|

Bailey

Products Corporation in World War Two

Union City, IN

This page added 12-14-2022.

Normally, when I find a World War Two

artifact with the company's name that manufactured it, I am able to

learn more about the company and what it made before and after the war.

In the case of the M1 mine fuze shown above, I was only able to find the

major contracts for the Bailey Product Corporation in Union City, IN.

Because Table 1 shows that it had contracts from 1941 through 1945, we

know it was in existence during the war period. There is also a

reference to it in 1948. Author's photo.

A 1943 newspaper article notes that it had two

plant sites in Union City, IN. Both were on streets that have

apparently been renamed. One plant was in a former hardware store

on Oak Street, which no longer exists. The main plant was on

Division Street, East Side. Currently, there is only a West

Division Street in Union City, IN. To complicate matters, there is

also a Union City, OH as both towns are on the Indiana-Ohio State

border. That being said, there is no Division Street on the Ohio

side of the border either.

Union City, IN currently has a population of

3,500 persons. Its claim to fame is in the 1960s being the home of

the McCoys, who became famous for their hit song "Hang On Sloopy."

"Hang On Sloopy" is Ohio's official rock song,

even though the group resided in Union City, IN. Go figure.

Bailey Products produced $1,511,000 worth of

M1 anti-tank mine fuzes like the one shown above. This fuze is on

display at the Museum of the Soldier in Portland, IN, 25 miles northwest

of Union City.

Table 1- Bailey Products

Corporation's

Major World War Two Contracts

The information below

comes from the "Alphabetical Listing of Major War Supply

Contracts, June 1940 through September 1945." This was

published by the Civilian Production Administration, Industrial

Statistics Division. |

|

Product - Customer |

Contract Number |

Contract Amount |

Contract Awarded

Date |

Completion

Date |

| Ordnance

Material - Army |

294-ORD-752 |

$315,000 |

6-1941 |

12-1941 |

| Housings -

Army |

294-ORD-763 |

$126,000 |

7-1941 |

4-1942 |

| Fuzes -

Army |

294-ORD-991 |

$122,000 |

3-1942 |

9-1942 |

| Fuzes -

Army |

294-ORD-1115 |

$614,000 |

4-1943 |

2-1943 |

| Mine

Fuzes M1- Army |

294-ORD-1210 |

$106,000 |

5-1942 |

11-1942 |

| Fuzes

Mine - Army |

294-ORD-2037 |

$248,000 |

12-1942 |

7-1942 |

| Fuzes

Mine - Army |

294-ORD-2372 |

$93,000 |

4-1943 |

4-1944 |

| Fuzes

Mine - Army |

294-ORD-2373 |

$328,000 |

4-1943 |

6-1944 |

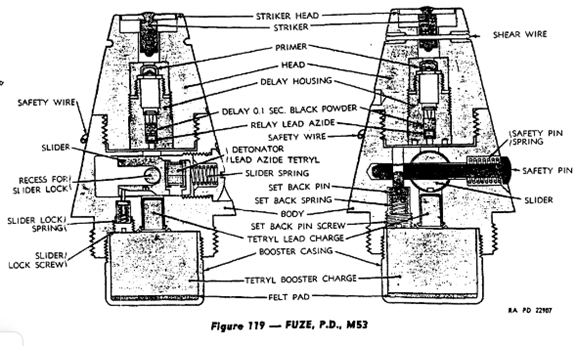

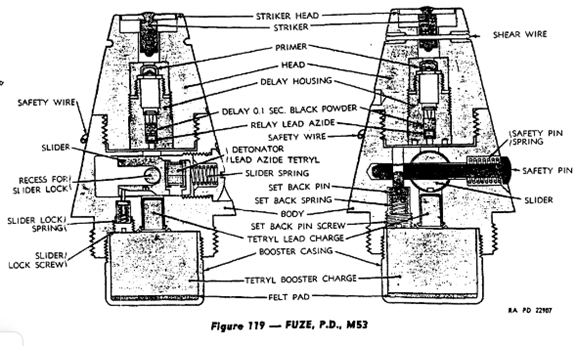

| Fuzes

PD M53 - Army |

33008-ORD-619 |

$378,000 |

2-1944 |

10-1944 |

| Fuzes

PD M53 - Army |

33008-ORD-1030 |

$672,000 |

6-1944 |

5-1945 |

| Fuzes

PD M53 - Army |

33008-ORD-1727 |

$333,000 |

12-1944 |

6-1945 |

| |

Total |

$3,335,000 |

|

|

|

Table 2 - Bailey Products

Corporation's Major World War Two Product Categories |

|

Product |

Amount |

Percentage |

| Fuzes,

Mine Fuzes M1, and Fuzes Mine - Army |

$1,511,000 |

45.3% |

| Fuzes

PD M53 - Army |

$1,383,000 |

41.4% |

| Ordnance

Material - Army |

$315,000 |

9.4% |

| Housings -

Army |

$126,000 |

3.9% |

| Total |

$3,335,000 |

100% |

There were 10,704,000 M1 anti-tank mines

produced from 1942 through the end of 1943. Bailey Products

produced a small share of the fuzes for the M1 anti-tank mine.

Those contracts were replaced with the M6 and M7 anti-tank mine starting in 1944.

The company began making M-53 81mm mortar fuzes.

Author's photo.

The fuze is in the "safe" position.

To arm it, the soldier would pull the safety fork out from the fuze.

The outside ring would then drop and the center post would be exposed.

When a vehicle ran over it, it would depress and set off the mine.

There was enough spring load on the center post that the weight of an

individual soldier would not set off the mine. Author's photo.

The Bailey-built fuzes were used in M1

anti-tank mines like this one built at nearby Durham Manufacturing

Company in Muncie, IN. Author's photo.

The M-53 fuze was for 81mm mortar shells and

had a delayed action. These were used with heavy charge shells

where penetration was desired.

An 81mm mortar is shown at the top of the

photo. 81mm mortar shells with M53 fuzes were very similar to the 60mm

mortar shells and fuzes on the sandbag. Author's photo.

|