|

Winged Target - Mark 1 Manual

Rudolf Wurlitzer Company During World War Two

DeKalb Division

DeKalb, IL

1919-1973

Rudolf Wurlitzer Company

1856-1986

This page added 8-3-2023.

The Rudolf Wurlitzer Company is best known for

its manufacture of musical instruments. Previous to World War Two,

the DeKalb Division in DeKalb, IL produced pianos. However, during

World War Two, the Wurlitzer DeKalb Division produced wooden air frames

for two of the U.S. Navy's most secret drone and guided bomb projects.

These aircraft were cutting edge technology for the era and would be labeled high-tech in the current vernacular.

The company also produced tubular steel air targets for the U.S. Navy.

While the U.S. Navy picked the Wurlitzer DeKalb Division for its wood

working ability for the drone and guided bomb project, the manufacture

of the steel air frames was not within its pre-war technology base.

The company had to develop new manufacturing methods within the division

to make this product.

The DeKalb Division of the Rudolf Wurlitzer

Company has not been recognized for the work it did on secret and

cutting edge military weapons during World War Two. This page will

show how the company helped to introduce new aviation technology during World War Two.

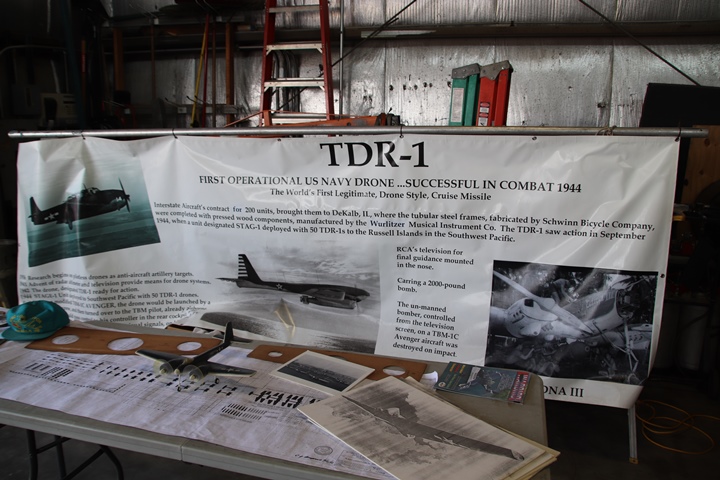

This TDR drone is on display at the National

Naval Aviation Museum in Pensacola, FL. While the Interstate

Aircraft and Engineering Corporation of El Segundo, CA was the prime contractor for the TDR series of drones, the Wurlitzer DeKalb Division manufactured all of

the wooden airframe components. This weapon was guided to its

target by a television camera located in the nose. Author's

photo.

This is ASM-N-2 Bat is on display at

the Udvar-Hazy Center of the National Air and Space Museum. All of

the gray airframe on this weapon was built by Wurlitzer DeKalb.

The Bat had its own radar and was able to paint the target and then

direct itself to the target. All of the electronics and guidance

systems were enclosed in the Wurlitzer-built steel and wooden air frame.

This was the world's first operational smart bomb. Author's photo.

Not only did Wurlitzer

DeKalb produce the wooden air frames for the first Navy drones and smart bombs,

but examples of them are in two of the premier aviation museums in the

United States.

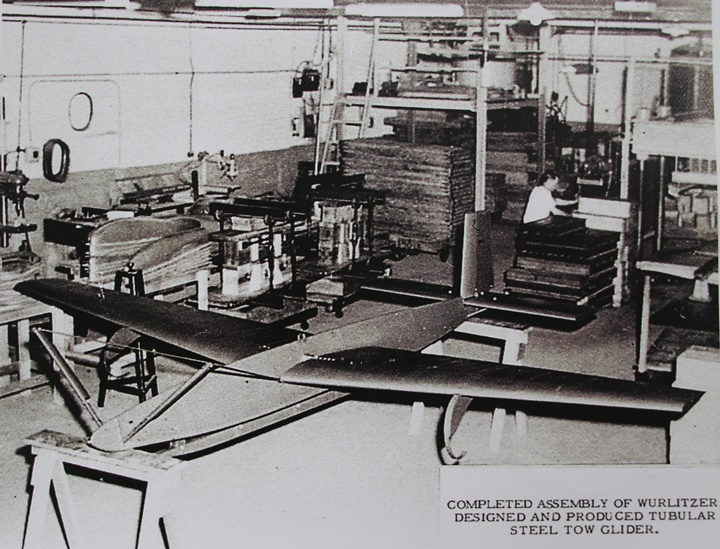

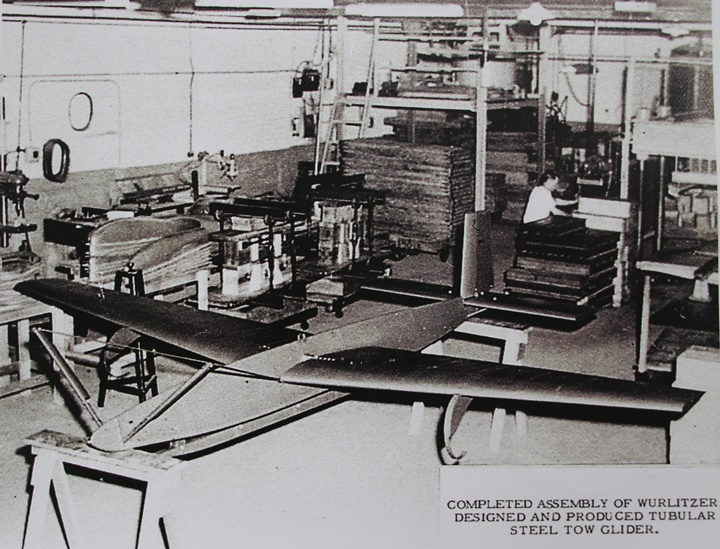

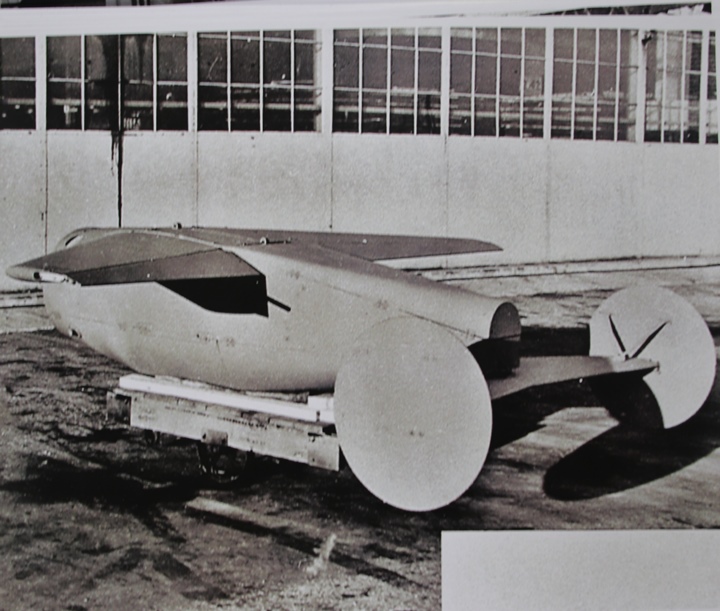

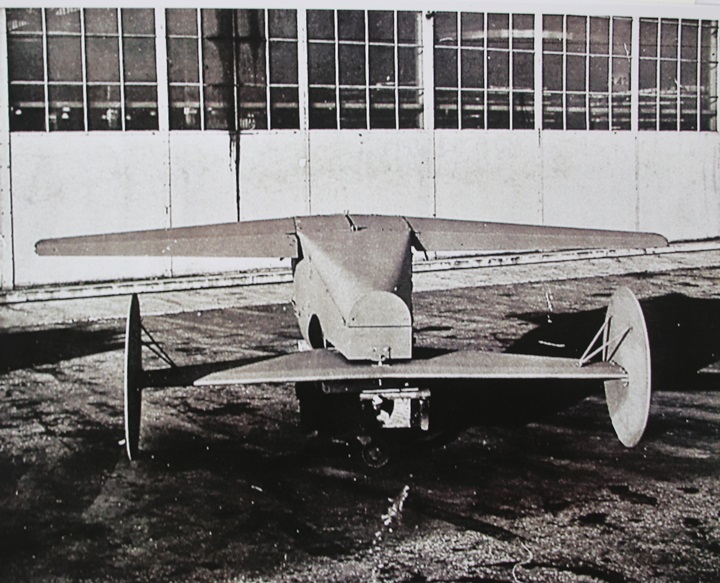

The third product Wurlitzer DeKalb designed

and manufactured was this steel tow target. While the previous two

products air frames were mostly wood, this had a steel frame and was

covered with plywood. Also, for the previous two products,

Wurlitzer DeKalb was given engineering drawings by the prime contractors

from which to make the air frames. In this case, a piano

manufacturer designed a small steel aircraft. This is confirmed by

the fact that Wurlitzer DeKalb Division is recognized as the designer

and supplier in the U.S. Navy's manual for the Mark I Aerial Target.

