|

Fisher

Body - Home

Fisher Body Craftsmanship Goes to War

Fisher Body - Craftsmanship

Fisher Body - Aircraft

Fisher Body - Aircraft

Instruments

Fisher Body - Guns

Fisher Body - Tanks

Fisher Body - Miscellaneous

The Plants

Fisher Body WWII Plant Database

Cleveland Plant #1, OH Plant

Cleveland Plant #2, OH Plant

Detroit Aircraft Unit,

Detroit, MI

Detroit Die and Machine Plant

Fleetwood, Detroit, MI Plant

Flint Plant #1, MI Plant

Grand Blanc, MI Tank Arsenal

Grand Rapids, MI Plant

Lansing, MI Plant

Memphis, TN Plant

Ternstedt Manufacturing Division,

Detroit, MI

Grand Blanc Tank Arsenal Built Tanks and Tank Destroyers

Grand Blanc

built M4A2 Sherman Tank Photos

Grand Blanc

Built M4A3 Tank Photos

Grand

Blanc M10 Tank Destroyer Photos

Cleveland, Ohio Fisher Body Plant One - General

Motors Corporation in World War Two

1921-1983

Rest in Peace

Gone but not Forgotten!

This

page added 11-14-2017.

The Fisher Body Cleveland Plant 1 won the

Army-Navy "E" award one time during WWII.

World War Two Products: The

main product during WWII of the Fisher Body Cleveland Plant 1 were B-29

engine nacelles.

Other products were B-25, B-29, XP-75 Aircraft Parts

and assemblies, M4, M18, M26, and M5 tank parts, 90mm and 120mm (4.7 inch)

AA gun parts,

155mm gun parts, 3 inch naval gun breech housing parts, diesel engine parts, machine tool parts

and Torquematic transmission parts

During World War Two the plant employed 14,000 workers.

A photo of the plant soon after it was built

in 1921. This was the "A" building and was 1,297 feet long by 72

feet wide. It was an Albert Kahn design, and was similar in design

to the Ford Highland Park plant.

East 140th Street runs north south

along the east side of the plant. Coit Road runs diagonally along

the south side of the plant. Note the location of the water tower.

In the next photo a newer and larger water tower has been built, and the

old one torn down.

The new water tower can be seen in the

foreground. It is still there today. Note the driveway out

of the salaried parking lot onto Coit Road in the lower left of the

photo. This location can be seen two photos down from this one in

a contemporary photo. The salaried office workers would have

worked in the small two story building.

This photo has 1960's era automobiles in it.

The office building is on the right.

In June 2017 standing to the east of the

previous photo. There is no curb where the salaried parking lot

driveway used to be. The legs of the second water tower can be

seen through the trees. The site is now the Cleveland Job Corps

Center. The buildings along the fence appear to be dormitories or

barracks for the students. Author's photo.

Author's photo.

Author's photo.

Author's photo.

Author's photo.

Author's photo.

The six story Fisher Body Cleveland Plant

One used to extend down to the railroad viaduct. Author's photo.

