|

Chrysler Main Page

Dodge Trucks in World War Two

Dodge Trucks in Service with the

Polish Army

Chrysler built M3

Grant/Lee Photos

Chrysler built M4 Sherman

Photos

Chrysler built M4A3 Sherman

Photos

Chrysler built M4A4 Sherman Photos

Detroit Tank Arsenal Photos

Chrysler Post WWII M60 Patton

Tank Photos

Chrysler Post WWII M103 Heavy Tank Photos

Chrysler T23 Tank Photos

Chrysler Corporation in World War Two

Detroit, MI

1925-2014

Rest in Peace!

Last updated 1-12-2023.

Through all of the post-World War Two turmoil and difficulties, the name Walter

Chrysler gave to his company always managed to remain in the title of

the corporation in some manner, even after two

bankruptcies. Then, on December 16, 2014, Chrysler Group LLC

announced it was now FCA USA LLC. Also gone are Dodge Trucks,

which played such an important part in the winning of World War Two. That

name disappeared from trucks in 2010, but still remains on the Dodge

brand of cars.

The one thing that really stands out about

Chrysler during World War Two was its diversity of products not related

to the core business of building cars and trucks. Chrysler

is probably best known for its Tank Arsenal in

Warren, MI, its aircraft engine plant in Chicago just south of Midway

Airport, and its Dodge Division line of trucks. It also produced

such items as anti-submarine netting, 15-40 man unit cook stoves (The

troops needed to eat three times a day.), very important and

difficult processing equipment for the Manhattan Project in Oak Ridge,

TN, along with airframe components for B-29 bombers including the "Enola

Gay".

The Chrysler Tank Arsenal on Van Dyke Avenue in Warren, MI received the Army-Navy "E" Award on August 10, 1942.

It was the first of its kind to be awarded after the Navy and Army

combined their individual awards into one. The plant added a star

in February of 1943.

Thirteen Chrysler Plants won a total of 37 "E" awards during WWII.

|

Chrysler Plants

that won the Army-Navy "E" Award during WWII |

|

Airtemp Division, Dayton, OH |

2 |

|

Amplex Division, Detroit, MI |

2 |

|

Chrysler Motors of California, Los Angeles, CA |

2 |

|

DeSoto, Wyoming Plant, Detroit, MI |

3 |

|

Detroit Tank Arsenal, Centerline, MI |

4 |

| Dodge

Plant, (Main and Forge), Detroit, MI |

2 |

|

Evansville Ordnance Plant, Evansville, IN |

1 |

|

Highland Park, MI |

3 |

|

Jefferson Plant, Detroit, MI |

3 |

| Lynch

Road Plant, Detroit, MI |

3 |

| New

Castle Plant, IN |

5 |

|

Plymouth Plant (Gun Arsenal), Detroit, MI |

5 |

| Tank

Arsenal Proving Ground, Utica, MI |

2 |

|

Total Awards |

37 |

Chrysler

World War Two Products:

Manhattan Project U-235 Separation

Equipment - 406 X-100 Type 1, 1,942 X-100 Type 2, 1,418

X-100 Type 3, 826 X-100 Type 4. These pieces of equipment took

100 railcars to ship from Detroit to Oak Ridge, TN.

Aviation -

300 A-20 Bomb Chute Assemblies,

364,871 Bomb Shackles, 568 B-29 Bomber Noses, 559 B-29 Wing

Leading Edges, 4,752 B-29 Bomber Cowling Sets, 1,586 B-26 Nose and

Center Fuselage Sections, 4,100 Douglas B-17 Cockpit

Enclosures, 18,413

R-3350 Radial Aircraft Engines for the B-29, 688 Flight Station

Cockpits for the Lockheed PV-2 Harpoon, 10,202 Landing Gear

and Arresting Gear Sets for Chance Vought F4U, 907 Nose Cap

Assemblies, 2,982 Propeller Balancing Stands,

163,290 Ski Pedestals, 5,669 Wing Center Sections for Curtiss SB2C.

Vehicles -

12,214 Partial Engine Assemblies,

9,965 Multi Bank M4 Tank Engines, 2,100 2 Speed Gear Boxes, 2,056

Grouser Kits, 22,207 Tanks, 3,272 Modified Tanks, 3,694

Modified Trucks, 1,542 1/2-Ton 4x2 Trucks, 6,216 1&1/2-Ton 4x2

Trucks, 72,286 1/2-Ton 4x4 Trucks, 255,193 3/4-Ton 4x4 Trucks, 43,278 1&1/2-Ton 6x6 Trucks, 15,000 3-Ton Trucks

for China, 20,404-

Fire Apparatus (This assumes these are fire trucks.)

Ammunition and Shot - 485,463,000 .30

carbine rounds of ammunition, 222,000,000 .50 Cores, 2,768,688,000

.45 rounds of ammunition, 3,000,000 20mm Practice Shells, 19,933,000

20mm Practice Balls, 671,446 3-Inch Shell Forgings, 1,989,801 20mm

Armor Piercing Shot.

Other -

14,370 Air conditioning and refrigeration

units, 238,109,000 Bearings, 30,095 Single 40mm air cooled Bofors Gun

Mechanisms

for the U.S. Army,

51,684 Single 40mm air cooled Bofors Gun Tubes

for the U.S. Army,

14,442 Dual 40mm water cooled Bofors Guns for the U.S. Navy, 101,232 E48 Incendiary Bombs,

119,814 Industrial Engines, 21,131 Marine Engines, 62,192 Field

Kitchen Cabinets, 233,118 Field Kitchens, 17,200 Gas and Oil Fired

Furnaces, 29,589 Domestic and Export Water Heaters, 1,994

Anti-Submarine Nets, 156,585 20mm Oerlikon Gun Magazine Lever

Assemblies, 9,002 Pontoons, 2,228 Marine Tractors, 328,367

4.5 Inch Rockets, 1,550 Searchlight Reflectors, 253 Smoke Screens,

37,932 Cook Stoves, 2,098 SCR-584 Anti-Aircraft Radar Antenna Mounts

and Parabolic Antennas, 352 Air Raid Sirens,

8,307,540 Aluminum Forgings

Sperry Shipboard Gyro-Compasses - Dodge

built 5,500 of these units which consisted of the main gyro that was

installed down in the bottom of the ship. This unit supplied the

compass reading to several repeater units throughout the ship.

These would be in such places as the captain's quarters and the bridge.

These were all very sophisticated and complex precision units consisting

of some 10,000 parts each. Dodge developed the mass production

methods needed to manufacture these in the large quantities needed.

Assembly took 5,000 tools, jigs, and fixtures which were all designed by Dodge engineers. It took between 11 and 16 large

wooden crates to ship these units to the shipyards for installation.

Pilot tanks - The Chrysler Engineering

Department built 38 different pilot tanks, including the T92 and T-93.

Tanks -

The Chrysler Tank Arsenal in Warren, MI

received the Army-Navy "E" for Excellence Award on August 10,

1942, which was the first of four total awards. There was a total of 6,258 M3 tanks built during World

War Two, with Chrysler

building 3,352 or 53% of the total. It built 17,947 of the M4

Sherman series tanks, or 36% of the total 49,234 built. At the end

of the war, Chrysler manufactured 473 T26E3/M26 and 185 T26E2/M45 tanks.

It also produced 250 T23 medium tanks, bringing the total of tanks built

by Chrysler at the Detroit tank arsenal to 22,207.

Chrysler

Shipments of World War Two Products (pdf)

- This document from the Chrysler archives

gives plant by plant and month by month production figures for all of

the company's World War Two products.

The Manhattan and B-29 Projects:

One might consider it very strange to have

as part of Chrysler information on World War Two a photo of this replica

of the first atomic bomb dropped during WWII that is located at the US

Air Force Museum. The device used U-235 as its fission matter.

Only one bomb was made of this, the second atomic bomb using

plutonium. However, the process to obtain the needed 132 lbs. of

U-235 was

complex and arduous, as it had to be separated from the original U-238.

Several processes were developed to accomplish this. One involved

hexafluoride gas and was done in the world's largest

building that was constructed in secrecy at Oak Ridge, TN (The Secret City)

during World War Two

to separate out the U-235.

The Manhattan Project asked Chrysler to design

and manufacture the miles of nickel tubing needed for the diffusers,

nickel being the only metal resistant to the highly corrosive

hexafluoride. However, there was not enough nickel in the world to make

the tubing out of pure nickel as was specified by the Manhattan Project

engineers. Chrysler engineers found a way to plate the diffusers

instead, which was considered impossible by the Manhattan Project group

due to all of the small holes and interior surfaces involved. But

Chrysler prevailed and found a way to plate the parts which also

provided a huge cost savings. It took 1,000 rail cars to ship the

diffusers from the Chrysler Plymouth Lynch Road Plant in Detroit to Oak

Ridge where it was installed in the huge plant known by the secret

number of K-35. The plant was a half mile long by 1,000 feet wide.

Chrysler's expertise in engineering and manufacturing was instrumental

in ending World War Two in August

of 1945.