Photo courtesy of the DeKalb County History Center.

Pianos don't fly and are made largely out of wood.

The World War Two products of the Wurlitzer DeKalb Division demonstrate

that during World War Two American companies made and developed products

totally outside of their pre-war product expertise. Product and

manufacturing engineers rolled up their sleeves, pulled out their

slide rules, and designed and built what was required to help win World

War Two.

The hard work at the Rudolf Wurlitzer Company, DeKalb

Division resulted in it winning the Army-Navy "E" Award three times during World War Two.

It won the first award on May 18, 1944, the second award on January 18,

1945, and its last award on September 8, 1945.

Company History: In 1856, Rudolf

Wurlitzer began selling musical instruments in Cincinnati, OH. Until 1908, the company was

exclusively a retail operation with one store in

Cincinnati. In 1908, the Rudolf Wurlitzer Company purchased a

musical instrument manufacturing company in North Tonawanda, NY.

With this and several other musical company purchases, Wurlitzer became

a well known manufacturer of a variety of musical instruments.

In 1919, Wurlitzer purchased the

Melville-Clark Piano Company of DeKalb, IL. This plant continued

to make pianos under several different brand names for Wurlitzer until the beginning

of World War Two, when it switched to war production as documented on

this webpage. After World War Two, the DeKalb plant once again

manufactured pianos until 1973, when it ceased production of the product

line. In 1977, the company's headquarters and engineering staff

from North Tonawanda moved to the DeKalb facility. It was here that the

Rudolf Wurlitzer Company made its last stand before being sold to the

Baldwin Piano Company in 1986.

Luckily, all of the corporate records were

saved and are now part of the historical collection of the Northern

Illinois University in DeKalb, IL.

Rudolf Wurlitzer Company World War Two

Products:

Table 1 -

Rudolf Wurlitzer

Company's Major World War Two Contracts

The information below

comes from the "Alphabetical Listing of Major War Supply

Contracts, June 1940 through September 1945." This was

published by the Civilian Production Administration, Industrial

Statistics Division. |

|

Product - Customer |

Contract Number |

Contract Amount |

Contract Awarded

Date |

Completion

Date |

| Pianos - Army

Quartermaster Corps |

950-QM-04160 |

$63,000 |

6-1942 |

11-1942 |

| Winged Targets -

Navy |

OA-3943 |

$779,000 |

6-1944 |

11-1944 |

| Winged Targets -

Navy |

OA-5322 |

$55,000 |

1-1945 |

5-1945 |

| Winged Targets Mk

2 - Navy |

OA-6200 |

$52,000 |

3-1945 |

4-1945 |

| Air Stabilizers -

Navy Ordnance |

ORD-8520 |

$3,397,000 |

3-1945 |

5-1946 |

| Total |

|

$4,346,000 |

|

|

Army Quartermaster Corps Contract 950-QM-04160

was for $63,000 worth of pianos. Wurlitzer DeKalb Division's first

contract was for its peacetime product. In 1942 a bottom line

spinet piano in the civilian market cost $225. If we assume the

Quartermaster Corps purchased basic spinets for its on-base service

centers and clubs at $225 each, then it purchased 280 pianos. If

the Army paid less because of the quantity purchase, such as $200 per

piano, then 315 were obtained. Every military unit seemed to have

several piano players in it who would entertain others with their talent. Pianos were

staples of service centers, USOs, officers' clubs, and enlisted men's

clubs.

Next, the Wurlitzer DeKalb Division began

producing wooden aircraft components for the war effort. The size

of these contracts were either smaller than the $50,000 minimum required

to appear

on the major contract list, or the division was contracting directly

with the aircraft manufacturers.

On September 26, 1942, it was announced in the

DeKalb Daily Chronicle headlines that "NAVY AIRPLANES ARE TO BE BUILT IN

DEKALB." This was a really big deal for the DeKalb area as it did

not previously have much war work. Building aircraft for the U.S.

Navy, which were important weapons in the war, was an exciting product

for the area. The article noted that DeKalb was picked because of

the Wurlitzer DeKalb Division's expertise in manufacturing wood

products.

Navy winged targets contracts OA-3943, OA-5322,

and OA-6200 totaled $886,000, which was 20% of the division's total World

War Two contracts. The Navy's $3,397,000 contract ORD-8520 for Air

Stabilizers was 78% of the division's contracts. The description

of Air Stabilizers appears to have been the contract for the ASM-N-2 Bat

air frames and was used to disguise the actual top secret nature of the

product.

Interstate Aircraft and Engineering

Corporation was awarded a $14,525,000 Navy contract to build TDR drones

in DeKalb, IL. A percentage of this amount was used to purchase

the molded wood air frame components from the Wurlitzer DeKalb Division.

TDR Drones:

This and the next five photos are of the TDR

drone that is on display at the National Naval Aviation Museum in

Pensacola, FL. The photos give different views and perspectives of

this aircraft. It is the only known example left of the 195 built.

This should not be surprising because firstly, they were flown directly

into the target and destroyed; and secondly, being made of wood, they

were subject to rot and insect destruction. Author's photo.

Author's photo.

Author's photo.

Author's photo.

Author's photo.

In the nose of the aircraft is the location

of a television camera. The signal from the camera was transmitted

to another aircraft where the drone operator monitored the drone's

signals on a television receiver. The drone operator then used a

joy stick to guide the drone to the target. Author's photo.

The Early Television Museum in Hilliard, OH

has some of the RCA television equipment used in the TDR drone. On the

left is the television camera that was located in the nose of the TDR;

and on the right is the receiver the operator looked at in the control

aircraft to direct the drone. Author's photo.

Author's photo.

Author's photo.

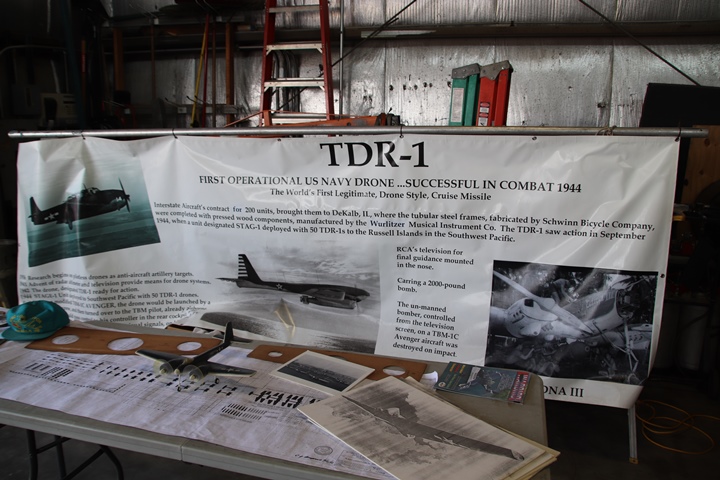

The Roger Keys Collection: Mr.

Keys has spent many years researching and collecting information on the

production of the TDR drone in DeKalb, IL. He is the subject

matter expert on TDR drone production. The following photos were

taken at the 2023 TBM Reunion in Peru, IL. Mr. Keys had both an

inside and outside display on the TDR at the event.

This and the next six photos are of Mr.

Keys' outside display. These are Wurlitzer-built components that

Mr. Keys rescued from the company's former factory. This and the

next three photos are examples of the wing spars. Author's photo.

Author's photo.

Author's photo.

Author's photo.

Mr. Keys was able to rescue this rear

fuselage section of the TDR from the former Wurlitzer plant.

Author's photo.

This pilot canopy is also part of Mr. Keys'

collection. The TDR could either be flown by a pilot or remotely

controlled from another aircraft. Once the aircraft was assembled

in the Interstate factory in DeKalb, U.S. Navy pilots then did test

flights in them to assure they were properly assembled. The TDRs

had a limited range. In the vast Pacific where they operated, a

pilot would fly the aircraft to a location near the final target.

There, navy technicians removed the canopy and replaced it with a

conformal fairing. Author's photo.

Author's photo.

This image shows Mr. Keys' display inside

one of the hangars during the TBM reunion. Author's photo.

