|

Tokheim

Oil Tank and Pump Company in World War Two

Fort Wayne, IN

1901-1918 as Tokheim Manufacturing Company in Cedar Rapids, IA

1918-2012 as Tokheim

Oil Tank and Pump Company in Fort Wayne, IN

2016-Present as part of Dover Fueling Systems

This page updated 6-29-2023.

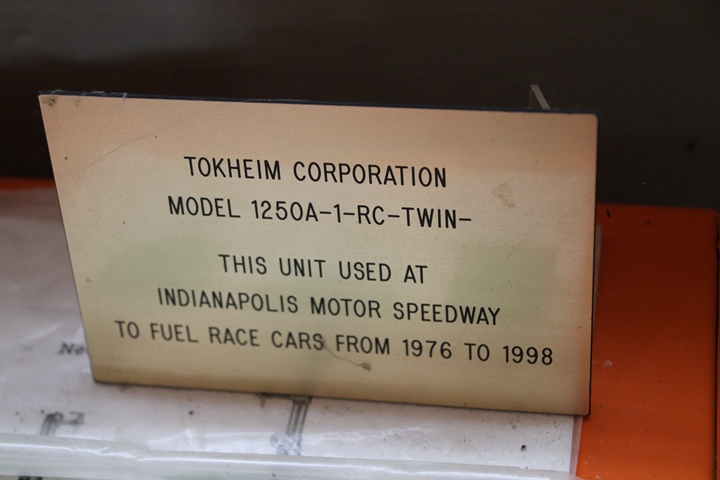

The Tokheim Oil Tank and Pump Company of

Fort Wayne, IN was best known for the manufacture of gasoline pumps

in the United States. Because at one time it was the largest

company in the world making gas pumps, most persons have filled up their

vehicle's gas tank using a Tokheim-built unit. The Tokheim

Oil Tank and Pump Company had its beginnings in the Tokheim

Manufacturing Company that was started by John J. Tokheim in Cedar Rapids,

IA. This Tokheim gas pump is on display at the National Auto and

Truck Museum in Auburn, IN. This photo was taken on a trip to the

museum in January 2022.

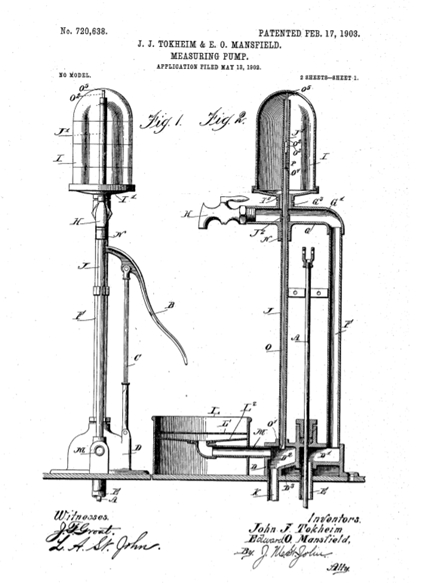

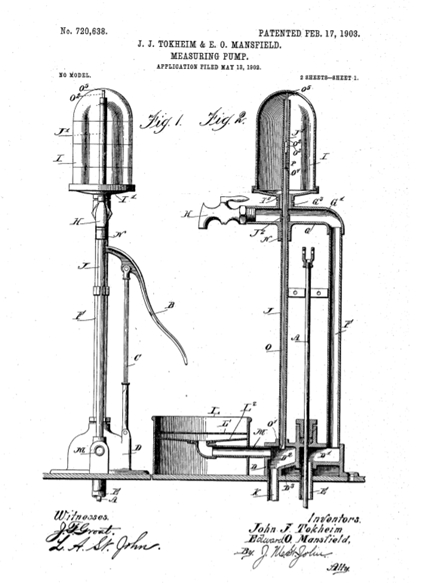

Mr. Tokheim's new company was based on his

patent for the first visible pump unit for dispensing gasoline for the

new automobiles that were becoming popular. He was so successful

that in 1918 a group of investors from Fort Wayne, IN purchased Mr. Tokheim's fuel and oil dispensing business and moved it to Fort Wayne. Tokheim was one of several companies

which began producing this

product line in Fort Wayne, making it for many years the world's gas

pump manufacturing capital. Today, Tokheim, along with another gas

pump company from Fort Wayne, are part of Dover Fueling Systems.