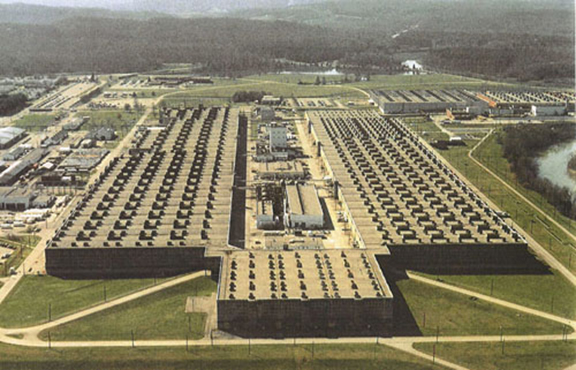

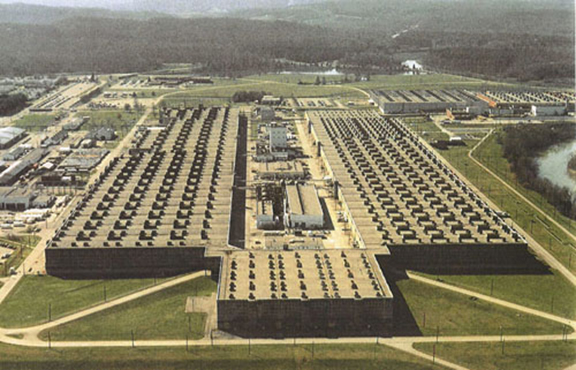

The image above is an aerial view of K-35 at Oak Ridge, where

the 4,582 Chrysler X-100 Diffusers were used to separate U-235 from

U-238 during World War Two.

And last but not least, Chrysler's DeSoto

Division on Warren Avenue in Detroit was the supplier of the forward fuselage section of the B-29

"Enola Gay" which dropped the atomic bomb "Little Boy" made with uranium

from Oak Ridge plant K-35. The name "Enola Gay " above is painted

on the eighteen foot forward fuselage built in Detroit, MI by Chrysler. Author's

photo added 9-22-2015.

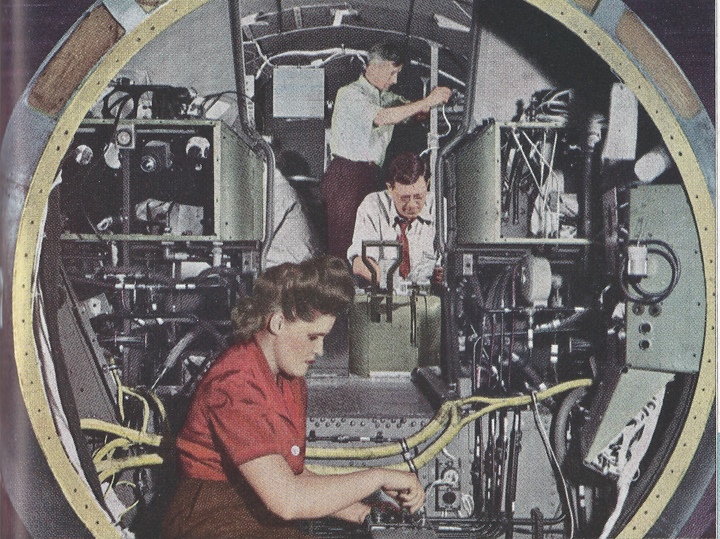

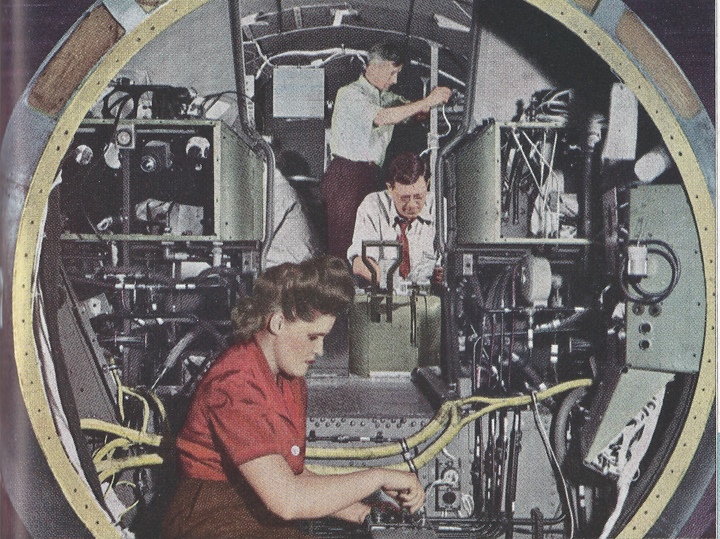

There was more than just stamping out the

aluminum sheet metal pieces and then riveting them together with 50,000

rivets to make the fuselage. DeSoto-Warren also assembled all of the

interior of the B-29 nose section, which included four of the eight

miles of wiring in the B-29. The workers shown above are

installing some of the 8,000 parts that went into the construction of

the Superfortress fuselage. The B-29 was the first insulated and

soundproofed bomber, and the insulation can be seen in this photo.

The fuselage sections were shipped via rail to Omaha using oversized

boxcars, which were one foot wider and one and a half feet taller than the

normal boxcar of the period. Photo added 9-22-2015.

This nose section is similar to the ones

that Chrysler manufactured during World War Two. From the serial

number, this nose section was built by Boeing in Wichita, KS.

Author's photo added 1-12-2023.

This and the next photo show some of

equipment and complexity of the B-29 cockpit section of the aircraft.

Author's photo added 1-12-2023.

Author's photo added 1-12-2023.

The second nuclear B-29, "Bockscar",

shows

several the Chrysler-supplied components for this aircraft, which were

the forward fuselage, engine cowlings, wing leading edges, and the Dodge-built R-3350 engine. Author's photo added 9-22-2015.

This photo shows the inboard and between the

engine leading edges. Chrysler also supplied the leading edge

outboard of the outside engines. Chrysler built 568 B-29 nose

sections along with 559 wing leading edge sets and 4,752 cowling sets for

the aircraft. Author's photo added 9-22-2015.

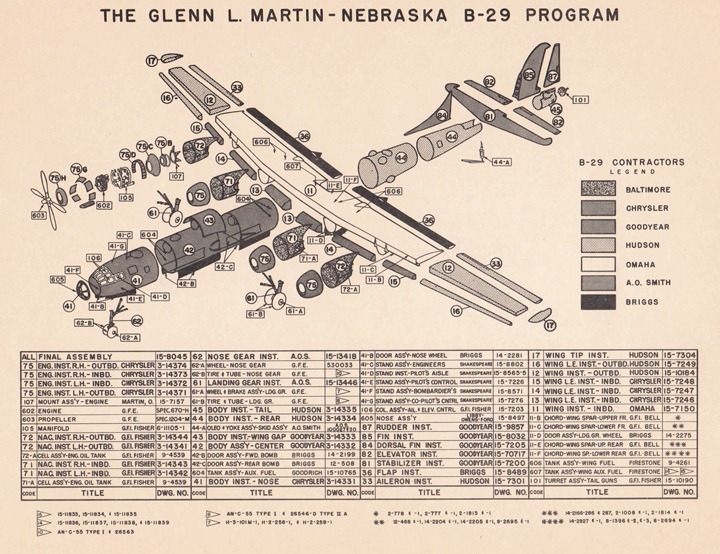

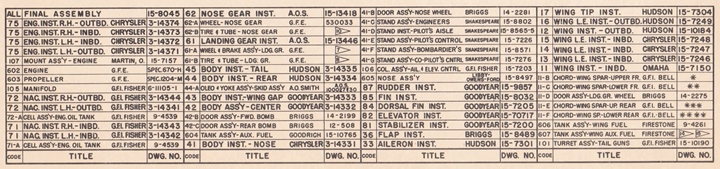

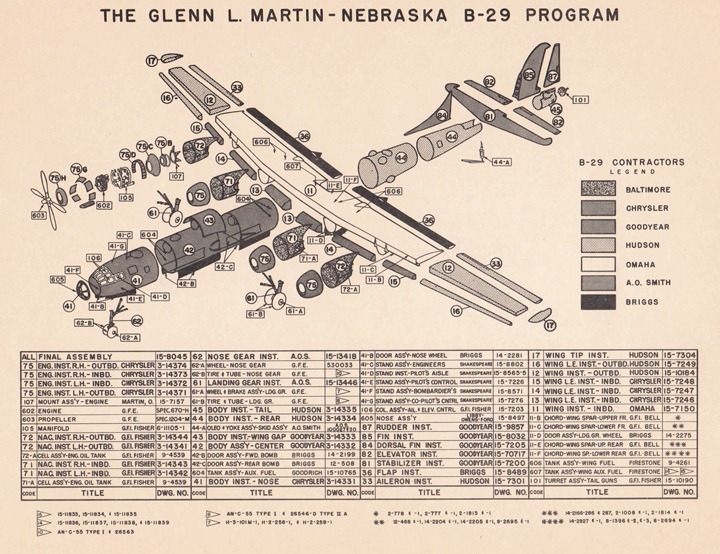

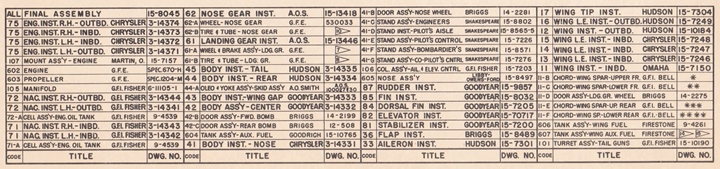

Above is information provided to me courtesy

of Chris Howlett of the UK that he found researching the B-29 for his book,

"The B-29 Manual," which was published by Haynes Publishing in

December 2015. His information has been invaluable in my research

and shows which auto companies were the major suppliers, including

Chrysler, for the Superfortresses that were built by Martin in Omaha,

NB. Of significance is that Omaha built the Silverplate B-29s, i.e.