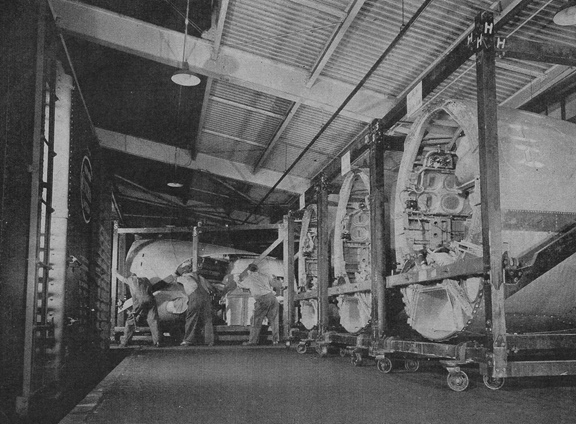

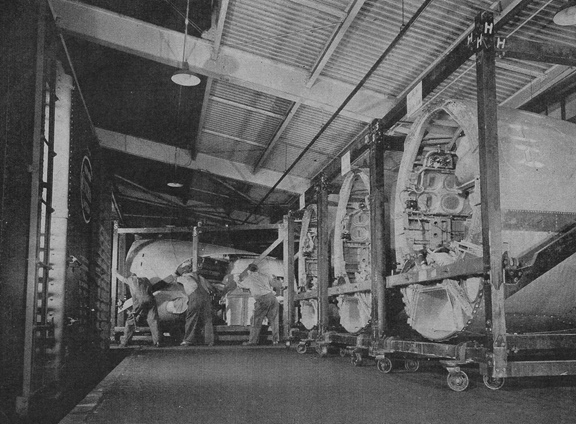

Four B-29 engine nacelles are on the dock of

Cleveland Fisher Body Plant 1 going through final inspection before

shipment. The B-29 engine nacelles were considered to be the most

complicated single component on the aircraft airframe. Each one

was made up of 3,000 parts and 1,300 sub-assemblies. They were 12

feet long and seven feet in height, and weighed one ton. By the end of

WWI Fisher Body had produced 13,772 B-29 engine nacelles. This was

87% of all of the B-29 engine nacelles required for the 3,970 B-29s

built.

The first two B-29 engine nacelles accepted by

the US Army Air Force at this plant were shipped off this dock on April

17, 1943.

The construction of the nacelles needed over

18,000 jigs, fixtures, tools and dies. Cleveland Plant 1 not only

built its own jigs, fixtures, tools and dies but supplied duplicate sets

to the main Glenn Martin plant in Baltimore, MD, and to the Lansing

Fisher Body Plant. Lansing Fisher Body also produced a number of

B-29 engine nacelles. Late in the war after the loss of the P-75

contract Cleveland Fisher Body Plant 2 started tooling up to make B-29

engine nacelles.

After final inspection and signoff the B-29

nacelles are loaded into a boxcar for shipment. Cleveland also

supplied the three other B-29 assembly plants with nacelles. They

were Boeing at Wichita, KS and Renton, WA. The Bell plant in

Marietta, GA was the fourth B-29 assembly plant.

