|

Other Lansing Companies that contributed

to winning World War Two

Dail

Steel Products Company

in World War Two

Recognizing a Company from my Hometown that contributed to the winning

of World War Two

Lansing, MI

1913-1972

This page added

9-23-2021.

Dail Steel Products of Lansing, MI was

originally formed in 1911 as the Dail-Gier Company, located on

North Grand Avenue at Ionia Street. The principal owners of the Dail-Gier Company were Ernest I. Dail and B.S. Gier. In 1913 the

two partners went their separate ways and Dail Steel Products moved to

750 East Main Street, occupying the former Cove Manufacturing Company

factory. Early products of Dail Steel Products were bread boxes

and metal card racks. The company initially had ten employees

which increased to 187 workers by 1948. During World War

One, the company produced products for the war effort. As the

company grew, it became a metal stamping house with customers in the

automotive, home appliance, and agricultural industries.

Ernest I. Dail

Before starting Dail Steel Products, Mr. Dail was a postcard salesman.

He invented a revolving metal rack to display his cards. Now these

are found in stores that display all sorts of wares, including

magazines. The metal racks were one of the first products of Dail

Steel Company.

In June 1937 Dail Steel Products had a public

open house of its new office building at the corner of South Hosmer and

East Main Streets to celebrate its 25 anniversary in business.

Another reason for the public open house was that the building had the

company's Dailaire Air Conditioning system installed. The company

wanted prospective customers to come in and experience how well it worked. The

new office building included six offices, a drafting room, a school

room, sales and accounting offices and storage space.

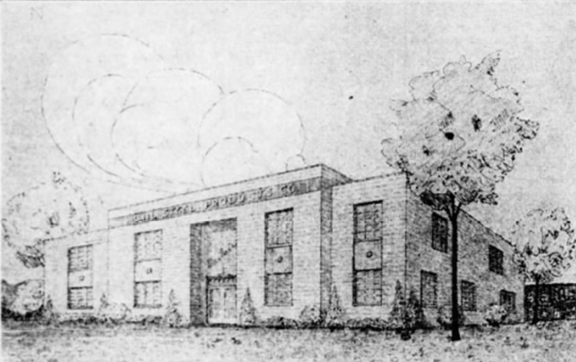

This artist's rendition shows the new Dail Steel Product administration

building.

Dail Steel Company Products: Along

with the revolving metal display racks mentioned above, Dail Steel

Products also manufactured steel shipping boxes that bakeries used to

ship bread as its first products.

In 1914, Dail Steel Products manufactured the

Wolverine Indoor Toilet System for use in dwellings that were not

connected to a sewer system. One potential use for the Wolverine

Indoor Toilet System was for small country schools. Dail Steel

Products specified one toilet bowl for every 20 students. The

company built six different steel tanks with capacities from 142 to 585

gallons. The 585 gallon tank accommodated six toilet bowls or 120

students. The tank was of copper steel construction, not stainless

steel that would be used in similar construction today. The

company supplied a germicide for the system. There was no outlet

for the tank as there is in a modern septic system and the tank would

have had a finite life to it. It is unknown how many units

were sold and installed.

During World War One, Dail Steel Products

could no longer procure the materials it needed for its product line of

the Wolverine Indoor Toilet System. However, the government had

requirements for stamped parts. It was in 1917 and 1918 that the

company began purchasing punch presses and was able to secure government

contracts. This was the transition point at which Dail Steel

Products moved into stamped parts rather than assembled products. After

World War One the company added a new building and focused on supplying

the automobile industry with stamped parts. In Lansing there were

several local customers for its stampings. At the end of World War

One, the Olds Motor Works, the Reo Motor Car Company, and The

Duplex Truck Company were in Lansing. In 1922 the Durant Motor

Company came to town with a new assembly plant on Verlinden Avenue.

Dail Steel Products could very well have

supplied for this 1919 Model T Oldsmobile 3/4-ton truck. Author's

photo.

This 1926 Durant Star was built by the

Durant Motor Company. It could also have Dail Steel Product stampings in it.

The Star was the low priced line of vehicles produced by Durant, for

which production ran from 1922 to 1928 at Lansing. Author's photo.