"The Enola Gay" and "Bockscar" as noted above. Photo added 9-22-2015.

Photo added 9-22-2015.

This is a SCR-584 anti-aircraft

radar unit. Chrysler produced 2,098 radar antenna mounts and

parabolic antennas; and then installed them in the ten-ton Fruehauf

built trailer. The radar antenna mount stowed inside the trailer

for travel. It dropped straight down to where the table and

mannequin are located. Note the cables on the wall have slack in

them, to allow for the up and down movement of the antenna unit.

This photo was taken at the National Electronics Museum in the

Baltimore, MD area, which exhibits a history of the former Westinghouse

Electronics Division (now Northrop-Grumman) located in the area.

Westinghouse installed the electronics within the trailer after

receiving it from Chrysler. Author's photo added 10-7-2016.

The SCR-584 antennas and mounts were

produced in Chrysler's Dodge Main plant. Production started in

April 1943 and concluded in April 1944. Author's photo added

10-7-2016.

|

Warren, MI

Chrysler

Tank Arsenal

Production during World War Two - Updated 11-28-2017 |

| Type |

Number built |

Dates |

Engines |

Hull |

| M3

Lee |

3,243 |

4-1941 to 8-1942 |

Continental

built Wright R975 radial aircraft |

Riveted |

| M3A4

Lee |

109 |

6-1942 to 8-1942 |

Chrysler multi bank. See photos below. |

Riveted, hull lengthened for engine |

|

Total M3 Series |

3,352 |

|

|

|

| |

|

|

|

|

| M4A4

(75) Sherman |

7,499 |

7-1942 to 9-1943 |

Chrysler multi bank.

See M4A4 and engine photos below. |

Welded, hull lengthened for engine.

Most of 7,499 M4A4 tanks went to the British under Lend-Lease.

There are 86 of the M4A4s still in existence. |

| M4A6

(75) Sherman |

75

|

10-1943 to

3-1944 |

Caterpillar

diesel radial |

Composite. Cast front welded sides

lengthened for engine |

| M4(105) Sherman |

1,641 |

2-1944 to

3-1945 |

Continental

built Wright R975 radial aircraft |

Welded |

| M4A3(105)

Sherman |

3,039 |

5-1944 to 6-1945 |

Ford GAA V8 |

Welded |

| M4A3(76) |

4,017 |

3-1944 to 4-1945 |

Ford GAA V8 |

Welded. |

| M4 Composite Sherman

(75) |

1,676 |

8-1943 to 1-1944 |

Continental

built Wright R975 radial aircraft |

Composite. Cast front, welded sides. There are four

of the composites still in existence. |

| Total M4 Series

|

17,947 |

|

|

|

| |

|

|

|

|

|

Total T23(76) |

250 |

11-1943 to 11-1944 |

Ford

GAN V-8 driving a generator driving two traction motors |

|

| |

|

|

|

|

|

Total T26E3/M26(90)

|

473 |

3-1945 to 9-1945 |

Ford GAF V8 |

Cast.

See photos below. |

| |

|

|

|

|

| Total

T26E2/M45(105)

|

185 |

|

|

|

| |

|

|

|

|

|

Total Chrysler built tanks |

22,207 |

|

|

|

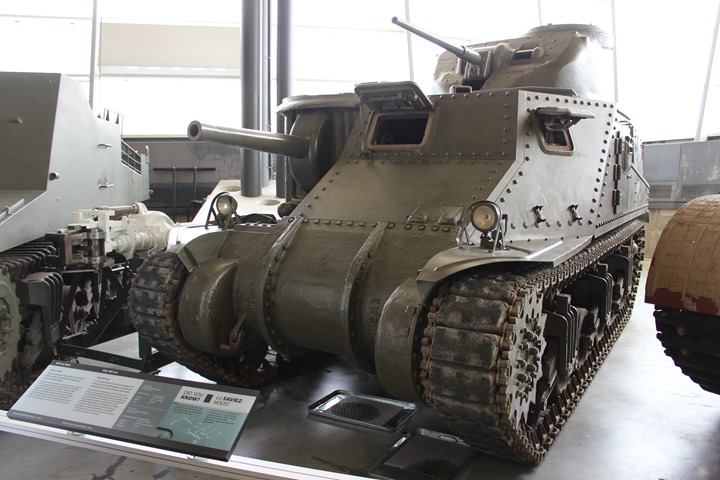

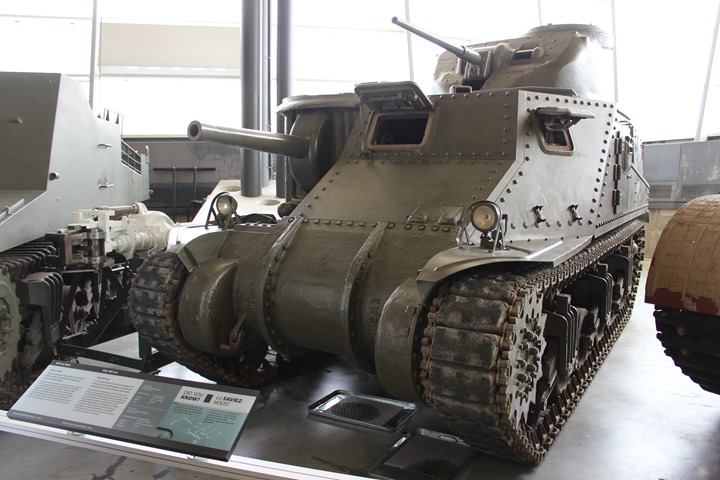

This Chrysler-built M3 Lee tank is on

display at the Canadian War Museum. It is serial number 3714.

Note the riveted construction. Author's Photo added 1-8-2017.

The first type of Sherman tank that Chrysler built was the M4A4 variant, powered by the Chrysler Multibank engine shown

below. This example is on display at the

Arnhem War Museum, Schaarsbergen

Netherlands. It is Serial Number 21169 and was built in June 1943.

Photo courtesy of David D Jackson, Jr.

