|

Horton

Manufacturing Company in World War Two

1883-1952 Fort Wayne, IN

This page added

12-19-2022.

An impromptu visit to the Fort Wayne

Historical Society on the day after Thanksgiving 2022 took me in an

unexpected direction. On display were four Horton Manufacturing

Company washing machines. These piqued my interest in that I had

never heard of the Horton Manufacturing Company and wondered, what did a

company that made washing machines do to help win World War Two?

Did the company furnish washing machines to the military or did it

re-tool and produce military type products? Those questions would

need to wait until I returned home. The information placard at the

Fort Wayne Historical Society indicates this is a Horton Manufacturing

Model 22 washing machine that was marketed in the early 1900s.

Note that it is largely of wood construction and everything on the

washer was hand operated. Author's photo.

This is a 1920s era Horton Manufacturing

Model 32 washing machine. The Model 32 was a hybrid model as both

the agitator and wringer could be hand operated or run by an electric

motor. The electric motor was built by the General Electric plant

a mile south of the Horton plant in Fort Wayne. Author's photo.

The tub is still of wooden construction.

Author's photo.

There had been a quantum leap in the

materials used in the

Model 40 which came out in the 1920s. The tub is now of steel

construction which was painted on the exterior. It is an

all-electric unit. Author's photo.

The interior of the tub has been plated to

keep the steel from rusting. Note the unusual type of agitator of

the Model 40. Author's photo.

By

1950 the company was no longer using numbered model numbers. This

is a Horton Laundeluxe automatic washing machine. Author's photo.

When I returned home from my trip, I opened up

the appropriate volume of the Alphabetical Listing of Major War Supply

Contracts to determine if and what major contracts the Horton

Manufacturing Company was awarded during World War Two. Table 1

shows that the company was exclusively contracted by the United States

Navy to produce $8,390,000 of 40mm Bofors anti-aircraft gun projectiles

and tracer bodies.

Table 1- Horton Manufacturing Company's

Major World War Two Contracts

The information below

comes from the "Alphabetical Listing of Major War Supply

Contracts, June 1940 through September 1945." This was

published by the Civilian Production Administration, Industrial

Statistics Division. |

|

Product - Customer |

Contract Amount |

Contract Awarded

Date |

Completion

Date |

| Projectiles -

Navy |

$2,138,000 |

7-1941 |

1-1942 |

| Projectiles -

Navy |

$4,409,000 |

7-1942 |

9-1944 |

| Projectiles -

Navy |

$240,000 |

10-1942 |

5-1943 |

| Bodies Tracer -

Navy |

$328,000 |

3-1943 |

12-1943 |

| Tracer Bodies -

Navy |

$323,000 |

6-1943 |

7-1944 |

| Tracer Bodies Mk

4 - Navy |

$245,000 |

3-1944 |

9-1945 |

| Projectiles 40mm

- Navy |

$1,158,000 |

8-1944 |

12-1944 |

| Total |

$8,390,000 |

|

|

The Horton Manufacturing Company is named

after Dr. Theodore Horton. Dr. Horton started business in

Bluffton, IN with two other individuals in 1873 as the T. Horton and

Co., which was producing corn planters. Dr. Horton was a half

owner of a patent that the T. Horton and Co. was marketing. During

this same period, the company purchased a patent for a washing machine

and began producing it under the name of "Improved Western

Washing-Machine." In 1879 Dr. Horton sold his interest in the

company to one of his partners, but kept his one-third interest in the

washing machine patent. Dr. Horton then moved to Fort Wayne and

found a group of interested investors led by a Mr. John Peters.

With new financing, Dr. Horton and his investors began production of

washing machines in a new factory at 731 Osage Street in Fort Wayne.

In the 1920's the company claimed to be supplying half of the world's

washing machines. The company survived the depression and won five

Army-Navy "E" awards during World War Two, only to succumb to the highly

competitive post-World War Two appliance market. It went out of

business in 1952.

Horton Manufacturing Company in

World War Two:

The Horton Manufacturing Company won the

Army-Navy "E" Award five times during World War Two.