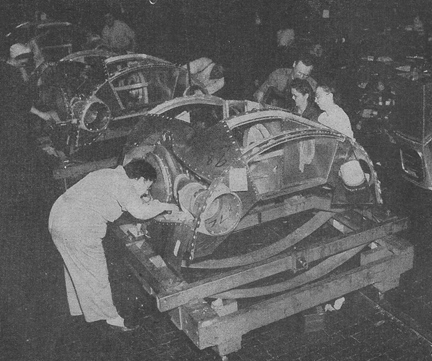

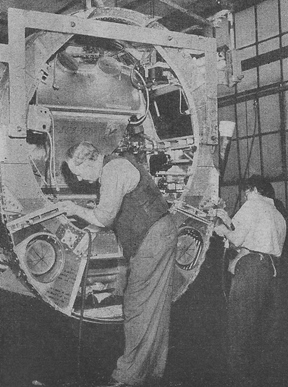

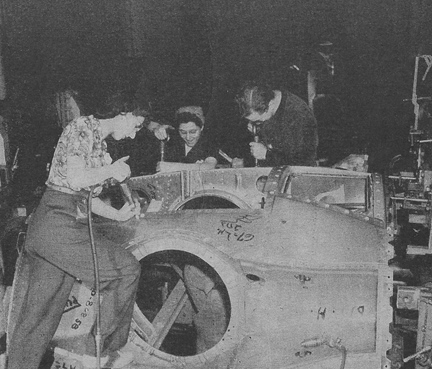

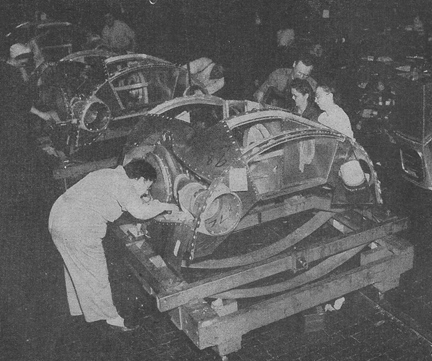

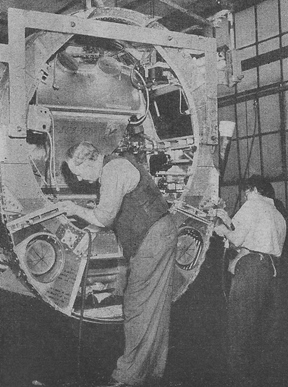

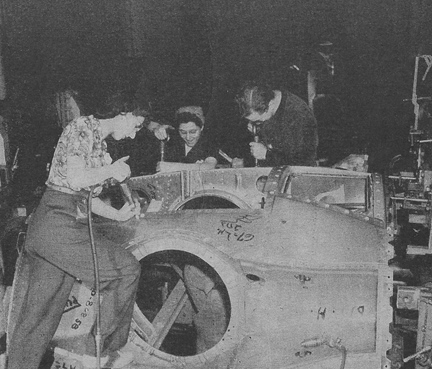

In the four photos below workers at Cleveland

Plant 1 are working on various stages of the B-29 engine nacelle.

Each B-29 engine nacelle built by Fisher

Body Cleveland Plant #1 had two GE turbo superchargers installed in it.

Author's photo added 11-14-2017.