Unfortunately, there is no longer any gas pump manufacturing done in Fort

Wayne.

Sometimes one needs to return to a museum to

see what new displays have been added. I found this Tokheim Model

14 glass dome during my second trip in 2022 to the National Auto and

Truck Museum in December 2022. It was stuck back in the corner of

the museum's basement. It had been placed on display since my

previous visit in January 2022. This is the same type of pump as

shown in the patent above and was built in Cedar Rapids, IA. This

may be the oldest Tokheim gas pump in existence. Author's photo

added 6-29-2023.

Note that the patent date of Feb 1, 1903,

matches the date on patent 720,638 shown above. This also shows it

was made in Cedar Rapids, IA. Author's photo added 6-29-2023.

This view shows the original company name of

The Tokheim Manufacturing Company as it was first known in Cedar Rapids,

IA. Author's photo added 6-29-2023.

It was this pump that created a business

that lasted seventeen years in Cedar Rapids, IA and then 96 years in

Fort Wayne, IN. This pump was the predecessor of hundreds of

models and thousands of pumps built in Fort Wayne. Author's photo

added 6-29-2023.

The Tokheim Oil Tank and Pump Company won

the Army-Navy "E" Award four times during World War Two.

The first award was announced on January 11, 1943.

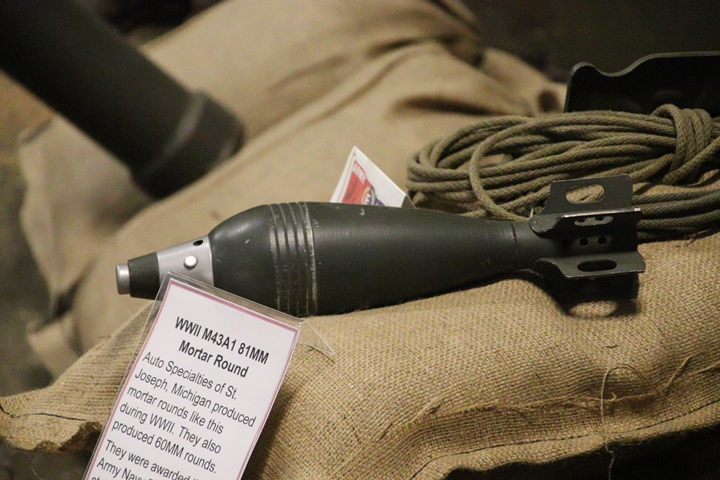

Tokheim World War Two Products:

Before Lend-Lease, which started on January 10, 1941, Tokheim contracted with the

British Contracting Commission in the United States to manufacture 250

pound aerial bombs and three-inch trench motor shells. This was

the start of Tokheim's war production that continued with the same type

of items after the United States entered World War Two in December 1941.

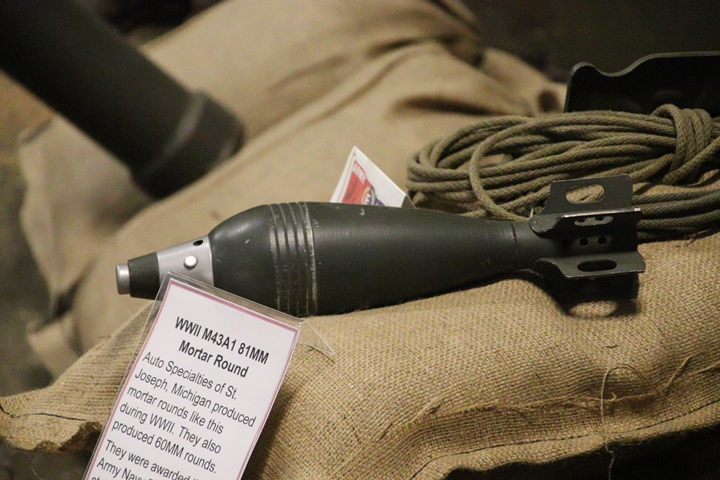

Table 1 shows that between October 1940 and March 1943, Tokheim

completed three U.S. government

orders for bombs totaling $6.3

million. Tokheim also had three contracts for rotary barrel pumps

and multiple contracts for 40mm armor piercing shot, 40mm high explosive shells, 81mm mortar shells, 60mm mortar shells, and one contract for

nozzle plate assemblies. The company had a total of $25,968,000 in

military contracts during World War Two.