The first award was given at a presentation on January 28, 1943.

Its final "E" flag had four stars like this

one. Photo courtesy of Mary Pamula.

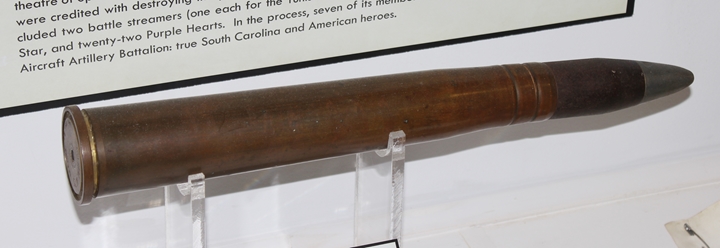

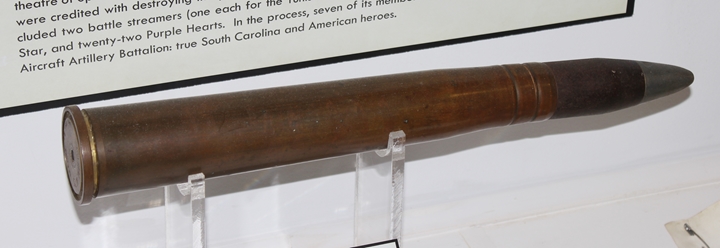

This image shows two finished 40mm shells.

Author's photo.

The 40mm shell consisted of a brass shell

casing, a projectile, and a fuze. In this example, the projectile

is painted black. Different companies produced the three main

components for the shell. They were all sent to a Navy ordnance

plant that assembled them into the final product as seen here.

Author's photo.

The shells were then assembled into

four-piece clips for feeding into the Bofors gun. Author's photo.

The black pieces show the black projectiles like Horton manufactured.

Author's photo.

