

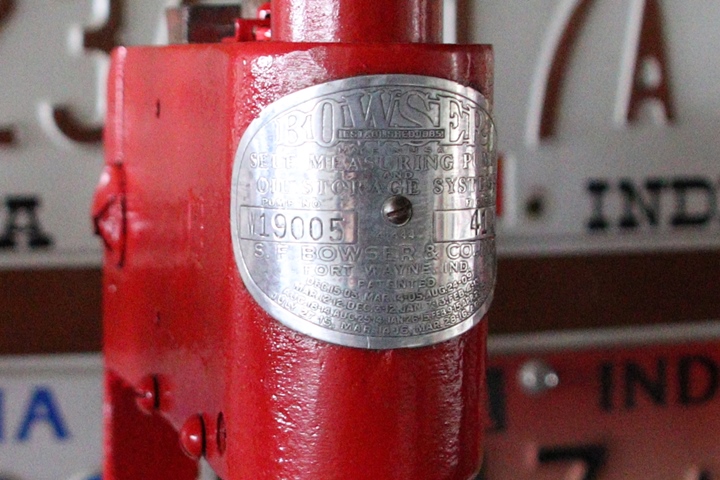

This was called a long distance pump because

the fuel tank did not need to be located at the pump and could be

located underground. Production of this type of pump ran between

1905 and 1920. Depending on where the stop lever was set, one turn

of the crank dispensed between one pint and one gallon of fluid.

Author's photo.

The visit to the Fort Wayne Historical Society

then led to a return visit two weeks later to the National Automobile

and Truck Museum in Auburn, IN. It was at this museum in January

2022, that initiated my research into both the Tokheim and Wayne Pump

companies. When I was there in January 2022, there were, to my

knowledge, no Bowser pumps on display. I thought maybe I had

missed a Bowser pump while there. So, I took a return trip in

December 2022 to make sure I had not missed anything.

It turns out my return trip was fortuitous,

as during 2022 a local gasoline pump collector placed his entire

collection of pumps at the museum for display. While 95% of the

new pumps were built by Tokheim, I was able to find two early Bowser

pumps on display. Author's photo.

Author's photo.

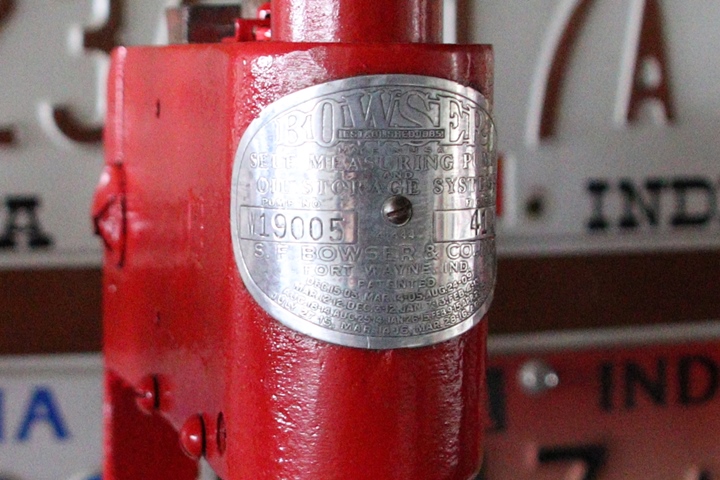

This is the data plate that was on the pump on the

left in the previous photo. It is a long distance gasoline storage

gasoline pump. Author's photo.

The pump on the right in the previous

photo is a self-measuring pump and oil storage system. Author's

photo.

S.F. Bowser formed S.F. Bowser & Co., and in

1885 began selling pumps. Mr. Bowser led the company until his

death in 1938. In 1969, the Keene Corporation, an insulation

manufacturer in Tennessee, purchased Bowser. The insulation Keene

produced contained asbestos, and in the early 1990s it went out of

business, taking Bowser along with it, due to asbestos related lawsuits.

I was familiar with the term 'fuel bowser'

which refers to an aviation fuel truck. In the early years of the

automobile, the gasoline pump was known generically as a bowser.

In some parts of the Australia and New Zealand, a gasoline pump is still

known as a bowser. So, while Mr. Bowser and his company are gone,

the name still remains.

On July 24, 1942, James Forrestal,

Secretary of the U.S. Navy, notified Bowser that it had won the "E"

award. The company added four stars to its original flag during

the next two years. Photo courtesy of Mary Pamula.

S.F. Bowser & Company World War Two

Products: Table 1 shows that the company had $32,406,000 in

major contracts during World War Two. None of them were related to

the company's non-war product line. Table 2 shows that 20mm

shells/projectiles were the largest in dollar value of the seven

different product categories the company produced for the war effort.

Bowser and several other Indiana companies I have researched were

contracted by the U.S. Navy to produce 20mm and 40mm projectiles for the

Navy's anti-aircraft weapons.

Until December 7, 1941, 7:55am Pearl Harbor

time, the U.S. Navy still did not fully realize or want to admit the

damage aircraft could do to its ships. This all changed at 7:55am

on that fateful morning. Two days later, the Royal Navy's

battleship Prince of Wales and battlecruiser Repulse were sunk in the

South China Sea by Japanese aircraft. American naval ships were

going to need more anti-aircraft weapons and the ammunition for them to

fire. While Bowser had an $864,000 Navy contract for

shells in 1941, it received two contracts in 1942 totaling $14,700,000 for 20mm

projectiles. By December 1942, Bowser had tooled up to produce six

million projectiles per quarter. However, by the end of 1943, the

company was out of the projectile making business. It is unknown

whether the tooling was moved to another company's plant that continued

to make the projectiles.