|

Table 1- Tokheim

Oil Tank and Pump Company's

Major World War Two Contracts

The information below

comes from the "Alphabetical Listing of Major War Supply

Contracts, June 1940 through September 1945." This was

published by the Civilian Production Administration, Industrial

Statistics Division. Table added 12-6-2022. |

|

Product - Customer |

Contract Amount |

Contract Awarded

Date |

Completion

Date |

| Bombs -

Foreign |

$2,132,000 |

10-1940 |

10-1941 |

| Bombs Body -

Army |

$4,195,000 |

8-1941 |

4-1943 |

| Shot - Army |

$1,564,000 |

10-1941 |

9-1942 |

| Shot - Army |

$944,000 |

12-1941 |

9-1942 |

| Shot - Army |

$2,079,000 |

4-1942 |

3-1943 |

| Bombs - Army |

$57,000 |

4-1942 |

7-1942 |

| Shells - Army |

$2,181,000 |

4-1942 |

4-1943 |

| Pumps Rotary

- Navy |

$57,000 |

11-1942 |

3-1943 |

| Shot - Army |

$1,909,000 |

2-1943 |

11-1943 |

| Fuel Pumps -

Army |

$66,000 |

3-1943 |

12-1943 |

| Conversion

Services - Army |

$511,000 |

4-1943 |

10-1943 |

| Shell HE 81mm

- Army |

$302,000 |

5-1943 |

11-1943 |

| Shells 81mm

HE - Army |

$626,000 |

7-1943 |

6-1944 |

| Shot 40mm AP

- Army |

$558,000 |

7-1943 |

6-1944 |

| Shot 40mm AP

- Army |

$975,000 |

9-1943 |

3-1943 |

| Shells 81mm

HE - Army |

$619,000 |

9-1943 |

3-1943 |

| Practice

Shells - Army |

$384,000 |

9-1943 |

1-1944 |

| Shells 60mm

HE - Army |

$1,223,000 |

1-1944 |

10-1944 |

| Rotary Barrel

Pumps - Army |

$134,000 |

2-1944 |

8-1944 |

| Shot 40mm AP

- Army |

$412,000 |

2-1944 |

10-1944 |

| Nozzle Plate

Assys - Army |

$66,000 |

4-1944 |

6-1944 |

| Rotary Barrel

Pumps - Army |

$57,000 |

6-1944 |

11-1944 |

| Shells 40mm

HE QF Mk 2 |

$181,000 |

6-1944 |

10-1944 |

| Shot AP 40mm

M81A1 - Army |

$622,000 |

7-1944 |

12-1944 |

| Shot 40mm AP

M81A1 - Army |

$667,000 |

10-1944 |

3-1945 |

| Pumps - Army |

$165,000 |

12-1944 |

12-1945 |

| Shot Assys

40mm M81A1 - Army |

$633,000 |

1-1945 |

6-1945 |

| Shot 40mm AP

M81A1 - Army |

$584,000 |

1-1945 |

10-1945 |

| Shells 81mm

HE - Army |

$1,151,000 |

1-1945 |

9-1945 |

| Shells 60mm

HE - Army |

$824,000 |

2-1945 |

10-1945 |

| Total |

$25,968,000 |

|

|

Table 2 shows that seven of the nine major

product types accounted for 96% of

Tokhiem's major contracts during World War Two.