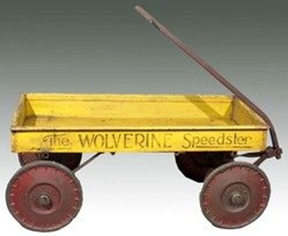

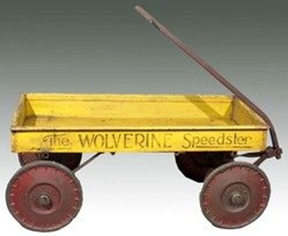

Most of us had a red steel wagon when we

were young. Most of them said "Radio-Flyer" on it. I still

have a Radio-Flyer wagon in the garage for the grandchildren to play

with. What I learned in researching Dail Steel Products is that it invented

the steel children's wagon. In 1920 Dail Steel Products entered

the toy market with the "The Wolverine Speedster" wagon, which

was the first all-steel children's wagon. It was an Ernest I. Dail design.

It was such a success that other companies quickly entered the market

with similar products, resulting in Dail Steel Products exiting the toy

business altogether. Today's wagons are historically linked to Dail

Steel Products and "The Wolverine Speedster." How cool is

this?

On May 21, 1935, Ernest I. Dail was awarded

patent number 2,002,312 for a "Furnace and Air Conditioner." The

term "Air Conditioner" was not the same as how it is currently used,

which is for a unit that takes the heat out of the air and cools a

dwelling. The way Ernest Dail used the term "Air Conditioner"

was to actually use water to clean the air as it moved through the

furnace. This is a quote from the first paragraph of the patent:

"This invention generally relates warm air furnaces of the type in which

air from the atmosphere may be washed or otherwise conditioned and

mechanically propelled to various points of distribution."

The complete patent can be found at this link:

Ernest I. Dail

Patent 2,002,312

Dail Steel Products then started selling

furnaces under the Dailaire name which later used city water or well

water to cool the air as it passed through coils in the furnace.

The downside of this system is that it used an extensive amount of

water. The company notes that the water used in the Dailaire

system in its new administration building was stored in a tank on the

roof that was then used to water the grass. In cold months the

Dailaire system allowed for the furnace to humidify the air that

went into the house.

This twenty page pamphlet published by the Dail Steel Company in 1938

explains in detail the theory behind heating and cooling with a Dailaire

product:

Taking the Mystery out of Air Conditioning

On April 1, 1940, Mr. Bruce McLouth purchased

the heating and air conditioning division of Dail Steel Products and

formed a new company named McLouth Air Conditioning Corporation.

Mr. McLouth had previously been the heating and air conditioning

engineer for Dail Steel Products for six years before starting the new

company and becoming its president. The new company employed Dail

Steel Products'

former engineers and installers from the Dailaire division of the company. After the April

1, 1940 announcement, there is no more information on the McLouth Air

Conditioning Corporation in the historical record.

Prior to World War Two, Dail Steel Products

did more than make metal stampings for other companies. I

personally know that the company built standard furnaces, because my

grandfather had a Dail Steel Products furnace in his basement. I

used to spend a considerable amount of time with my grandfather working

on projects in his basement. I distinctly remember the furnace.

It was typical of the furnaces in many houses in Lansing that were

originally coal burning and then converted to burn natural gas or

fuel oil. The 1934 Cooperative Tractor Catalog shows Dail Steel

Products of Lansing, MI as being a supplier of steel sheet. The

Cooperative Tractor Catalog also had a category for steel stampings and Dail Steel Products was not listed there. In the 1928 edition of

the Cooperative Tractor Catalog, Dail Steel Products was shown as

being a supplier of agricultural tanks.

On April 30,1942, Lansing industrialist and

president of Dail Steel Products, Ernest I. Dail passed away. He was replaced

with his

brother Elmer Dail, who had been general manager of the Jarvis

Engineering Company of Lansing.

The End of Dail Steel Products:

-

In June 1971, there were

rumors that the company would either close or move out of Lansing.

Dail Steel Products had no comment on the matter. By this time Lewis

Dail was president of the company and the address of the company was

now 1000 South Hosmer. It is unknown whether Dail Steel

Products workers were represented by a union. There is nothing

in the historical record of any strikes against the company nor any

other union activity. After World War Two there were numerous

strikes at most of the union represented companies in Lansing which,

for the most part, included all of the manufacturing companies.

Several companies, including John Bean and Motor Wheel, eventually

moved production out of Lansing due to labor issues. So, when

there was word that a company will move out of Lansing area, it was

assumed to be

labor related. So, Dail Steel may have been having labor

problems or its labor cost was too high to compete with non-union

companies. We will never know.

