|

International Harvester in World War Two

Chicago, IL

1902-1985 (For combined farm

implement and truck operations.)

Navistar International continues IH trucks today.

This page

updated 3-2-2023.

International Harvester started producing motor vehicles with the "Auto

Buggy" in 1907, and built the first 100 at the McCormick Works in

Chicago, IL, before moving production to Akron, OH in 1908.

Production moved once again in 1922 to Springfield, OH with a second

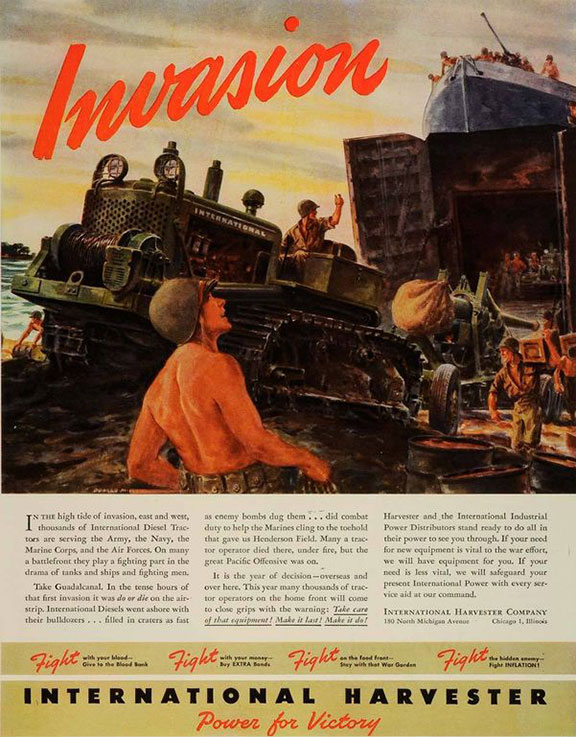

plant added in Fort Wayne, IN a year later. The 13,622 half-tracks were built at the Springfield facility from October 1942 through

January 1944. Many of the trucks built by International were used

by the Navy or Marine Corps or became part of the Lend-Lease program.

In 1944 International

Harvester employed an average of 68,940 employees.

This is a 1909 International Harvester Auto

Wagon, its first truck. 3,441 were built in Akron, OH. It came with a 16 hp engine. Author's photo at the National Auto and Truck Museum in Auburn,

IN.

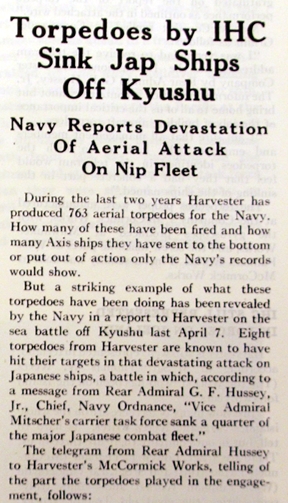

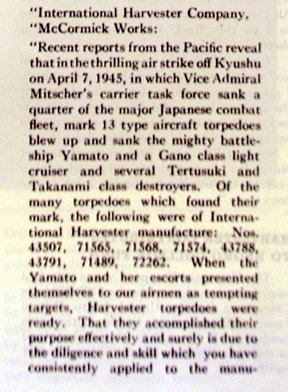

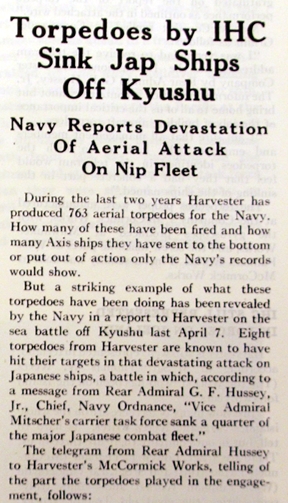

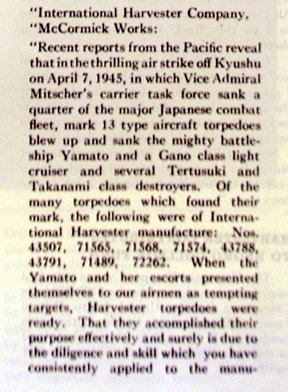

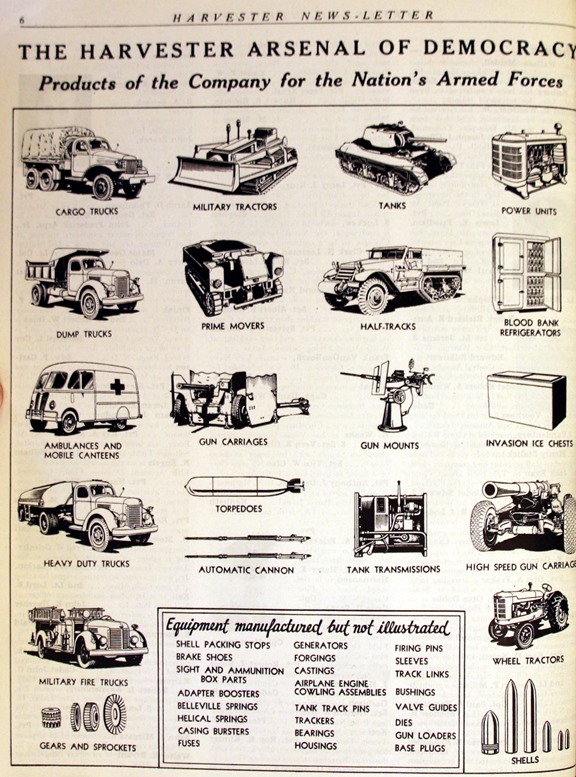

International Harvester-built Mark XIII torpedoes

help sink the Japanese super-battleship Yamato!

How cool is this? Of the 763 torpedoes

built by IH during World War Two, the U.S. Navy was able to identify by

serial number those built by the company used in this attack. They

were Serial Numbers 43507, 71565, 71568, 71574, 43788, 43791, 71489 and

72262. The full story is below.

Added 2-9-2020.

Added 2-9-2020.

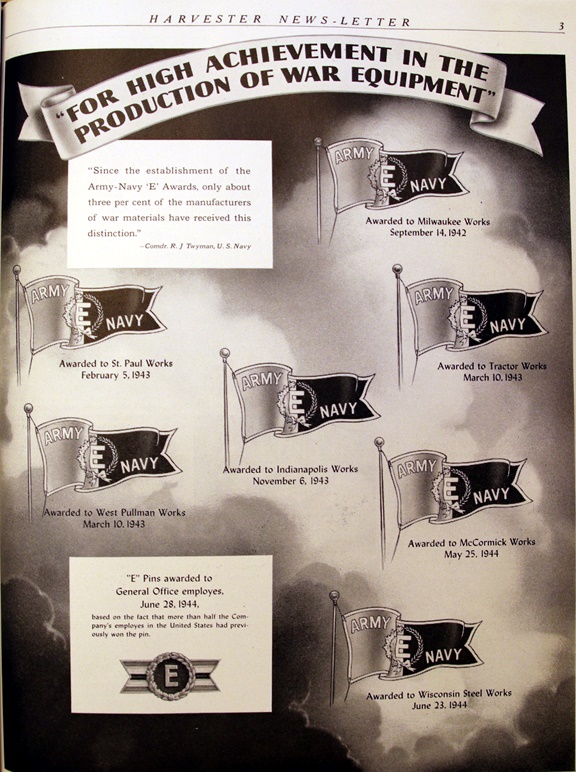

International Harvester won 24 Army-Navy "E" Awards during World War

Two.

|

International Harvester Army-Navy "E" Awards during World

War Two |

|

Plant |

Location |

Product |

Date of First Award |

Total Number of "E" Awards |

| McCormick Works |

Chicago, IL |

Mark XIII Aerial Torpedoes |

5-25-1944 |

2 |

| Tractor Works |

Chicago, IL |

Farm Tractors and Military Bulldozers |

3-10-1943 |

5 |

| West Pullman Works |

Chicago, IL |

37mm cannon shells, Bellevue springs for artillery recoil

mechanisms, screw machine parts for torpedoes |

3-10-1943 |

2 |

| Wisconsin Steel Works

|

Chicago, IL |

Steel |

6-23-1944 |

3 |

| Indianapolis Works |

Indianapolis, IN |

Truck engines,

20mm Oerlikon anti-aircraft gun mounts |

11-6-1943 |

3 |

| St Paul Works |

St. Paul, MN |

57mm anti-tank guns |

2-5-1943 |

4 |

|

Milwaukee Works |

Milwaukee, WI |

75mm cannon shells, tracked

crawlers, stationary engines, gyroscopes for torpedoes |

9-14-1942 |

5 |

|

Total |

|

|

|

24 |

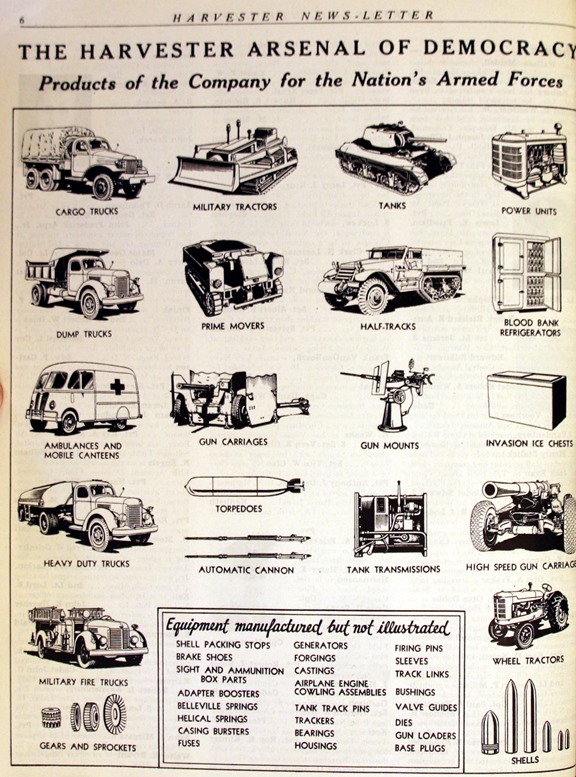

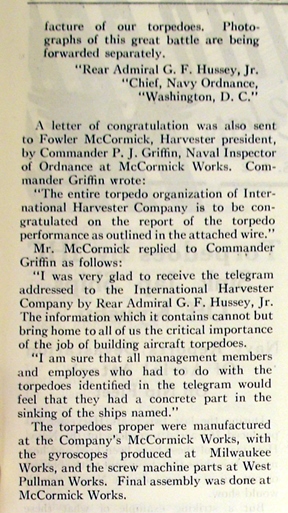

This page from a 1944 edition of the

Harvester News-Letter shows the dates when the plants won their

first awards. Of interest is that the General Office employees

were awarded "E" pins. Added 2-9-2020.

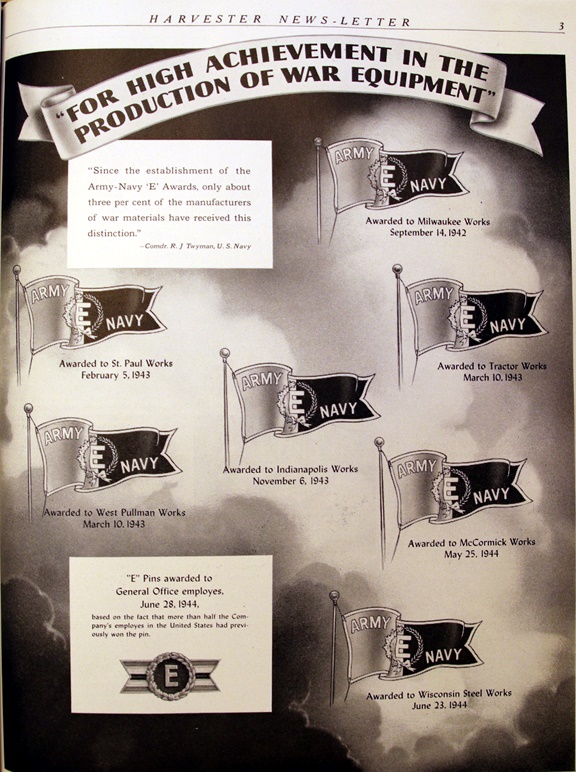

International Harvester was prolific in

the number of products it built to help win World War Two. It

was one of the largest suppliers of war goods and supplies to the

U.S. military during the war. Added 2-9-2020.

International Harvester World War Two Production Statistics:

In 1944 52.5% of the output of International Harvester was for military

products, as the company was also building commercial trucks and

tractors that were needed to keep the American war economy going.

Vehicles: International Harvester had both the US Army and

US Navy/USMC as customers for its trucks in World War Two.

US Navy/USMC from Tables 2A,

2B, 2C: 1,123 M-1-4 1/2-Ton 4x4 Utility Trucks, 9,904

M-2-4 One-Ton 4x4 Trucks, 6,532 M-3-6 1-1/2-Ton 4x4 Trucks, 40,087 M-5-6 2-1/2-Ton 6x6 Cargo

Trucks, and 20 Low Silhouette M-5-6.

US Army from Table 1:

28,723

trucks of various types and sizes as shown below.

Half-tracks from Table 3:

13,622 half-tracks

Crawlers/Tractors from Table 5: 3,865 TD-6,

19,524 TD-9, 8,848

TD-14, and 7,485 TD-18. These are total production numbers from 1942-1945 by IH,

including all military services and any

civilian needs.

Below is a table showing

acceptances by Army Ordnance of tractors in World War Two. Starting

in 1944, the US Army Corps of Engineers took over responsibility for the

acceptances of construction-type tractors. Therefore, the

information for the US Army is incomplete. There were also 5,290

M5 and 266 M5A1 13-ton high speed tractors (artillery prime movers)

built by International Harvester as noted below.

Armament:

20mm aircraft cannons, 40mm Bofors anti-aircraft gun loading mechanisms, 37mm cannon shells, Bellevue springs for artillery

recoil mechanisms, 57mm anti-tank guns, 75mm cannon shells, 105mm shell

casings, Thunderbolt 20mm Oerlikon Quad gun mounts, 7 M7 tanks. (Another

20 were still unfinished on the production lines.)

Tank Refurbishment:

166 M3A3 light tanks were refurbished in April, May and June 1945.

269 M4 medium tanks were refurbished between August 1944 and March

1945. 737 M4A1 medium tanks were refurbished between November

1944 and March 1945.

Tank Conversion: 50 T14E1 tank retrievers were converted

from M4A3(105)s, which were pulled off of the Chrysler Tank Arsenal assembly

line in March and April 1945. These were intended for

the USMC to be used in the invasion of Japan.

Other: 830

M22 tank transmissions and differentials, C-46 aircraft engine cowlings,

20mm aircraft cannons, airfield command trucks, armored scout car hulls,

gun

loaders, blood bank refrigerators, 155 mm high speed gun carriages, 57mm

anti-tank gun carriages, USMC invasion ice

chests, 763 Mark VIII aerial torpedoes, and tracking units for the M9 gun

director.