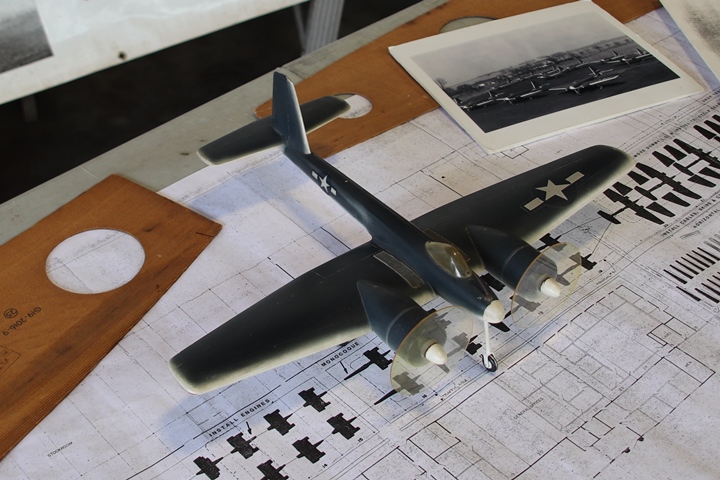

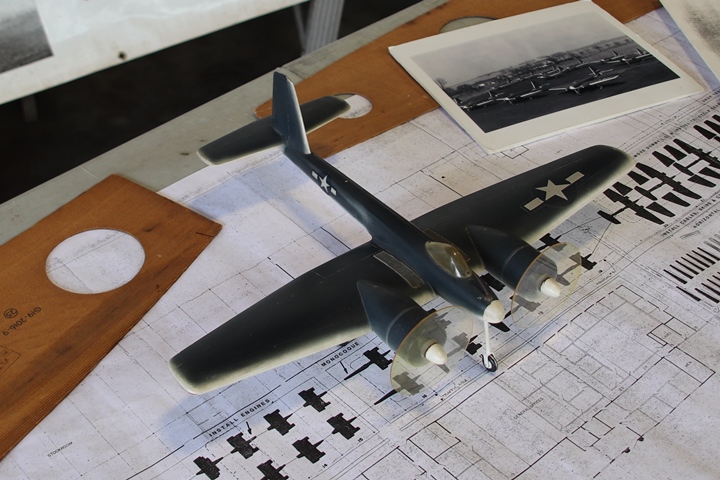

This model of the TDR drone set Mr.

Keys on his lifetime research of the aircraft. He found this many

years ago at a rummage sale and purchased it. However, he did not

know what it was and for many years attempted to find out what type of

aircraft this was. Finally, he met a person that explained its

significance and that it was built in DeKalb, IL. He then began

his research project on the TDR and the collection of the parts from the

Wurlitzer factory. Author's photo.

Mr. Keys was able to rescue two cockpit

canopy assemblies. This one is on display at the DeKalb County

History Center. Author's photo.

ASM-N-2 Bat: Wurlitzer

performance in building air frames for the TDR drone must have impressed

the U.S. Navy. Once the TDR contract was terminated, the company

was awarded U.S. Navy contract ORD-8520 for $3,397,000 to build the air

frames for the ASM-N-2 Bat. One source shows that Wurlitzer built

2,580 air frames for the Bat, making it the company's largest production

run of World War Two. However, it appears that production only ran

between March 1945 and September 1945. The 2,580 figure may well

be overstated. The important fact to remember is that a piano

maker made the airframes for this World War Two high-tech secret weapon.

This Wurlitzer-built ASM-N-2 Bat is on display at

the Udvar-Hazy Center of the National Air and Space Museum.

Author's photo.

Author's photo.

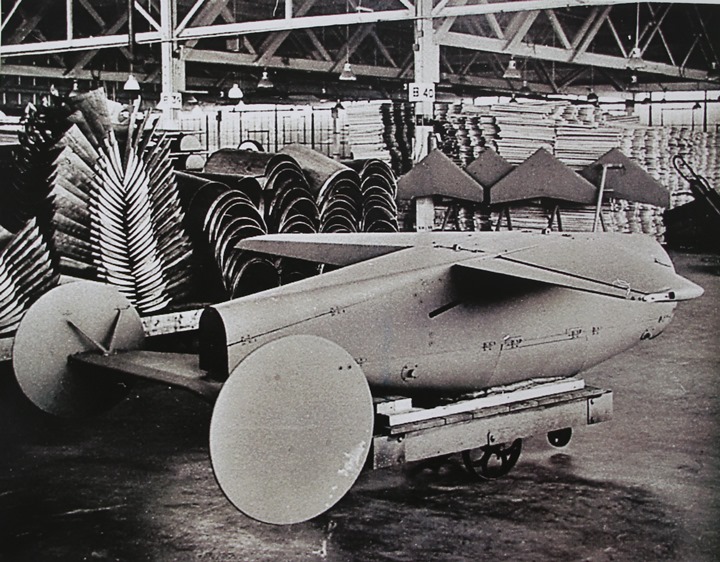

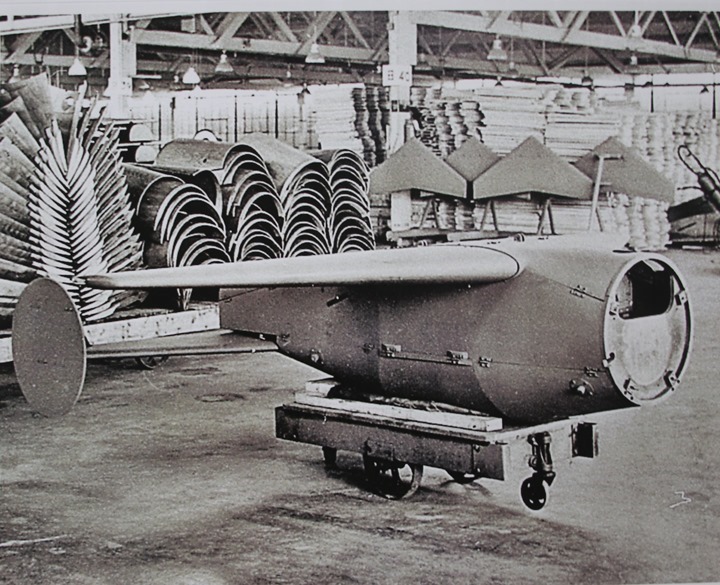

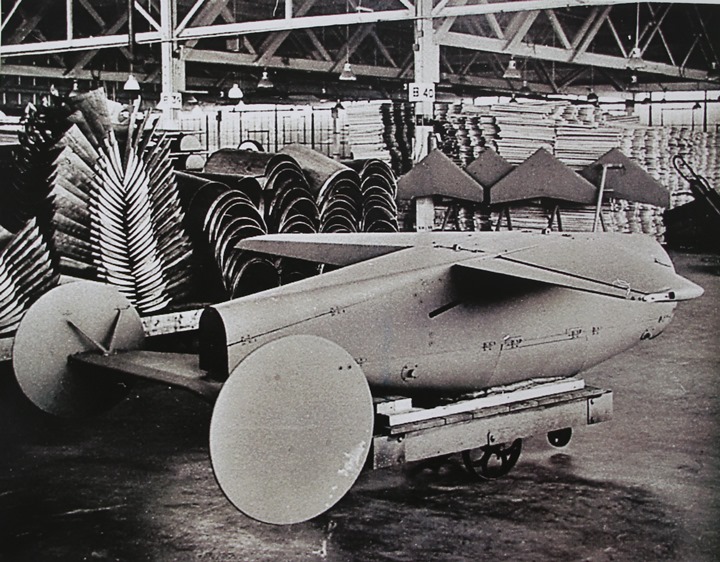

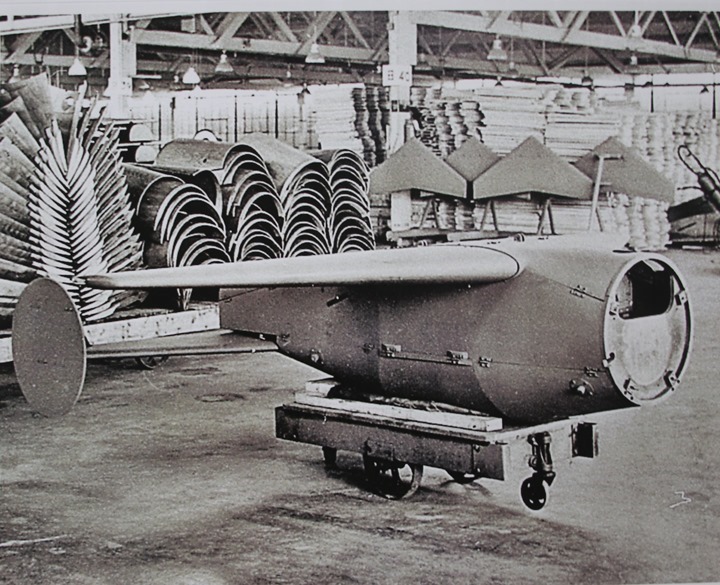

This and the next two images show a finished

Bat and the inventory of parts in the former Interstate plant.

Once the TDR project ended, the U.S. Navy gave possession of the former

Interstate final assembly plant to Wurlitzer to build the ASM-N-2.

Photo courtesy of the DeKalb County History Center.

Photo courtesy of the DeKalb County History

Center.

Photo courtesy of the DeKalb County History

Center.