-

In August 1971 the

company put 35 punch press machines and other related equipment up

for sale. The address for the auction was 1000 South Hosmer,

not 750 East Main Street. This is because I-496 was laid right

over Main Street in Lansing. This may have also resulted in

the demolition of the administration building. The

construction of

I-496 may have been one of the causes of Dail Steel Products

closing.

-

In December 1971 the

company had two forklift trucks up for sale.

-

On June 8, 1972, the

remaining equipment of Dail Steel Products was put up for auction. This

was authorized by the company's Board of Directors.

-

On October 8, 1972, Dail

Steel Products was listing its factory for sale or lease. The

factory was described as a 46,000 square foot heavy industrial building with

modern office space. The facility was located on 2.6 acres.

-

In May 1974 the Lansing

Storage Company used the former Dail Steel Products factory as an

auction site. Several other companies in Lansing used the

former Dail facility to hold auctions.

When Dail Steel Products closed, it was the

longest existing family owned business in Lansing. This is such a

sad ending for this Lansing company.

The current building on the site of the

former Dail Steel Products Company in Lansing, MI is now the home of

Ideal Instruments, a division of Neogen Corporation. In 2017

Neogen spent $1.3 million for a complete rehabilitation of the former Dail Steel Products plant. The rehabilitation of the building

added over 39,000 square feet and 25 new jobs. It can be seen in

this photo that the north side of the building was completely redone and

looks very modern. If I had arrived before the work was done, I

would have seen the building like it was when Dail Steel owned and

operated the facility. Author's photo.

Ideal makes precision veterinary drug delivery

instruments in the facility. Ernest I. Dail would be proud of the

fact that Ideal Instrument division of the Neogen Corporation is making

use of his former plant to make high tech products.

The parking lot was the former location of

the Dail Steel administration building that was built in 1937. It

may have actually been partially located where I-496 was built at in the

late 1960s. At this location I-496 was built directly over East Main

Street in Lansing. This may have resulted in the demolition of the

administration building. It caused the address of the company

to change from a Main Street address to 1000 South Hosmer Street.

Author's photo.

This photo shows where the newly restored

building on the right joins with the original factory building.

Author's photo.

The south side of the complex shows a

building of an earlier construction type. Author's photo.

Author's photo.