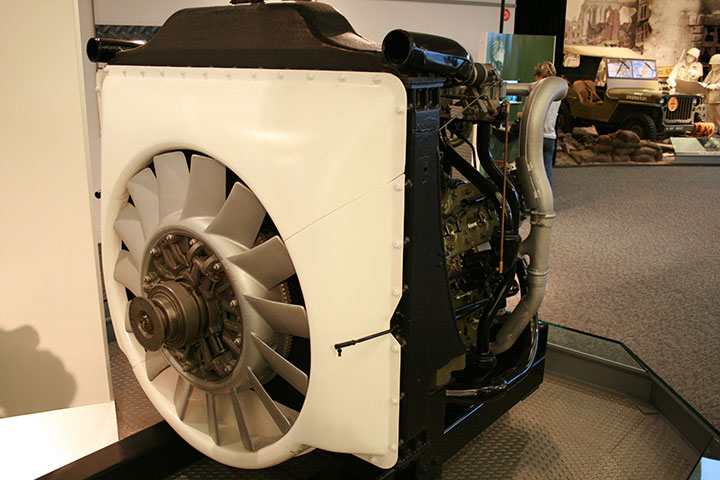

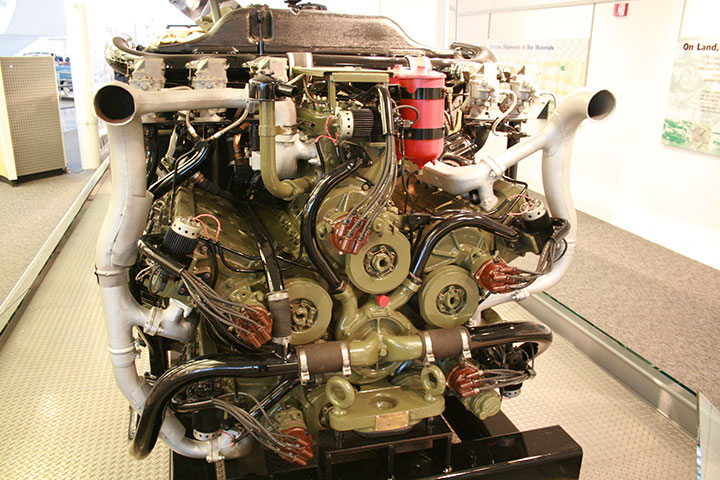

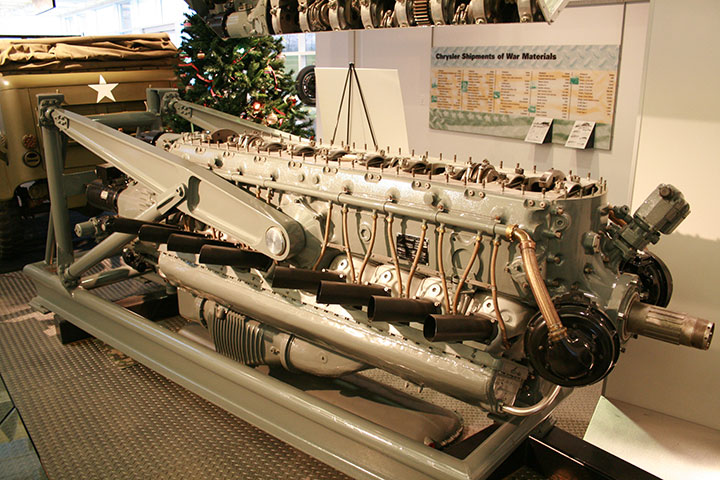

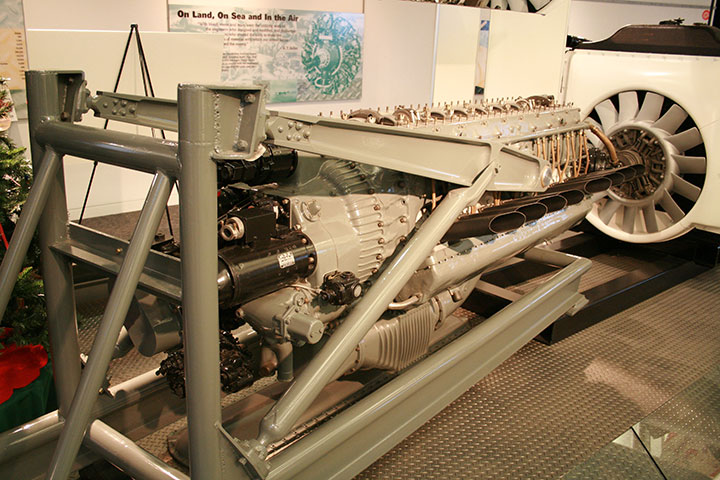

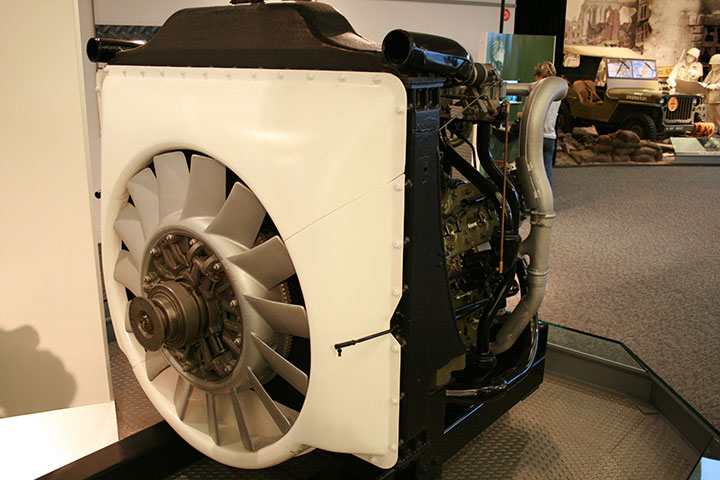

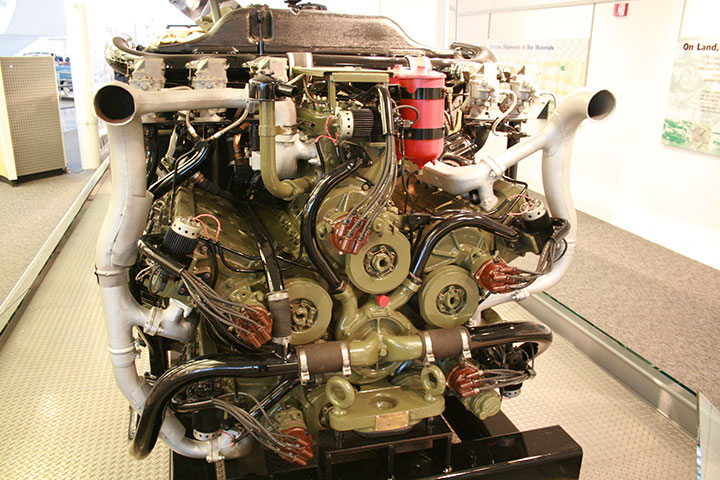

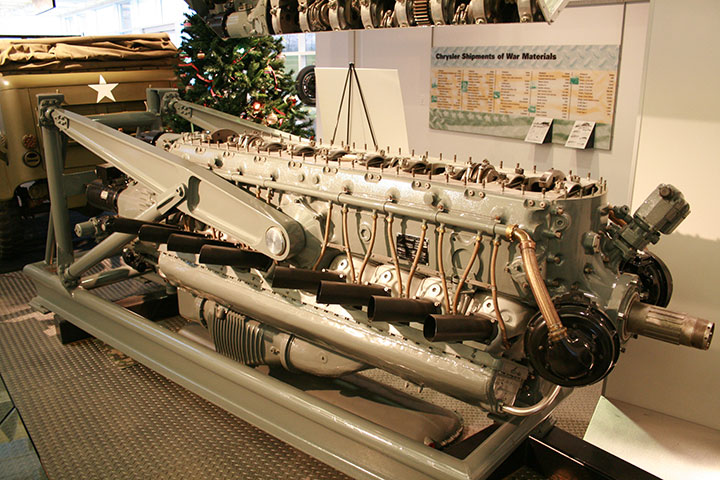

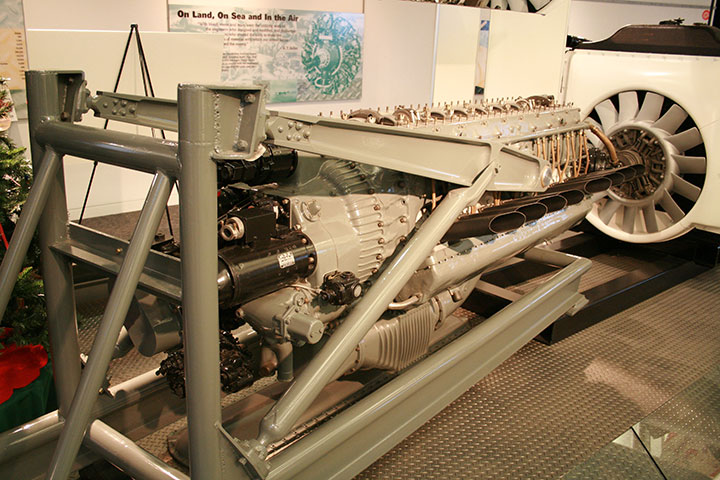

During WWII there was a shortage of engines

to power both the M3 Lee and the M4 Sherman tanks. Chrysler developed and built 9,965

multibank engines which were five six-cylinder engines driving a single

crankshaft. Author's photo from the Walter P. Chrysler Museum in

Auburn Hills, MI.

The engine produced 450 hp from 1,500 cubic

inches of displacement and had lots of low end torque. Note the

top of the radiator extending above the engine. Author's photo.

One can see the five distributors for

each of the five engines. In total 7,499 M4A4 tanks and 109 M3A4 Lee

tanks received this

type of engine. Author's photo.

This M4(105) Composite, photographed at

Historic Fort

Wayne in Detroit, is interesting in that it is a one of a kind.

Chrysler was the only manufacturer of the M4 Composite, and they were all armed with a 75mm cannon, not the 105mm cannon

that is shown here. This M4 Composite was used as the prototype

for the use of the 105mm main gun in the Sherman. The reason it is named a Composite is the front

glacis is cast, and the rest of the hull is of a welded construction.

Author's photo added 4-21-2015.

One can see the cast section welded to the rest of the hull which

is constructed of thick plate armor. Author's photo added

4-21-2015.

This Chrysler-built M4A3E8 was built in

August 1944 and is part of a Battle of the Bulge diorama at the First

Division Museum in Wheaton, IL. Author's photo added 11-2-2015.