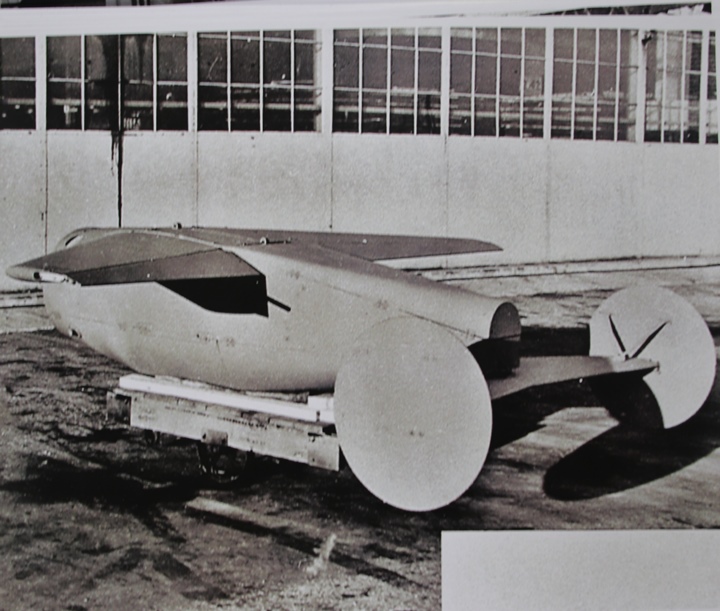

This and the next image show ASM-N-2 outside

the factory. Photo courtesy of the DeKalb County History Center.

Photo courtesy of the DeKalb County History

Center.

This image shows the ASM-N-2 Bat on the wing

of a PB4Y-2.

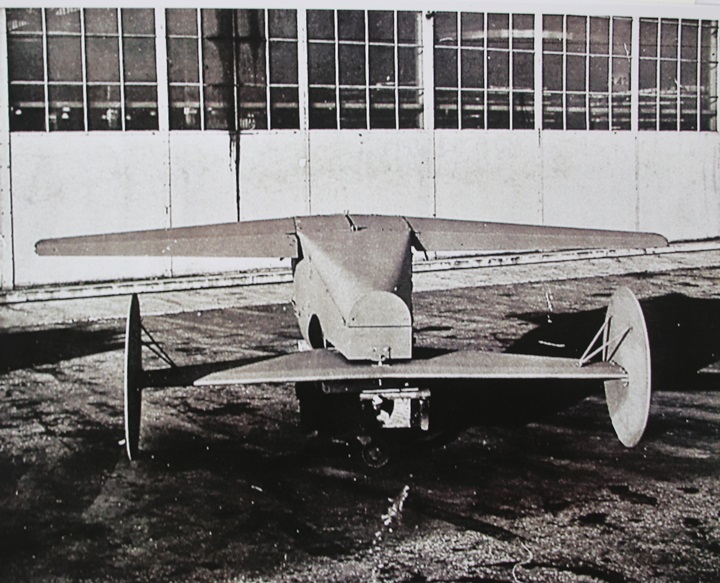

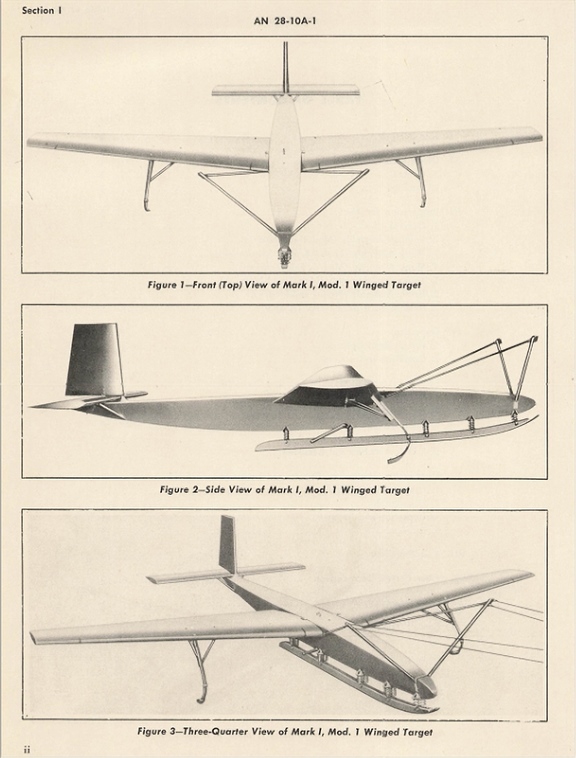

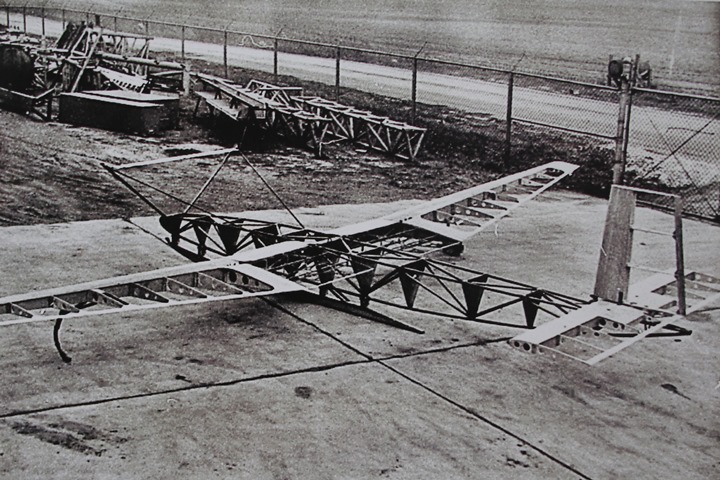

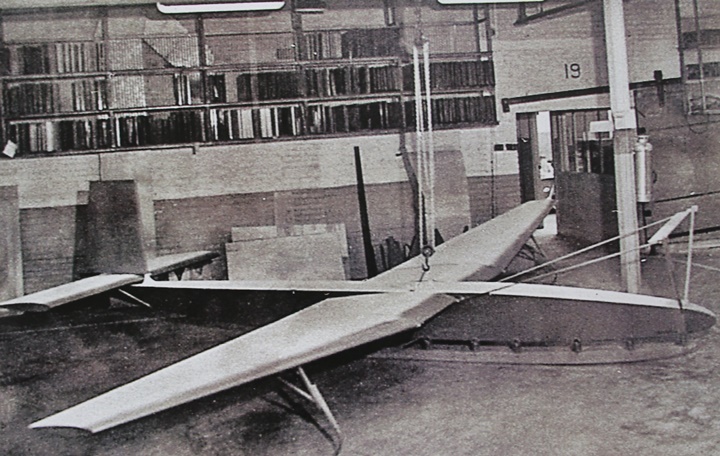

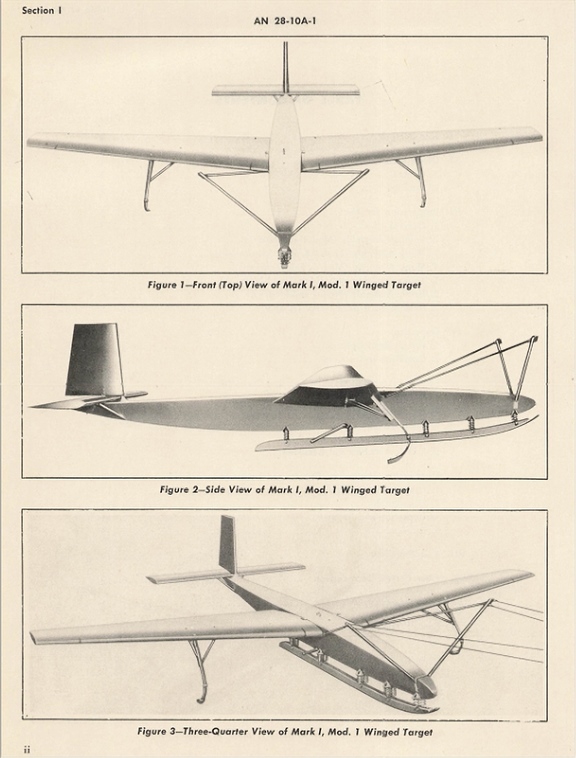

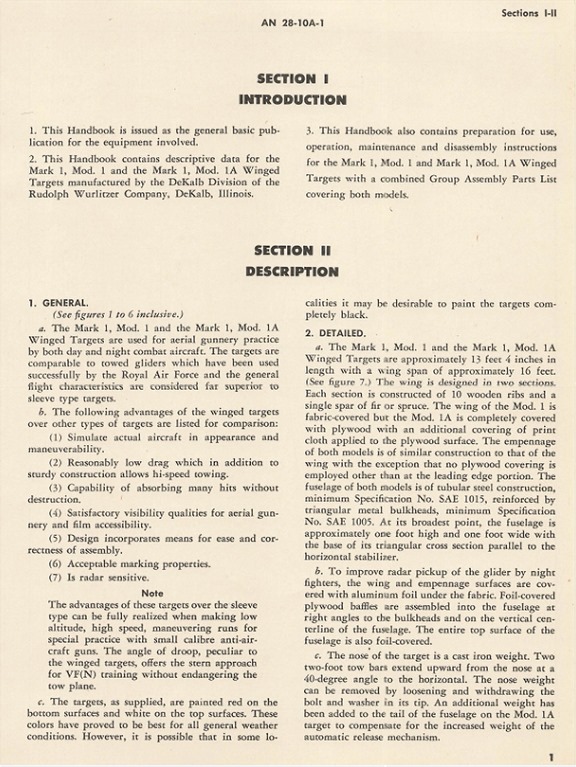

Winged Targets:

This is the most interesting and, at the same time, the most unknown

of the DeKalb Division of Wurlitzer's World War Two products. It

is interesting in that it was a metal frame winged target covered with

either plywood or fabric, depending on the model. Steel

fabricating was not Wurlitzer's forte, so it may have performed the

design work and had the steel frame welded at an outside supplier.