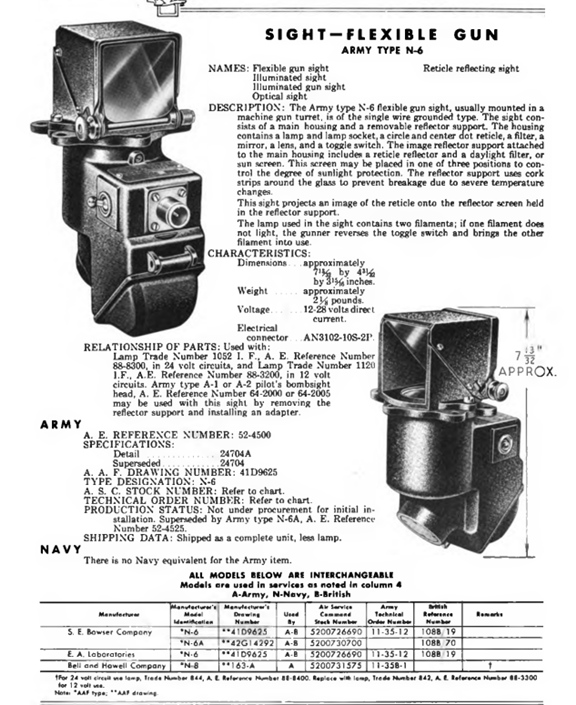

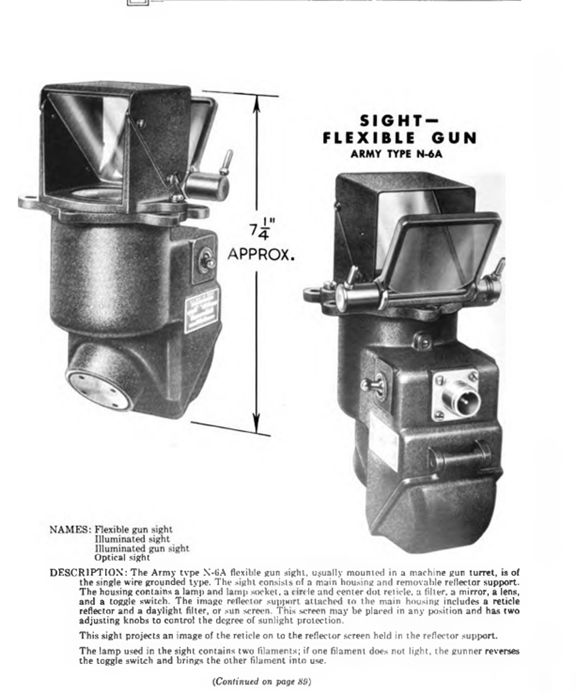

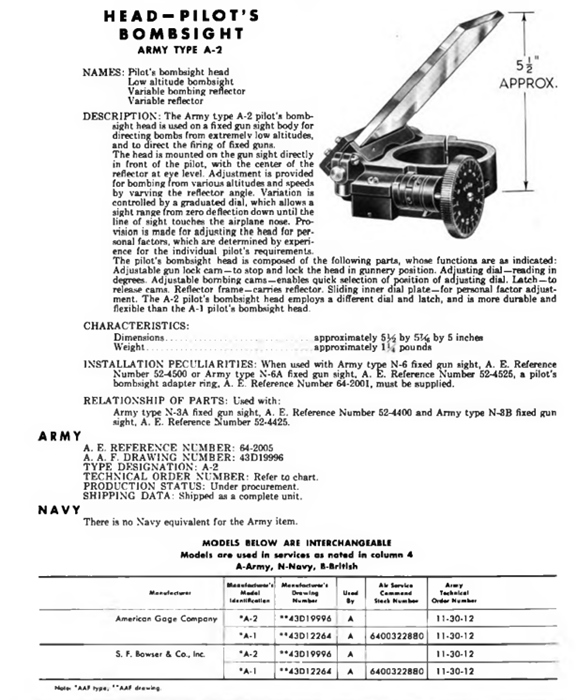

S.F. Bowser & Co. then began to focus on

providing gun sights and pilot bomb sights for the US Army Air Forces.

It actually received its first contract for the N-6 flexible gun sight

in November 1941 just before Pearl Harbor. The company produced

these types of products under ten contracts through June 1944.

The next phase of the company's World War Two

production was bomb nose fuzes and fire bomb cluster adaptors.

There was also one Army Ordnance contract issued in January for 20mm

high explosive incendiary shells. The U.S. Army did not use 20mm

anti-aircraft guns during World War Two. This order most likely

was for the 20mm shells used in the tail guns of the B-29. This

was a different sized projectile than what the company had produced for

the Navy.

Bowser, like many other companies during World

War Two, manufactured products totally alien to its peacetime product

line. The company showed its versatility by providing five

different major products to help win World War Two.