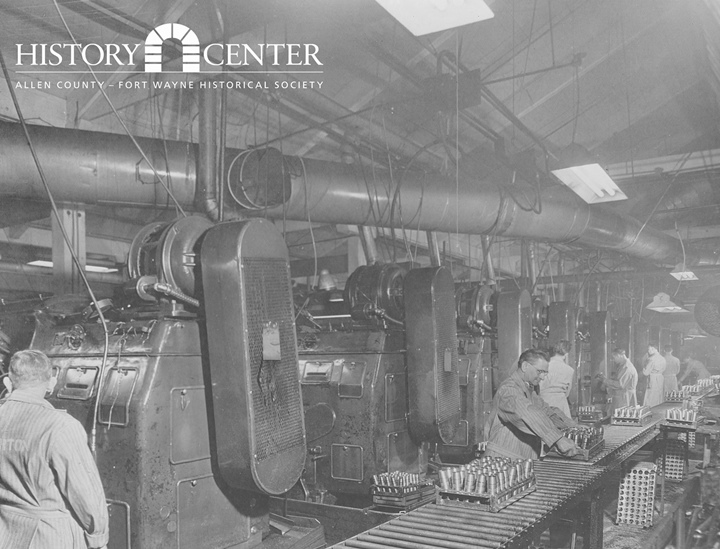

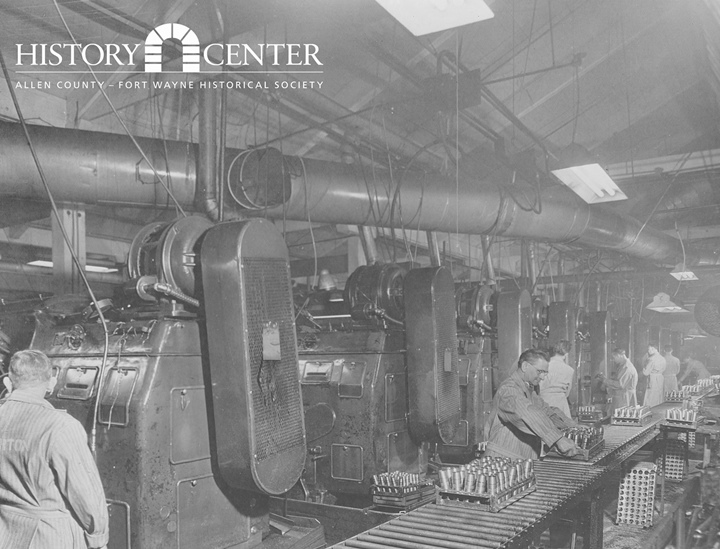

Horton Manufacturing received $373,000 in

both private and public funding to purchase equipment for the

manufacture of 40mm projectiles and tracer bodies for the U.S. Navy.

Most likely, Horton obtained rough forgings from a nearby forge.

The company then machined and heat treated the forgings to their final

dimensions. Photo courtesy of the Fort Wayne Historical Society.

The

funding program allowed Horton to tool up to produce 464,000 projectiles per

month by January 1943 and 365,000 tracer bodies by December 1943.

This image shows the final inspection of the projectiles before they are

boxed up and shipped out. This appears to be a random inspection

of the projectiles. A 40mm projectile weighed 1.985 lbs.

There are 50 projectiles in each metal rack, resulting in each rack

weighing 99.25 pounds. Photo courtesy of the Fort Wayne Historical

Society.

As the World War Two progressed in the Pacific, the 40mm Bofors

anti-aircraft with Horton Manufacturing-made projectiles and tracer

bodies became more important with the beginning of the Japanese kamikaze

attacks. This 40mm gun mount is one of several that are on the

destroyer USS Sullivans. Author's photo.

The USS Massachusetts bristles with 16-inch, 5-inch and 40mm guns.

Battleships and cruisers provided anti-aircraft protection for American

aircraft carriers during World War Two. Author's photo.

There are two gun tubs of four 40mm Bofors

guns each on the fantail of the USS Massachusetts with two dual 40mm Bofors

mounts in each. These are just eight of the many 40mm guns on the

ship. Author's photo.

Author's photo.

This photo of the Horton Manufacturing

Company shows a product that the company produced under subcontract from

the Stewart-Warner Company. The products shown in this photo are

aircraft engine heaters. In the foreground the workers are

assembling the heater sections of units. In the background, fuel

tanks are on an assembly line. Behind the heaters in the left of

the image are long tubes that transferred the heat to the aircraft

engines. Stewart-Warner had a plant in Indianapolis, IN, which had

a contract for the heaters which subcontracted the work to Horton in

Fort Wayne. Photo courtesy of the Fort Wayne Historical Society.

This image shows a typical heater.

These were very similar to today's "salamander" heaters.

This image shows two heaters warming the

engines and the B-24's cockpit area.