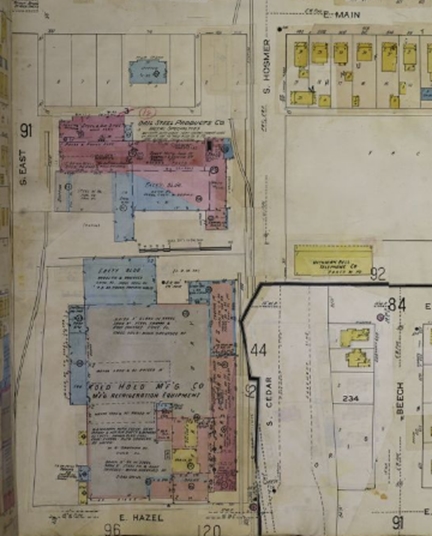

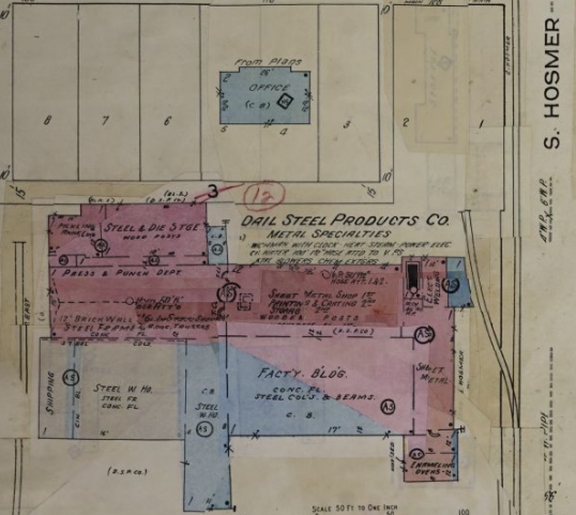

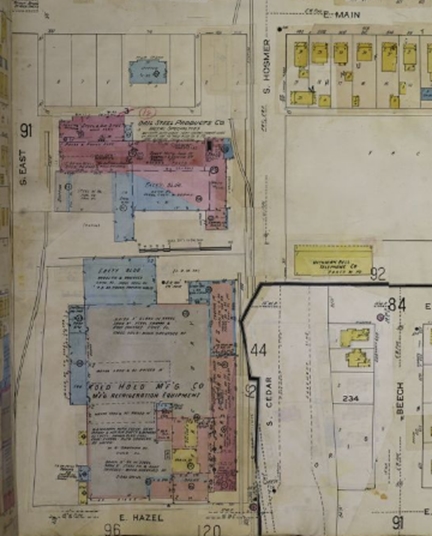

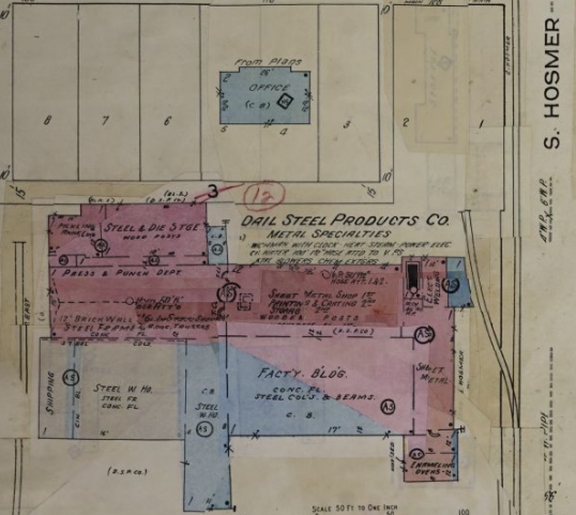

This Sanborn Insurance Company map shows the

Dail Steel Products in 1951 at the location of East Main and South

Hosmer Streets. In 1951 the plant to the south of Dail Steel Products

was owned by the Kold Hold Manufacturing Company. However, from

1915-1945 this building was the home of John Bean, which made

agricultural spraying equipment. John Bean most likely was a

customer of Dail Steel Products for many of the metal stampings it needed in its

products. During World War Two John Bean manufactured chemical

decontamination products for the U.S. Army Chemical Corps which may have

used Dail Steel Products stampings. John Bean also built crash

trucks for the U.S. Navy that may have required Dail Steel Products

stamped parts.

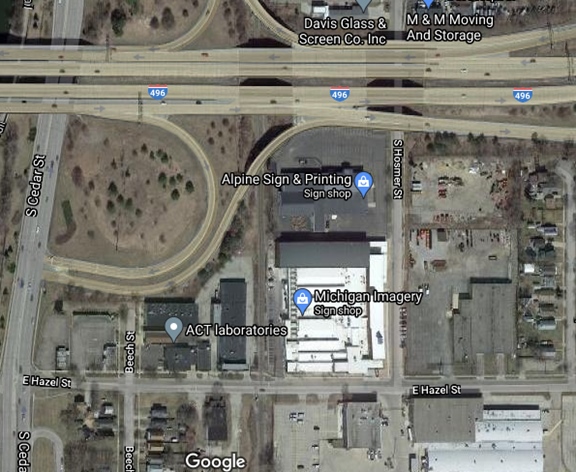

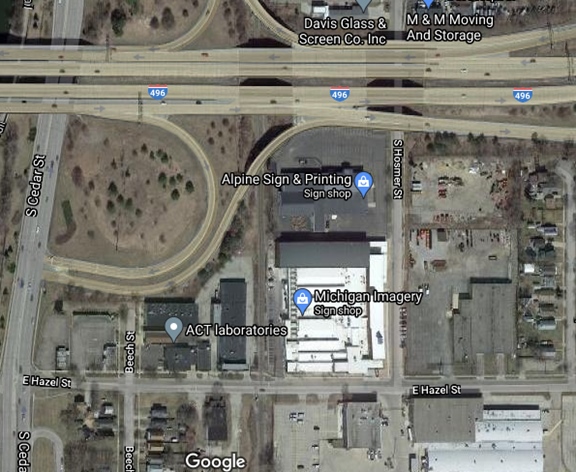

This Google Maps Satellite view shows the

same location as the Sanborn map above does. However, Alpine

Sign and Printing is not in the former Dail Steel Products plant.

This is incorrect. This view shows that I-496 was laid down right

over East Main Street and possibly onto the property of the Dail Steel

Products.

This enlarged Sanborn map shows the detail

of the factory in 1951. The northeast building had two floors for

painting and coating metal stampings.