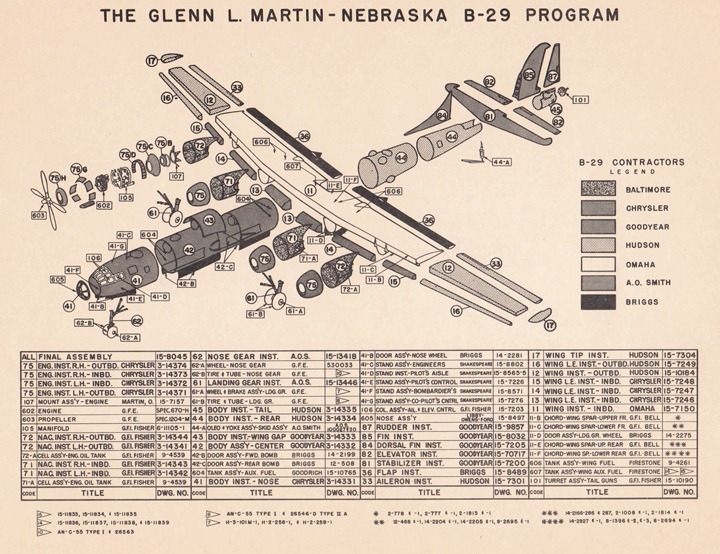

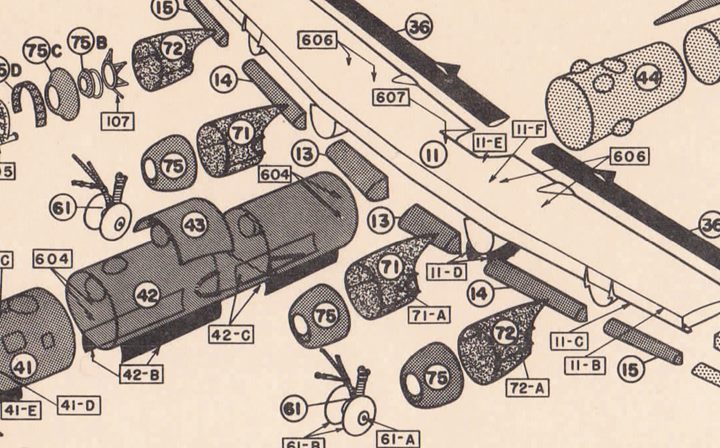

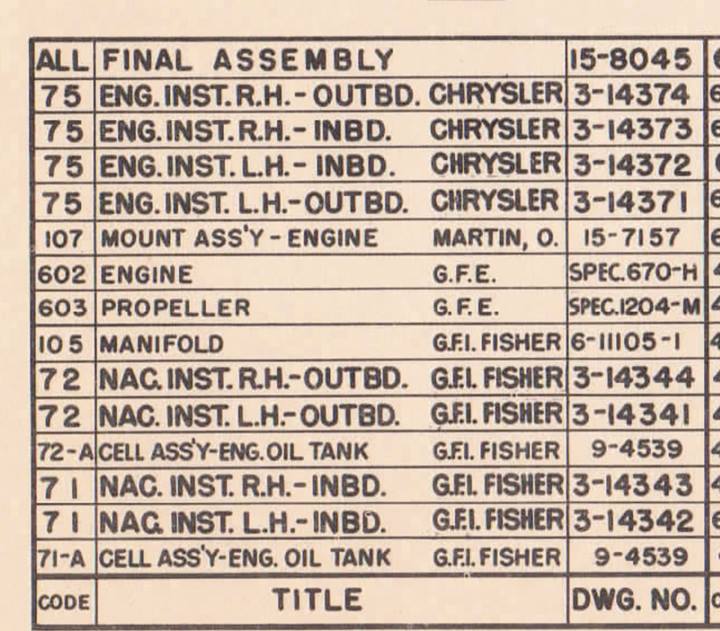

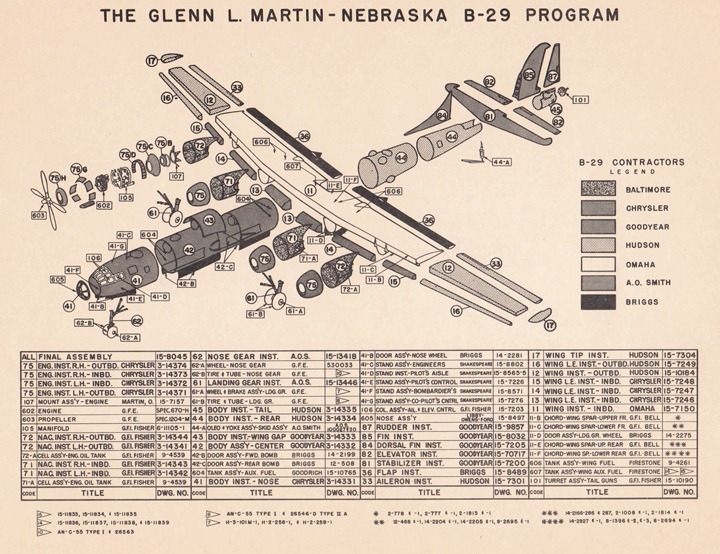

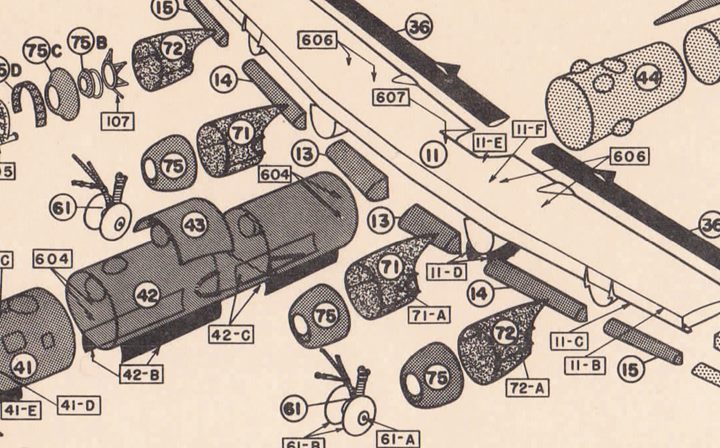

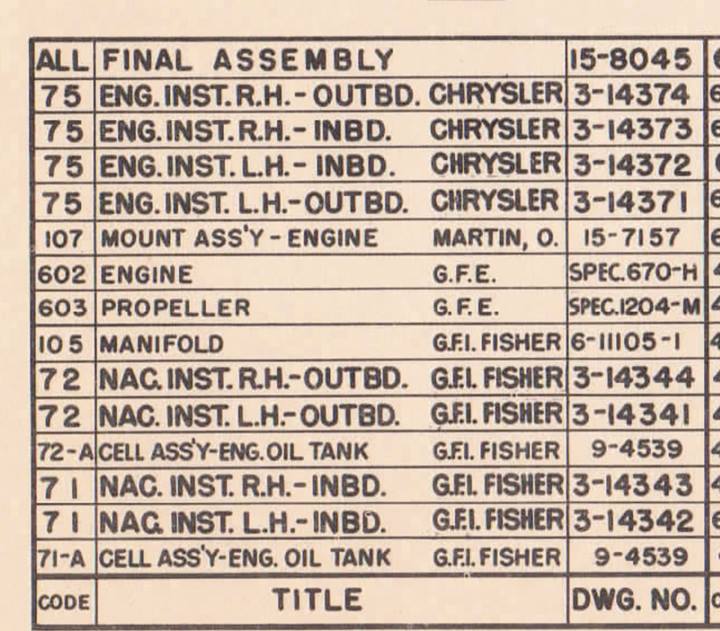

This document is a listing of the suppliers

for the Martin B-29 plant in Omaha, NE.

Parts number 71 and 72 were Cleveland Fisher

Body Plant 1 engine nacelles. The fact that Cleveland Plant 1

built B-29 engine nacelles for Martin Omaha is significant..

The significance of Cleveland Plant 1

furnishing B-29 engine nacelles to Martin in Omaha is that Martin built

the "Enola Gay."

B-29 "Bockscar" built by Martin Omaha is on

display at the National Museum of the US Air Force in Dayton, OH.

Tank Components

Fisher Body Cleveland Plant 1 supplied parts for several types of tanks and tank destroyers

as show below.

Fisher Body Cleveland Plant 1 supplied

components for the M26 Pershing heavy tank series that were built at the

Fisher Tank plant in Grand Blanc, MI.

It also supplied parts for the M4 Sherman

tank.

This M10 tank destroyer has components

manufactured by Cleveland Plant 1.

M5A1 Stuart tanks built by Cadillac included

parts from Cleveland Plant 1.

Gun Components

Fisher Body Cleveland Plant 1 supplied parts for several types of guns

as show below.

Parts made at Fisher Body Cleveland Plant 1

were shipped to the Grand Rapids, MI Fisher Body plant to be included in

the assembly of 90mm anti-aircraft guns.

Breeches for the three inch naval guns

were built by the Fisher Body Die and Machine plant in Detroit, MI.

Some of the components for the breech assemblies came from Cleveland

Plant 1.

155 MM cannon parts were provided by the

plant.

Torquematic Transmission Components

Torquematic transmissions were built by the Detroit

Transmission Division of General Motors. The Torquematic

transmission was used in both the M18 Hellcat tank destroyer and the M26

Pershing heavy tank. Fisher Body Cleveland Plant 1 supplied parts

for the transmissions that were used in these two vehicles.

The M18 "Hellcat".

The Torquematic transmission in the M18.

A Fisher Body Grand Blanc, MI tank plant

built M26 Pershing tank with a Torquematic transmission.