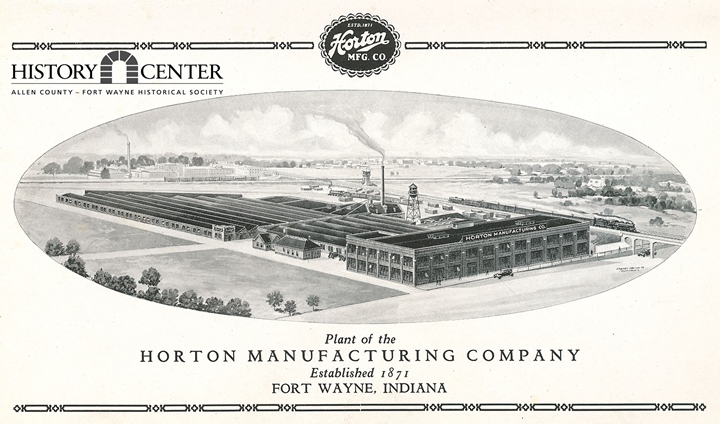

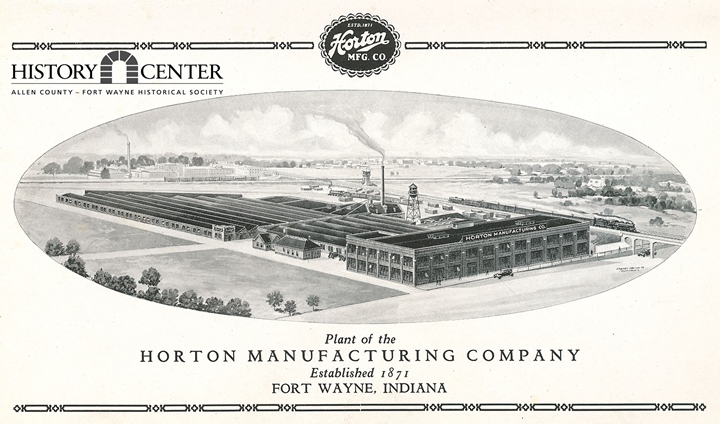

The Horton Manufacturing Company Factory:

The factory was located at 731 Osage Street in Fort Wayne.

This image is looking northwest with the

Osage Street running in front of the two story office building.

Image courtesy of the Fort Wayne Historical Society.

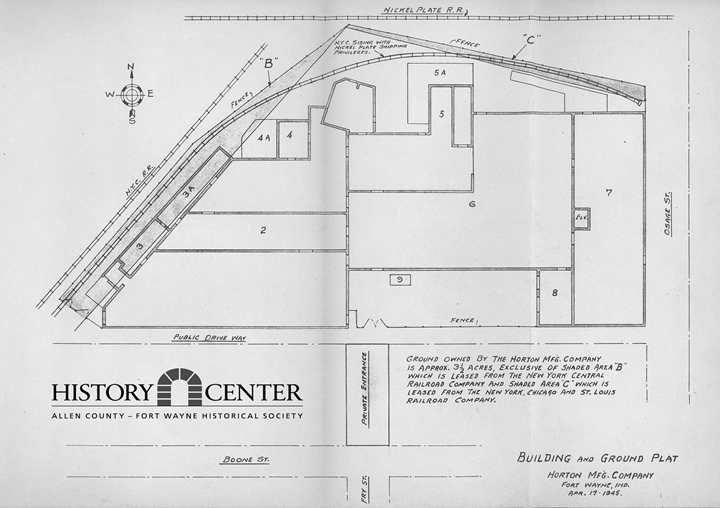

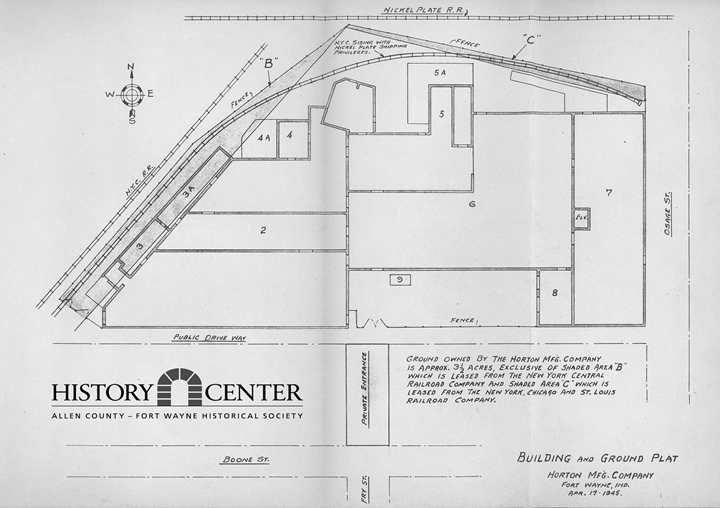

This image shows the factory layout in April

1945. Photo courtesy of the Fort Wayne Historical Society.

Seventy years after the Horton Manufacturing

Company went out of business, half of the 1945 plant is still in

existence and has been re-purposed for other uses. The office

building along Osage Street has been torn down along with the

manufacturing building on the west end of the complex. Image

courtesy of Google Maps.

This street view is from Osage Street and

shows the parking lot where the two story office building used to be.

Image courtesy of Google Maps.

|