Editor's note:

The 155mm High Speed Gun Carriages were an early war product. The

1941 Congressional Record shows that production of the gun carriages was

temporarily suspended due to a strike at its casting supplier in May

1941. I have not yet found a 155 gun carriage built by

International-Harvester. At the same time, I have found several by

other manufacturers.

International Harvester ranked 33rd in

dollar value of World War Two production contracts.

|

Table 1 - International Harvester Trucks

Accepted by Detroit Ordnance, US Army

The information below comes from "Summary Report of

Acceptances, Tank-Automotive Material, 1940-1945."

Published by Army Services Forces, Office, Chief of

Ordnance-Detroit, Production Division, Requirements and

Progress Branch.

January 21, 1946. |

|

Type |

IH Model |

1940 |

1941 |

1942 |

1943 |

1944 |

1945 |

Total |

| 1-ton 4x2

chassis (Metro Body) |

|

|

|

1 |

|

|

|

1 |

| 2-1/2-ton 6x4

cargo |

|

|

|

3,000 |

|

|

|

3,000 |

| 2-1/2-ton 4x2

chassis for 37 passenger bus |

|

|

|

|

|

1,194 |

1,859 |

1,194* |

| 2-1/2-ton 4x2

chassis for 37 passenger bus |

K-7 |

|

|

|

|

6 |

|

6** |

| 2-1/2-ton 4x2

cargo |

K-7 |

|

5 |

68 |

|

|

|

73 |

| 2-1/2-ton

chassis 4x2 for 1000 gal gas tank |

K-7 |

|

100 |

2 |

|

|

|

102 |

| 2-1/2-ton 4x2

dump truck |

K-7 |

|

1,324 |

3,461 |

1,129 |

225 |

|

6,139 |

| 2-1/2-ton 4x2

stake |

K-7 |

|

|

2 |

|

|

|

2 |

| 2-1/2-ton

stand platform 4x2 |

K-7 |

|

7 |

18 |

|

|

|

25 |

| 2-1/2-ton 4x2

stake and pole derrick |

K-7 |

|

|

1 |

|

|

|

1 |

| 2-1/2-ton 4x2

tractor |

K-7 |

|

|

220 |

|

|

|

220 |

| 2-1/2-3-ton

6x6 low silhouette |

DF6x6 |

10 |

|

|

|

|

|

10 |

| 3-ton 4x4 low

silhouette |

DF4x4 |

10 |

|

|

|

|

|

10 |

| 3-1/2-ton 4x2

chassis |

|

|

1,500 |

|

|

|

|

1,500 |

| 3-1/2-ton 4x2

tractor |

|

|

500 |

|

|

|

|

500 |

| 5-ton 4x2

cargo |

KR-11 |

|

100 |

2 |

|

|

|

102 |

| 5-ton 4x2

dump |

KR-11 |

|

70 |

644 |

500 |

1,031 |

1,063 |

3,308 |

| 5-ton 4x2

tractor 161 inch WB |

|

|

|

|

30 |

981 |

221 |

1,232 |

| 5-ton

4x2 tractor SWB light duty 120 inch WB M425 |

H-542-9 |

|

|

|

|

4,030 |

610 |

4,640 |

| 5-ton

4x2 tractor SWB heavy duty 120 inch WB M426*** |

H-542-11 |

|

|

|

|

4,850 |

1,828 |

6,678 |

| Total |

|

20 |

3,606 |

7,419 |

1,659 |

12,317 |

5,581 |

28,723 |

Author's Note

and Disclaimer: The Detroit Office

of Ordnance of the U.S. Army was the primary purchasing entity for

vehicles for the U.S. Army during World War Two. It also purchased vehicles

for the USMC, US Navy, and for Lend-Lease. However, there were

other organizations that also purchased vehicles including the Army

Corps of Engineers, U.S. Army Air Force, U.S. Army Signal Corps, Navy

Bureau of Ordnance, Navy Bureau of Aeronautics, and foreign countries

making direct purchases.

In the case of International Harvester the

US Navy/USMC purchased many trucks as shown above.

* Includes 1,859 trucks scheduled for the fourth quarter of 1945.

** These were provided to the Surgeon General.

*** In 1944-45 3,200 M426 tractors were built by Marmon-Herrington and

1,100 by Kenworth. Marmon-Herrington converted 1,200 M425 to M426

specifications in 1945.

Table 2 -

International

Harvester Fort Wayne, IN and Springfield, OH Truck

Production during World War Two

Information in this table comes from "International

Trucks" by Fred Crismon via Bill Kreiner.

While automobile production stopped in February 1942,

commercial trucks were still produced during the war,

although not at the pre-war rate. This table shows how

the Fort Wayne, IN and Springfield, OH assembly plants

balanced both military and civilian truck production during

the war. The totals at the bottom of the table include only

the years 1941-1945, when the two truck plants were

producing military vehicles. 1940 is used as the reference

year, to give a pre-war civilian truck baseline.

Most of the 1942 civilian truck production went to the

military. |

|

Year |

Fort Wayne Military |

Fort Wayne Civilian |

Fort Wayne Total |

Springfield Military |

Springfield Civilian |

Springfield Total |

Total Military |

Total Civilian |

Grand Total |

|

1940 |

0 |

22,187 |

22,187 |

0 |

64,439 |

64,439 |

0 |

86,626 |

86,626 |

|

1941 |

500 M-5-6 |

26,516 |

27,016 |

Trucks:

74 M-1-4

53 M-2-4

341 M-3-4

= 468 |

86,047 |

86,515 |

968 |

112,563 |

113,531 |

| 1942 |

3,932 M-5-6

20 Low Silhouette M-5-6 |

22,420 |

26,372 |

Trucks:

437 M-1-4

1,600 M-2-4

1,508 M-3-4

= 3,545

Half-tracks:

152 M5

5 M14

= 157 |

31,972 |

35,674 |

7,654 |

54,322 |

61,976 |

| 1943 |

6,843 M-5-6 |

10,773

|

17,616 |

Trucks:

615 M-1-4

4,583 M-2-4

3,503

M-3-4

= 8,701

Half-tracks:

4,473 M5

1,859 M5A1

2,026 M9

1,407 M9A1

1,600 M14

400 M17

= 17,765 |

30,908 of

which 12,986 were K5 War Specials |

57,374 |

33,309 |

41,681 |

74,990 |

| 1944 |

9,741

M-5-6 |

10,768 |

20,509 |

Trucks:

1,865 M-2-4,

1,180 M-3-4

4,030 H-542-9 (M425)

4,850 H-542-11 (M426)

= 11,925Half-tracks:

1,100 M5A1

600 M17

= 1,700 |

9,452 |

23,077 |

23,366 |

20,220 |

43,586 |

| 1945 |

17,472 M-5-6 |

6,864 |

24,336 |

Trucks:

5,058 H-542-11* (M426)

Half-tracks:

589 M5A1**

1 M5A3*** |

35,901 |

41,548 |

23,119 |

42,765 |

65,884 |

|

Total 1941-1945 |

38,508 M-5-6

20 Low Silhouette M-5-6 |

77,341 |

115,829 |

1,126 M-1-4

8,101 M-2-4

6,532 M-3-4

4,030 H-542-9 (M425)

4,850 H-542-11 (M426) |

194,280 |

244,188 |

88,416 |

271,551 |

359,967 |

*This does not

match up with the Army Ordnance figure of 1,828 accepted

during 1945 in Table 1. Also, there were 610 H-542-9

(M425) vehicles accepted by Army Ordnance not shown produced

by the Springfield plant. It could be that these were shown

as H-542-11s by Springfield in its accounting. Adding

1,828 and 610 =2,468, which is still 2,590 in excess of this

type of truck accepted by the Army in 1945. The excess of

those accepted may have ended up in the post-war civilian

market.

**This does not match up with the Army Ordnance figure of 0

accepted during 1945 in Table 3.

***This does not match up with the Army Ordnance figure of 0

accepted during 1945 in Table 3. This may have been a

prototype. There is no known documentation on what it

could have been. Development work on the IH half-track

series ended in October 1943 with the M5A2.

|

Table 2A - Half-Ton Truck 4x4 Production Data |

|

IHC Model Number |

Type |

Quantity |

IHC Serial Numbers |

Contract |

Customer |

|

M-1-4 (214) |

Cargo |

57 |

501-570 |

NOm 28692 |

USMC |

|

M-1-4 (214) |

Cargo with Radio Shielding |

4 |

|

M-1-4 (214) |

Ambulance |

9 |

|

M-1-4 (233) |

Cargo |

66 |

571-697 |

NOm 29992 |

USMC |

|

M-1-4 (233) |

Cargo with Radio Shielding |

71 |

|

M-1-4 (233) |

Ambulance |

60 |

|

M-1-4 (233) |

Ambulance |

28 |

698-725 |

NOs LL-95051 |

USN |

|

M-1-4 (233) |

Cargo |

26 |

726-758 |

NOm 32660 |

USMC |

|

M-1-4 (233) |

Cargo with Radio Shielding |

7 |

|

M-1-4 (233) |

Ambulance |

100 |

759-858 |

NOm 32755 |

USMC |

|

M-1-4 (233) |

Ambulance |

80 |

859-938 |

NOs LL-95051 supplement |

USN |

|

M-1-4 (233) |

Ambulance |

25 |

939-963 |

NOs 4605A |

USN |

|

M-1-4 (233) |

Ambulance |

100 |

964-1063 |

NOm 35773 |

USMC |

|

M-1-4 (233) |

Ambulance with Radio Suppression |

490 |

1064-1553 |

NOm 37671 |

USMC |

|

Total |

|

1,123 |

|

|

|

|

Table 2B - One-Ton 4x4 Truck

Production Data |

|

IHC Model Number |

Type |

Quantity |

IHC Serial Numbers |

Contract |

Customer |

|

M-2-4 (233) |

Cargo |

38 |

501-548 |

NOm 29690 |

USMC |

|

M-2-4 (233) |

Cargo with Winch |

10 |

|

M-2-4 (233) |

Cargo |

250 |

553-866* |

NOm 29948 |

USMC |

|

M-2-4 (233) |

Cargo with Winch |

60 |

|

M-2-4 (233) |

Cargo |

226 |

867-1152 |

NOm 32660 |

USMC |

|

M-2-4 (233) |

Cargo with Winch |

60 |

|

M-2-4 (233) |

Cargo with Winch with Radio Suppression |

1,000 |

1153-2152 |

NOm 33887 |

USMC |

|

M-2-4 (233) |

Cargo with Winch with Radio Suppression |

150 |

2153-2302 |

NOm 35075 |

USMC |

|

M-2-4 (233) |

Cargo with Winch with Radio Suppression |

500 |

2303-2802 |

NOm 35773 |

USMC |

|

M-2-4 (233) |

Cargo with Winch with Radio Suppression |

100 |

2803-2902 |

NOm 35942 |

USMC |

|

M-2-4 (233) |

Cargo with Winch with Radio Suppression |

4,900 |

2903-7802 |

NOm 37471 |

USMC |

|

M-2-4 (233) |

Cargo with Winch with Radio Suppression |

1,200 |

7803-9002 |

NOm 40397 |

USMC |

|

M-2-4 (233) |

Cargo with Winch with Radio Suppression |

600 |

9003-9602 |

Amendment to NOm 40397 |

USMC |

|

Total |

|

9,094 |

|

|

|

*There is a quantity of 310 units for contract NOm

299948. The quantity of serial numbers is 314. Four serial

numbers are not included. These are 549, 550, 551, and 552.

This discrepancy may affect the final total of 9,094 units built or the

proper order of serial numbers for the later built vehicles. It is

unknown what is correct and what is incorrect.

|

Table 2C - One and a Half-Ton 4x4

Truck Production Data |

|

IHC Model Number |

Type and Body Manufacturer |

Wheelbase (Inches) |

Quantity |

IHC Serial Numbers |

Contract |

Customer |

|

M-3L-4 (259) |

Cargo (Galion) |

139 |

132 |

501-632 |

NOm 28827 |

USMC |

|

M-3L-4 (259) |

Cargo (Galion) |

139 |

30 |

633-684 |

NOm 29412 |

USMC |

|

M-3L-4 (259) |

Tank (Columbia) |

139 |

2 |

|

M-3L-4 (259) |

Cargo (Galion) |

139 |

20 |

|

M-3L-4 (259) |

Cargo (Anthony) |

139 |

129 |

685-821 |

NOm 29419 |

USMC |

|

M-3L-4 (259) |

Wrecker (Gar Wood) |

139 |

8 |

|

M-3L-4 (259) |

Wrecker (Gar Wood) |

139 |

3 |

822-824 |

NO 2655 10661 |

USN |

|

M-3L-4 (259) |

Cargo (Anthony) |

139 |

107 |

825-935 |

NOm 32660 |

USMC |

|

M-3L-4 (259) |

Wrecker (Gar Wood) |

139 |

4 |

|

M-3L-4 (259) |

Wrecker (Gar Wood) |

139 |

7 |

936-942 |

NOx 99040 |

USN |

|

M-3L-4 (269) |

Refueler (Gar Wood) |

139 |

820 |

943-1762 |

NOx 786A |

USN |

|

M-3L-4 (269) |

Refueler (Gar Wood) |

139 |

900 |

1763-2662 |

NXa 7730 |

USN |

|

M-3L-4 (269) |

Wrecker (Gar Wood) |

139 |

100 |

2663-2762 |

|

M-3L-4 (269) |

Crash (Bean) |

139 |

400 |

2763-3162 |

|

M-3L-4 (269) |

Refueler (Gar Wood) |

139 |

400 |

3163-3562 |

N268a 15373 |

USN |

|

M-3L-4 (269) |

Crash (Bean) |

139 |

230 |

3563-3792 |

|

M-3L-4 (269) |

Crash (Bean) |

139 |

450 |

3793-4242 |

NXSA 32148 |

USN |

|

Total |

|

|

3,742 |

|

|

|

|

M-3H-4 (259) |

Cargo (Galion) |

150 |

20 |

501-520 |

NOm 26887 |

USMC |

|

M-3H-4 (269) |

Cargo (Anthony) |

150 |

860 |

521-1380 |

NOs 786 |

USN |

|

M-3H-4 (269) |

Crash (American LaFrance) |

150 |

210 |

1381-1590 |

NOs 3995A |

USN |

|

M-3H-4 (269) |

Cargo (Meteor Wood) |

150 |

1440 |

1591-3090 |

NSx 7730 |

USN |

|

M-3H-4 (269) |

Chassis Only |

150 |

60 |

|

M-3H-4 (269) |

Floodlight |

150 |

100 |

3091-3190 |

NSx 7730 |

USN |

|

M-3H-4 (269) |

Floodlight |

150 |

100 |

3191-3290 |

NXSA 32148 |

USN |

|

Total |

|

|

2,790 |

|

|

|

|

Grand Total |

|

|

6,532 |

|

|

|

|

Table 2C - Two and a Half-Ton

6x6 Truck Production Data |

|

IHC Model Number |

Type and Body Manufacturer |

Wheelbase (Inches) |

Quantity |

IHC Serial Numbers |

Contract |

Customer |

|

Trucks with International

Harvester FBC-361B Engines |

|

M-5H-6 |

Cargo

(Anthony) |

169 |

800 |

501-1680 |

NOm-33976 |

USMC |

|

M-5H-6 |

Dump (Heil) |

149 |

200 |

|

M-5H-6 |

Wrecker (Gar

Wood) |

149 |

20 |

|

M-5H-6 |

Refueler (Gar

Wood) |

149 |

10 |

|

M-5H-6 |

Cargo

(Anthony) |

169 |

150 |

NOm-34956 |

USMC |

|

M-5H-6 |

Cargo

(Anthony) |

169 |

260 |

1681-1972 |

NOs-3538A |

USN |

|

M-5H-6 |

Dump (Heil) |

149 |

32 |

|

M-5H-6 |

Cargo

(Anthony) |

169 |

450 |

1973-2472 |

NOm-35402 |

USMC |

|

M-5H-6 |

Dump (Heil) |

149 |

50 |

|

M-5H-6 |

Cargo

(Anthony) |

169 |

750 |

2473-3282 |

NOm-35941 |

USMC |

|

M-5H-6 |

Wrecker (Gar

Wood) |

149 |

35 |

|

M-5H-6 |

Refueler (Gar

Wood) |

149 |

25 |

|

Total

M-5H-6 with FBC-361B

Engines

|

2,782 |

|

|

|

|

Trucks with International

Harvester RED-361B Engines |

|

M-5H-6 |

Cargo

(Anthony) |

169 |

2,700 |

3283-11067 |

NOm-37471 |

USMC |

|

M-5H-6 |

Dump (Heil) |

149 |

3,800 |

|

M-5H-6 |

Dump (Galion) |

149 |

400 |

|

M-5H-6 |

Dump (St.