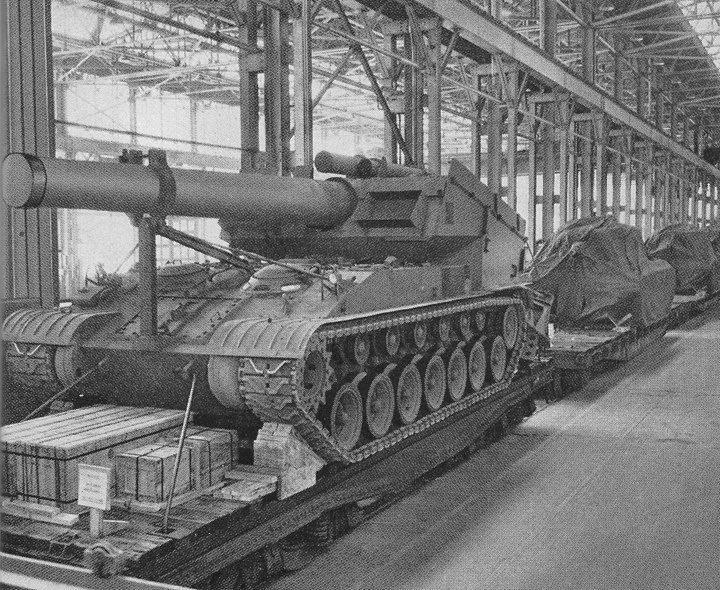

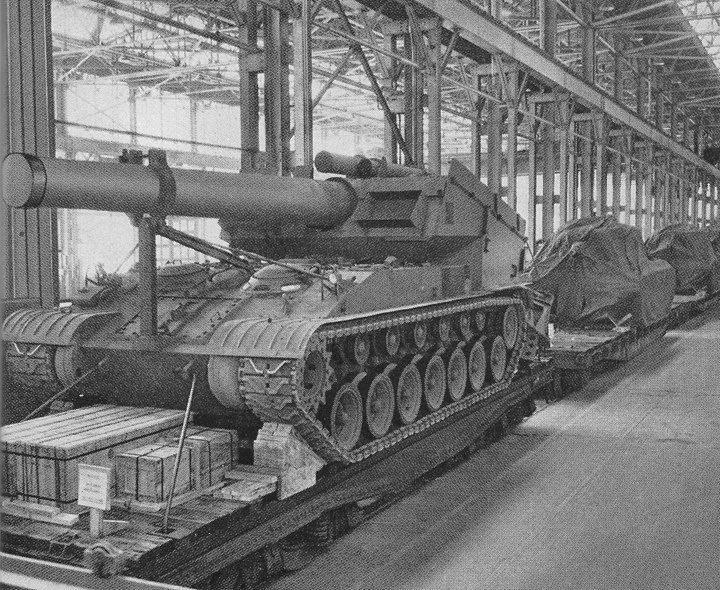

Chrysler built 250 T23s between November

1943 and December 1944. The tank had a Ford GAN V8 engine that

drove an electrical generator. The generator in turn powered two

electrical traction motors. Author's photo added 10-17-2018 from

the U.S. Army Armor and Cavalry Museum Collection at Fort Benning, GA.

This is one of three remaining T23s that the Museum Collection has.

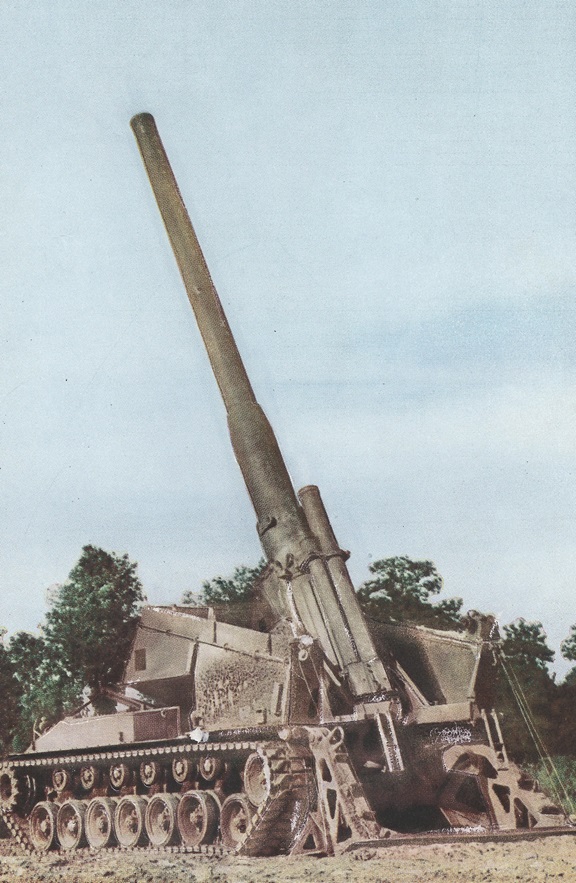

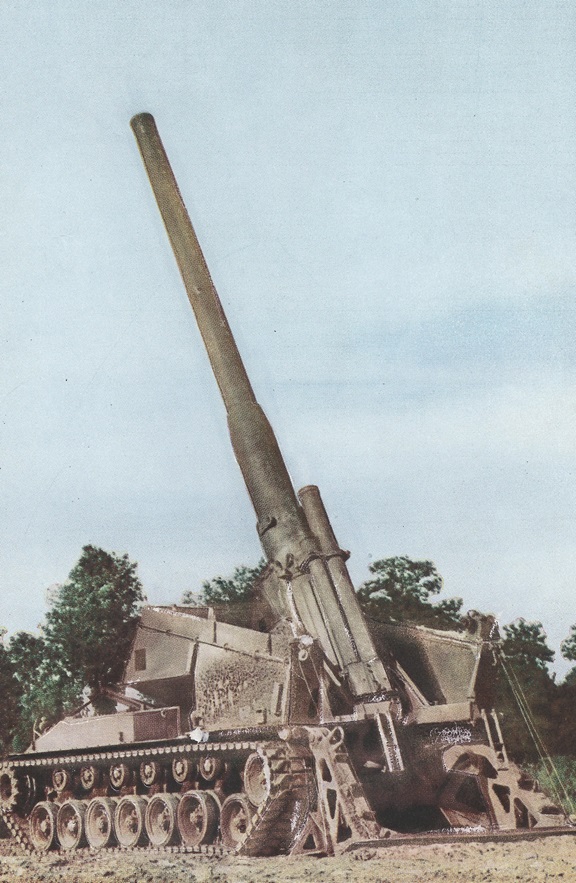

Here is the 65 ton T92 240mm Howitzer Gun

Carriage built by the Chrysler Engineering Department. It was built

on a Pershing chassis. Photo added 11-3-2015.

The next experimental weapon built by the

Chrysler Engineering Department was an eight-inch gun on the Pershing

chassis. Photo added 11-3-2015.

Chrysler built 14,442 Dual 40mm water cooled Bofors Guns for the US Navy

under license from the Bofors Company of Sweden during WWII. After

Chrysler engineers set up the manufacturing and assembly based on mass

production techniques, the weapon could be assembled in ten

hours. Bofors in Sweden was taking 450 hours to assemble a weapon.

This example is located on the USS Sullivans in Buffalo, NY, and is

located on the middle of the ship on the starboard side. Author's photo added 10-12-2017.

There is a data plate on each barrel

and assembly. This one is mounted on the breech of the gun facing

the rear of the ship. This Chrysler-built 40mm Bofors gun

mechanism is

serial number 29869. Author's photo added 10-12-2017.

This is the other gun of the pair. Author's photo added

10-12-2017.

Here is the data plate for the gun mechanism for the gun facing the front of the ship.

This one is serial number 39869. What are the chances of a gun

mount having two Chrysler 40mm guns with serial numbers separated by

exactly 10,000 units? Author's photo added 10-12-2017.

This is the USS Massachusetts at Fall River,

MA. A visit to the USS Massachusetts in June 2019 revealed that

most, if not all, of the 40mm Bofors anti-aircraft guns onboard were

built by Chrysler in 1942. This makes sense because the

Massachusetts was launched in September 1941 and commissioned on May 12,

1942. The Chrysler-built Bofors outfitted the battleship in 1942

as the weapons were coming off the assembly lines. All of the 40mm

Bofors I was able to visit on the USS Massachusetts were built by

Chrysler. Author's photo added 12-16-2019.

The USS Massachusetts bristles with 16-inch,

5-inch and 40mm guns. Author's photo added 12-16-2019.

There are two gun tubs on the fantail

of the USS Massachusetts with two dual 40mm Bofors mounts in each. Author's photo added 12-16-2019.

The serial numbers from the four

Chrysler-built 40mm Bofors in the starboard side rear quad 40mm gun tub

are shown below. Author's photo added 12-16-2019.

This is serial number 25067.

Author's photo added 12-16-2019.

I adjusted the lighting on this data plate, as it was on the shaded side of the

weapon. It is so worn that it is hard to read. This is

serial number 25065, just two less than the previous matching gun in the

twin mount. Author's photo added 12-16-2019.

This is serial number 35065. Author's photo added 12-16-2019.

This is serial number 35067, two more than

the matching gun above. Author's photo added 12-16-2019.

Author's photo added 12-16-2019.

Chrysler also built 30,095 Single 40mm air cooled Bofors Guns for the US

Army like this one seen here at the Indiana Military Museum in

Vincennes, IN. Author's photo added 9-22-2015.

The information for the two tables below

comes from "The History of the Americanization of the Bofors 40mm

Automatic Antiaircraft Gun" written by the Historical Section of the

Ordnance Department in May 1944.

Chrysler produced 83.5% of the gun mechanisms

and 60.2% of the gun tubes for the US Army 40mm Bofors like the one

shown above. Note that the information comes from an article

written in May 1944. There was still over a year of war remaining,

and the need for gun tubes and gun mechanisms continued.

|

Production

of 40mm Gun Mechanisms for the US Army as of March 1944 - US

Ordnance |

|

Company |

Date |

Quantity |

Percentage |

Comments |

|

Chrysler |

3-31-1944 |

24,802 |

83.5% |

|

|

Pontiac |

After

12-1943 |

4,900 |

16.5% |

This was the scheduled amount that was completed some time

in 1944. |

|

Total |

|

29,702 |

|

|

Chrysler's information shows 30,095

40mm guns which would include both the mechanism and tube.