World War Two Products: Metal stampings

are ubiquitous and are used in many types of products. It is unknown

what stampings Dail Steel Products produced to help win World War Two, as

that information is unavailable. It is known that the company's

resources were 100% dedicated to the war effort. However, if we

assume it was a supplier to local companies in Lansing, there are

several possible products it could have produced during the war.

The following is educated conjecture.

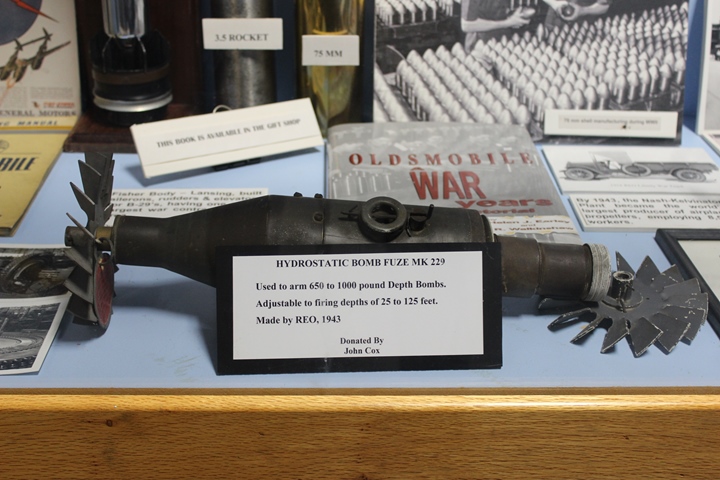

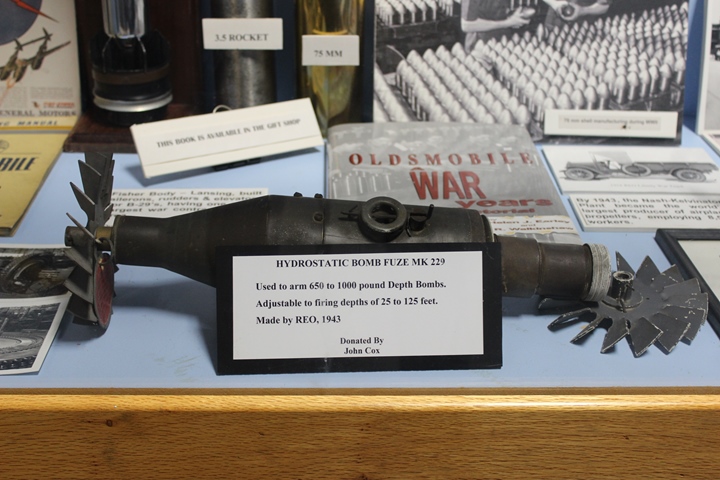

The Reo Motor Car Company, which was just a

mile away from Dail Steel Products, produced 1,424,473 aerial and depth

charge fuzes for the U.S. Navy. Two examples below show how Dail

Steel could have stamped out parts for these fuzes. Making fuzes

was not part of Reo's peacetime product line, as it was a truck

manufacturer, and probably did not have the presses for the stampings used on

the fuzes. Even in peace time, any small stampings Reo needed for

its trucks could have been provided by Dail Steel Products or other

dedicated stamping houses.

Having the stamping house within walking

distance during World War Two was helpful while gas rationing was in force. This allowed the product responsible engineer at Reo and

the tool design engineer at Dail Steel Products to talk face-to-face

about the requirements for the Navy fuzes. It also allowed for

quick review of a sample run to make sure that the Navy inspector on

location at Reo approved the parts. It allowed for communication and

prompt turn-around of new parts to move smoothly and quickly.