Paul) |

149 |

400 |

|

M-5H-6 |

Wrecker (Gar

Wood) |

149 |

40 |

|

M-5H-6 |

Refueler (Gar

Wood) |

149 |

345 |

|

M-5H-6 |

Chassis Only |

149 |

100 |

|

M-5H-6 |

Dump (Heil) |

149 |

60 |

11068-11287 |

N288S-11512 |

USN |

|

M-5H-6 |

Tractor |

149 |

100 |

|

M-5H-6 |

Chassis Only |

169 |

60 |

|

M-5H-6 |

Cargo

(Anthony) |

149 |

2,200 |

11288-15637 |

NOm-40397 |

USMC |

|

M-5H-6 |

Dump

(Anthony) |

169 |

1,800 |

|

M-5H-6 |

Wrecker (Gar

Wood) |

149 |

150 |

|

M-5H-6 |

Cargo

(Anthony) |

149 |

200 |

|

M-5H-6 |

Tractor |

149 |

250 |

15638-18287 |

NXSA-32148 |

USN |

|

M-5H-6 |

Chassis Only |

169 |

200 |

|

M-5H-6 |

Refueler (Gar

Wood) |

149 |

1,100 |

|

M-5H-6 |

Cargo

(Anthony) |

169 |

1,000 |

|

M-5H-6 |

Dump

(Anthony) |

149 |

100 |

|

M-5H-6 |

Cargo

(Anthony) |

169 |

1200 |

18288-19487 |

Nom-40397

Ext. |

USMC |

|

M-5H-6 |

Dump

(Anthony) |

149 |

150 |

19488-19987 |

NXSA-32148 Ext. |

USN |

|

M-5H-6 |

Chassis Only |

169 |

250 |

|

M-5H-6 |

Cargo

(Anthony) |

169 |

100 |

|

M-5H-6 |

Cargo

(Anthony) |

169 |

800 |

19988-20787 |

NOm-40397

Ext. |

USMC |

|

M-5H-6 |

Dump

(Anthony) |

149 |

1,800 |

20788-22587 |

NOm-40397

Ext. |

USMC |

|

M-5H-6 |

Tractor |

169 |

6,000 |

22588-38687 |

NOm-43833 |

USMC |

|

M-5H-6 |

Dump

(Anthony) |

149 |

7,600 |

|

M-5H-6 |

Dump

(Anthony) |

149 |

500 |

|

M-5H-6 |

Chassis Only |

149 |

400 |

|

M-5H-6 |

Chassis Only |

169 |

1,600 |

|

M-5H-6 |

Cargo

(Anthony) |

169 |

700 |

38688-40587 |

NXSA-57539 |

USN |

|

M-5H-6 |

Chassis Only |

169 |

100 |

|

M-5H-6 |

Tractor |

149 |

300 |

|

M-5H-6 |

Refueler (Gar

Wood) |

149 |

800 |

|

Total

M-5H-6 with RED-361B

Engines |

37,305 |

|

|

|

|

Total

M-5H-6 with FBC-361B

and RED-361B

Engines |

40,087 |

|

|

|

|

Table 3 - International Harvester Half-tracks

Accepted by Detroit Ordnance, US Army

The information below comes from "Summary Report of

Acceptances, Tank-Automotive Material, 1940-1945."

Published by Army Services Forces, Office, Chief of

Ordnance-Detroit, Production Division, Requirements and

Progress Branch.

January 21, 1946. |

|

Type |

1940 |

1941 |

1942 |

1943 |

1944 |

1945 |

Total |

| M9 |

|

|

|

2,606 |

|

|

2,606 |

| M9A1 |

|

|

|

1,407 |

|

|

1,407 |

| M5 |

|

|

152 |

4,473 |

|

|

4,625 |

| M5A1 |

|

|

|

1,859 |

1,100 |

|

2,959 |

| Carriage,

twin cal .50 MB, M14 |

|

|

5 |

1,605 |

|

|

1,505 |

| Carriage,

multiple gun, M17 |

|

|

|

400 |

6,00 |

|

1,000 |

| Total |

|

|

157 |

11,765 |

1,700 |

|

13,622 |

Author's Note

and Disclaimer: The Detroit Office

of Ordnance of the U.S. Army was the primary purchasing entity for

vehicles for the U.S. Army during WWII. It also purchased vehicles

for the USMC, US Navy, and for Lend-Lease. However, there were

other organizations that also purchased vehicles including the Army

Corps of Engineers, U.S. Army Air Force, U.S. Army Signal Corps, Navy

Bureau of Ordnance, Navy Bureau of Aeronautics, and foreign countries

making direct purchases.

|

Table 4 - International-Harvester Half Track Production |

| Year |

Number built |

Type |

Comments |

| 1942-1943 |

(4,625)

|

M5 |

Similar to the M3

built by Autocar, Diamond T, and White. Due to differences,

International units did not see combat with US combat forces.

Some were used in state-side training, but the majority were

supplied to Allied Forces under Lend-Lease. |

| 1943-1944 |

(2,959)

|

M5A1 |

Similar to the

M3A1 built by Autocar, Diamond T, and White. Due to

differences, International units did not see combat with US

combat forces. Some were used in state-side training, but the

majority were supplied to Allied Forces under Lend-Lease. |

| 1943 |

(2,026) |

M9 |

Similar to the M2

built by Autocar, Diamond T, and White. Due to differences,

International units did not see combat with US combat forces.

Some were used in state-side training, but the majority were

supplied to Allied Forces under Lend-Lease. |

| 1943 |

(1,407) |

M9A1 |

Similar to the

M2A1 built by Autocar, Diamond T, and White. Due to

differences, International units did not see combat with US

combat forces. Some were used in state-side training, but the

majority were supplied to Allied Forces under Lend-Lease. |

| 1942-1943 |

(1,605) |

M14 |

Similar to the

M13 built by Autocar, Diamond T, and White. Due to

differences, International units did not see combat with US

combat forces. All went to the British Army. |

| 1943-1944 |

(1,000) |

M17 |

Similar to the

M16 built by Autocar, Diamond T, and White. Due to

differences, International units did not see combat with US

combat forces. All went to the Soviet Union. |

| Total |

13,622 |

|

|

|

Table 5 - International Harvester Tractors

Accepted by Detroit Ordnance, US Army

The information below comes from "Summary Report of

Acceptances, Tank-Automotive Material, 1940-1945."

Published by Army Services Forces, Office, Chief of

Ordnance-Detroit, Production Division, Requirements and

Progress Branch.

January 21, 1946.

In 1944 the Army Corp of Engineers took over the

responsibility of accepting construction type tractors.

Therefore, 1944 and 1945 have

been blanked out for most of the tractors below.

|

|

Type |

Same As |

1940 |

1941 |

1942 |

1943 |

1944 |

1945 |

Total |

| Tractor,

light, w/w, M2 |

|

|

|

|

155 |

|

|

155 |

| Tractor,

light, M2 |

Caterpillar,

Cleveland Tractor |

0 |

3 |

459 |

|

|

|

462 |

| Tractor,

medium, M1 |

Allis

Chalmers, Caterpillar, Cleveland Tractor |

0 |

275 |

260 |

|

|

|

535 |

| Tractor, High Speed, 13 ton, M5 |

|

|

|

|

965 |

3,503 |

812 |

5,290 |

| Tractor, High

Speed, 13 ton, M5A1 |

|

|

|

|

|

|

582 |

582 |

| Tractor, High

Speed, 13 ton, M5A3 |

|

|

|

|

|

|

1 |

1 |

| Tractor, Med,

diesel , 45 hp |

Allis

Chalmers |

|

102 |

332 |

39 |

|

|

473 |

| Tractor,

Heavy, M1 |

Allis

Chalmers, Caterpillar |

180 |

699 |

456 |

460 |

|

|

1,795 |

| Tractor,

Crane, 1 ton, M1 |

Allis

Chalmers |

|

120 |

57 |

|

|

|

177 |

| Tractor,

Crane, 2 ton, M5 |

|

|

|

|

321 |

|

|

321 |

| Tractor,

Crane, medium, M3 |

Caterpillar |

|

92 |

438 |

1,210 |

|

|

1,740 |

| Tractor,

Crane, heavy, M4 |

Caterpillar |

|

5 |

9 |

|

|

|

14 |

| Tractor, Snow, T29 |

Willys-Overland |

|

|

|

5 |

|

|

5 |

| Total |

|

180 |

1,296 |

2,011 |

3,155 |

3,503 |

1,395 |

11,550 |

Author's Note

and Disclaimer: The Detroit Office

of Ordnance of the U.S. Army was the primary purchasing entity for

vehicles for the U.S. Army during WWII. It also purchased vehicles

for the USMC, US Navy, and for Lend-Lease. However, there were

other organizations that also purchased vehicles including the Army

Corps of Engineers, U.S. Army Air Force, U.S. Army Signal Corps, Navy

Bureau of Ordnance, Navy Bureau of Aeronautics, and foreign countries

making direct purchases.

This 1942 International Harvester TD-18 was

at the 2020 Tri-State Antique Gas Engine and Tractor Show in Portland,

IN. See more photos in the tractor section below. Author's

photo added 8-28-2020.

Table 6 - International Harvester New and

Rebuilt Tanks

Accepted by Detroit Ordnance, US Army

The information below comes from "Summary Report of

Acceptances, Tank-Automotive Material, 1940-1945."

Published by Army Services Forces, Office, Chief of

Ordnance-Detroit, Production Division, Requirements and

Progress Branch.

January 21, 1946. |

|

Type |

|

1940 |

1941 |

1942 |

1943 |

1944 |

1945 |

Total |

| Tank, Medium,

M7 |

New |

|

|

3 |

4 |

|

|

7 |

| Tank recovery

vehicle T14E1 |

Conversion |

|

|

|

|

|

50 |

50 |

| Tank, Light,

M3A3 |

Rebuild |

|

|

|

|

|

220 |

220 |

| Tank, Medium,

M4A1, 75mm gun |

Rebuild |

|

|

|

|

249 |

488 |

737 |

Author's Note

and Disclaimer: The Detroit Office

of Ordnance of the U.S. Army was the primary purchasing entity for

vehicles for the U.S. Army during WWII. It also purchased vehicles

for the USMC, US Navy, and for Lend-Lease. However, there were

other organizations that also purchased vehicles including the Army

Corps of Engineers, U.S. Army Air Force, U.S. Army Signal Corps, Navy

Bureau of Ordnance, Navy Bureau of Aeronautics, and foreign countries

making direct purchases.

This period photo shows one of the seven M7 tanks

that were produced by IH during WWII. Army Ordnance realized the

M7 had no significant improvements over the M4 Sherman tank, and

production was halted.

|

Table 7 - International Harvester Products during World War Two |

|

Plant |

Location |

Product |

Comments |

| McCormick Works |

Chicago, IL |

Mark XIII Aerial Torpedoes |

|

| Tractor Works |

Chicago, IL |

Farm Tractors and Military Bulldozers,

40mm Bofors anti-aircraft gun loading mechanism |

|

| West Pullman Works |

Chicago, IL |

37mm cannon shells |

|

| Wisconsin Steel Works

|

Chicago, IL |

Steel |

|

| Indianapolis Works / Truck Engine Works |

Indianapolis, IN |

Truck engines,

20mm Oerlikon anti-aircraft gun mounts |

|

| Indianapolis

Branch House |

Indianapolis, IN |

M22

tank transmissions and differential assemblies |

This was the sales branch office located at 230 South

Capital Ave. Temporary space was found in the

building for the assembly of the M22 tank transmissions and

differential assemblies. Twenty persons working in a

10,000 square foot area began building the assemblies in

April 1943. The completed assemblies were then shipped to the nearby

Marmon-Herrington plant for installation into the tanks. |

| Fort Wayne Works |

Fort Wayne, IN |

Trucks |

|

| Bettendorf Tank Arsenal |

Bettendorf, IA |

M7 tanks, M5, Crawlers |

This

tank arsenal was built to produce 3,000 M7 tanks. The

contract was cancelled in 1943 after only 7 M7s had been

completed. Another 20 were partially built on the

assembly line. |

|

East Moline Works |

East Moline, IL |

Gun Trackers for M9 Gun Directors |

This product, due to security reasons, was not announced by

IH until December 1944. The M9 was used on the 90mm

anti-aircraft gun and was credited with being responsible

for shooting down a large number of V-1 "Buzz Bombs" over

southern England and Antwerp, Belgium. |

| St Paul Works |

St. Paul, MN |

57mm anti-tank guns |

|

| New Brighton Works,

|

New Brighton, MN |

105mm shell casings |

|

| Springfield Works |

Springfield, OH |

M5, M9 half-tracks, trucks |

|

| Chatham Works |

Chatham, ONT |

Trucks |

|

|

Milwaukee Works |

Milwaukee, WI |

75mm cannon shells, tracked

crawlers, wheeled tractors, stationary engines |

|

| Auburn (Osborne) Works |

Auburn, NY |

C-46 Engine cowlings |

|

Aerial Torpedoes:

International-Harvester received its order for the production of the

Mark VIII aerial torpedo in early 1942 and began production five months

ahead of the schedule given to it by the U.S. Navy for the spring 1943.