Table 1 - S.F. Bowser & Company's

Major World War Two Contracts

The information below

comes from the "Alphabetical Listing of Major War Supply

Contracts, June 1940 through September 1945." This was

published by the Civilian Production Administration, Industrial

Statistics Division. |

|

Product - Customer |

Contract Number |

Contract Amount |

Contract Awarded

Date |

Completion

Date |

| Shells - Navy |

NOS-4569L |

$864,000 |

4-1941 |

2-1942 |

| Optical Equipment

- USAAF |

535-AC-22707D |

$415,000 |

11-1941 |

4-1942 |

|

Wrenches - USAAF |

535-AC-24652 |

$301,000 |

1-1942 |

6-1942 |

| Projectiles -

Navy |

ORD-286L |

$6,180,000 |

2-1942 |

12-1942 |

| Sight Assemblies

- USAAF |

535-AC-31871 |

$486,000 |

8-1942 |

6-1943 |

| Projectiles -

Navy |

ORD-612 |

$8,520,000 |

12-1942 |

12-1943 |

| Head Pilot Bomb

Sight - USAAF |

11107-AC-19170 |

$201,000 |

1-1943 |

1-1945 |

| Gun Sight

Assemblies - USAAF |

535-AC-37484 |

$492,000 |

2-1943 |

6-1943 |

| Pilot Bombsight

Heads - USAAF |

535-AC-38798 |

$310,000 |

3-1943 |

7-1943 |

| Pilot Bombsights

- USAAF |

11107-AC-113 |

$279,000 |

10-1943 |

2-1944 |

| Sight Assemblies

- USAAF |

30053-AC-266 |

$663,000 |

10-1943 |

3-1944 |

| Bomb Nose Fuzes -

Army Ordnance |

11022-ORD-595 |

$1,409,000 |

10-1943 |

6-1944 |

| Sight Assemblies

- USAAF |

11107-AC-142 |

$997,000 |

11-1943 |

12-1943 |

| Sight

Assemblies - USAAF |

11107-AC-280 |

$280,000 |

12-1943 |

6-1944 |

| Bomb Nose Fuzes -

Army Ordnance |

11022-ORD-2231 |

$1,185,000 |

2-1944 |

8-1944 |

| Bomb Nose Fuzes

M110-A1 - Army Ordnance |

11022-ORD-3105 |

$1,974,000 |

5-1944 |

10-1944 |

| Cluster Adaptors

- Army Chemical Warfare |

11021-CWS-365 |

$2,516,000 |

8-1944 |

7-1945 |

| Cluster Adaptors

- Army Chemical Warfare |

11021-CWS-375 |

$1,617,000 |

8-1944 |

12-1945 |

| Bomb Nose Fuzes

M110-A1 - Army Ordnance |

11022-ORD-5545 |

$1,406,000 |

10-1944 |

3-1945 |

| Bomb Nose Fuzes

M110-A1 - Army Ordnance |

11022-ORD-6349 |

$1,627,000 |

12-1944 |

6-1945 |

| Shells 20mm HEI -

Army Ordnance |

11022-ORD-6367 |

$461,000 |

1-1945 |

1-1946 |

| Bomb Nose Fuzes

M110-A1 - Army Ordnance |

11022-ORD-9160 |

$223,000 |

5-1945 |

7-1945 |

| Total |

|

$32,406,000 |

|

|

|

Table 2 -

S.F. Bowser & Company's

Major Product

Categories |

|

Product |

Dollar Value |

|

|

Shells and Projectiles, 20mm Navy |

$15,564,000 |

48.0% |

| Bomb Nose Fuzes

and Bomb Nose Fuzes

M110-A1 - Army Ordnance |

$7,824,000 |

24.1% |

| Cluster Adaptors

- Army Chemical Warfare |

$4,133,000 |

12.8% |

| Sight

and Gun Sight

Assemblies - USAAF |

$3,333,000 |

10.3% |

| Pilot Bombsight

Heads - USAAF |

$790,000 |

2.4% |

| Shells 20mm HEI -

Army Ordnance |

$461,000 |

1.4% |

|

Wrenches - USAAF |

$301,000 |

0.93% |

| Total |

$32,406,000 |

99% =~ 100% |

48% of Bowser's World War Two dollar volume came from manufacturing 20mm

projectiles for the U.S. Navy. These were used in its 20mm Oerlikon

anti-aircraft gun. The project is the silver cylindrical piece in

this example. At the tip of the projectile is the fuze. The

brass portion is the shell casing. Author's photo.

In early 1942, the 20mm Oerlikon started appearing on U.S.

Navy ships. By the end of the war, every Navy and

U.S. Merchant Marine ship was armed with the 20mm Oerlikon for close-in

defense against air attack. Bowser was a significant contributor

to keeping these weapons firing and protecting American ships and

sailors by making $15,564,000 worth of 20mm projectiles. Author's

photo.