|

Table 2 -

Tokheim Oil Tank and Pump

Company's Major World War Two Product Categories

Table added 12-6-2022. |

|

Product |

Amount |

Percentage |

| Bombs and

Bomb Shells |

$6,384,000 |

24.6% |

| Shot -

(Assumed to be 37mm) |

6,496,000 |

25.0% |

|

Shot 40mm |

$4,451,000 |

17.2% |

| Shells 81mm |

$4,879,000 |

18.8% |

| Shells 60mm

HE |

$2,047,000 |

7.9% |

| Shells 40mm

HE QF Mk 2 |

$181,000 |

0.7% |

| Pumps -

Various |

$479,000 |

1.8% |

| Total

|

|

96% |

It is unknown what size aerial bombs Tokheim

made for American forces. This is an example of a 500 pound bomb

that was used extensively during World War Two. Author's photo.

An 81mm mortar round is shown in this image. Author's photo.

An 81mm mortar is shown at the top of the

image. Author's photo.

Tokheim also manufactured shells for the

60mm mortar. Author's photo added 12-6-2022.

The yellow shell is a high explosive shell like Tokheim made.

Author's photo added 12-6-2022.

Tokheim produced both 40mm armor piercing shot

and

high explosive shells. The company was tooled to make 263,000 40mm

shells per month. Author's photo.

Members of the 466th AAA

Automatic Weapons Battalion (Colored) are depicted in this full scale

diorama of loading a 40mm Bofors gun in readiness for an enemy attack on

Dreger Airfield in northeast New Guinea during World War Two. This and other

dioramas are on display at the National Museum of the United States Army

at Fort Belvoir, VA. The 466th AAA Automatic Weapons Battalion was

one of two segregated all African-American anti-aircraft units that

served at Dreger Airfield in 1944. Author's photo.

U.S. Army acquisition of 12,062,000 rounds of armor-piercing 40mm

ammunition started September 1942 and ceased production in June 1945.

Tokheim would have produced a portion of this volume. Each 40mm round weighed 4.75

pounds. Each four round clip weighed over nineteen pounds.

This diorama depicts the size of the clip in relation to the soldier

holding it. Author's photo.

This is a collection of three different

types of 37mm ammunition with an M17 armor piercing round at the top and

an M16 armor piercing at the bottom. Author's photo.

Tokheim was tooled to manufacture

187,000 37mm armor piercing shot per month. Author's photo.

The size of the entire 37mm shell and the

shot made by Tokheim can be seen in relation to the World War Two

tanker's helmet in the photo. Author's photo.

Author's photo.

This is a 37mm shot with a brass ring on

it. It is unknown whether Tokheim added the ring. Author's

photo.

The hole in the rear of the shot allowed for

tracer material to be added. Author's photo.

Below is a series of photos showing the

different types of weapons used 37mm armor piercing shot produced by Tokheim in World War Two.

At the beginning of World War Two, the 37mm

anti-tank gun was the primary towed weapon of this type used by the U.S.

Army. It soon became obsolete as German tanks added more armor

plate. Author's photo.

The M3 and M3A1 series light tank was the

light tank of the U.S. Army and USMC at the start of the war. It

was superseded in American service by the M5 series light tank.

However, other Allied forces continued to use the M3 and M3A1 series

light tank until the end of the war.

Author's photo.

The M5A1 replaced the M3 series light tank with U.S. forces and was

still in use at the end of the war. Author's photo.

The M3 towed anti-aircraft gun also used

armor piercing ammunition. Author's photo.

The M15A1 half-track was used to carry anti-aircraft weapons. Author's photo.

This photo shows the M1A2 37mm anti-aircraft

gun mounted above the M2 .50 Browning machine guns. Author's

photo.