Diesel Engine

Components

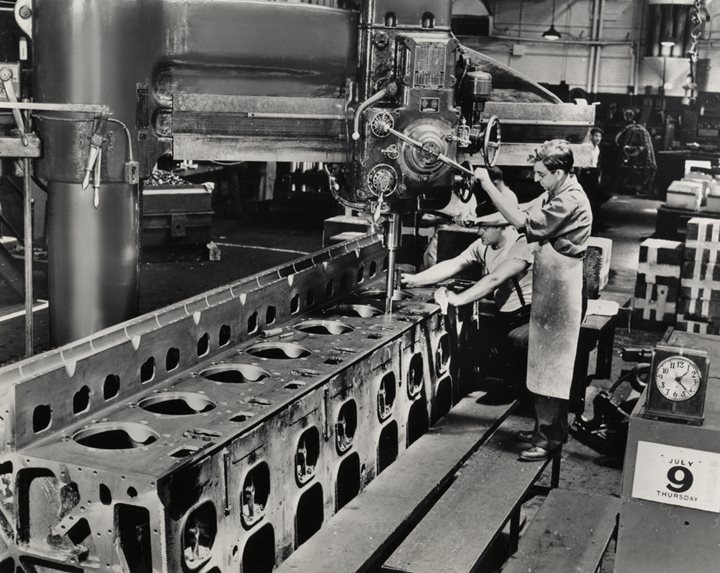

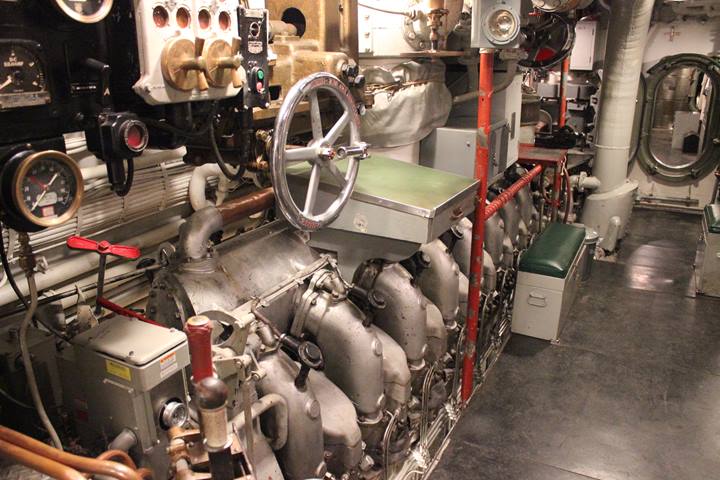

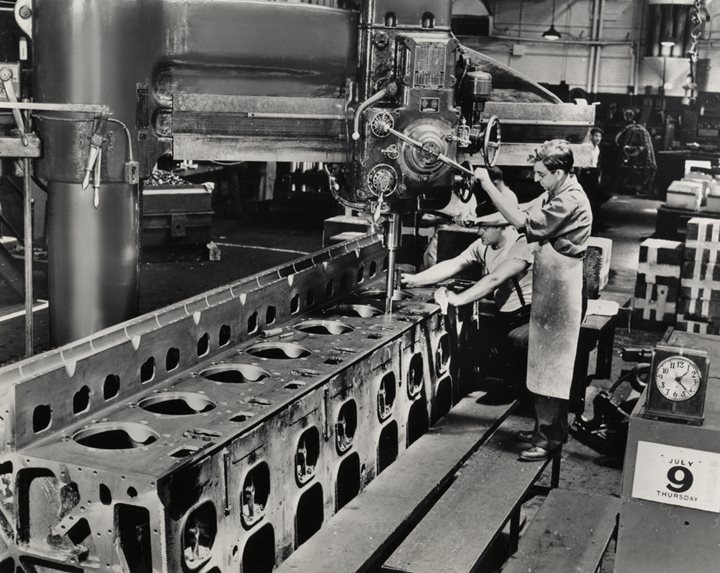

Fisher Body Cleveland Plant 1 provided large machined

crankcases for the neighboring Cleveland Diesel Division of General

Motors, which made marine engines for use in submarine, destroyer

escorts, and other types of ships during WWII.