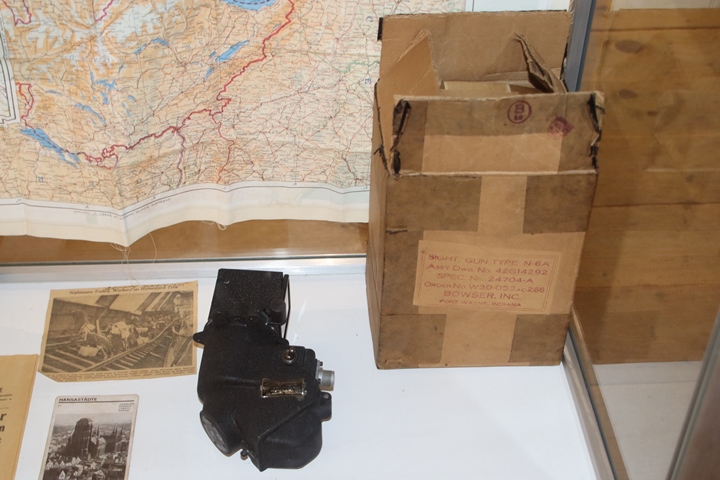

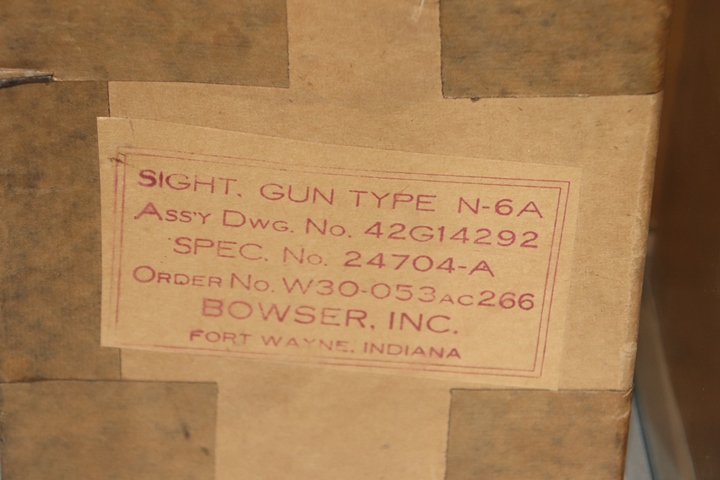

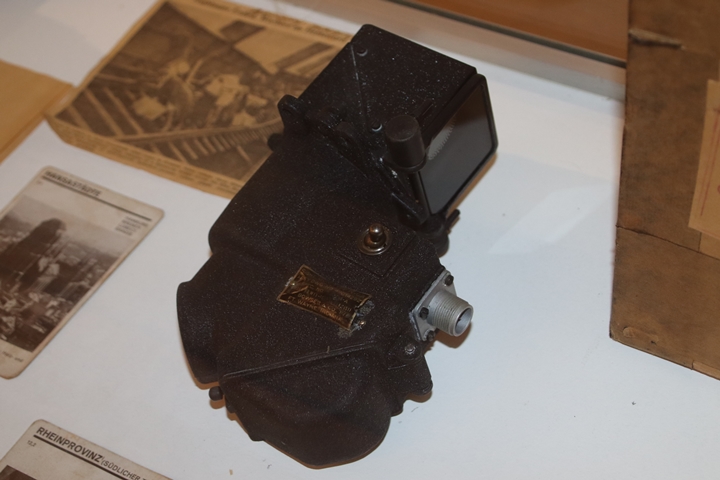

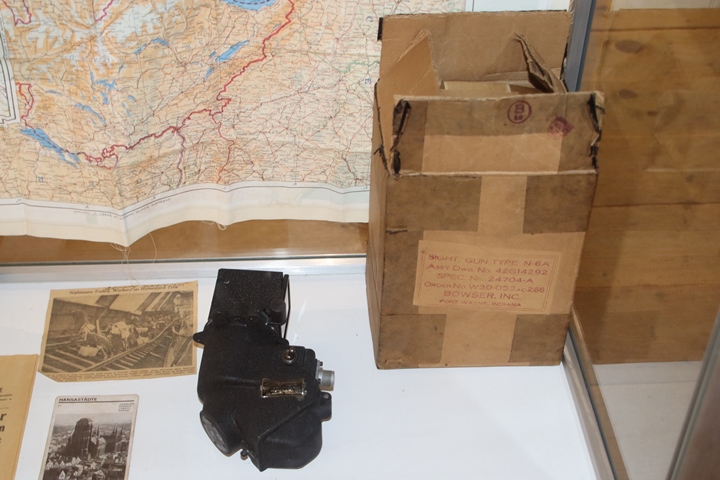

How cool is this? The Tri-State

Warbird Museum in Batavia, OH has on display a Bowser-built N-6A gun

sight with the original box and packing. Author's photo added

10-30-2024.

Author's photo added 10-30-2024.

Author's photo added 10-30-2024.

Author's photo added 10-30-2024.

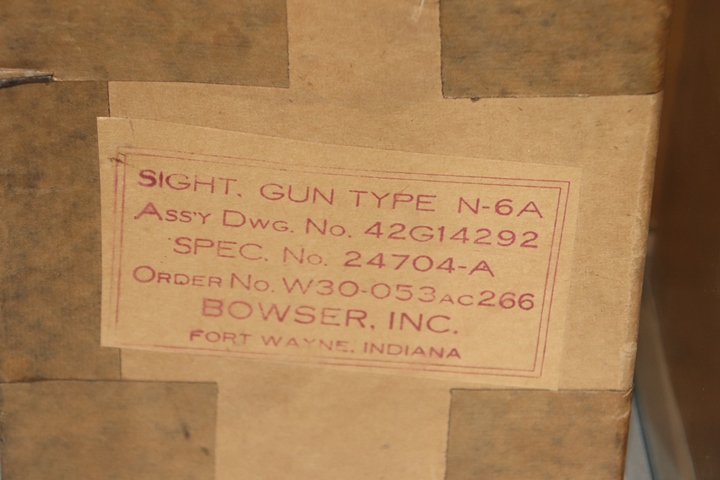

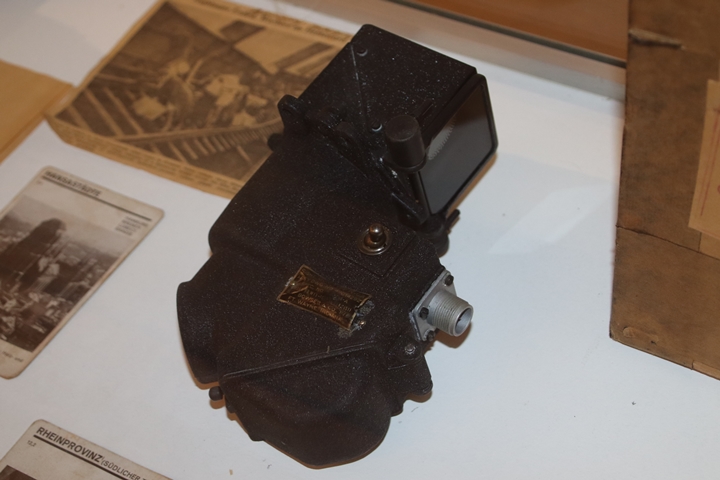

Bowser had five contracts for the N-6 and

N-6A flexible gun sight. This and the photo below show Bower-built

N-6A ordered by the US Army Air Forces on contract a sight under

11107-AC-14 for $997,000 in November 1943. Author's photo added

10-30-2024.