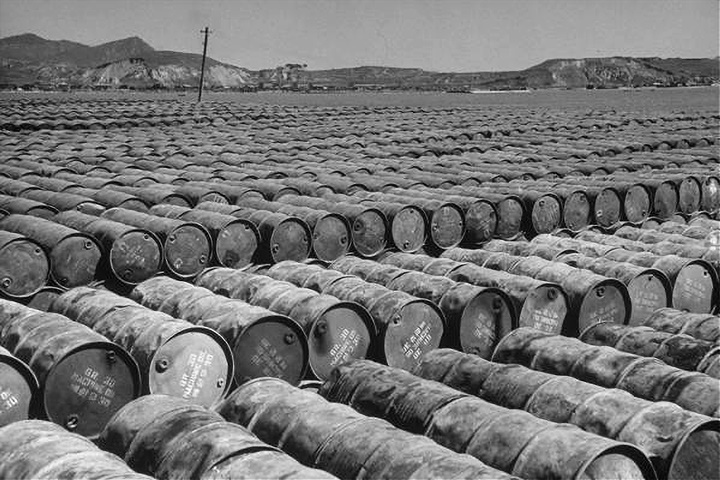

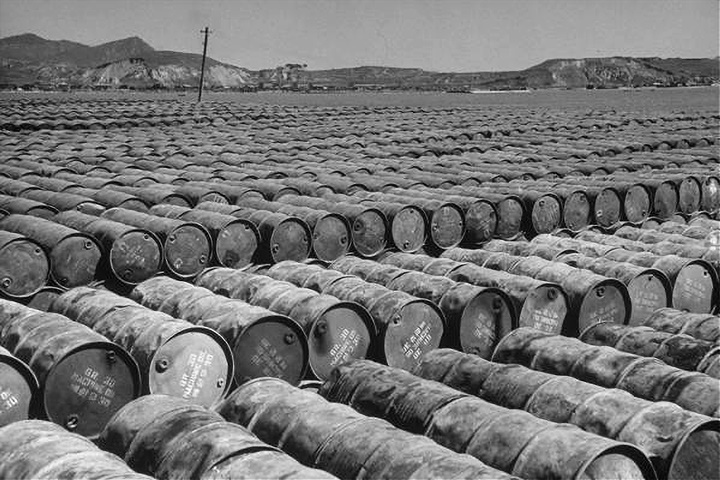

This World War Two B-29 base in China has

hundreds of 55 gallon fuel barrels in storage. A B-29 could take

on 1,350 gallons of fuel in its center section wing tanks which was 24.5

barrels. The fuel was pumped out of the barrels at the pumping

station behind the storage area into fuel trucks which then delivered

the fuel to the aircraft. One B-29 attack on Japan in July 1945

consisted of 75 B-29s which required 1,840 barrels to be emptied.

Pumps made by Tokheim were a very important, but unrecognized tool to

keep the United States' fleet of aircraft, PT boats, trucks, armored

vehicles, electrical generators, and other motorized equipment running.

A soldier is pumping fuel from a 55 gallon

barrel in the Aleutian Islands.

A barrel storage area in the Aleutians.

A barrel storage area in southern France at

the end of World War Two. From the damage many of the barrels have

suffered, these appear to be empties.