The first torpedo came off the IH assembly line in November 1942.

The company also built the gyroscopes that helped direct the torpedoes

to their target. 7,000 employees were involved in building the

torpedoes.

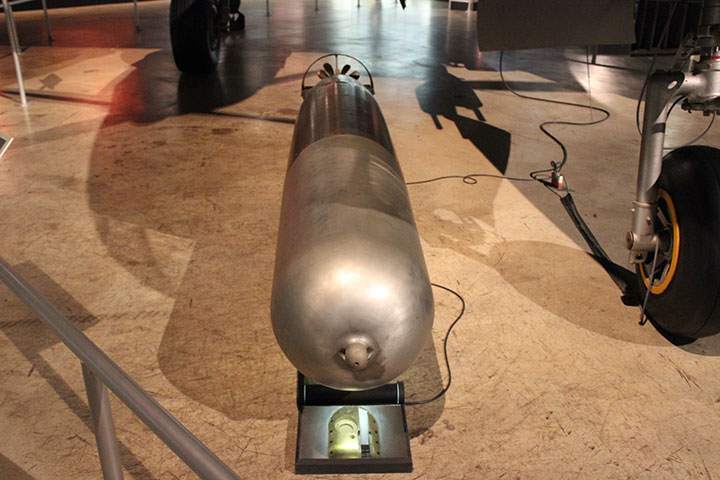

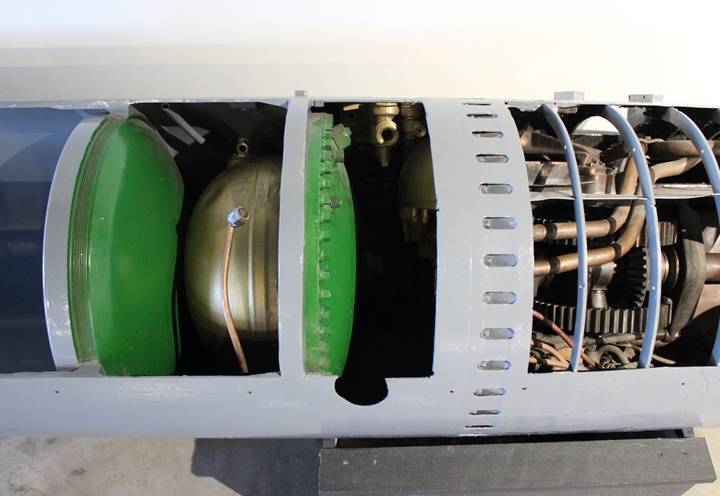

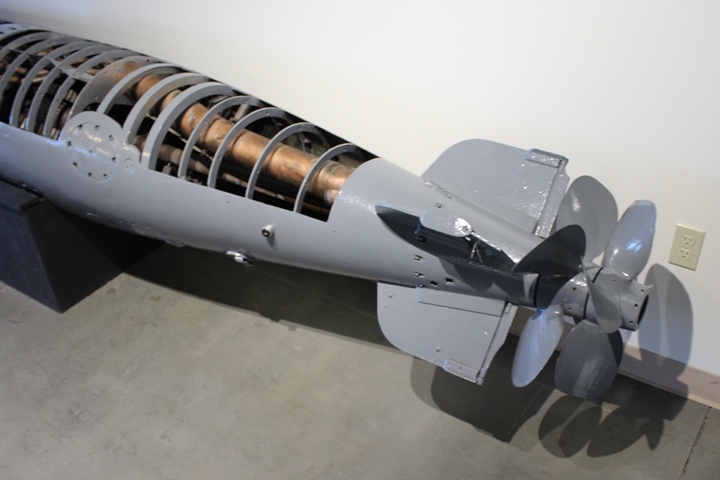

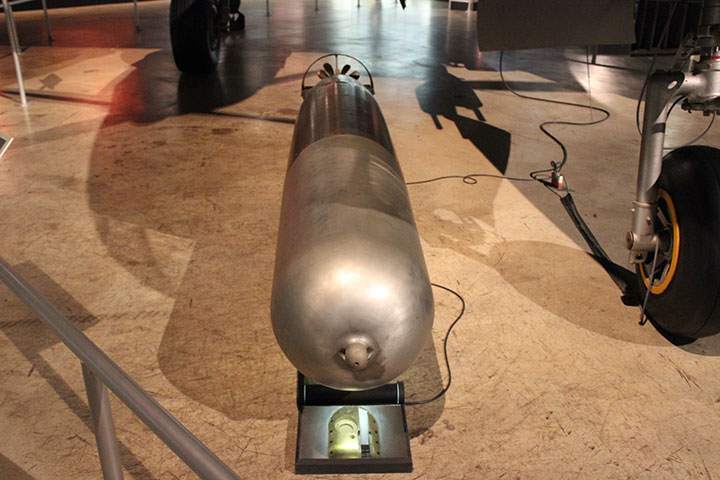

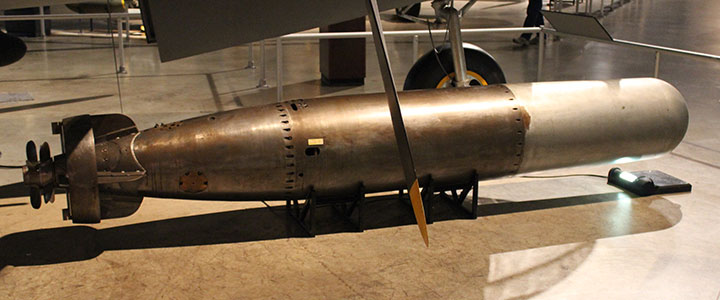

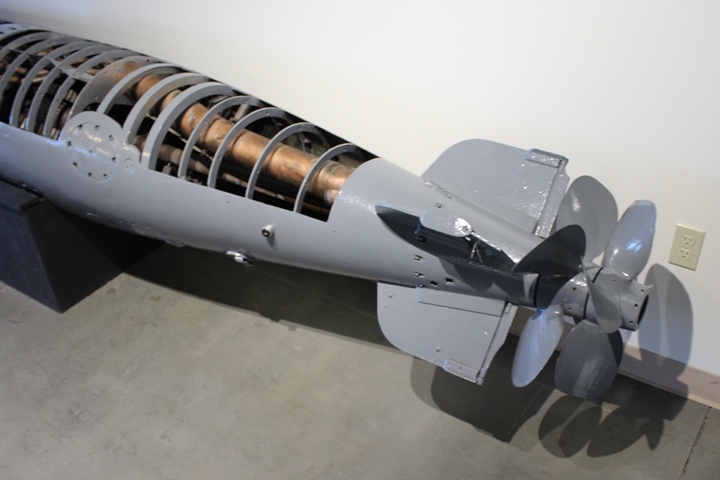

The view is looking down the business end of a Mark XIII aerial

torpedo. The Mark XIII was also used by PT boats but would not

have the ring around the propellers. International Harvester

produced the Mark XIII along with Pontiac Motor Division of General

Motors, The Naval Torpedo Station at Newport, RI, and Amertorp

Corporation. Author's photo from the National Museum of the

Air Force.

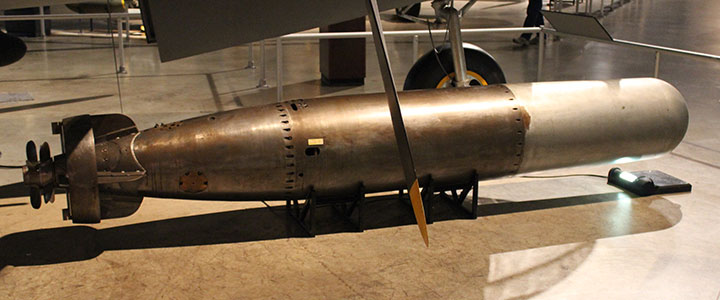

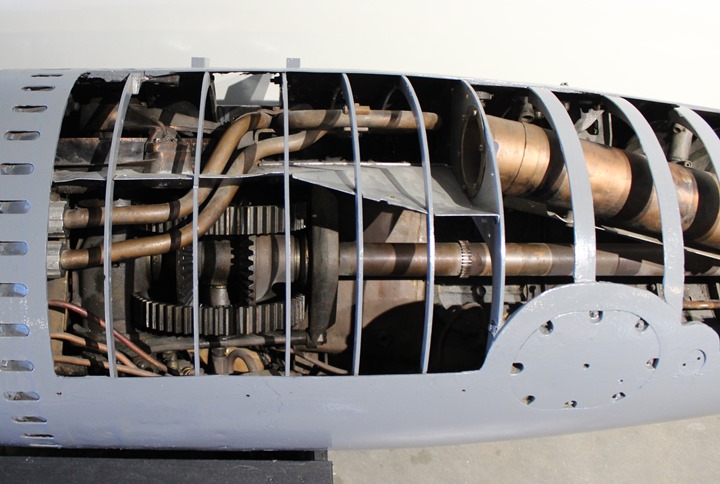

This was one of the most complicated and

difficult weapons of World War Two to build, containing 5,222 individual

parts and 1,225 assemblies. Author's photo from the Air Force

Museum.

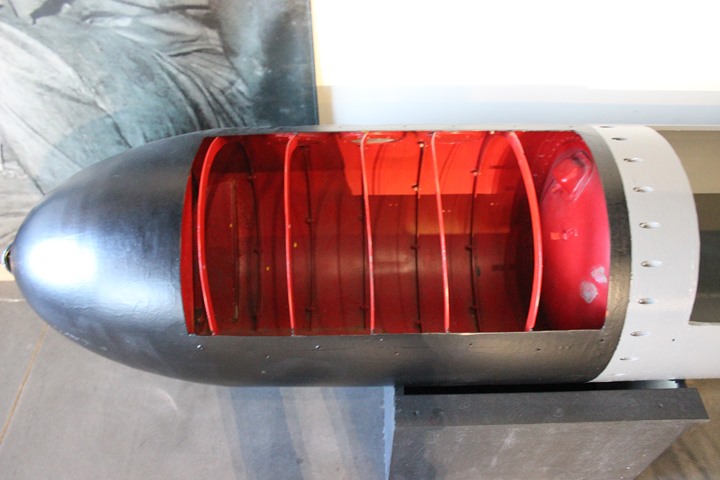

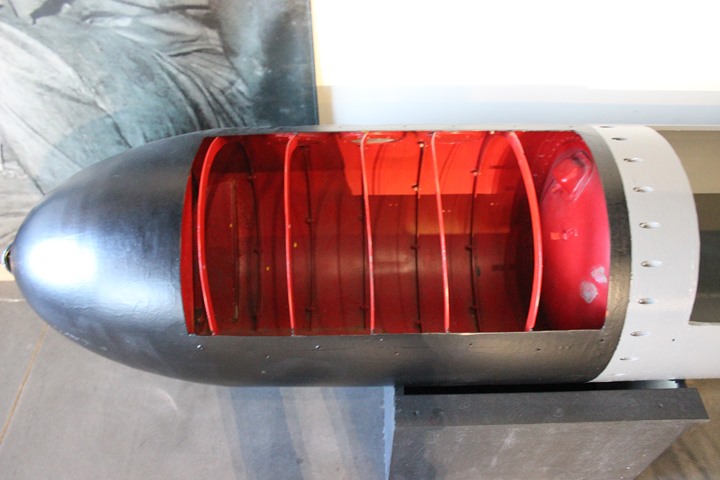

This warhead section of the torpedo

would have the detonator and 600 pounds of Torpex explosive.

Torpex was 1.5 times

more powerful than TNT. Author's photo from the USS Silversides

Museum in Muskegon, MI.

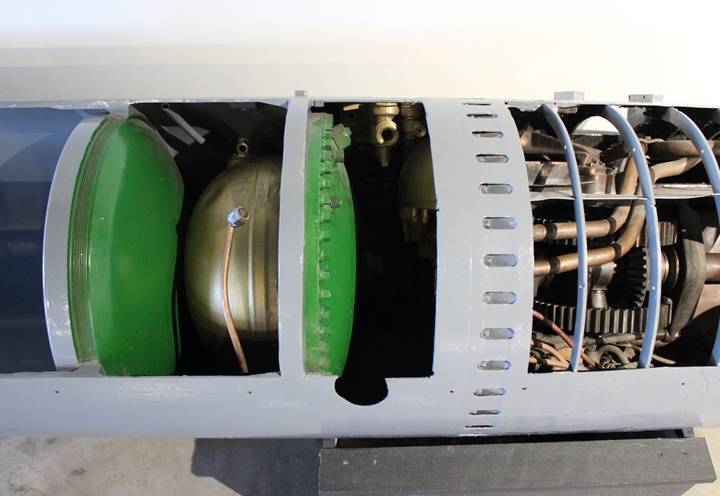

This area would contain the alcohol fuel and

compressed air to power the steam turbine. Author's photo.

Author's photo.

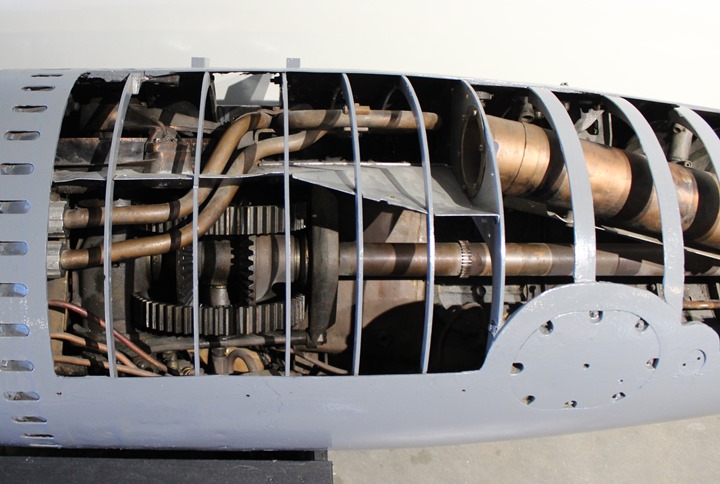

At the rear of the Mark XIII is the steam

turbine. Author's photo.

Author's photo.

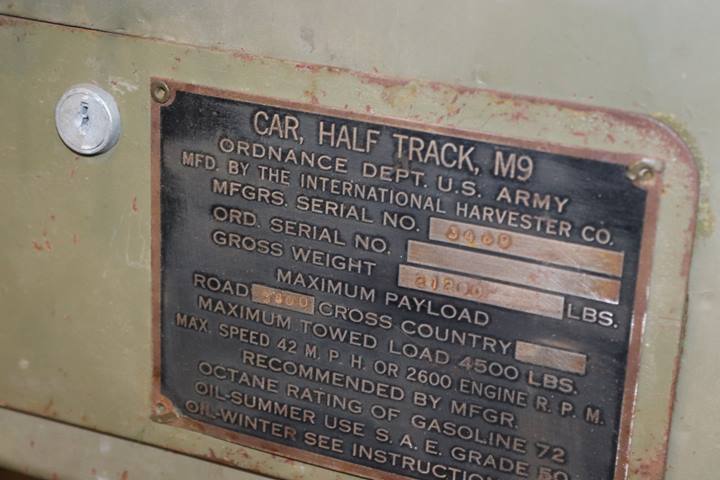

Halftracks:

This International Harvester M9 half-track was built at its Springfield,

OH plant. IH half-tracks are not that prominent in the United

States as they were given to our allies under Lend-Lease. This is

the first and only one I have found in four years of searching.