The Mark 1 winged targets are virtually unknown to current historians.

It was only because the DeKalb County History Center has photos in its

collection that I was able to discover that Wurlitzer manufactured them

for the U.S. Navy during World War Two.

It is unknown how many were produced and if

any of them were actually used as tow targets. The normal World

War Two target was a fabric sleeve that was pulled behind an aircraft.

Only the photos shown below from the DeKalb County History Center and

manual AN-28-10A-1 survive.

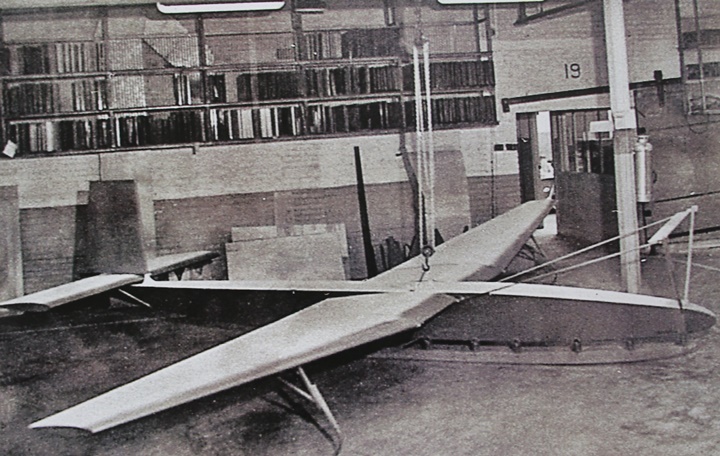

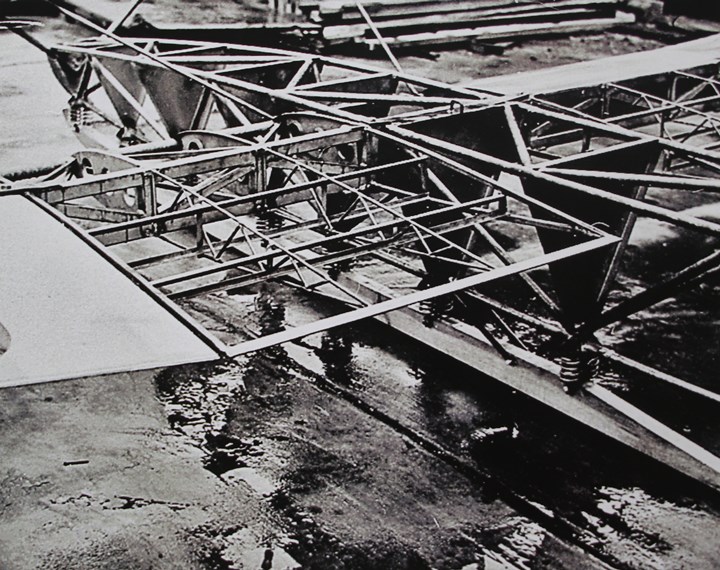

Photo courtesy of the DeKalb County History

Center.

Photo courtesy of the DeKalb County History

Center.

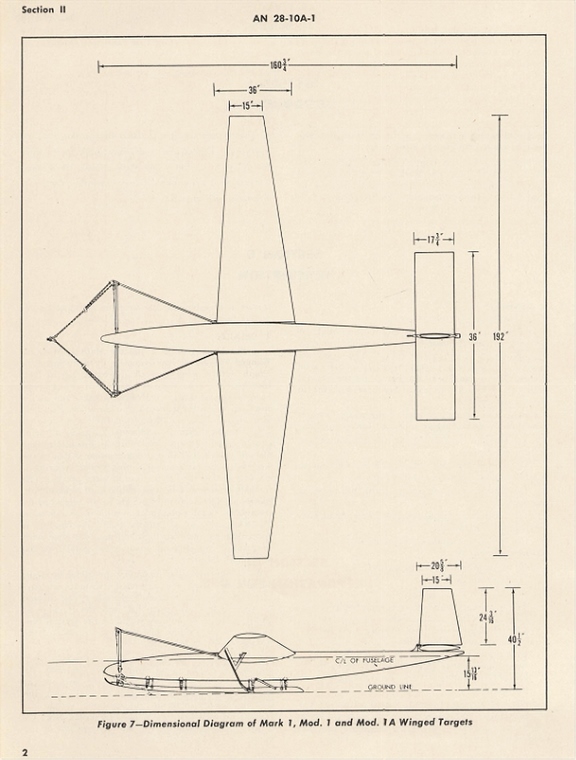

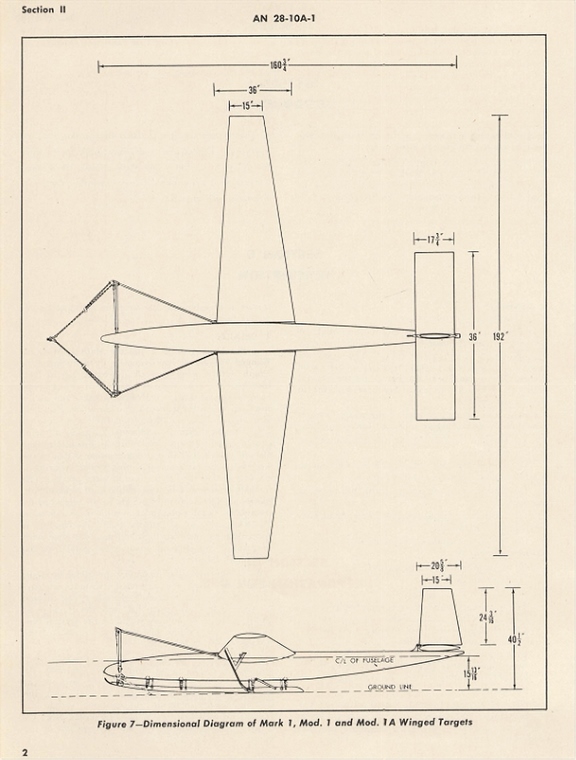

The wing span of the winged target was 13

feet, 4 inches. Photo courtesy of the DeKalb County History

Center.

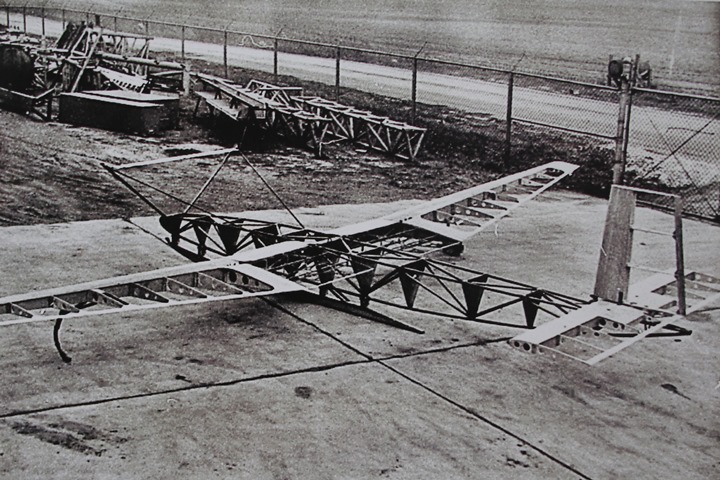

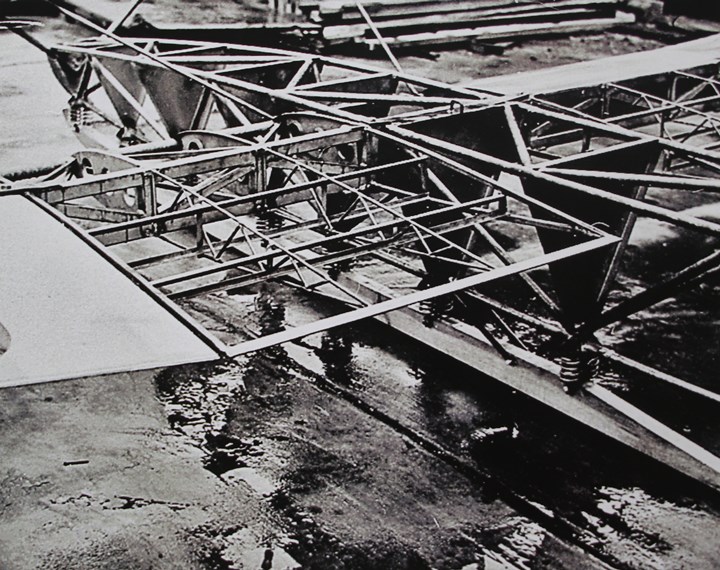

The Schwinn Bicycle Company of Chicago, IL

was subcontracted for the welding of the steel frame components on the

TDR project. Schwinn may well have also been contracted to do all

of the welding for Wurlitzer on the winged target. The welded

components shown here are very similar to those on a bicycle.