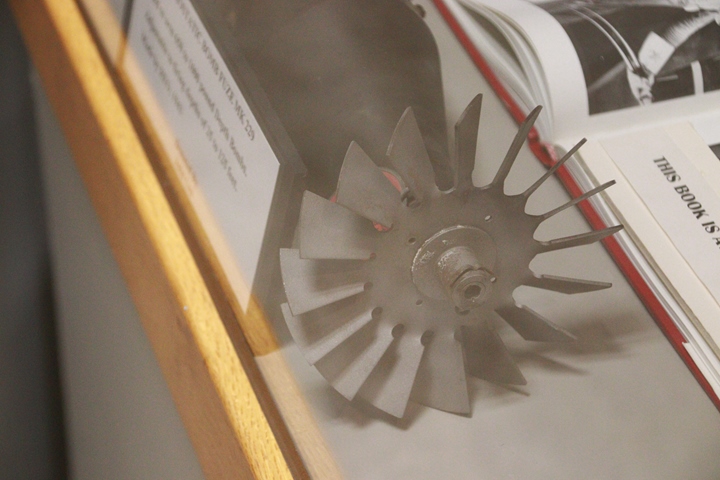

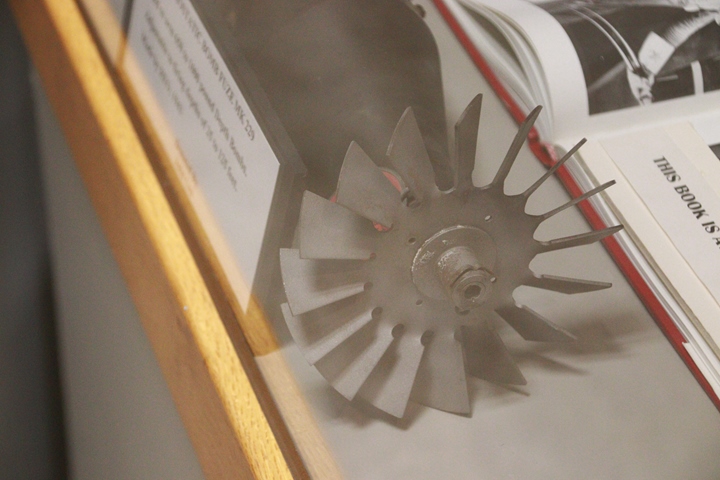

This photo shows the sixteen blade arming vane attached to the tail of a

Mark 229 Hydrostatic Tail Fuze as

a separate piece. The arming van was 5.25 inches in diameter.

Author's photo taken in 2015 at the RE Olds Museum in Lansing, MI.

This Reo-built Mark 229 Hydrostatic Tail Fuze was used by the U.S. Navy during World War Two in its 650 and 1,000

pound depth

charges. Reo built 100,933 of these through July 1944. The fuze

is 16.33 inches long with a diameter of 3.25 inches, while the sixteen

blade arming vane is 5.25 inches in diameter. Depth settings were

made by a hand dial on the device and could be set for 25, 50, 75, 100,

and 125 feet. The small hole on the left end of the body was used

to insert a pin into the device to disarm it. Reo did not arm

the fuzes it built. They were inert when they left the factory.

The units were armed at another location.

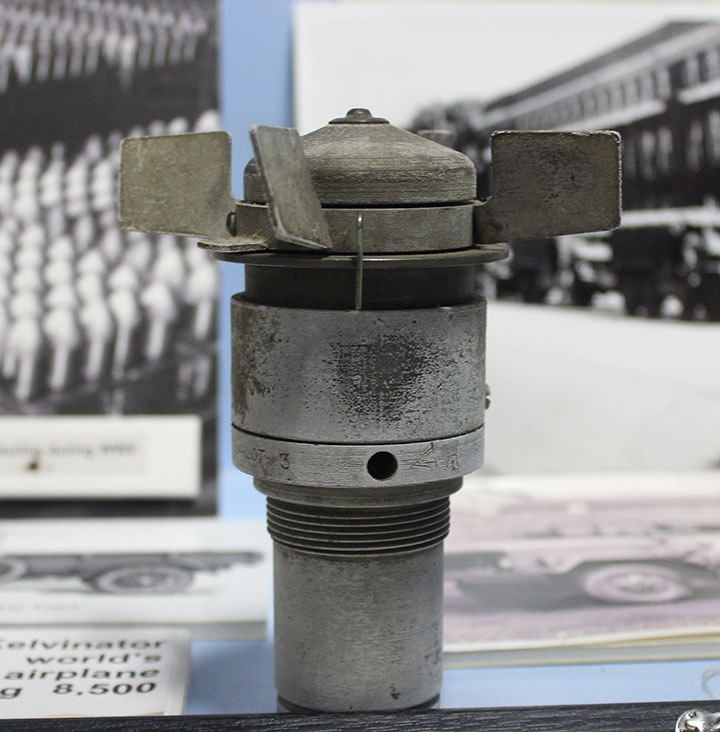

The Olds Museum changes its displays around

for variety. This is the same Mark 229 Hydrostatic Tail Fuze in

2021. This presentation shows the arming vane's three components

of two stampings and a machined or powder metal part in more detail. The two

stampings were good candidates for Dail Steel Products to make. Author's

photo taken in 2021 at the RE Olds Museum in Lansing, MI.