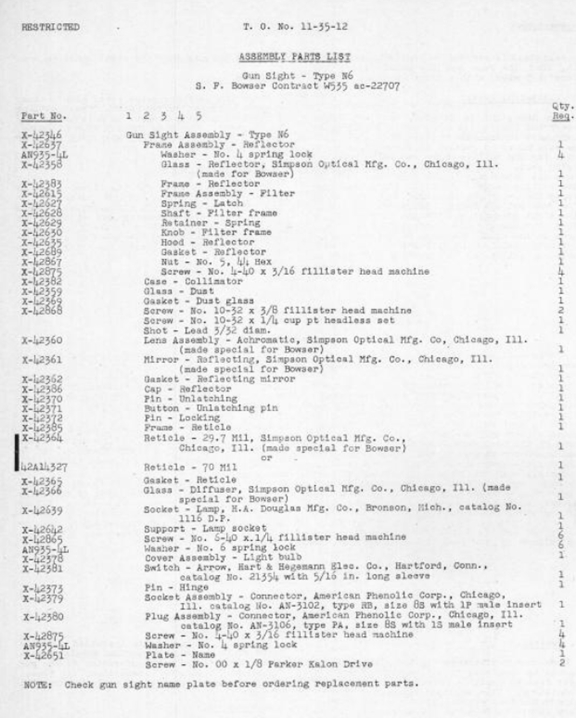

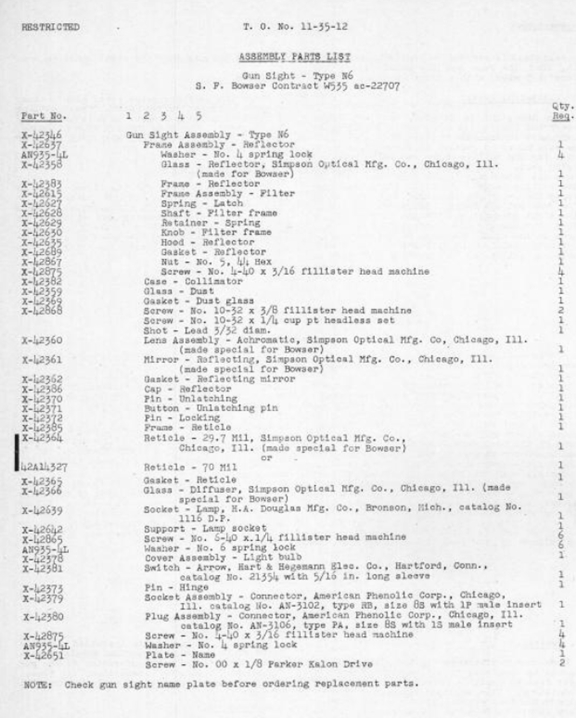

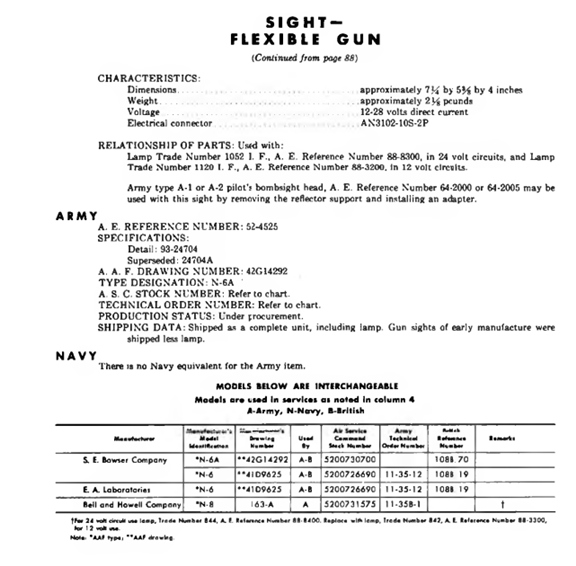

This document shows that the contract

535-AC-22707D issued in November 1941 was for the N-6 version of the gun

sight. This was the first of the five contracts that Bowser had

for gun sights.

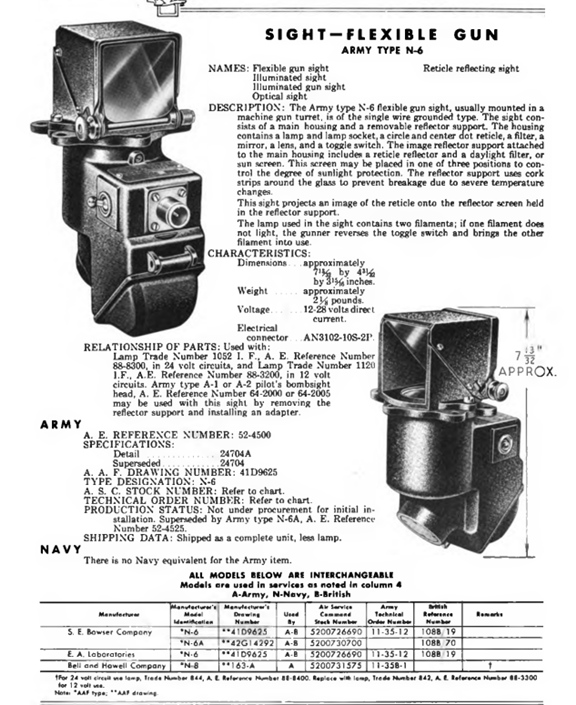

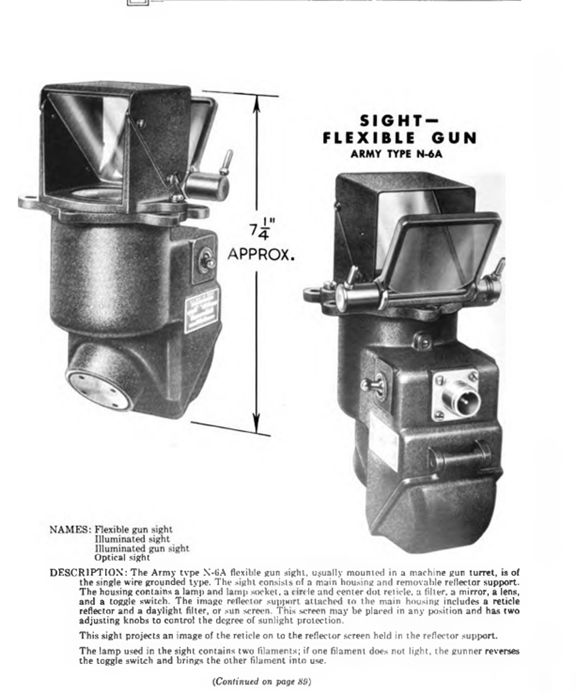

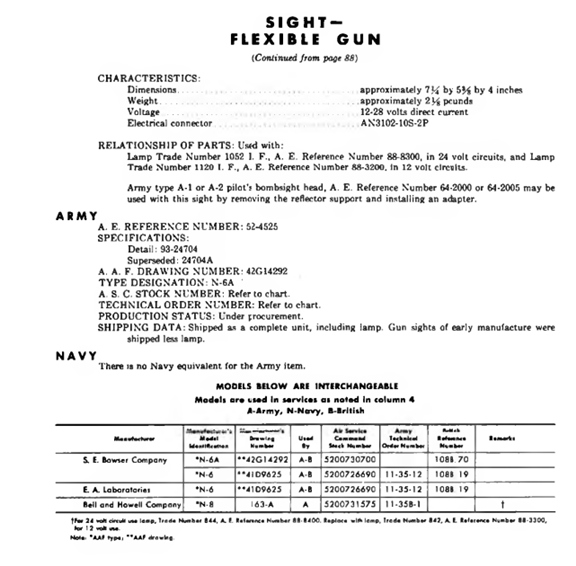

This document shows that Bowser was the only

company during World War Two to manufacture both the N-6 and N-6A gun sight.

Both types of sights were used by both the US Army Air Forces and the

Royal Air Force.

The most noticeable difference between the

N-6 and the N-6A is the mechanism for flipping the sunshade up and

down.