Photo courtesy of the DeKalb County History Center.

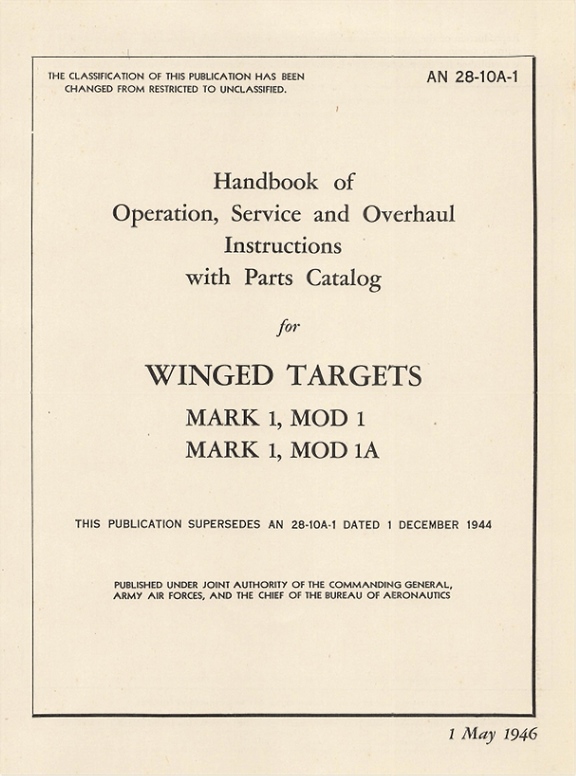

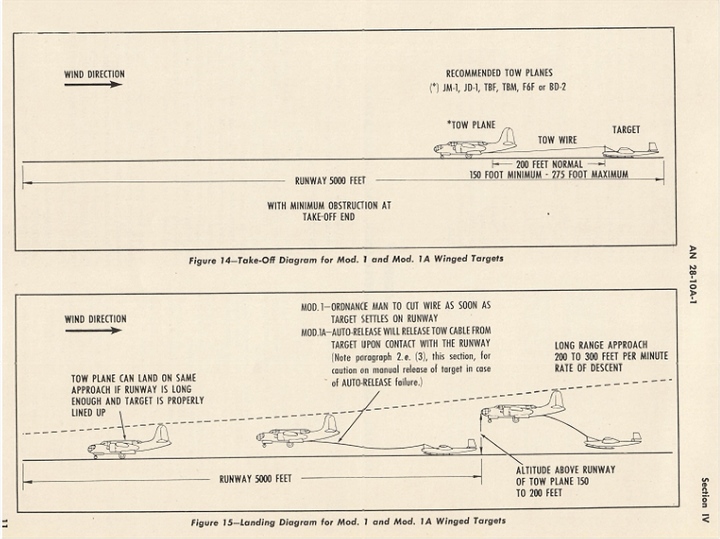

While the printed date on this manual is May

1, 1946, the original date was issued was December 1, 1944. This

would imply that the wing targets were used for the duration of the war.

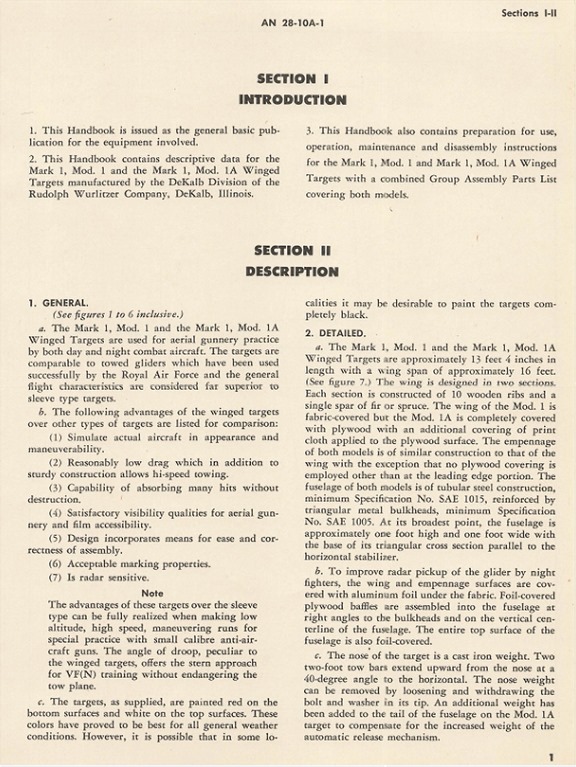

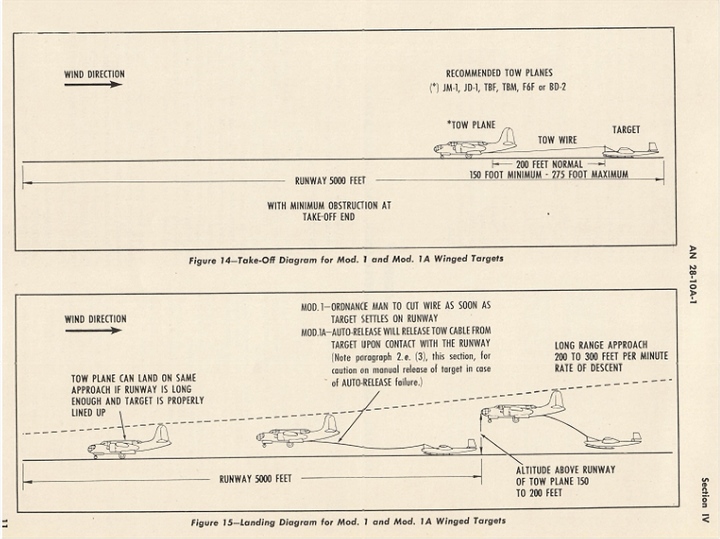

Section 1 notes that this product was

manufactured by the DeKalb Division of the Rudolph Wurlitzer Company.

Section II gives an excellent description of the winged target.

Paragraph a. indicates that this is based from an RAF design of a

similar winged target.