Below is a modified version of the table above using Chrysler end-of-war information.

|

Production

of 40mm Gun Mechanisms for the US Army - Chrysler end of war

data |

|

Company |

Date |

Quantity |

Percentage |

Comments |

|

Chrysler |

3-31-1944 |

30,095 |

86.0% |

|

|

Pontiac |

After

12-1943 |

4,900 |

14.0% |

This was the scheduled amount that was completed some time

in 1944. |

|

Total |

|

34,995 |

|

|

In either case, Chrysler

supplied over 83% of the Bofors gun mechanisms for the US Army during

WWII.

|

Production

of 40mm Gun Tubes for the US Army as of March 1944 - US

Ordnance |

|

Company |

Date |

Quantity |

Percentage |

Comments |

|

Chrysler |

3-31-1944 |

51,684 |

60.2% |

|

|

Pontiac |

3-31-1944 |

17,892 |

20.8% |

|

|

Otis Fensom |

3-31-1944 |

16,258 |

18.9% |

|

|

War Supplies |

10-42 |

40 |

0.1% |

|

|

Total |

|

85,874 |

|

|

Chrysler sent complete

40mm guns consisting of the mechanisms and tube to Firestone, Koppers

and J.I. Case for installation on the carriage.

|

Production

of 40mm Gun Carriages for the US Army as of March 1944 - US

Ordnance |

|

Company |

Date |

Quantity |

Percentage |

|

Firestone |

3-31-1944 |

20,021 |

84.5% |

|

Koppers |

4-1944 |

2,270 |

9.6% |

|

J.I. Case |

12-1943 |

1,414 |

5.9% |

|

Total |

|

23,705 |

|

This is a rare Lockheed PV-2 Harpoon, which

was a Navy patrol bomber during the war and built in Burbank, CA.

Chrysler in Los Angeles, CA built 668 flight decks for this type of aircraft.

This particular PV-2 is "Attu Warrior." Author's photo.

The Flight Deck of the PV-2 Harpoon "Attu

Warrior" as seen at the Great Georgia Airshow in 2013.

Author's photo.

Author's photo.

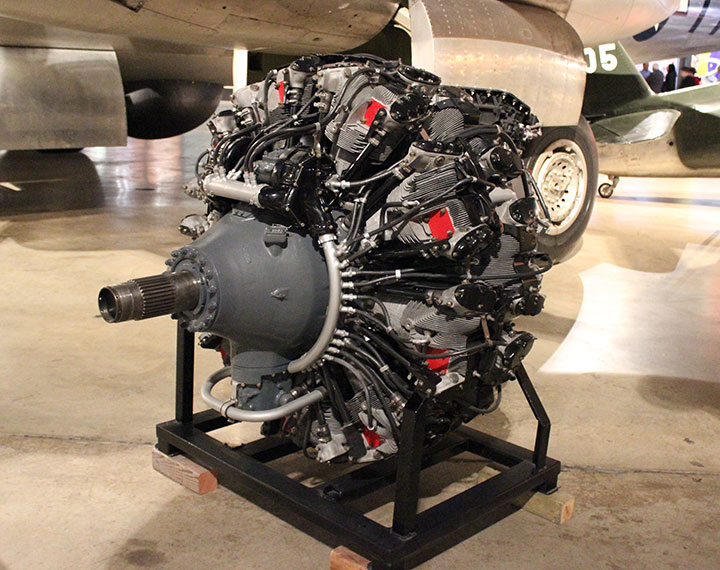

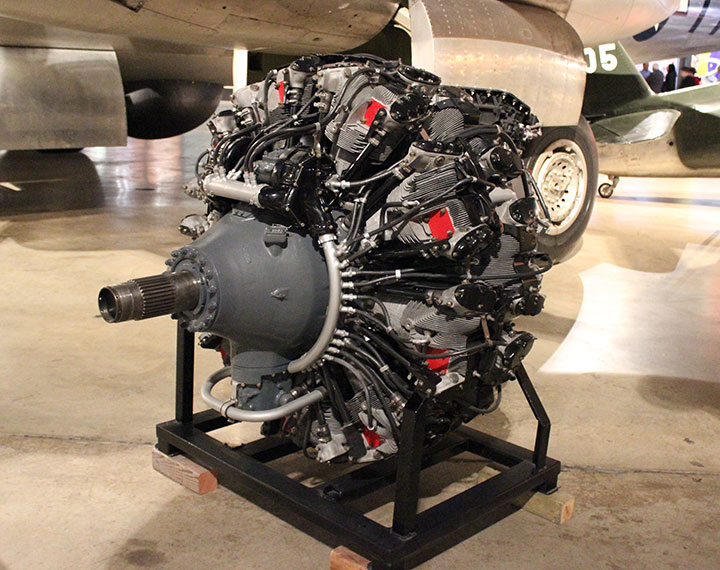

This is a Wright R-3350-23 Duplex Cyclone

engine, similar to the 18,413 that Dodge built in Chicago for the B-29

project during World War Two. There were a total of 30,293 R-3300

engines produced during World War Two. Dodge produced 60% of this

of

type engine for the war effort. Author's photo.

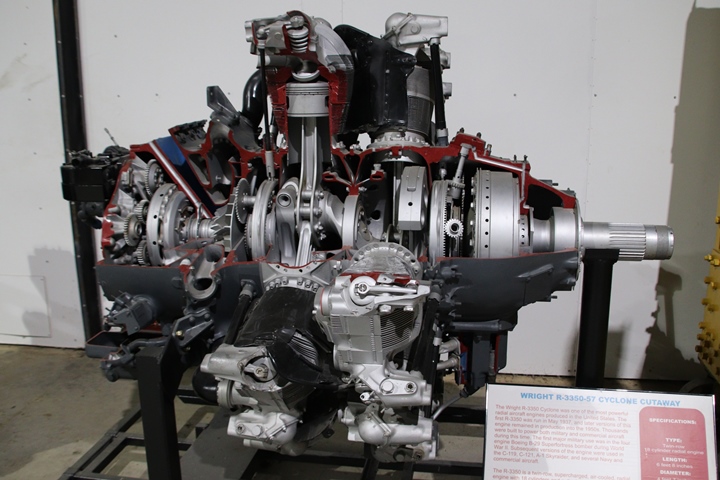

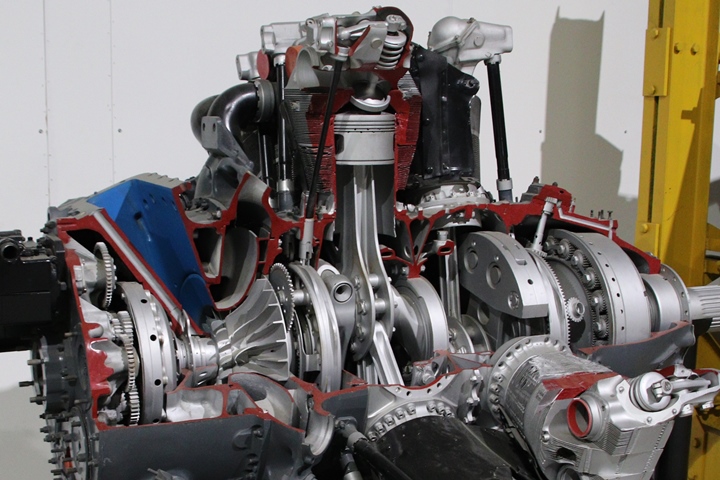

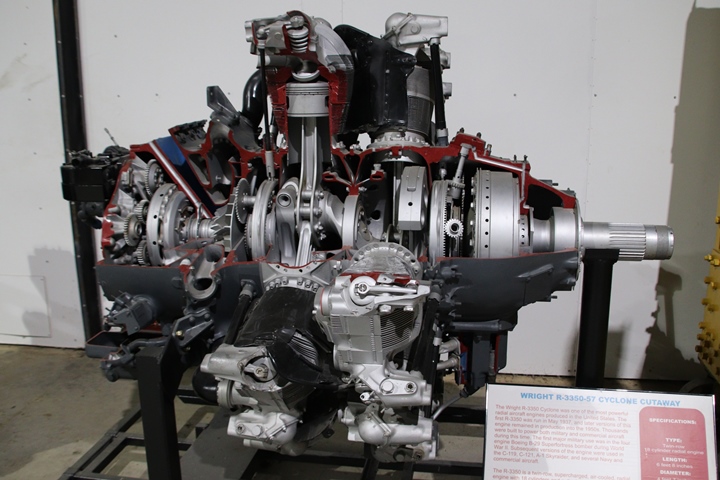

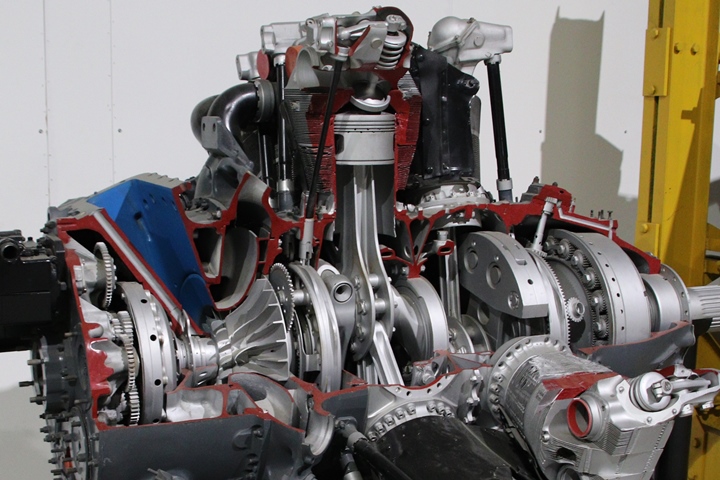

This cut-away of a R-3350 at the Museum of

Aviation Robbins AFB, GA shows the complexity of the engine.