Author's photo added 10-7-2017.

This M9 was on display at the 2017 Military

Vehicle Preservation Association convention at the Cleveland IX Center

at the Cleveland Airport. The facility is also known as the

Cleveland Tank Plant, as it produced tanks after WWII. Author's

photo added 10-7-2017.

Author's photo added 10-7-2017.

The main external distinguishing feature between the IH half-tracks and

those built by White, Autocar, and Diamond T, is the rounded sheet metal

corners. The other companies had square corners.

Author's photo added 10-7-2017.

Author's photo added 10-7-2017.

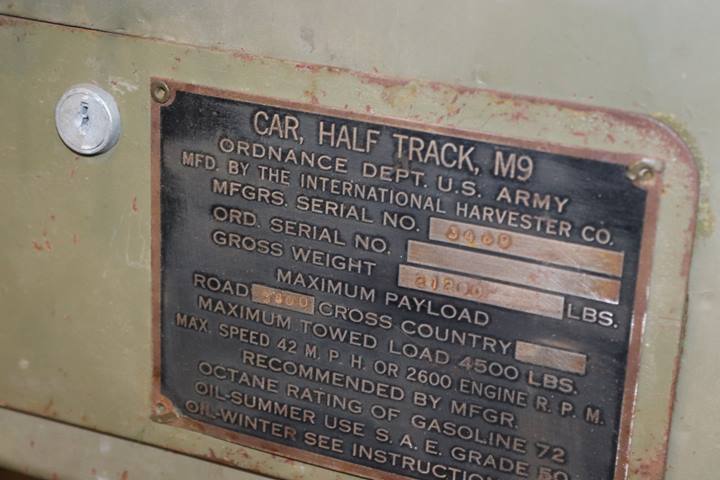

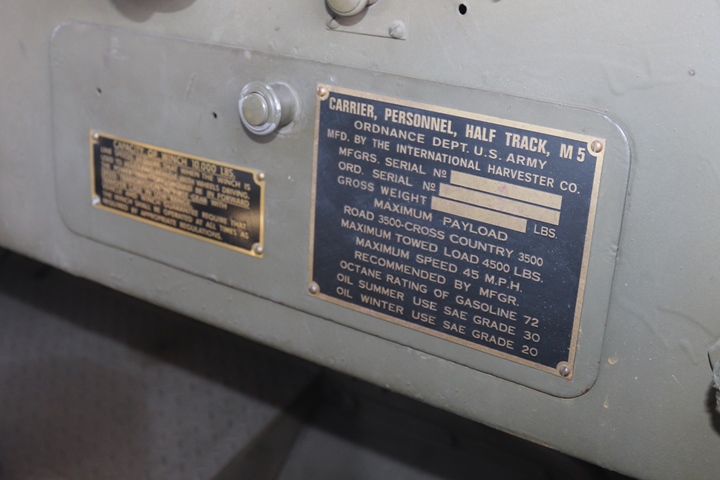

This International Harvester has the original data plate still in it

and is Serial Number 3469.

Author's photo added 10-7-2017.

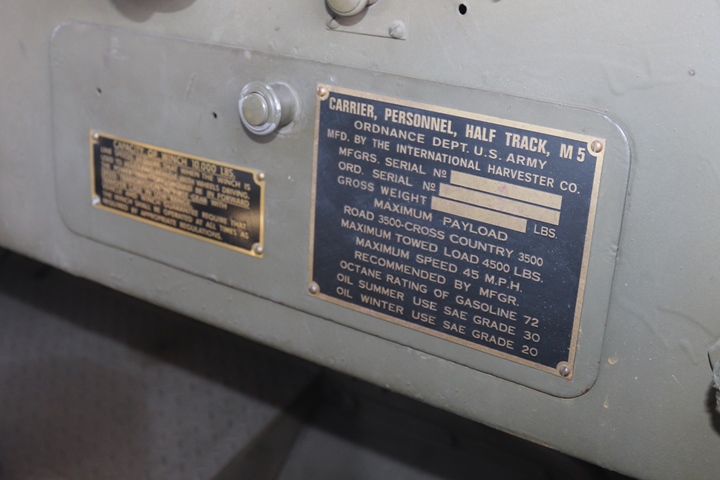

This excellent restoration of an

International M5 half-track was on display at the 2019 MVPA convention in

York, PA. The M5 is owned by the Wheels of Liberation Museum in

New Oxford, PA. Author's photo added 10-4-2019.

Author's photo added 10-4-2019.

Author's photo added 10-4-2019.

M5 High Speed

Tractors:

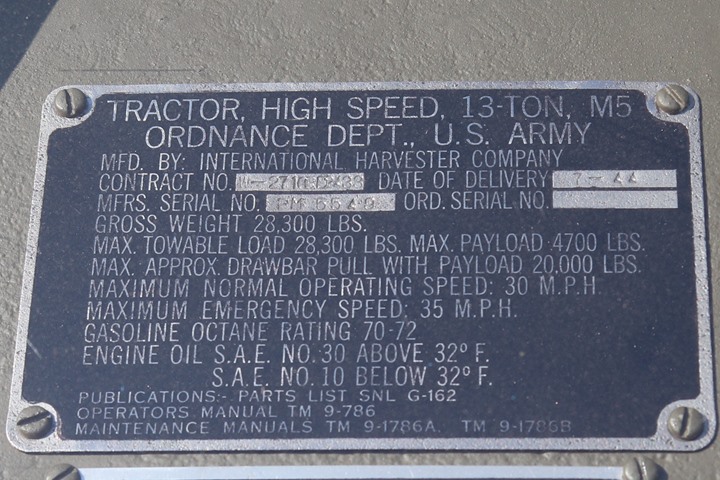

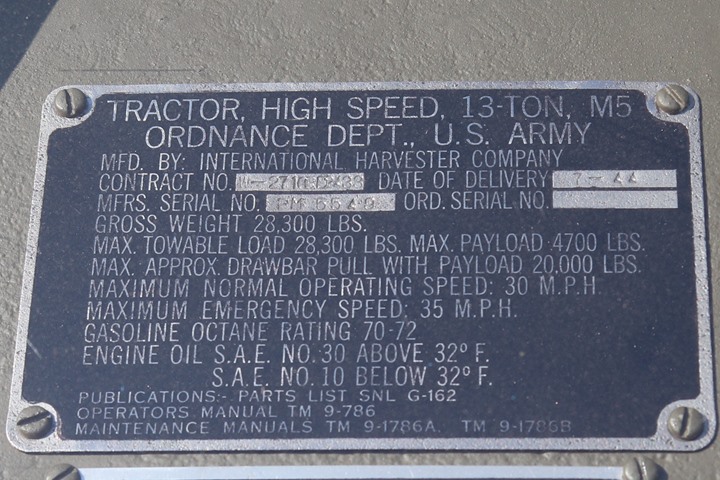

This pristine restoration of an

International Harvester M5 High Speed Tractor was photographed at the

2019 Thunder over Michigan Airshow. It was restored and is owned

by Chris Kurtz of St. George, MO. He has two more that he hopes to

also restore providing he can find the necessary parts. Author's

photo added 10-4-2019.

The restoration is highly detailed with all

of the data and information plates attached. Author's photo added

10-4-2019.

Author's photo added 10-4-2019.

The M5 is IH Serial Number PM5549 which was

built in July 1944. Author's photo added 10-4-2019.

Author's photo added 10-4-2019.

The M5 has an unusual seating arrangement

for the driver and passengers. The driver sits in the middle front of the vehicle, and crew members

sit along the side and the

back. The crew members enter and exit out of the front on either side

of the driver's station. Author's photo added 10-4-2019.

This view is looking into the right side of the

M5 from the front. There are seat cushions for four soldiers along

the right side of the vehicle. A partial seat can be seen along the

rear row of seats. Another seat is in the center section behind

the driver. Author's photo added 10-4-2019.

This view is looking in the left side of the

driver's station. Not all the positions have cushions on this side

along the left-hand side. There is also another seat across the

back row and one behind the driver. The M5 could carry an

artillery crew of twelve persons plus the driver. Author's photo

added 10-4-2019.

The driver sits in the center and has padded

arm rests on either side of his seat. Author's photo added

10-4-2019.

This 1942 International Harvester M5A4 high speed tractor is shown as it

was used as an artillery prime mover during WWII.

Author's photo added 5-21-2018.

Author's photo added 5-21-2018.

This International Harvester-built M5A4 is on display at the Kansas

National Guard Museum at the Topeka, KS airport. Author's photo added 10-7-2017.

Author's photo added 10-7-2017.

Author's photo added 10-7-2017.

Author's photo added 10-7-2017.

Author's photo added 10-7-2017.

Author's photo added 10-7-2017.

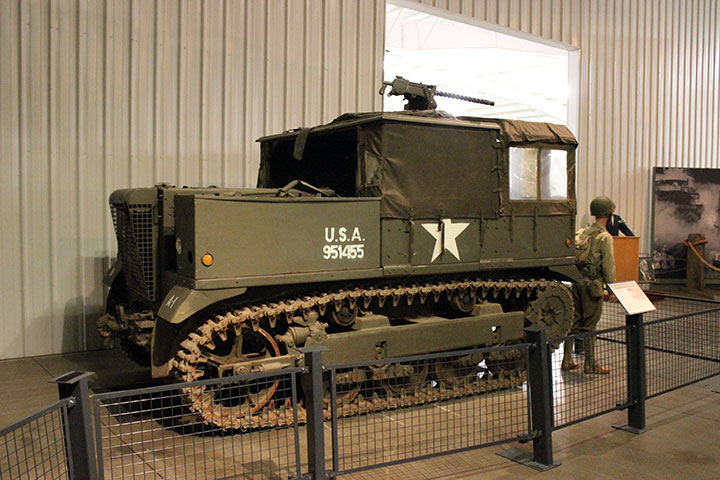

This International Harvester M5 High Speed Tractor is part of the

collection of equipment at WW2 Armor in Osteen, FL. Author's photo

added 3-24-2019.

Author's photo added 3-24-2019.

This M5 high speed tractor was on display

for many years at the National Military Historical Center, Auburn, IN.

It, with the rest of the collection, was sold when the museum found

itself in financial straits. This is the only M5 I have found that

has the tarp installed to protect the crew in foul weather. The

photos of this M5 shall remain on the webpage for historical purposes.

Author's Photo.

Author's Photo.