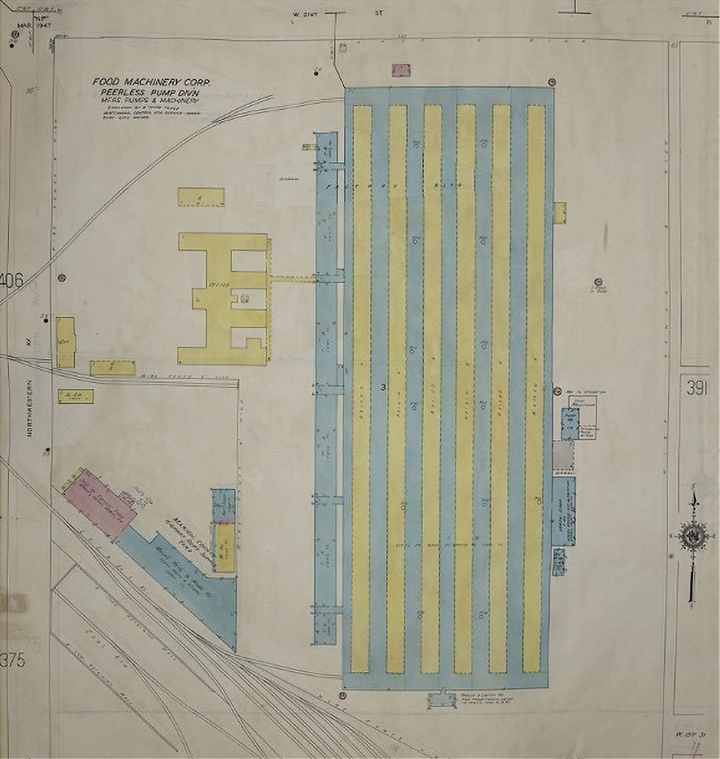

The Plants: The Tokheim plant was

located at the intersection of Wayne Trace and Wabash Avenue in Fort

Wayne during World War Two.

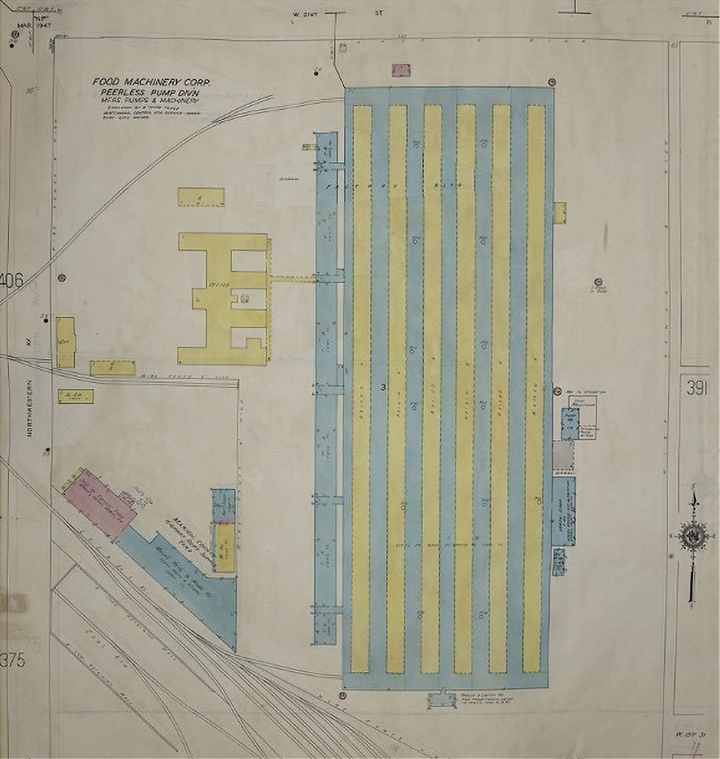

This 1951 Sanborn fire insurance map shows

the location and size of the factory as it was during World War Two.

This current Google Maps satellite view

shows the former Tokheim plant at present. The houses that were on

the east side of Fletcher Avenue in 1951 were razed as the plant

expanded to the west. The plant also expanded east with the houses

on Wabash Avenue and Dubois Street razed.

The plant in the center of the above photo has

been razed. The remaining plants are still standing and in use.

Current Photos of the former Tokheim plant

in Fort Wayne: It is always so depressing to visit a former

plant site like the former Tokheim plant complex. It did not help

that it was an overcast day in early December 2022 which helped set the

somber mood.

The former Tokheim water tower still stands

tall over what remains of the Tokheim facility. Some of the plants

in the complex have been razed, while others have not, and are still

being used by other companies. It is a familiar story I have

unfortunately seen too many times. Author's photo added 6-29-2023.

Author's photo added 6-29-2023.

Author's photo added 6-29-2023.

There is a small traffic circle in the

center of this Google satellite view. There appears to have been a

flag pole at this location when Tokheim occupied the site. Also,

where the pointer is located there is some blue on the former plant

floor. This appears to have been the visitor entrance to the

facility.

This is the traffic circle looking south.

To the right in the photo, a small amount of the blue floor of the

visitor entrance can be seen. Author's photo added 6-29-2023.

This is the traffic circle looking east.

Behind me is where the visitor entrance to the plant appears to have

been. It appears that a flag pole was located in the in center

concrete pad in the center of the circle. Author's photo added

6-29-2023.