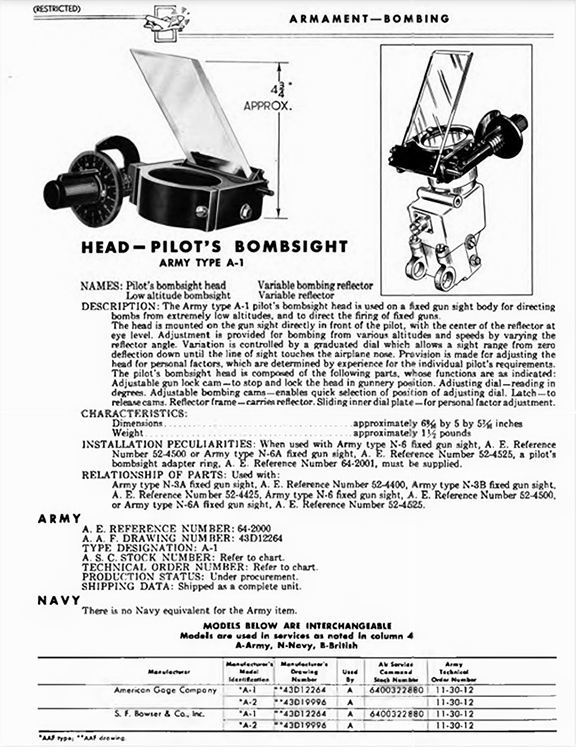

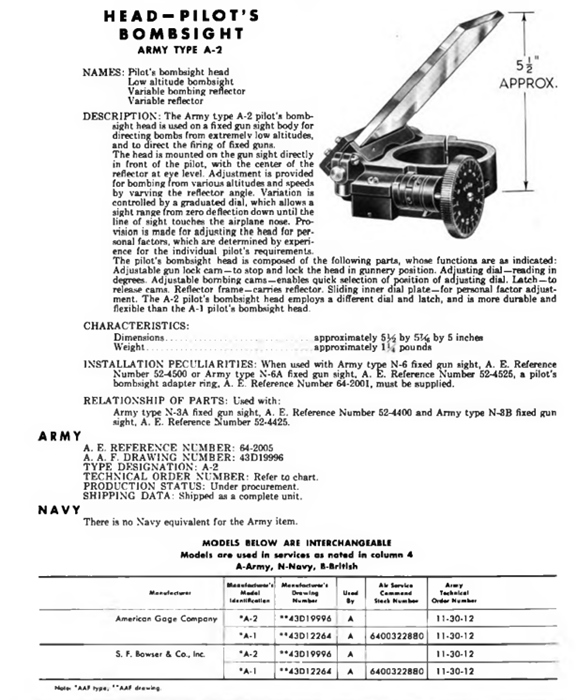

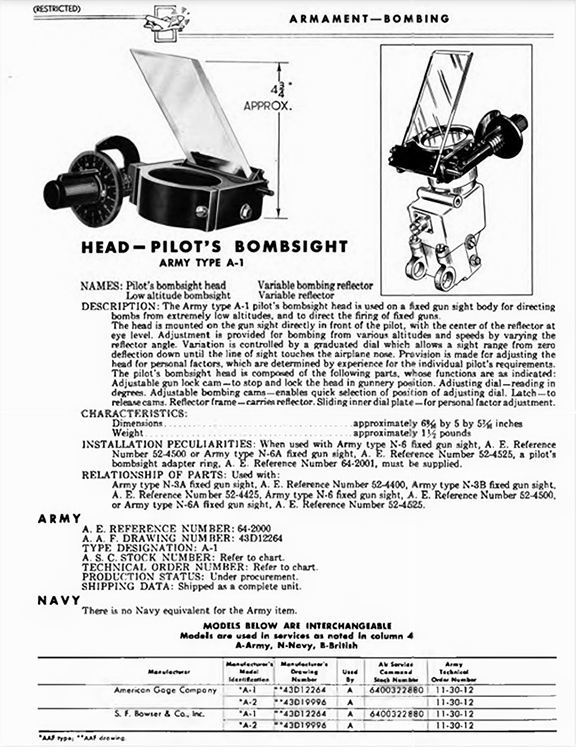

The description for the N-6 and N-6A notes

that it is usually mounted in a machine gun turret. But then it

also notes that the Army type A-1 or A-2 pilot's bombsight can be added

to the N-6 and N-6A. This implies these gun sights were also used

in fighter aircraft.

Bowser had two contracts to also manufacture

the Army Type A-1 and A-2 pilot's bombsight which attached to the N-6

and N-6A gun sights. This implies that these were used in American

and/or British fighters.

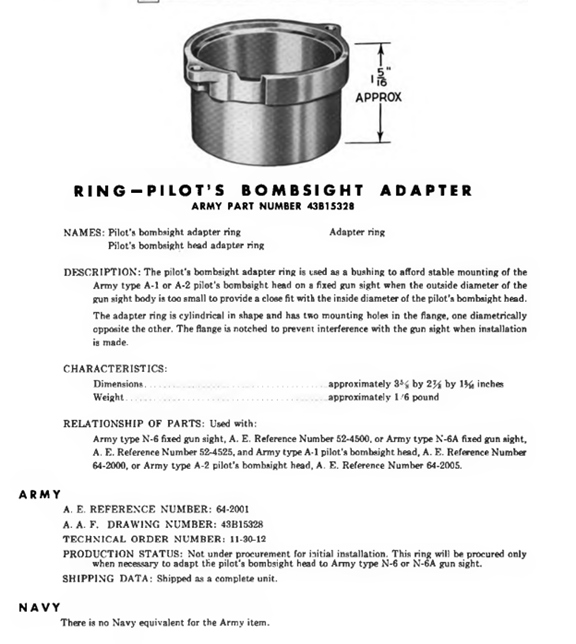

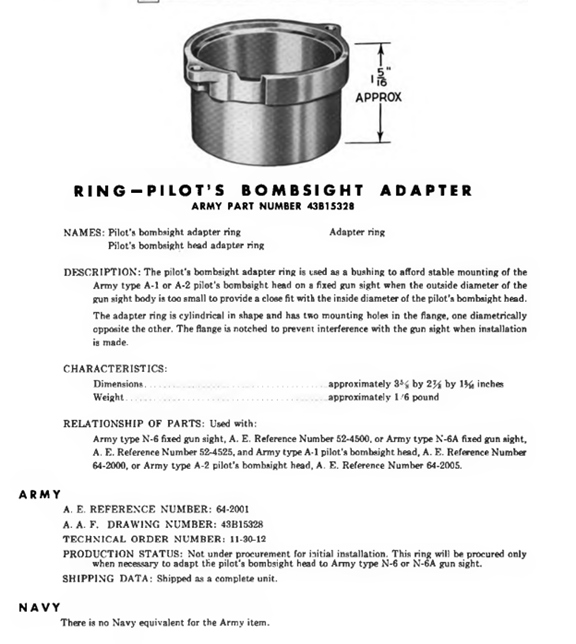

The function of the bombsight adaptor is to

attach the A-1 and A-2 bombsight to the N-6 and N-6A gun sight. It

is unknown whether this was attached prior to the mission or by the pilot

during flight, depending on whether he was in air-to-air combat, or

dropping bombs. There is not enough information to explain how

these units were used and by which aircraft.