|

International-Harvester World War Two M5 High Speed Tractor

Production Output |

| Year-Month |

5-43 |

6-43 |

7-43 |

8-43 |

9-43 |

10-43 |

11-43 |

12-43 |

1-44 |

2-44 |

3-44 |

4-44 |

5-44 |

6-44 |

7-44 |

8-44 |

9-44 |

10-44 |

11-44 |

12-44 |

1-45 |

2-45 |

3-45 |

4-45 |

5-45 |

Total |

| |

9 |

3 |

23 |

60 |

123 |

202 |

278 |

277 |

375 |

342 |

375 |

375 |

376 |

395 |

266 |

200 |

200 |

200 |

200 |

200 |

150 |

163 |

200 |

200 |

99 |

5,290 |

|

International-Harvester World War Two M5A1 High Speed

Tractor Production Output |

| Year-Month |

5-45 |

6-45 |

Total |

| |

66 |

200 |

266 |

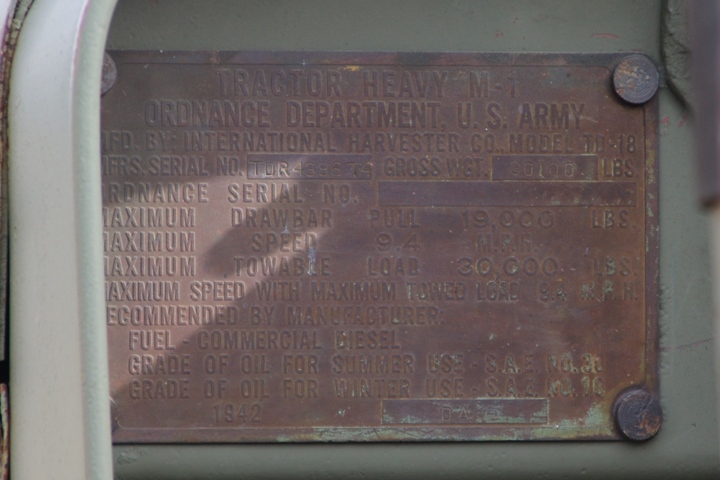

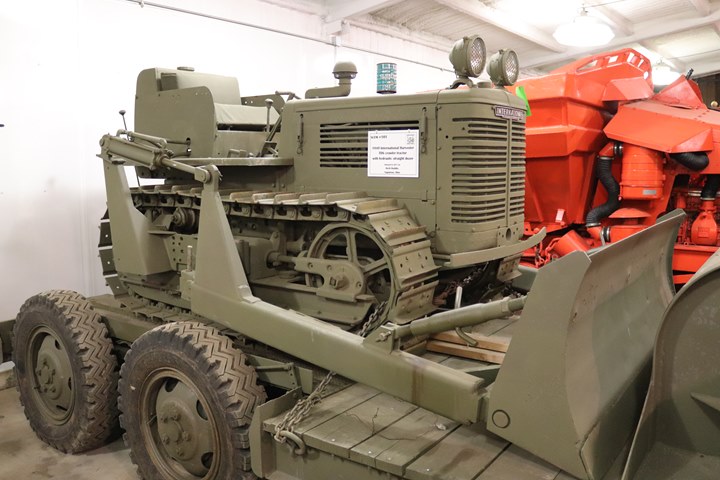

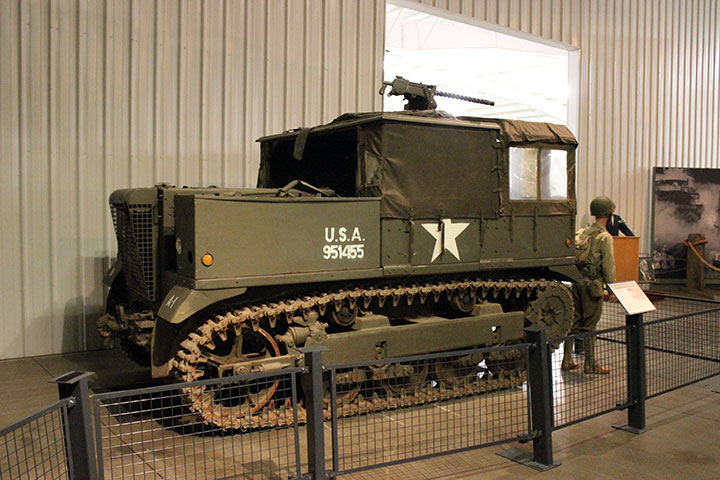

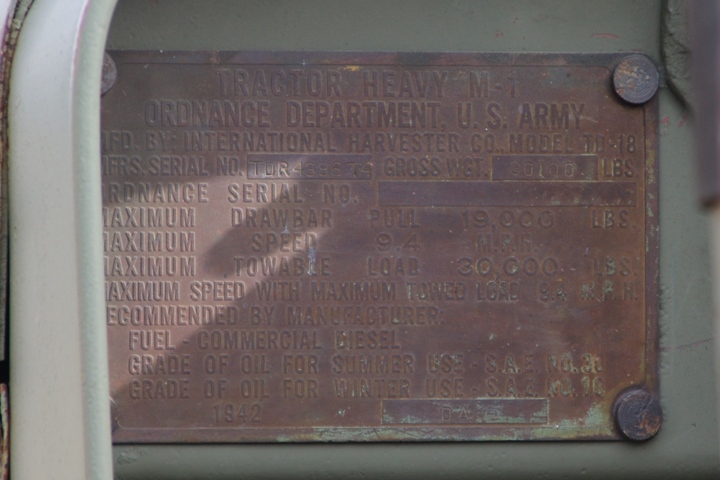

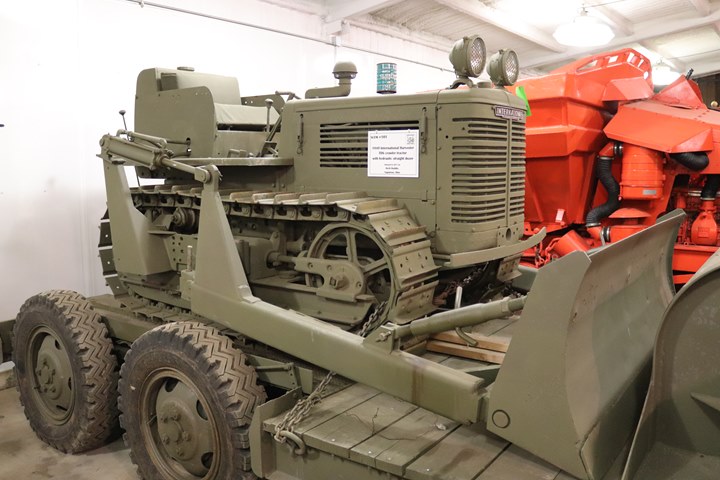

M1 (TD-18) Heavy

Crawler Tractor: This was on display at the 2020 Tri-State

Antique Gas Engine and Tractor Show in Portland, IN.

This is a 1942 International Harvester

TD-18 M1 Heavy Tractor. Author's photo added 8-28-2020.

Author's photo added 8-28-2020.

Author's photo added 8-28-2020.

Author's photo added 8-28-2020.

The owner was not around, but there was

a can of gasoline on the tracks and a battery charger in operation.

Author's photo added 8-28-2020.

Author's photo added 8-28-2020.

This side of the engine bay shows that

the sparkplug wires and an electrical ignition system used to start

the diesel engine. Author's photo added 8-28-2020.

This side of the engine shows the diesel

fuel filters, injection pump, and fuel lines to the diesel engine.

It apparently has been in storage for a while, as there is a bird's

nest on top of the engine. Author's photo added 8-28-2020.

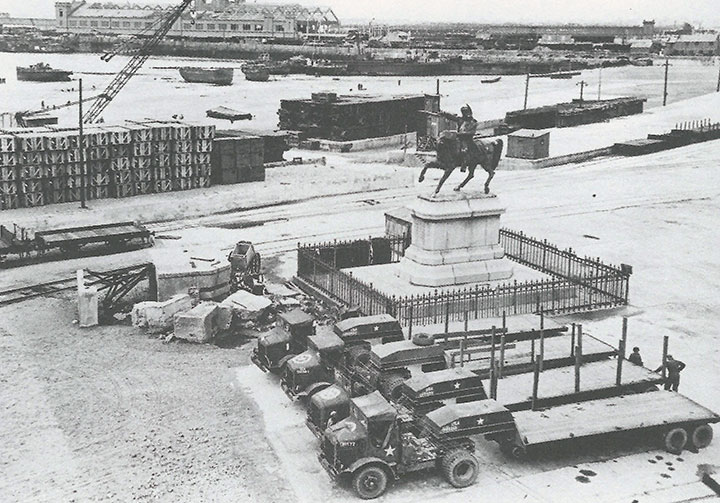

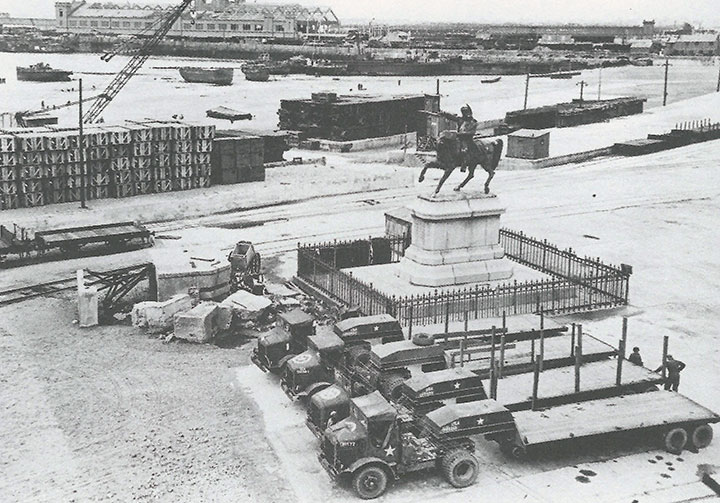

Trucks:

Here are four International Harvester 4x2

M425/M426 tractors with ten-ton trailers,

parked

in Cherbourg, France in July 1944. The stake and platform trailers

are typical of the trailers the IH tractors pulled during World War Two.

Below are photos of an M425 owned by Navistar as part of the

company's truck collection.

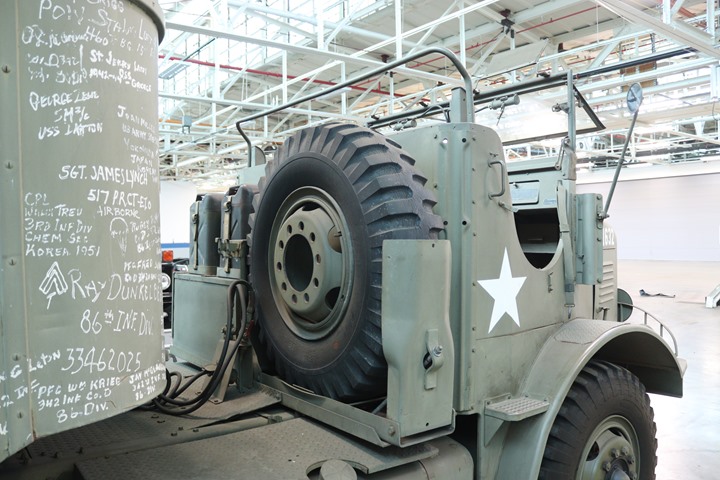

Pictured here is the International

H-542-9, 5-ton 4x2 tractor owned by the Navistar Corporation and

stored at its Melrose Park, IL plant. The military designation

for the H-542-9 was the M425. International built 4,640 in

1944 and 1945. International also built 6,678 H-542-15 with

military designation M426. They were nearly identical, except

for larger tires and a heavier duty suspension which allowed it to

pull larger loads.

I want to thank Navistar Historian Tom Clark for spending a day with

me in late June 2019 and taking me on a tour of the truck collection

at the company's Melrose Park, IL plant. This is a very rare

International Harvester-built tractor.

The Melrose Park plant was built during

World War Two by the Buick Motor Division of General Motors for the production of R-1830 engines for the B-24 bombers. After the war, it

was purchased by International Harvester, which produced truck engines

in it

until about 2015. Today the plant does special projects for the

company and stores the company's collection of historical trucks.

Author's photo added 10-4-2019.

The trailer is thirty feet in length and is

not typical of the trailers the M425/426 series tractors pulled.

The M425 normally pulled 5-ton stake and platform trailers while the

M426 pulled 10-ton trailers of the same type. While the GMC 2-1/2

ton 6x6 truck gets a lot of well deserved credit for carrying supplies

during World War Two, it was tractors like the IH M425/426 and those

built by other truck manufacturers that pulled the semi-trailers that

were able to haul larger tonnages of the supplies needed to fight a

modern war. Author's photo added 10-4-2019.

Author's photo added 10-4-2019.

The tractor is fully operational, and the

company loans it out to dealers for special occasions, as it does other

trucks in the collection. Author's photo added 10-4-2019.

Author's photo added 10-4-2019.

Author's photo added 10-4-2019.

Author's photo added 10-4-2019.

Author's photo added 10-4-2019.

Author's photo added 10-4-2019.

Author's photo added 10-4-2019.

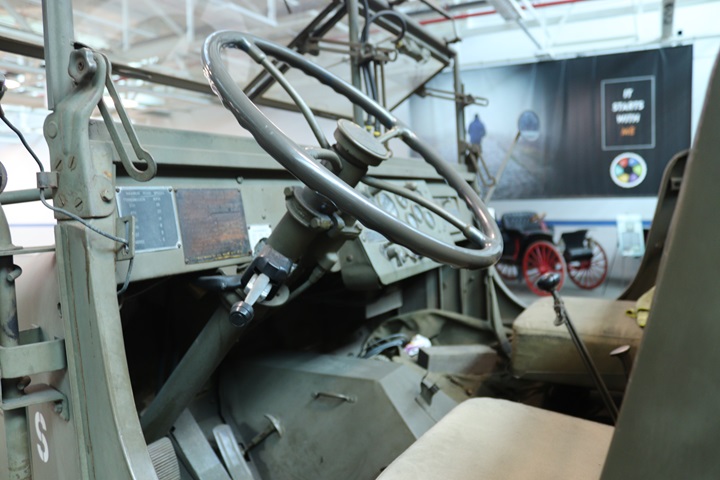

This is an interesting data plate. While two data plates show the

truck as an H-542-9, this shows the truck as being a model HHAH-2850.

Author's photo added 10-4-2019.

Author's photo added 10-4-2019.

Author's photo added 10-4-2019.

Author's photo added 10-4-2019.

Author's photo added 10-4-2019.

Here is a small part of the Red Diamond 450D

6-cylinder engine. Author's photo added 10-4-2019.

Author's photo added 10-4-2019.

Author's photo added 10-4-2019.

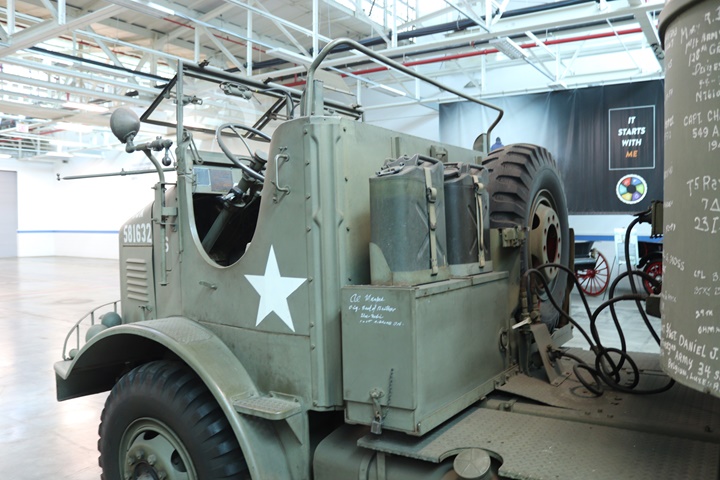

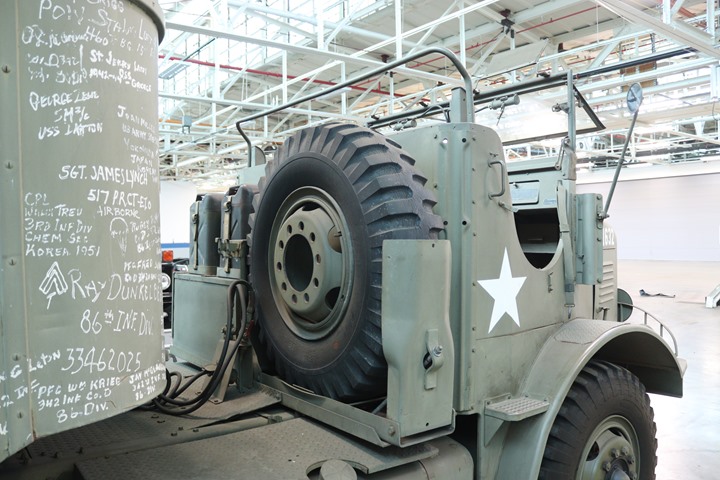

Three years after visiting the H-542-9 in

Melrose Park, I found this H-542-11 at the World War Two American

Experience in Gettysburg, PA. Author's photo added 3-2-2023.

Author's photo added 3-2-2023.

The data plate shows this as serial number

6943. It was delivered in May 1945. Author's photo added

3-2-2023.

Author's photo added 3-2-2023.

Author's photo added 3-2-2023.