The main entrance appears to have been to

been on the left. Guests and visitors would enter and be greeted

by a receptionist at a desk directly beyond the entrance. In the

remaining area, there would have been chairs for visitors to sit on

while waiting to be escorted into the plant. The special floor and

traffic circle outside indicates to me that this was the visitor

entrance. Author's photo added 6-29-2023.

I spent many years picking up visitors in the

lobby of the plant where I worked. At the same time, I visited

many supplier factories as part of my job. As soon as I saw this,

I knew what it was.

Author's photo added 6-29-2023.

Looking south from the plant lobby, one can

see that this plant has been razed. The plants on either side of

this former building still stand. Author's photo added 6-29-2023.

When the plant was taken down, the factory

floor was left in place. The building to the west that was not

taken down is either of newer metal construction or has been recovered.

Author's photo added 6-29-2023.

Author's photo added 6-29-2023.

There is still some red brick rubble on the

ground indicating this used to be a red brick building. Author's

photo added 6-29-2023.

Here is more evidence that the building was

constructed of red brick. Author's photo added 6-29-2023.

This is looking north from Wayne Trace at

the same floor of the razed building as shown in the above photos.

Author's photo added 6-29-2023.

Directly to the west of the razed building

is this three story red brick factory building that was not razed and is

still in use. Author's photo added 6-29-2023.

This Google Maps satellite view shows a

building to the east of the razed factory.

This view shows that this building was a

single story structure. To me, it has the looks of an engineering

test laboratory. Author's photo added 6-29-2023.

Author's photo added 6-29-2023.

I found this sign among the trees. Not

everything was razed or removed. Author's photo added 6-29-2023.

Because the sign still exists, it allowed me

to determine that this was the former Tokheim Athletic Clubhouse.

Author's photo added 6-29-2023.

Tokheim Engineering Company in

Indianapolis, IN - This was a subsidiary of Tokheim that was set up

to operate the Fall Creek Ordnance plant at 2005 Northwestern Avenue in

Indianapolis, IN. The plant, managed by another company,

originally made armor plate for the Army, but the operation ceased in

December 1944. In December 1944, Tokheim proposed to the U.S.

Army, which owned the plant, to take over management of the facility and

make 105mm artillery shells.

The $5 million Fall Creek Ordnance plant at the corner of 2005

Northwestern Avenue and 21st Street in Indianapolis, IN was built for

the manufacture of armor plate. It began production with 700

employees in early 1943 and ended in December 1943. Lack of demand

for the armor plate resulted in the closure of the 270,000 square foot facility.

In December 1944, Tokheim proposed to Army Ordnance to take over the

plant and produce much needed 105mm artillery shells. The Tokheim

Engineering Corporation, a subsidiary of Tokheim Oil Pump and Tank

Company, was formed to run the plant. In February 1945, work began

on installing $990,000 worth of equipment in the plant to produce the

shells. The expected work force for the plant at full production

was 2,000 persons. With the end of war six months later,

production never got under way.

The above photo is looking northeast.

Currently, I-65 is located just to the east of the plant, and all of the

houses shown no longer exist.

After the war, the plant was sold to the Food Machinery Corporation for

its Peerless Pump Division. Peerless Pump is still in the

facility, although the ownership of it has changed.

This Sanborn map shows the former Fall Creek

Ordnance plant in 1950.

This current Google Maps Satellite view

shows I-65 going around the facility on the near north side of

Indianapolis, IN.

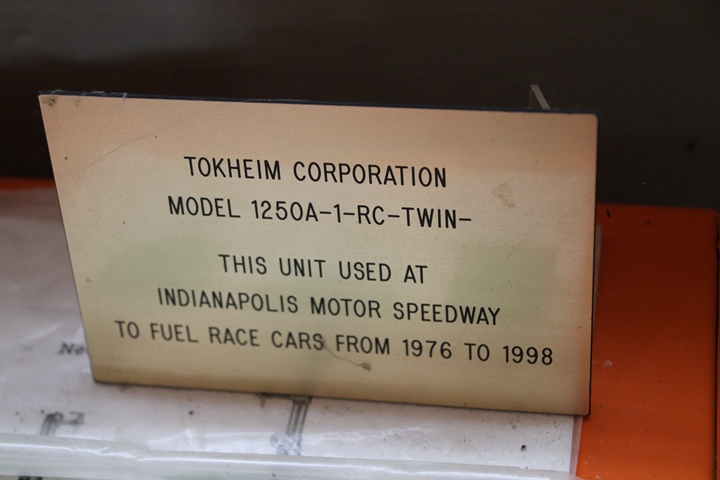

Tokheim Dispensing Equipment:

The Tokheim Oil Tank and Pump Company's main

product line for which it is best known is its gasoline dispensing

pumps. Most adults who have stopped at a gas station to put gasoline

in their vehicle have used a Tokheim gas pump. For many years, the

company was the largest manufacturer of gas pumps in the United States.

All of the photos of Tokheim products in this

section were taken by the author at the National Automotive and Truck

Museum in Auburn, IN. The museum not only has an excellent

collection of cars and trucks on display, but it also has a large number of Tokheim gas and oil pumps. Many of the vehicles at the museum can

be seen in the backgrounds of these gas pump photos.

This is a 1920s era Tokheim Model Cut 140 self-measuring oil dispenser.

This appears to be the manner in which persons purchased their engine

oil before the large scale use of quart containers. During World

War Two, Tokheim supplied rotary barrel pumps to the military. Tokheim's experience in producing these for the civilian market allowed

it to furnish similar items for the war effort.

This is a Hi-Way Visible Gas Dispenser

produced between 1920-1924 to dispense White Eagle gasoline.

This is the earliest dated Tokheim gasoline

pump in the museum.

This pump is serial number 406331.

The early pumps had no means of indicating

the amount of fuel that was being dispensed.

The 1923 model is the oldest Tokheim gas pump on

display that

indicates the gallons dispensed with a clock-type dial face. It also has a

white hose and brass nozzle which were common for the era. This

pump was designed exclusively for the Gulf Oil Company.

This is a 1930 Tokheim Model 850 Twin.

With the introduction of Ethyl into gasoline to reduce knock, gas

station owners had two types of fuel to sell. With today's mega

gas stations with dozens of pumps with multiple grades of gas, it is

probably unknown to many that in the 1930's, a gas station had just about this amount of

space for its pumps. The service stations of that era were not

all that large, as there were not that many vehicles on the road.

Many gas stations were located on the corner of intersections and had

just enough room for a couple of cars at a time. The Tokheim Model

850 Twin saved valuable space with being able to dispense two

types of fuel.

Clock-type dial faces gave the number of

dispensed gallons of fuel. The pumps had white hoses, brass

nozzles, and glass containers at the top of the pumps to allow the

customer to see the fuel going into the hose.

Shown here is a Tokheim Model 800 commercial dispensing unit that was in

production from 1934-1950. This pump would have been one of

Tokheim's products that was in use during World War Two.

The Tokheim gas pumps at the museum are also

a look back at many of the former companies that sold gasoline and have

gone by the wayside.

This 1935-1938 model 36 pump with

merchandise display case is the oldest dated Tokheim gas pump with a

digital display. The display case allowed the gas station owner to

display merchandise at the gasoline point of sale location.

This oil pump dispensed one quart per stroke

of the handle.

I remember the lighted crowns on the

Standard gas pumps.

These Standard Oil pumps don't have the

crown.

The Tokheim

Model 300 was manufactured 1955-1960. Behind the Model 300 is a 1966 Olds Toronado and

a 1963 Studebaker

Avanti.

I also remember the shell on top of the

Shell gasoline pumps.

A Marathon MILE-maker Tokheim gas pump with

a 1962 Pontiac Grand Prix and an Oldsmobile 1966 442 behind it.

This Tokheim pump was used by companies that had

their own supply of gasoline. Therefore, there was no need to show

the cost of the gasoline pumped. Only the number of gallons was

needed to be shown on the pump. I used similar pumps during my

work career.

I remember pumping regular gasoline from

pumps like this prior to 1973, when I lived in Michigan.

|