S.F. Bowser & Co. had two orders from the

Army Chemical Warfare Corps for cluster adapters which were the

containers that carried four pound thermite incendiary bombs. The

cluster adaptor is the long gray bomb shaped item in the photo.

The long thin hexagonal shaped items are the thermite bombs. The

cluster adaptor could carry 38 thermite bombs. Once dropped from

the bomber, the cluster adaptor detonators shown at the bottom of the

photo would detonate in mid-air, opening the doors on the adaptor and

spreading the 38 incendiary bombs over a wide area. Author's

photo.

Author's photo.

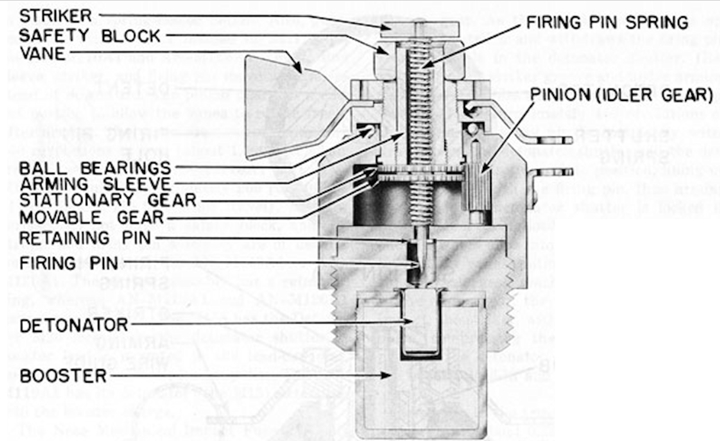

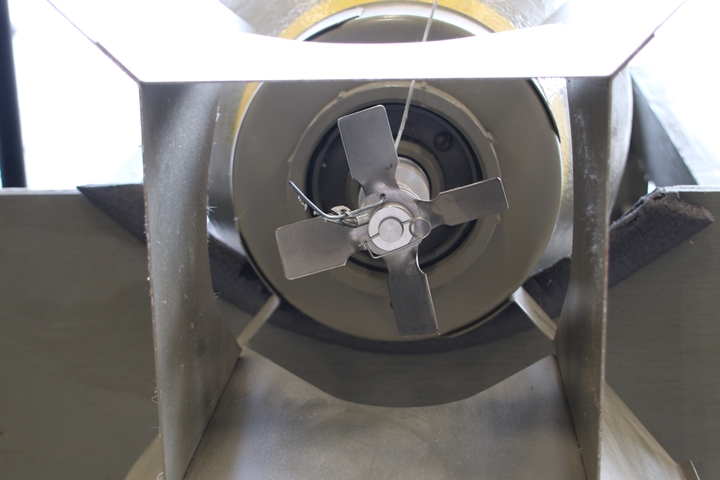

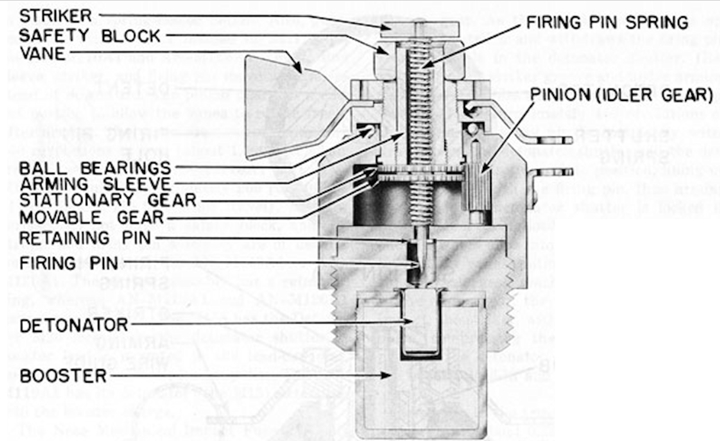

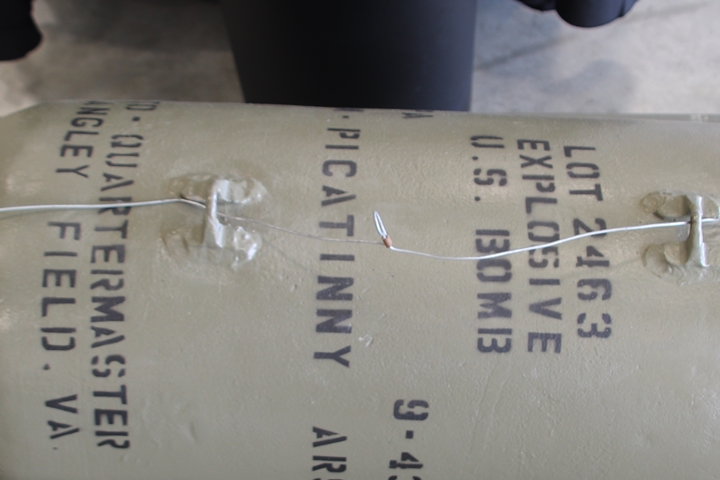

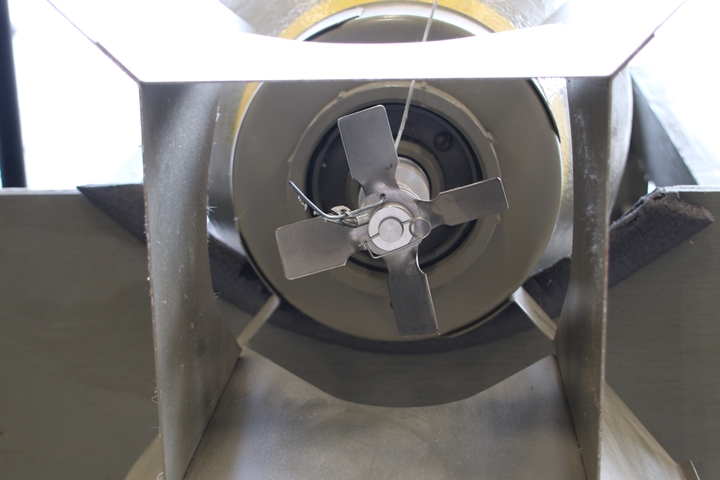

This photo shows an M110-A1 point contact

bomb nose fuze. It took 270 revolutions of the vane to arm the

detonator. The M110-A1 was the last product group manufactured by

Bowser during World War Two.