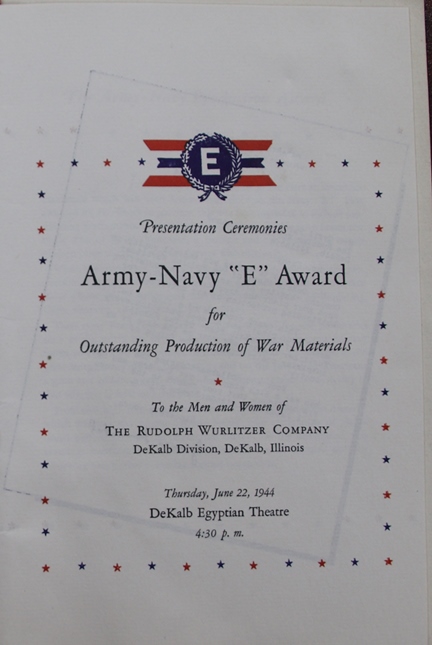

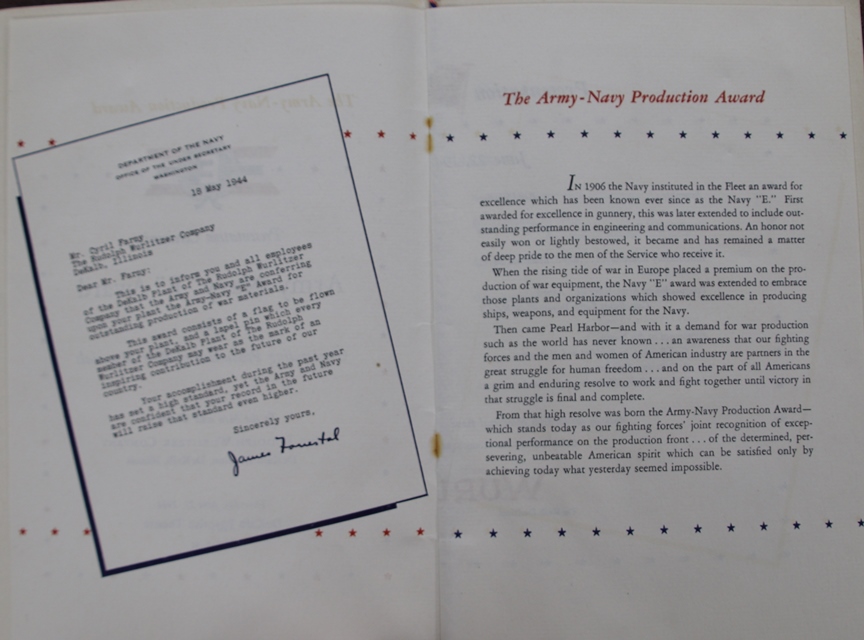

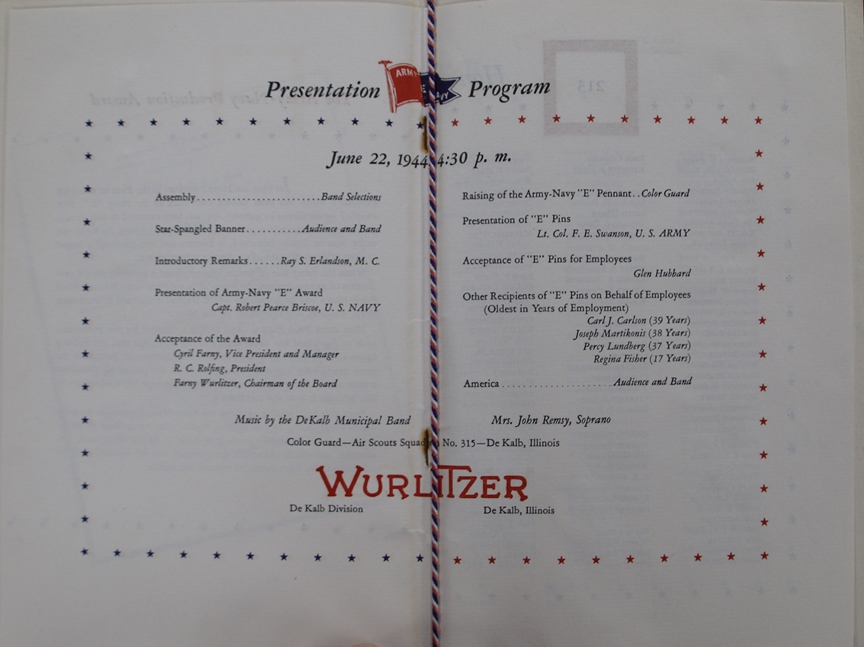

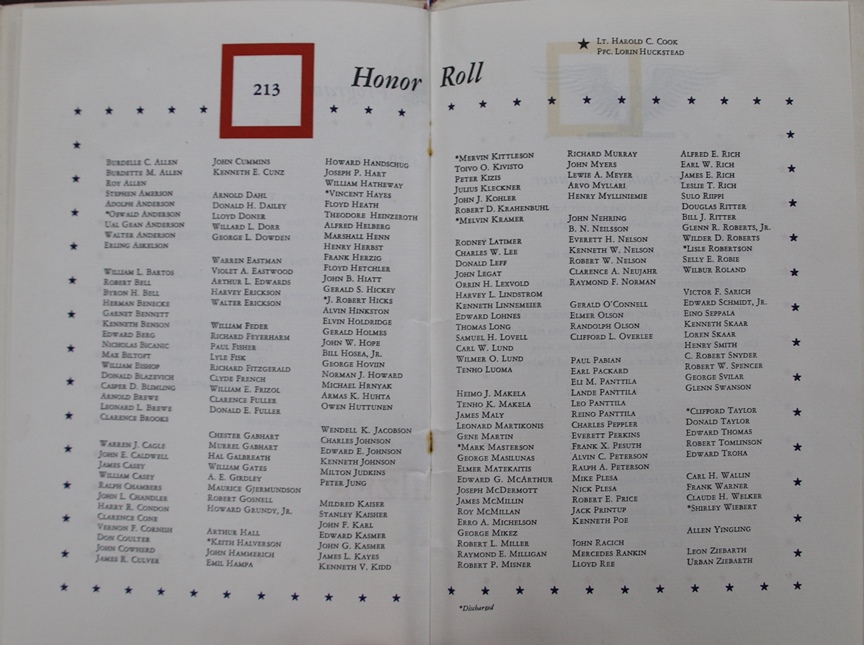

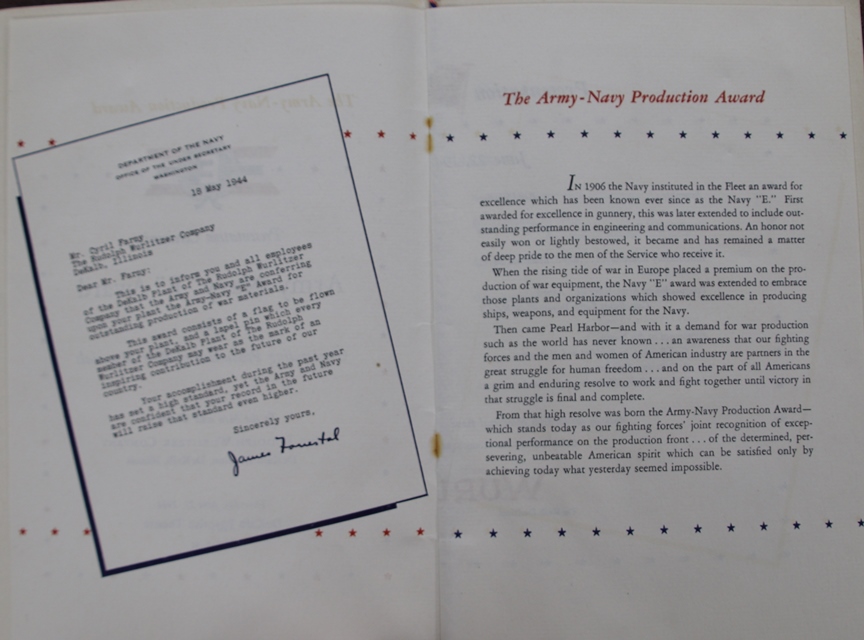

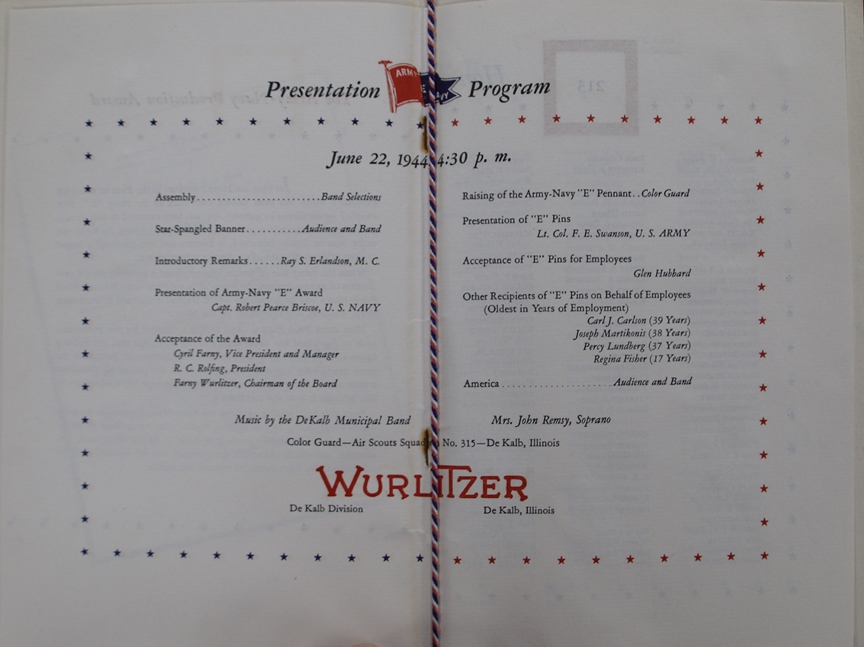

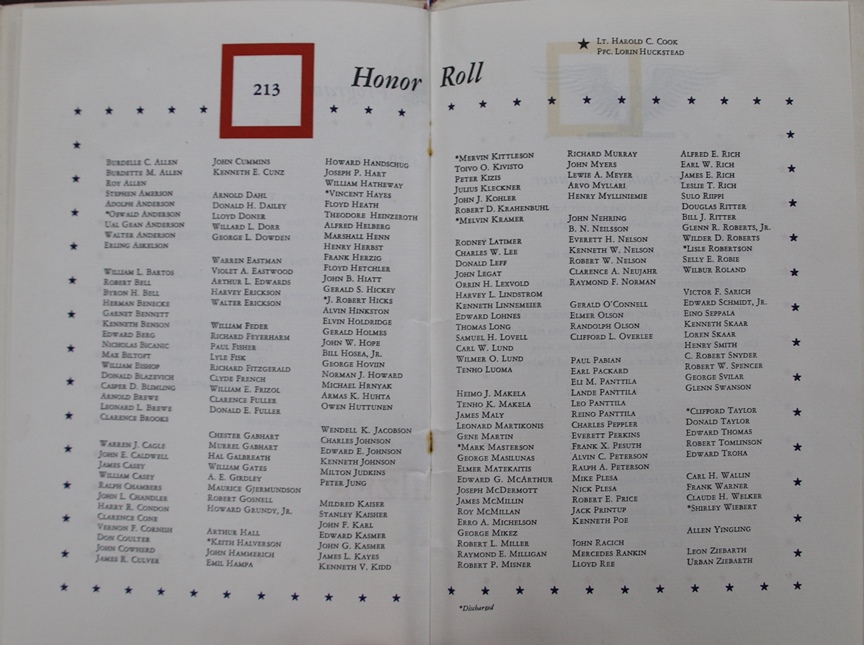

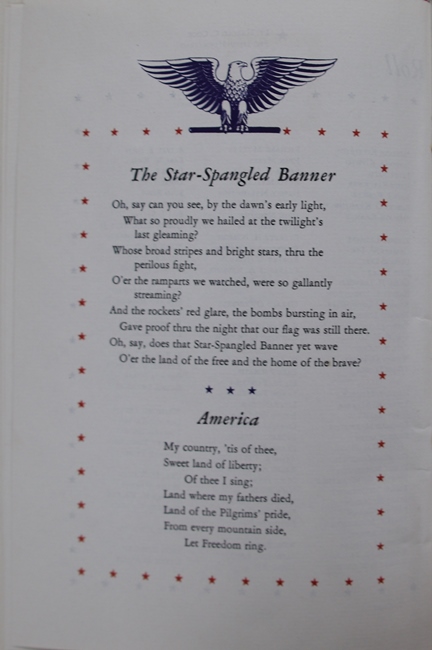

Army-Navy "E" Award: Below is the

pamphlet each employee received for the presentation of the first "E" on

June 22, 1944.