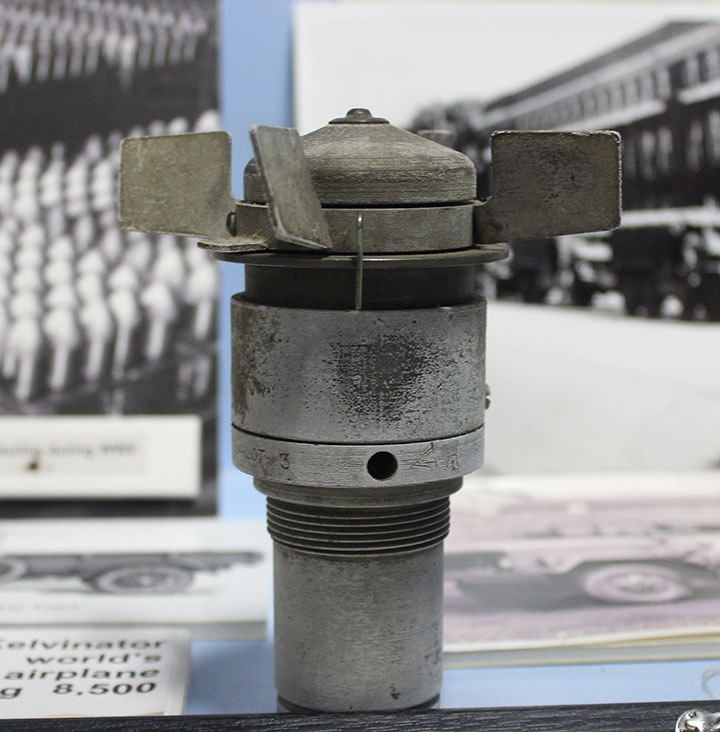

This Reo-built depth torpedo arming fuze was on display at the R.E.

Olds Museum in 2015. Note the cotter pin that keeps the vanes from

spinning until armed, maintaining it in a safe mode. Author's

photo.

This fuze was also re-oriented when I

photographed it in 2021. It shows more clearly than the

2015 photo that the arming vanes on the device are actually two stamped

parts attached with screws. It also more clearly shows the cotter safety pin.

Just over a mile to the north of Dail Steel

Products was the Abrams Instrument Company that made the U.S. Army Air

Force CF-8 stereoscope map reader. Abrams was a small shop and

most likely did not have its own metal stamping capabilities. It

mostly designed the instruments it built and then had other manufacturers

like Dail Steel Products provide all of the components for final

assembly. The embossed black steel frames are steel stamped

parts. Dail Steel Products had the capability on the second floor

of its plant to paint steel

stampings like this. Abrams'

original order for the CF-8 was 26,000 units in 1942. It had other

contracts for them later in the war and continued building them up

through the end of the war. Author's

photo taken in 2021 at the RE Olds Museum in Lansing, MI.

These two Abrams-built instruments on

display at the RE Olds Museum in Lansing, MI have stamped metal covers

and deep drawn metal boxes. The stamped metal covers could very

well have been done at the nearby Dail Steel Products. Dail had

the capability to stamp out and then paint the covers. However,

the metal boxes may have been beyond the capability of the presses that

Dail Steel Products owned. To make these it took multiple steps

from a large tonnage press with a progressive die. Author's photo.

This Abrams Instrument-built intervalometer

on display at the National Museum of the United States Air Force in

Dayton, OH may well have a stamped out face plate by Dail Steel Products.

Author's photo.

Also at the National Museum of the United

States Air Force is this Abrams CF-8 stereoscope map reader, which could

have a Dail Steel Products manufactured frame. Author's photo.

The National Museum of the United States

Air Force is the largest aviation museum in the world and the biggest

tourist attraction in Ohio. While it is all conjecture, products

that Dail Steel Company may have manufactured for the two Abrams

Instrument Company's products may be hiding in plain sight. Parts

from the company that Ernest I. Dail founded in Lansing, MI in 1913 may

well be on display for the many visitors to the Museum.

Other Lansing Companies that contributed

to winning World War Two

|