|

Chris-Craft

Main Page Navy

LCVP Contract Page

Chris-Craft in World War Two

Landing Craft Construction Photos

This page added 3-15-2020.

All of the photos on this page are courtesy of the Algonac-Clay

Township Historical Society.

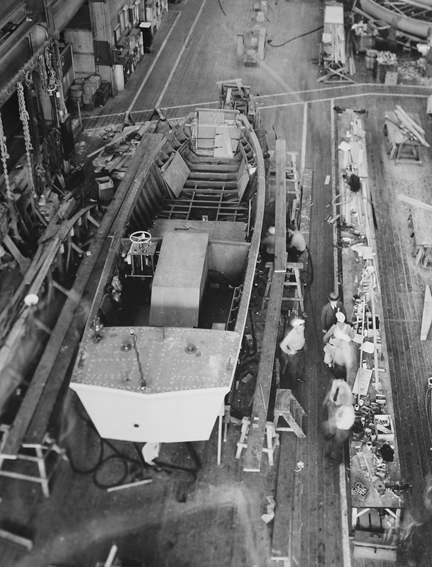

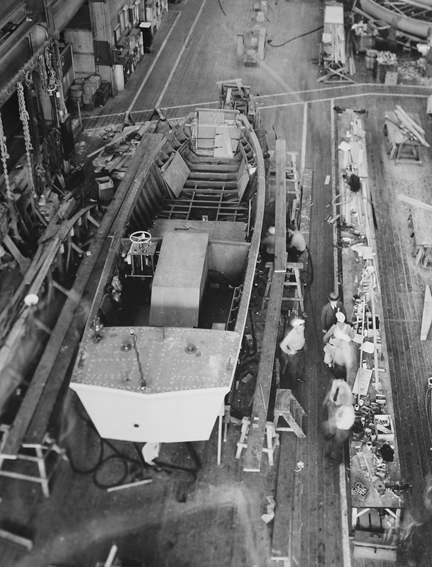

Unknown type of landing craft:

The next two photos show the aft section of a landing craft.

Because all the rest of the photos are of an LCP(L) or LCP(R)s, it is

assumed to be one of the two. From the rear, it is hard to tell.

LCP(L): This is the only photo of

an LCP(L).

This LCP(L) is powered by a Gray Marine

6HN9/Detroit Diesel 6-71 engine.

LCP(R) Longitudinal Knock-down Reassembly:

This is a collection of photos that show a modular build up of an

LCP(R). The boat has a non-standard location of the coxswains

position next to the engine. This demonstrates the re-building of

the boat after it has been disassembled after being knocked-down for

shipment in the longitudinal configuration.

It appears that this group of photos shows

how the LCP(R) can be built up after being shipped in this knocked-down

form. At least that is what I get out of it. The

descriptions on the photos did not say.

The workers are getting ready to install a

Gray Marine 6HN9/Detroit Diesel 6-71 engine.

Mounted to the front of this assembly are

two hand bilge pumps.

Here the transom is being installed.

The emergency steering mechanism can be seen. This was also

included in the LCP(L), LCV and LCVP.

This is new to me. I have never seen a

construction photo of a landing craft where the sides came as one piece

and then were installed like this.

There is an alternate explanation for this.

The LCP(R) was built up in the traditional manner and then cut apart

like it was shown in the second photo. This series of photos shows

how it is put back together after being shipped in pieces.

Glue is used between the side and the

bottom. Some of it can be seen. Some of the nails have

already been driven in.

This is the only photo that gave evidence

that the boat was being put back together. Without this photo, it

could actually be the reverse process of taking it apart for shipment in

a knocked-down condition.

This photo shows the exhaust side of the

Gray Marine 6HN9/Detroit Diesel 6-71 engine. The voltage

regulator, starter and DC generator were all built by the Delco-Remy

Division of General Motors. The U.S. Navy provided a plant in

Kings Mill, OH in 1944-45 for Delco-Remy to add capacity for starting motors for landing craft like this one.

The worker is adding the bulkhead at the

rear of the boat where the fuel tanks will be located. The

bulkhead has a circular cut-out for the exhaust pipe from the diesel

engine.

The fuel tanks and fuel lines can be seen in

this photo. The filler tubes for pouring in diesel fuel are at the

top of each tank.

The photo below was on the back side of this

photo,

and is the description of the of the contents inside the two crates on

the flatcar. It is LCP(R) with

hull number C-88002 that is being shipped as a longitudinal knock-down.

This would be the method just shown above.

LCP(R) Transverse Knock-down Reassembly:

This series of photos shows an LCP(R) being reassembled after it was

taken apart in three sections. This is another method of doing a

knock-down for shipment. This appears to be a demonstration of how

easy it is to put the boat back together with a minimum of equipment.

This is a simpler method than the one above.

This is the center section with the front

ramp section loaded into it.

This is the center section after the ramp

section has been removed.

This is the rear section. Note the

hand operated bilge pumps on the bulkhead.

The rear section is being manhandled into

position to assemble with the center section.

A small crane or a wrecker truck is needed

to lift the ramp section into place.

Workers put the finishing touches on the

LCP(R) by installing the combing.

As the photo below shows, this type of

knock-down shipment is the transverse method. The two LCP(R)s were

two hull numbers apart and shipped differently.

|