Author's photo added 1-12-2023.

Author's photo added 1-12-2023.

The Martin B-26. DeSoto Division of Chrysler built 1,586

nose and center fuselage sections for this medium bomber which were

supplied to the Martin Plant in Omaha, NB. When Martin Omaha

converted to the B-29, DeSoto then produced the B-29 forward fuselage

sections for the aircraft. Author's

photo.

This is the world's only remaining flying

Curtiss SB2C Helldiver, seen here at the 2014 Tico Airshow.

Chrysler built 5,669 of the wing center sections, which is the portion

between the wing folds. Author's Photo.

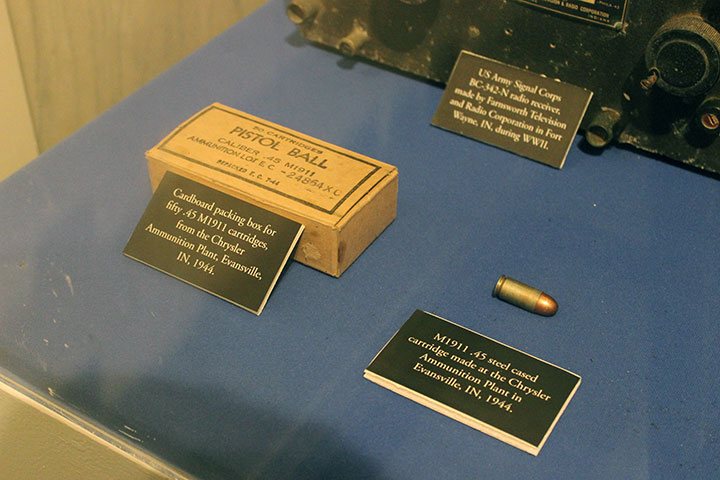

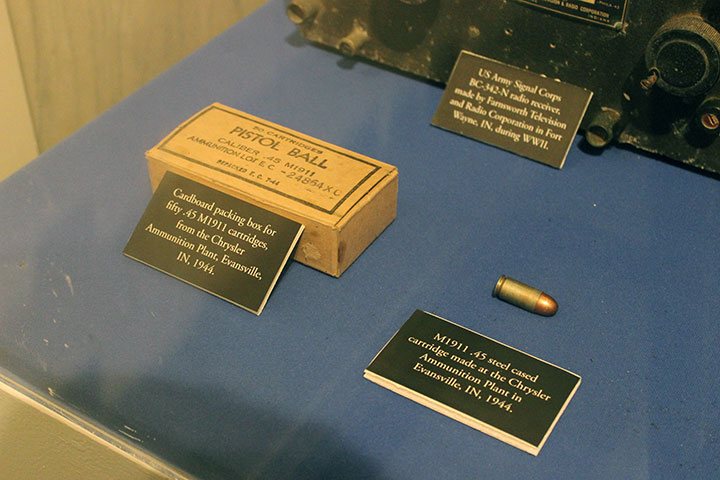

On the left is a .30 caliber M1 Carbine

round. Chrysler manufactured 485,463,000 of these for the US

military during WWII. However, the real accomplishment was the

manufacture of 2,768,688,000 rounds of .45 ACP rounds like the one seen

on the right. Chrysler did such a good job on making the .45 ACP

round that the government stopped production due to the fact it had too

many and was still using the ammunition in Vietnam. The Chrysler

Desoto plant in Evansville, IN was the sole source of .45 ACP ammunition

during the war. Author's photo.

Author's photo from the Indiana War

Memorial.

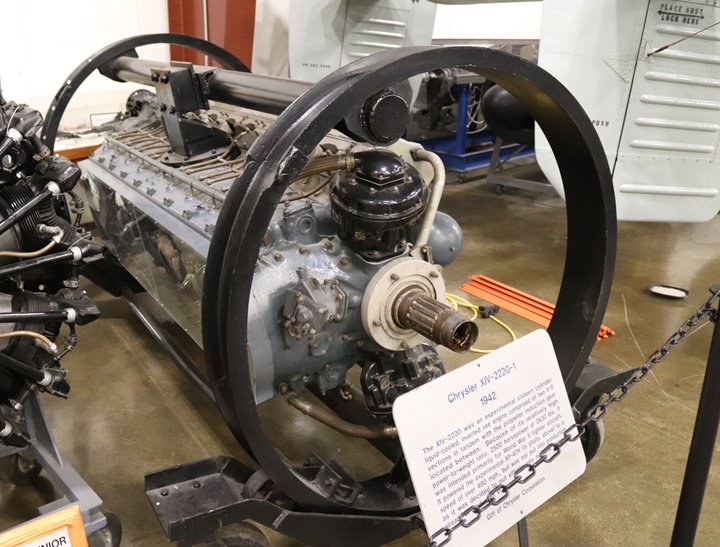

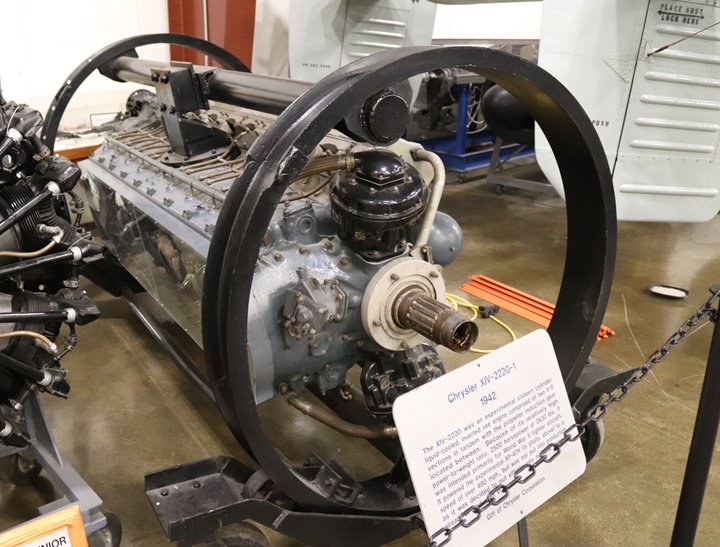

In 1944 Chrysler developed and built

five inverted V-16, 2,500 hp engines at the request of the US Army Air

Force. Author's photo from the Walter P. Chrysler Museum.

Weighing in at 2,430 lbs. and displacing

2,220 cu. in., the engine beat the goal of more than one horsepower per

pound of weight and per cubic inch of displacement. Author's

photo.

The engine was successfully tested in this

modified Republic P-47 as shown here. Even though it met all of

the design criteria, the new jet engines spelled its doom.

However, all was not lost, as one of the design features that

contributed to the success of the engine was the hemi-spherical shaped cylinders. Today we

know that design feature as the Hemi!

This example of the Chrysler V-16 engine is

on display at the New England Air Museum at Windsor Locks, CT.

Because the Chrysler Museum is now closed, this may be the only example

available for the public to see. Author's photo added 11-14-2017.

Author's photo added 11-14-2017.