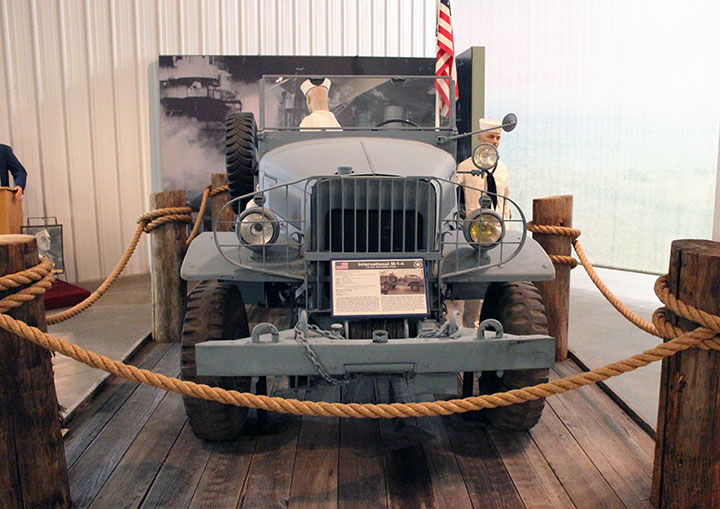

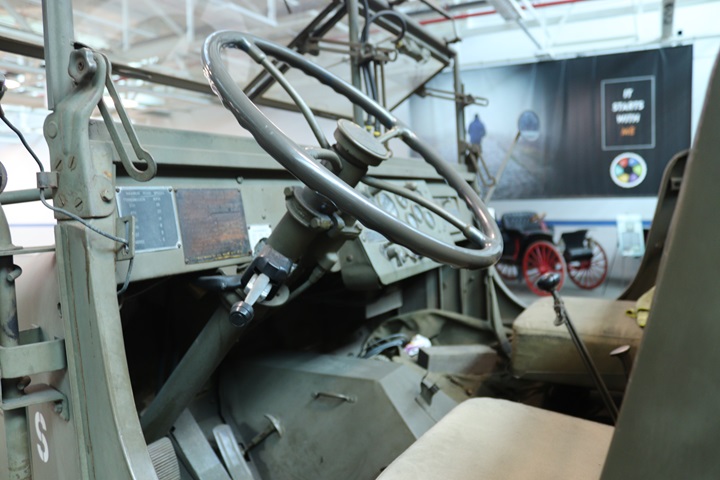

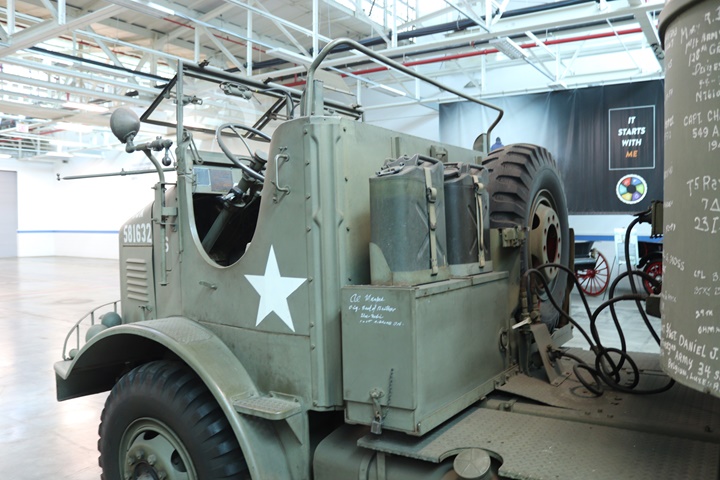

The International Harvester M-1-4 4x4 trucks were used extensively by

the US Navy and Marine Corps. From the collection at the former National

Military Historical Center, Auburn, IN. Author's Photo.

Since only 1,123 M-1-4 trucks were

built, this example is very rare.

Author's Photo.

Author's note: The above vehicle is no

longer on display at the Museum. The Museum no longer exists.

DDJ 6-11-2018

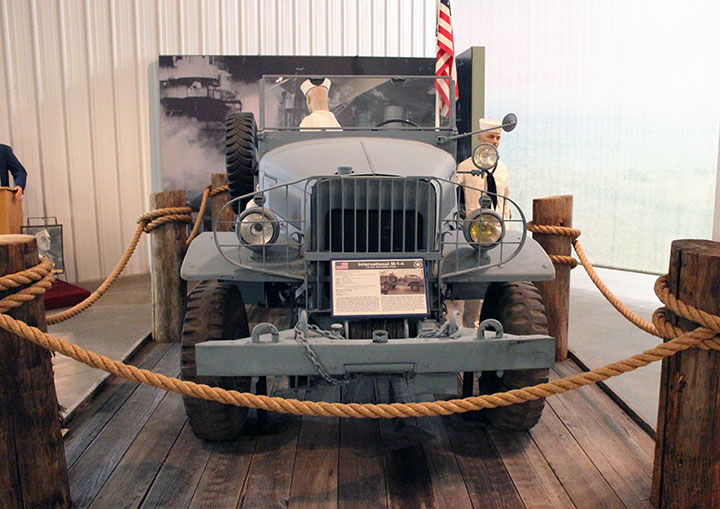

This International Harvester-built M-1-4 233

1/2-ton 4x4 truck is on display at the Boyertown Museum of Historic

Vehicles in Boyertown, PA. The ambulance body was built on the IH

chassis by the Boyertown Auto Body Works in this same building that is

now the museum. The Boyertown Auto Body

Works built 900 of these ambulances on the M-1-4 chassis. This is only

one of two Boyertown-built ambulances still in existence.

International Harvester built 1,123 M-1-4 chassis and the Boyertown Auto

Body Works made 80% of them into front line ambulances. Author's

photo added 10-4-2019.

Author's photo added 10-4-2019.

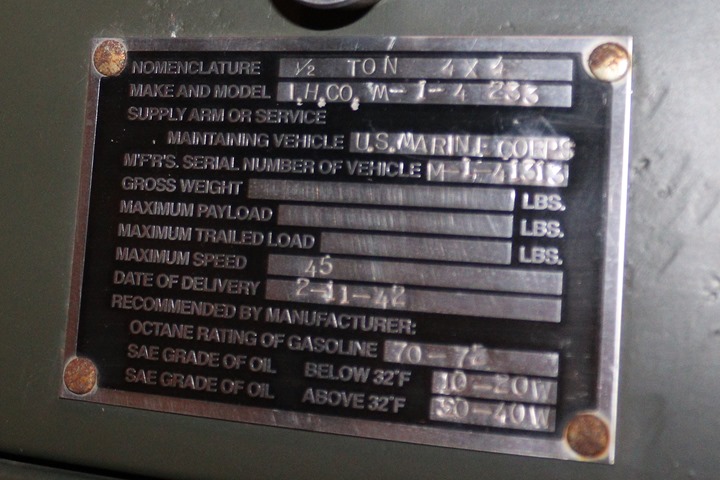

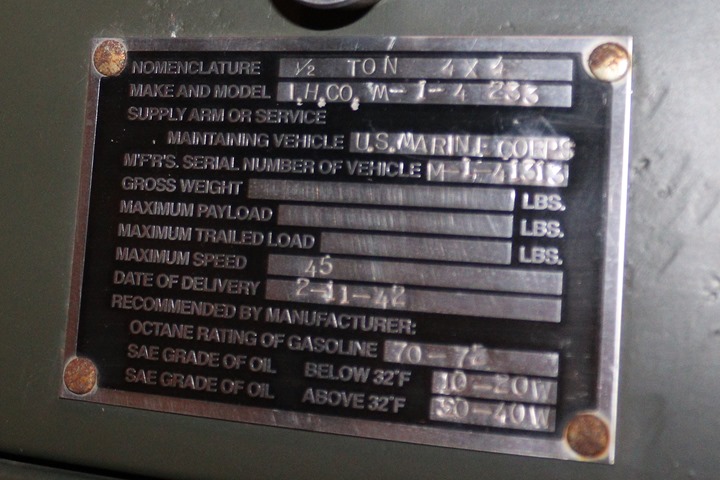

The date plate describes this as a M-1-4 233

1/2-ton 4x4 that was built on 2-11-1942. It has a maximum speed of

45 mph and is IH Serial Number M-1-4 1313. Author's photo added 10-4-2019.

Author's photo added 10-4-2019.

Author's photo added 10-4-2019.

The M-1-4 field ambulance could carry

several litter patients in the Boyertown-built ambulance body.

This frontal view of the vehicle shows it was a very robust

vehicle. Author's photo added 10-4-2019.

This M-2-4 was on display at the 2019 World

War Two Weekend in Reading, PA. Author's photo added 10-4-2019.

Author's photo added 10-4-2019.

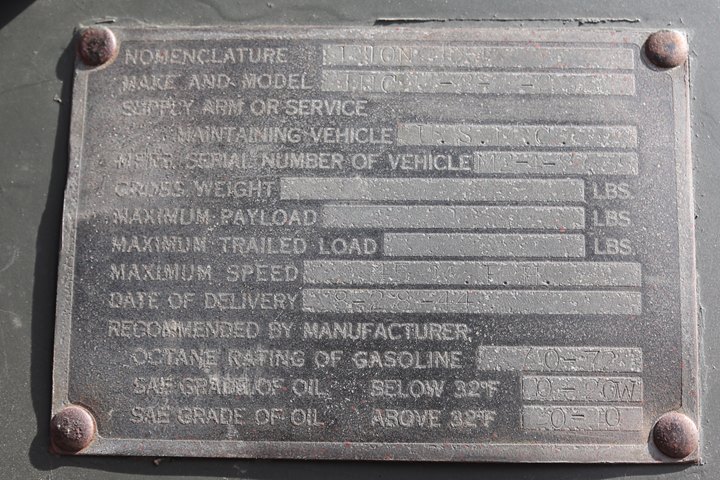

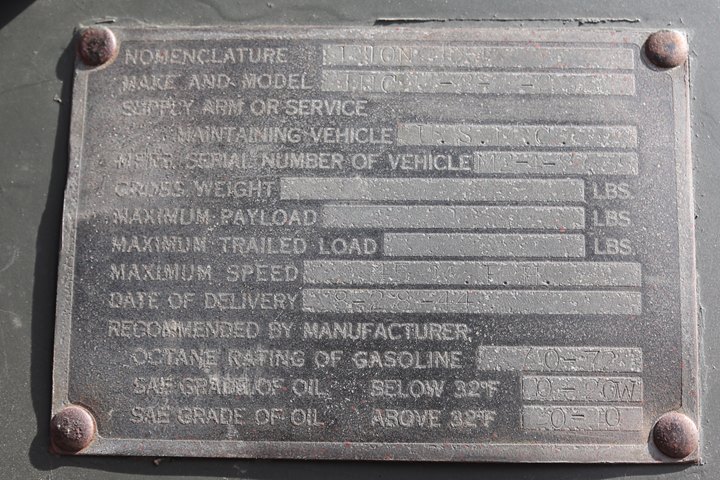

This International M-2-4-233 was built on

8-28-1944. Seventy-five years later, the numbers are worn on the

data plate, but the serial number can be discerned as M2-4-8635. Author's photo added 10-4-2019.

This International M-2-4 truck was seen at

the 2019 World War Two Weekend as it drove across the ramp. Author's photo added 10-4-2019.

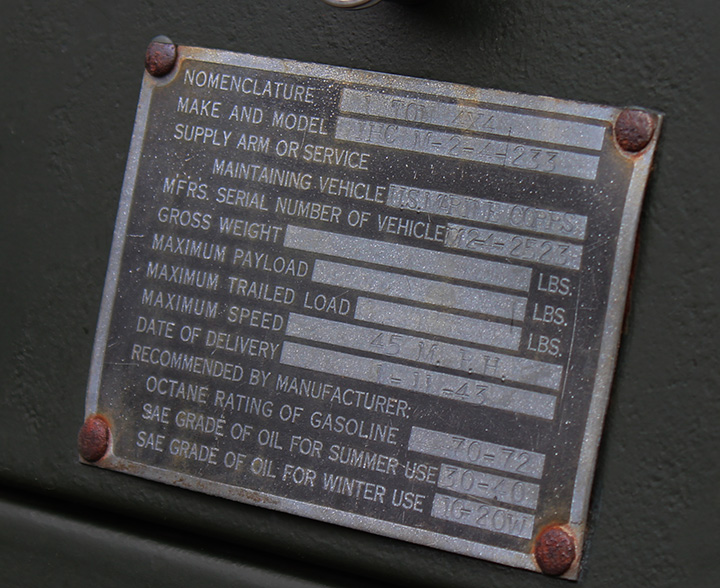

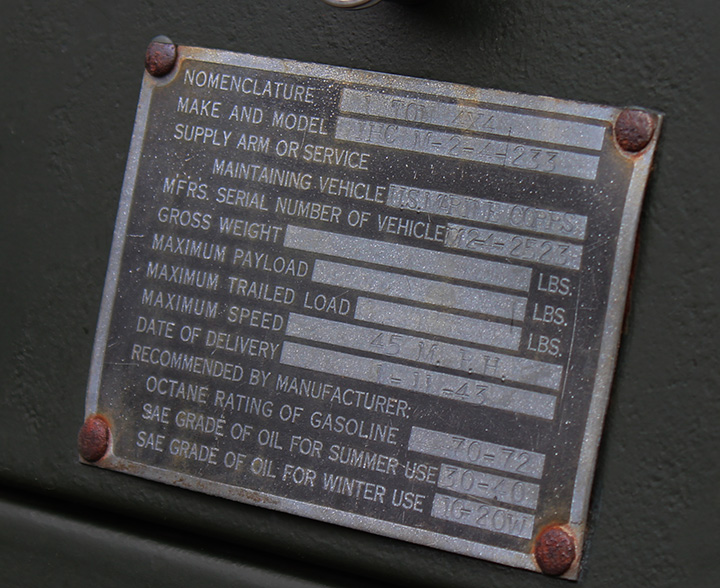

This M-2-4-233 one-ton 4X4 truck was seen at the 2014 MVPA National

Convention in Louisville, KY. This particular unit was delivered

to the USMC on 1-11-1943. Author's photo added 7-28-2014.

This is one of 10,450 built for the Navy and

USMC during WWII. Author's photo added 7-28-2014.

Author's photo added 7-28-2014.

Author's photo added 7-28-2014.

Author's photo added 7-28-2014.

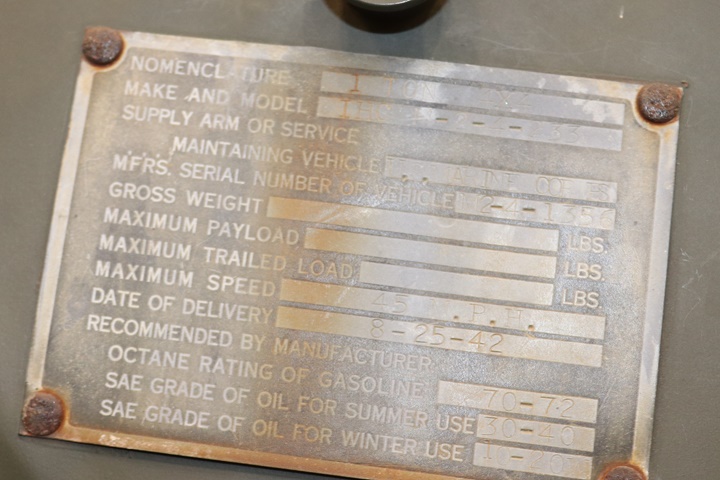

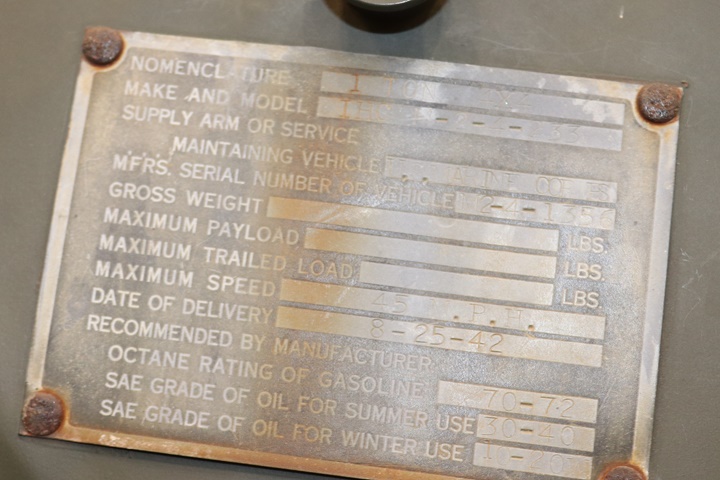

M-2-4-1356 was on display at the 2017 MVPA

National Convention in Cleveland, OH. It was built on 8-25-1942.