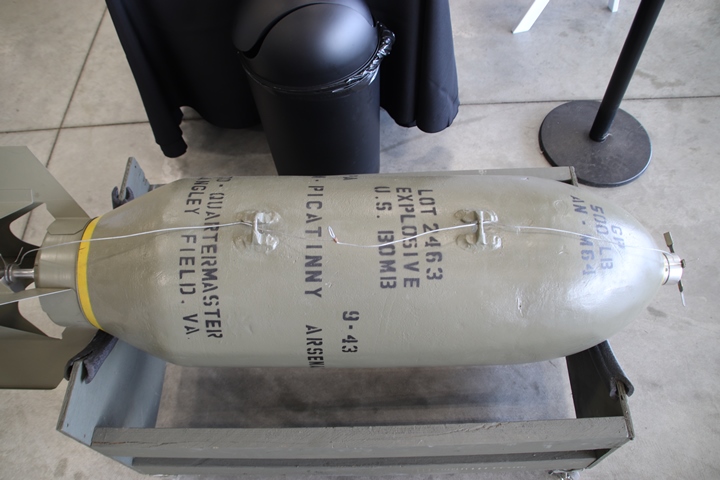

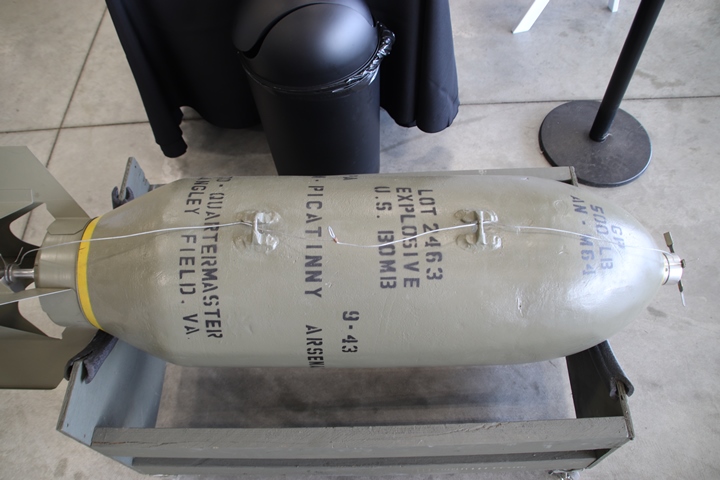

This 500 lb bomb display is located at the

Tri-State Warbird Museum in Batavia, OH. It is the only example I

have found that demonstrates the fuzing system on American World War Two

bombs. This display shows a nose fuze similar to the type

manufactured by Bowser. American bombs also had tail fuzes.

Connected to each fuze and attached to the aircraft was a steel safety

wire. Author's photo.

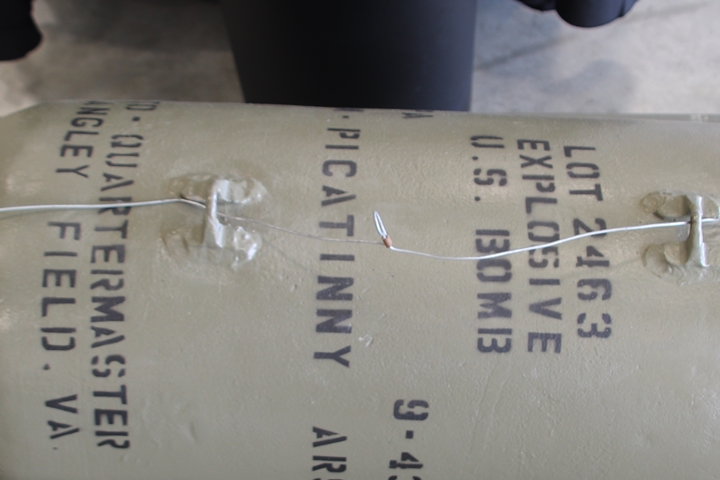

The steel wire was attached to the

aircraft's bomb shackle. Author's photo.

There were a number of different nose fuzes

built during World War Two. Some were instantaneously detonating

on contact, like the Bowser-built M110-A1, and others were delayed fuzes.

All were hooked to the safety wire which kept the vane from accidently

spinning in the bomb bay and accidentally arming the bomb. When

the bomb was dropped, the safety wire, which was attached to the bomb

shackle, pulled out of the vane. As the bomb fell through the air,

the small vanes spun a specified number of revolutions to arm the

detonator. For the M110-A1 this was 270 revolutions. By this

time, the bomb should have been far enough away from the aircraft so if

it accidently exploded it would not destroy the aircraft that carried

it. The small button on the end of the detonator initiated the

firing sequence once it struck the target. Author's photo.

The tail fuze is not only attached to the

safety wire, but also has a cotter pin attached to it. In both the

B-17 and B-24, it was possible in flight to access the bomb bay.

Once the aircraft was on the way to the target, the bombardier would go

into the bomb bay and remove the cotter pin from each of the bombs.

He would then keep these as proof that he had removed each one upon his

hopeful return to base. If for some mechanical reason the aircraft

had to return home after the cotter pin was removed, the bombardier was

required to reattach them before landing. Author's photo.

Once dropped from the aircraft, the rear

fuze vane also had to spin a required number of revolutions to arm the

detonator. While the nose fuze detonated on contact, the tail fuze

used the sudden change in inertia to detonate. Author's photo.

On the B-17 and B-24 bombers, if a bomb hung

up in the bomb bay, the bombardier was required to enter the bomb bay

with the doors open and kick the bomb free. The danger to the

aircraft and crew was that if the safety wire had been pulled on one or

both of the detonators, the vanes could be spinning inside the bomb bay

and arm the bomb. If the bombardier was not able to get to the

bomb bay, most likely the flight engineer, who was the closest crew

member would kick the bomb free.

|