Photo courtesy of the DeKalb County History

Center.

Photo courtesy of the DeKalb County History

Center.

Photo courtesy of the DeKalb County History

Center.

Photo courtesy of the DeKalb County History

Center.

Photo courtesy of the DeKalb County History

Center.

Photo courtesy of the DeKalb County History

Center.

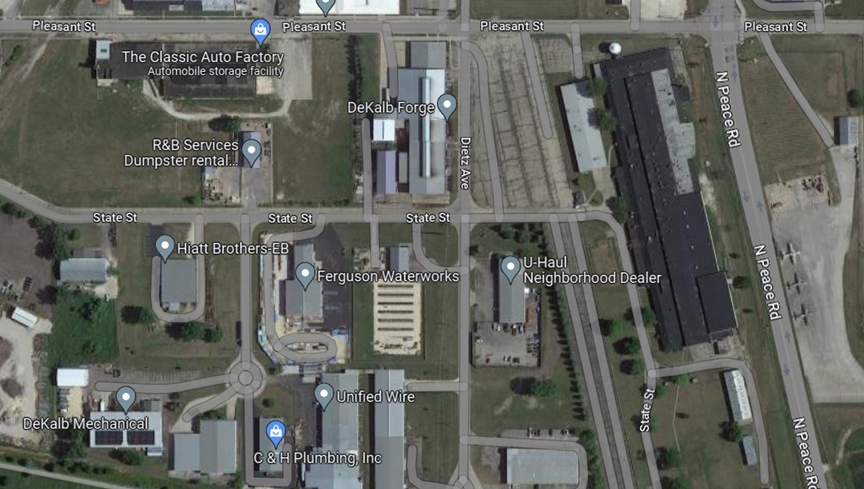

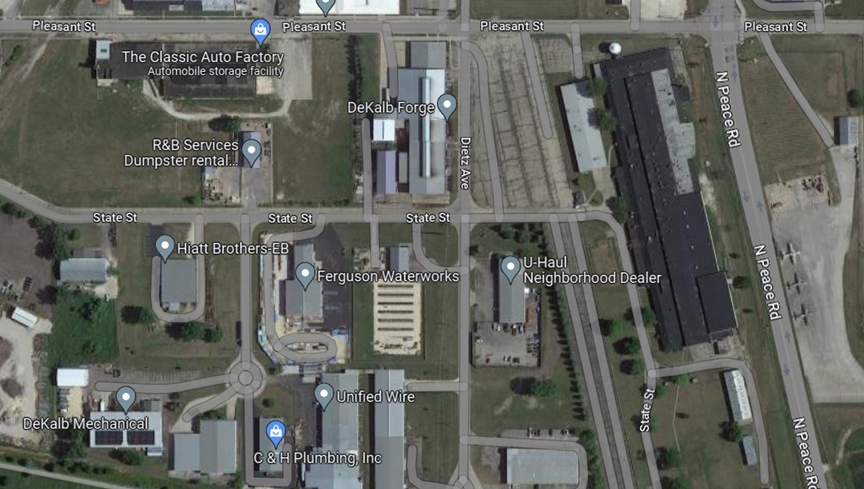

The Wurlitzer Plants: During

World War Two, Wurlitzer operated out of two factories. The first

was its normal manufacturing plant between Pleasant and State Streets in

DeKalb. In March 1945 it took over the plant previously used by

Interstate to assemble the TDR. In this plant, Wurlitzer produced

the ASM-N-2 Bat.

The only remaining portion of the Wurlitzer

plant is now occupied by the "Classic Auto Factory." The long

north-south building at the intersection of Pleasant Street and North

Peace Road is the plant used by Interstate to assemble TDR drones and

Wurlitzer to assembly the ASM-N-2 Bat. This plant was originally

built to be the world's longest factory for the manufacture of

furniture. After the war, General Electric purchased the plant.

Image courtesy of Google Maps.

Image courtesy of Google Maps.

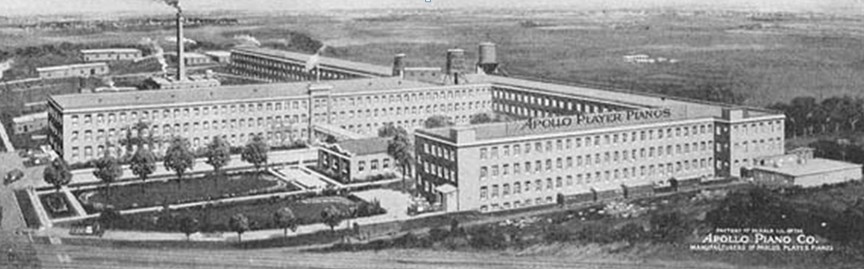

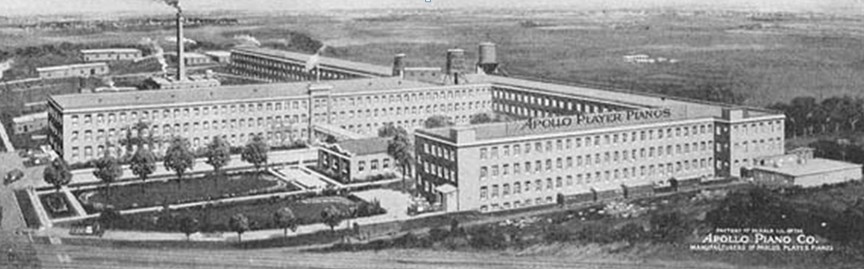

This early 20th century postcard photo shows

the DeKalb Wurlitzer complex when it was still Apollo Piano Company.

Apollo was one of the several trade names Wurlitzer used to market

pianos.

This is another early view of the factory.

I was at the location of the former

Wurlitzer factory complex in May 2023. There is only one two story

building still standing. This photo is looking to the northeast

from State Street and the railroad tracks. I tried to capture the

emptiness of the area. All of the grassy area at one time was

occupied by factory buildings. Author's photo.

Author's photo.

This image is looking east with Pleasant

Street on the left. Author's photo.

Author's photo.

Author's photo.

This image with Pleasant Street in the

foreground is looking west. Author's photo.

Author's photo.

There is not much left of this factory

complex that was no doubt the largest employer in DeKalb for many years.

This is the same sad story that I keep finding as I research the

companies that helped win World War Two. Author's photo.

Wurlitzer, DeKalb Division. Plant Number 2: Wurlitzer management announced on February 25, 1945, that the U.S. Navy

Bureau of Aeronautics requested that the company take on a project.

The company officials did not say what the project was except that the

components it produced would go to Goodyear. Goodyear, well known

for its tires and rubber products, also had an aviation division, for

which the Wurlitzer-built components' would be used. The

company also noted that the U.S. Navy would make available the former

Interstate Aircraft and Engineering plant that Interstate had previously

used for the final assembly of the TDR drone. This plant became

the Wurlitzer, DeKalb Division. Plant Number 2. Wurlitzer also took

control of the airfield and its hangar for its use. The company

leased the above mentioned facilities from the Defense Plant Corporation

effective March 1, 1945.

On September 25, 1945, this plant was

considered to be surplus and was put up for disposal by the Surplus

Property Administration. The value of the property was listed as

$1,422,000. The 190,000 square foot facility was located on 53

acres.

During World War Two Peace Road was a

railroad track. TDR drones came out of the south end of the long

building and then were towed across the tracks to the airfield that the

Navy built for test flying the drones. Image courtesy of Google

Maps.

This is the former Interstate TDR final

assembly plant and also the former Wurlitzer DeKalb Division plant #2.

After World War Two, General Electric purchased this facility from the

Surplus Property Administration. Author's photo.

This is the south end of the building.

The doors are the same ones shown in the period photos above.

Author's photo.

Author's photo.

Author's photo.

This factory also stands vacant now that

General Electric has left DeKalb. Author's photo.

Author's photo.

This is the north end of the building with

Pleasant Street in the foreground. Author's photo.

The complete manual for the Mark 1 Winged

Targets is located at:

Winged Targets |