Author's photo added 12-24-2019.

Author's photo added 12-24-2019.

Author's photo added 12-24-2019.

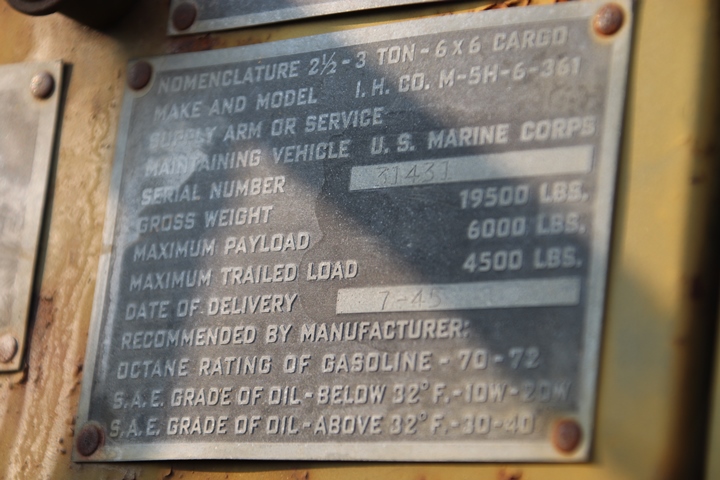

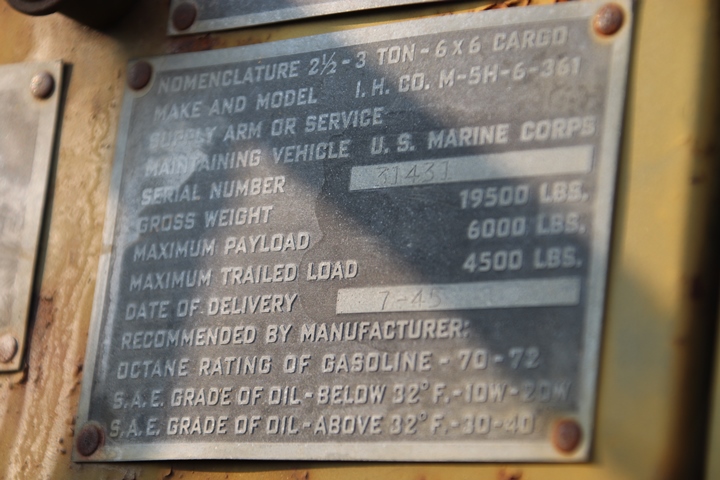

This is a very rare International Harvester

M-5H-6 2-1/2-ton 6x6 truck that the company built for the USMC.

This is the only one I have personally found, and it is awaiting restoration at the

World War II American Experience in Gettysburg, PA. Author's photo

added 3-2-2023.

This vehicle is serial number 31431 and was delivered in July 1945.

It is one of 40,087 that were built during World War Two.

Note that this was built for the USMC. Author's photo added

3-2-2023.

The truck has Navy registration number 284687 painted on the door.

Author's photo added 3-2-2023.

The image in the lower right hand corner of

the driver's door indicates that this was used not by the USMC, but by the

Navy Seabees. Author's photo added 3-2-2023.

There is nothing left of the cloth covering

on the bench seats. The museum has used a cardboard to sit on

while moving the vehicle for a special outside display. Author's

photo added 3-2-2023.

Author's photo added 3-2-2023.

The truck came equipped with an Anthony dump

truck bed for use by the Seabees. Author's photo added 3-2-2023.

Author's photo added 3-2-2023.

Author's photo added 3-2-2023.

Author's photo added 3-2-2023.

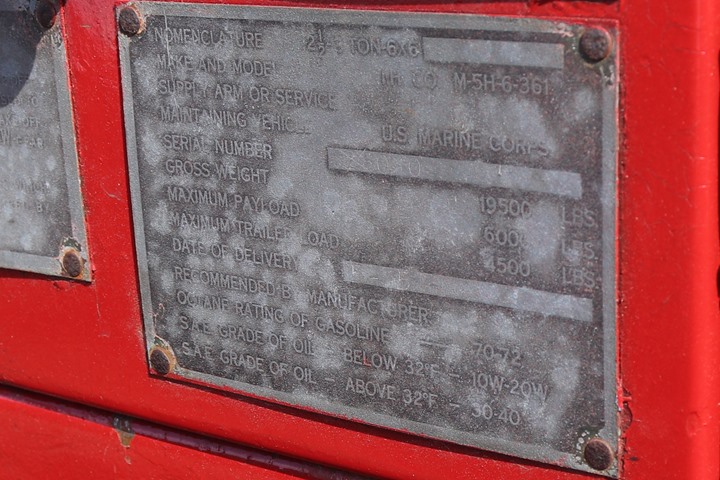

This World War Two era International

Harvester-built U.S. Navy crash truck was built in May 1945. It

was on display at the 2019 World War Two Weekend at Reading, PA.

Author's photo added 10-4-2019.

Author's photo added 10-4-2019.

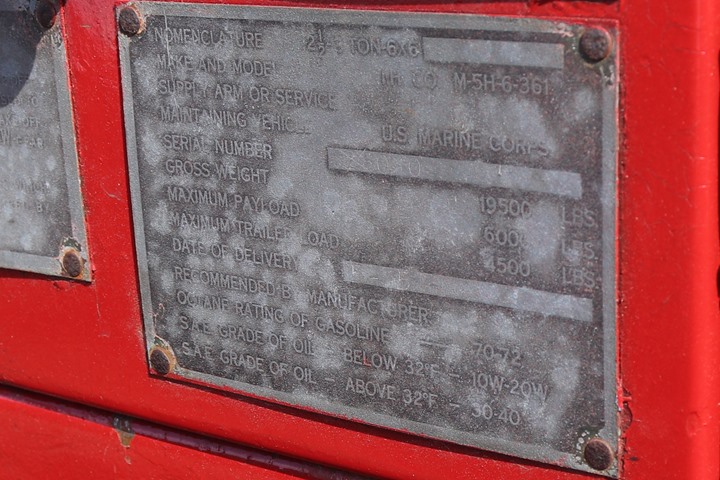

Interestingly, the data

plate identifies this as an M-5H-6-361 2/-1/2 to 3-ton 6x6 and yet it is

a 4x4. The Serial Number appears to be 8010 as the leading number

2 has been 'x' out. It was delivered to the USMC in May 1945.

The data plate shows it was a Marine vehicle, but the markings on the

side are U.S. Navy. Author's photo added 10-4-2019.

Author's photo added 10-4-2019.

Author's photo added 10-4-2019.

This International former military crash

truck is in the storage yard at the Sam Werner Military Museum in

Monteagle, TN. Its previous owner was an excavating company in

Battleground, WA. Author's photo added 10-4-2019.

This vehicle has no data plate on it for

date of manufacture and serial number information. Author's photo

added 10-4-2019.

Author's photo added 10-4-2019.

This World War Two era International

commercial pickup truck with U.S. Navy markings was at the 2019 World

War Two Weekend in Reading, PA. Author's photo added 10-4-2019.

Author's photo added 10-4-2019.

Author's photo added 10-4-2019.

An International M-2-4 undergoes

testing in the winter snow.

A Marine M-2-4 (R) and an

International TD-18 tractor (L) on the beach at Okinawa.

Marine M-2-4s at Camp Pendleton, near San

Diego, CA.

The International M-2-4 in combat.

Other International

Harvester World War Two Products:

During World War Two International Harvester produced

3,865 TD-6 crawler tractors similar to this 1949 model on display at

the Heavy Construction Equipment Museum in Bowling Green, OH.

Author's photo added 1-22-2018.

Author's photo added 1-22-2018.

Author's photo added 1-22-2018.

The Indianapolis Works built the

transmission and differential for the 830 M22 light tank built by

Marmon-Herrington in Indianapolis, IN. The transmission and

differential were located in the front of the tank. Author's photo

taken at 2015 Rockford, IL military show.

This International Harvester 20mm Oerlikon

Quad Mount is on the USS West Virginia. These IH-built Quad mounts

were also experimentally installed on the USS Arkansas, USS Colorado,

USS Maryland, USS Washington, and USS Massachusetts. These quad

mounts were known as Thunderbolts and were designed to increase the

anti-aircraft firepower on the ships. After testing, the Navy

decided not to install any more, as they required power to

operate. The manually operated 20mm cannons could still operate

when electrical power was lost during battle.

International Harvester built engine

cowlings for the Curtiss C-46 Commando. Author's photo.

This 57mm anti-tank gun is on display at the

Louisiana Maneuvers and Military Museum at Camp Beauregard in Pineville,

LA. It has an International Harvester-built M1 gun carriage.

Author's photo added 3-22-2018.

The gun carriage, built in 1942, is serial

number 1704. Author's photo added 3-22-2018.

Author's photo added 3-22-2018.

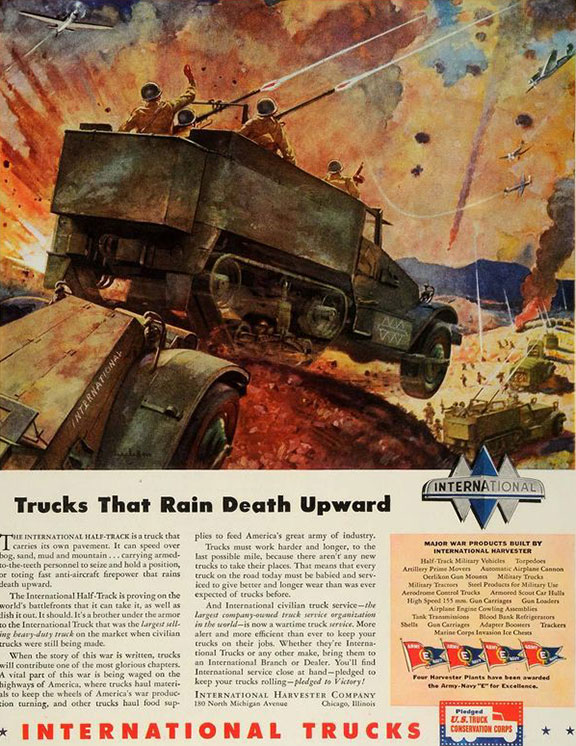

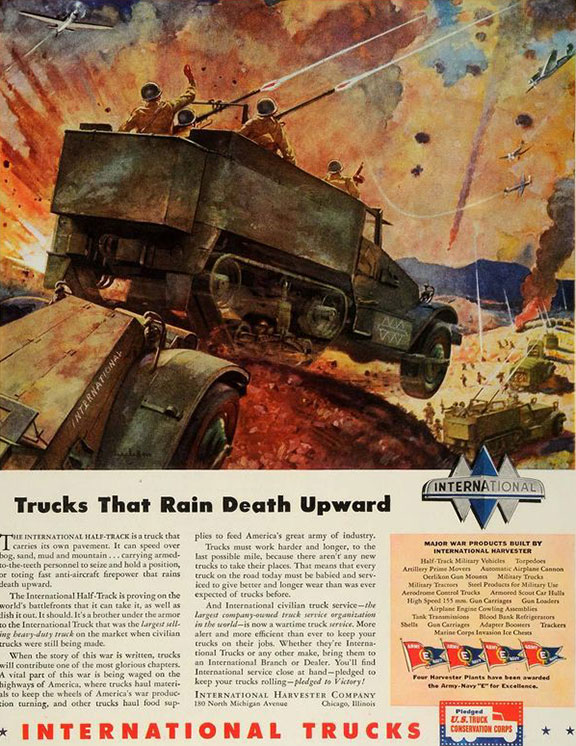

This ad provides a listing of all war

products International Harvester was making for the war effort as of the

date of the ad. Half-Track Military Vehicles, Torpedoes,

Artillery Prime Movers (M5s), Automatic Airplane Cannons, Oerlikon Gun

Mounts, Military Trucks, Military Tractors, Steel Products for Military

Use, Aerodrome Command Trucks, Armored Scout Car Hulls, High Speed 155mm

Gun Carriages,

Gun Loaders, Airplane Engine Cowling Assemblies, Tank Transmissions,

Blood Bank Refrigerators, Shells, Adapter

Boosters, Tractors, and Marine Corps Invasion Ice Chests.

What a beautiful and classic looking truck!

This is a 1947 International Harvester dump truck, which displays the

styling of its trucks right after the Second World War.

Author's photo at the National Auto and Truck Museum in Auburn,

IN.

The International Harvester Fort Wayne

Truck Plant 1923-1983: On July 15, 1983 the International Harvester

Fort Wayne truck plant closed and put 2,200 workers out of jobs.

It was a sad day for Fort Wayne and Indiana. Currently, much of

the plant still stands and has been repurposed by other companies for

their use. It has been renamed International Park.

I knew two persons that lost their jobs when this plant closed.

All of the International Harvester trucks

shown on this webpage were built at this location. This plant

produced many of the International trucks used by the U.S. military

during World War Two.

The former International Harvester Fort

Wayne truck plant is in the lower right hand corner of the Google Maps

satellite view. It is now called International Park. This

map shows the plant was located at the south end of Coliseum Boulevard

south of New Haven Avenue. No doubt, in 1923 this area was all farm

land, and the construction of the plant was what is known today as a

"green field" factory. Most likely, the Harvester Community

residential area developed after the opening of the factory and was the

home of many International workers. Image courtesy of Google Maps

added 3-2-2023.

Image courtesy of Google Maps added 3-2-2023.

This image is looking south along Coliseum

Blvd. This image and the next two scan the front of the factory

from south to north. Author's photo added 3-2-2023.

Author's photo added 3-2-2023.

The rainy and dreary day that I took these

photos very well fit my mood. It is always a sad occasion to go out

and photograph a factory that once had 2,200 workers turning out trucks

and earning paychecks to feed their families. Previously located

north of the International Harvester truck plant was the location of the

Magnavox headquarters and factory. It is gone and has been

replaced by a new structure. Author's photo added 3-2-2023.

This image is looking east down Pontiac

Street. This photo was taken from the location of the former

Farnsworth Television and Radio Corporation headquarters and factory.

There is nothing left of it as it was razed in the early 2000s.

Author's photo added 2-2-2023.

Post-World War Two Products:

International Harvester purchased the former

World War Two P-47 plant in Evansville, IN. During the Korean War

International built M1 Garand rifles in this facility. This

M1 is on display at the Indiana War Memorial in downtown Indianapolis,

IN. Author's photo added 9-30-2018.

During the wars in Iraq and Afghanistan

International built over 9,000 MaxxPro Mine Resistant Ambush Protected

vehicles. This one is part of the collection National Amour and

Cavalry Museum at Fort Benning, GA. Author's photo added

9-30-2018.

Author's photo added 9-30-2018.|

|