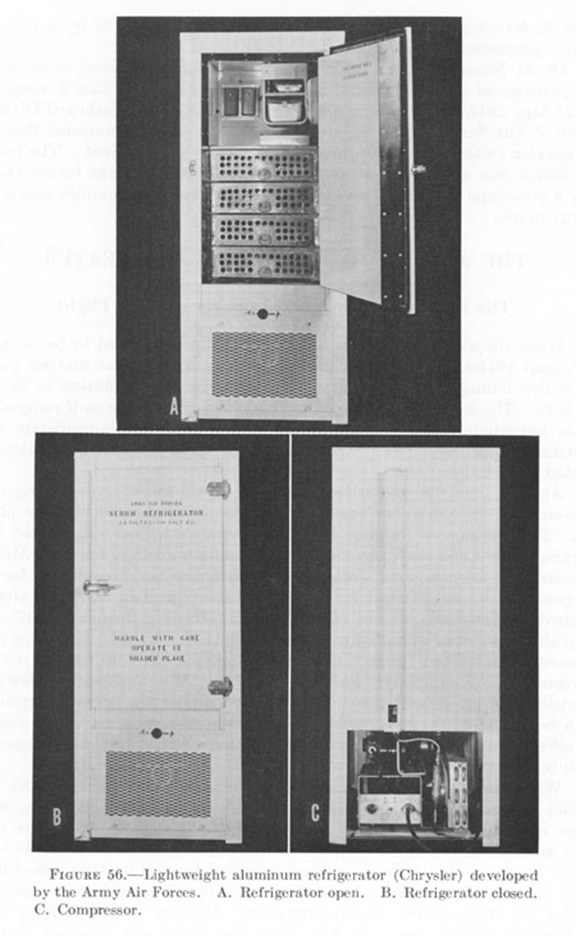

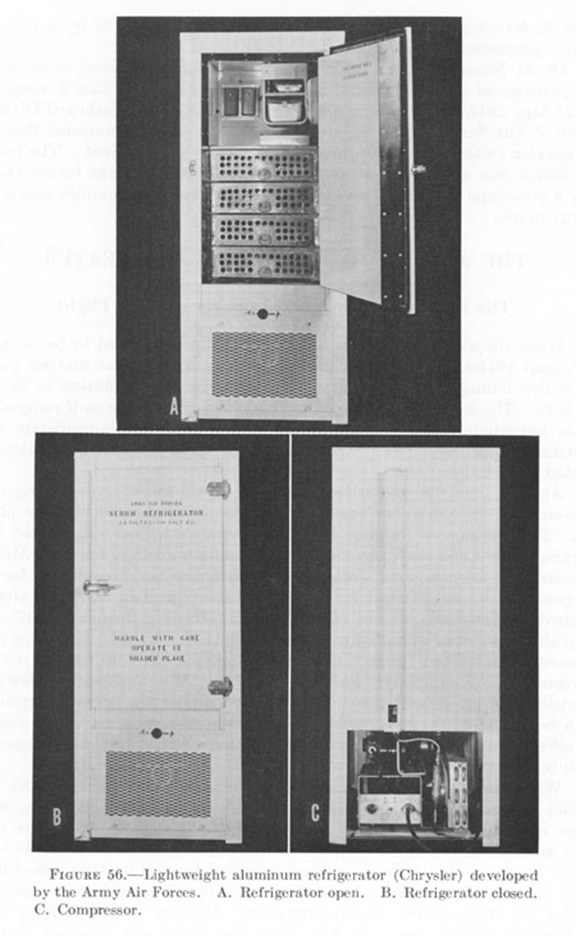

Listed above were 14,370 air conditioning and refrigeration units, all

of which had a military need or helped the war effort, such as this blood

serum refrigerator unit produced by Chrysler's Airtemp Division in

Dayton, OH. Air conditioning units were used by US Army Field

Hospitals and in the manufacture of close tolerance parts.

Also, Airtemp refrigerators were used on U.S. Navy vessels to keep the food

stuffs cool or frozen.

"Sentimental Journey"

is one of the three B-17Gs that is still flying of the original 3,000

that Douglas built. Chrysler built 4,100 cockpit enclosures for

the Douglas-built Flying Fortresses. Other Douglas B-17s still

flying are "Memphis Belle"( Movie Version) and "Fuddy Duddy."

This work was done at its Los Angeles, CA plant. Author's photo.

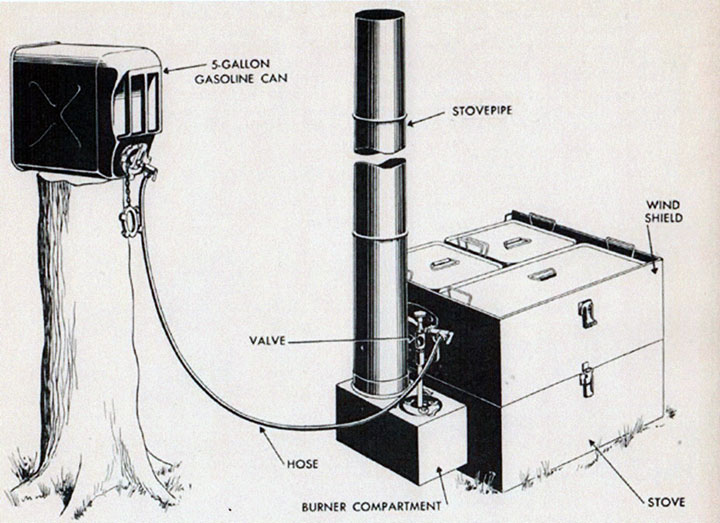

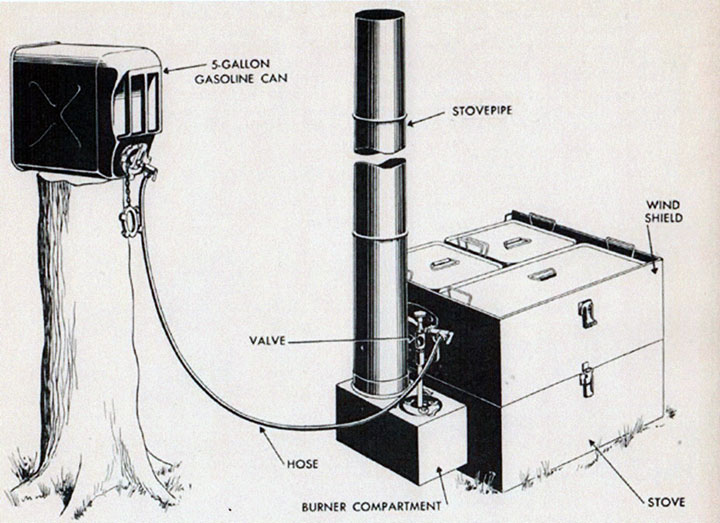

Also, from Airtemp Division of Chrysler was

this cook stove for squad to platoon size units that used gasoline as

fuel. 37,932 of these units were produced at the Dayton, OH plant.

This is a Dodge WC-52 Weapons Carrier as seen at the

2012 Tico Airshow. Author's photo.

Author's photo.

This is a Goodyear FG-1D built Corsair. Chrysler built

10,202 landing gear for the Corsair. Author's photo.

Chrysler also built 10,202 tail hook

assemblies for the aircraft, seen here in the retracted position.

Author's photo.

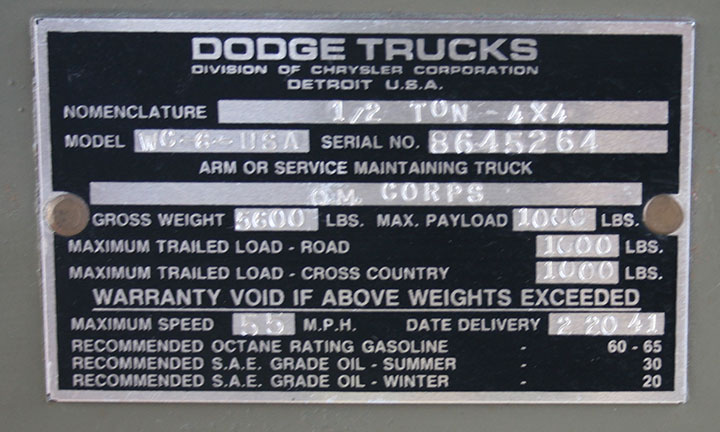

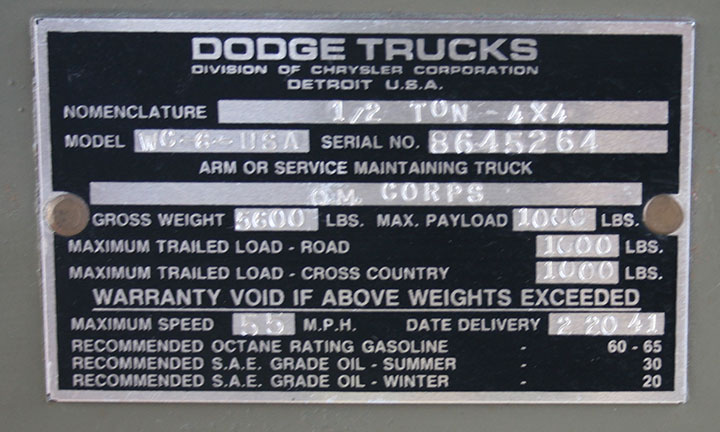

Dodge WC-6 1/2-ton 4x4 Command and Reconnaissance Car was on display in

September 2013 at the MPVA Rally at the former Ropkey Armor Museum.

Author's photo.

Author's photo.

Author's photo.

This WC-6 was built on 2-20-1941.

Author's photo.

This is the Douglas A-20G that is on display

at the National Museum of the United States Air Force. Chrysler built 300 bomb chute

assemblies for this type of aircraft.

Seen here is a dual 20mm Oerlikon

anti-aircraft gun located on the USS Kidd in Baton Rouge, LA.

Chrysler built 156,585 Magazine Lever Assemblies that can be seen in

more detail in the following photo. Author's photo.

Author's photo.

This is one of 119,814 industrial engines

built by Chrysler with a fire pump attached. Author's photo from

the Michigan Military Technical and Historical Society added 11-29-2017.

Author's photo from the Michigan Military Technical and Historical

Society added 11-29-2017.

Author's photo from the Michigan Military

Technical and Historical Society added 11-29-2017.

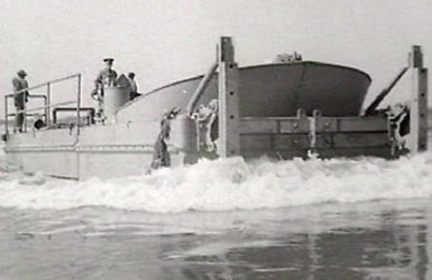

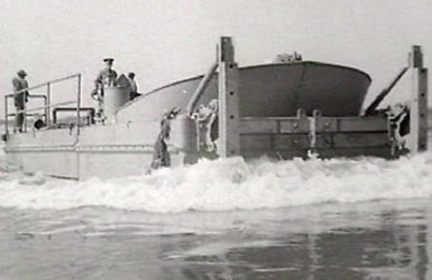

Chrysler also built 2,228 Marine Tractors, or

Sea Mules, like the one pictured here to be used as small tugboats inside

harbors. Each was powered by two Chrysler Marine Engines.

|