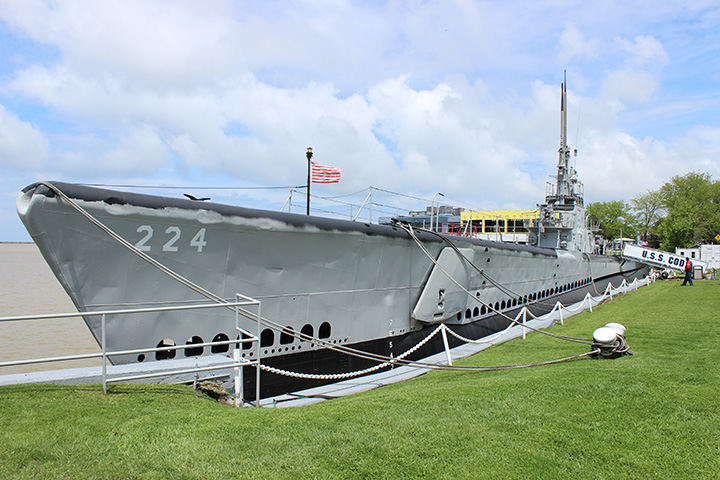

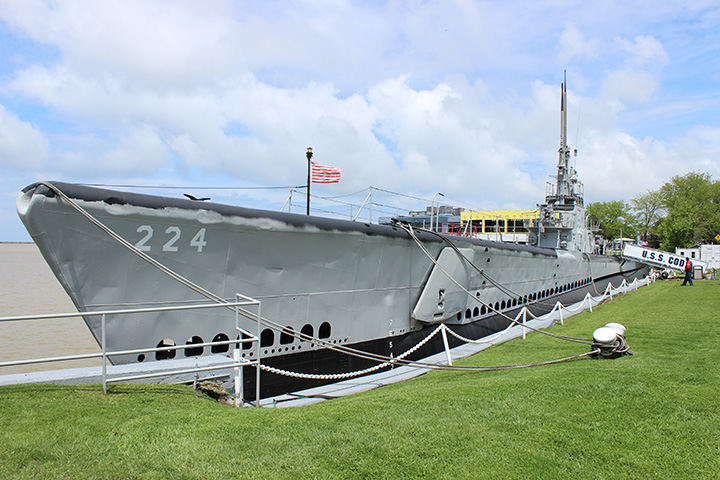

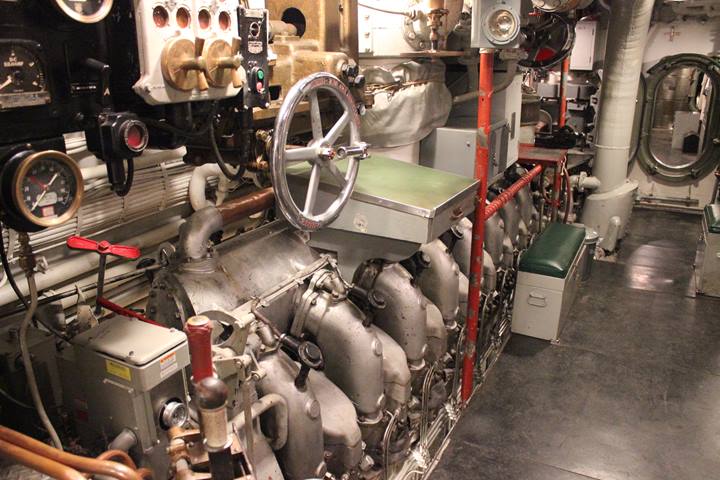

The USS Cod in Cleveland has Cleveland Diesel

engines in it.

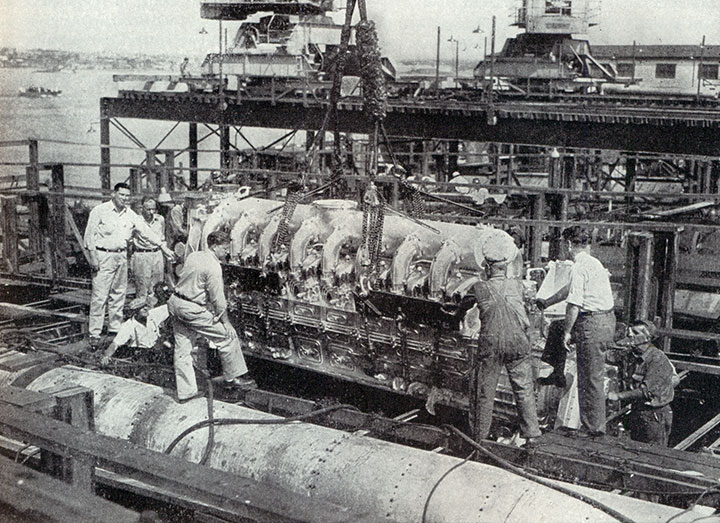

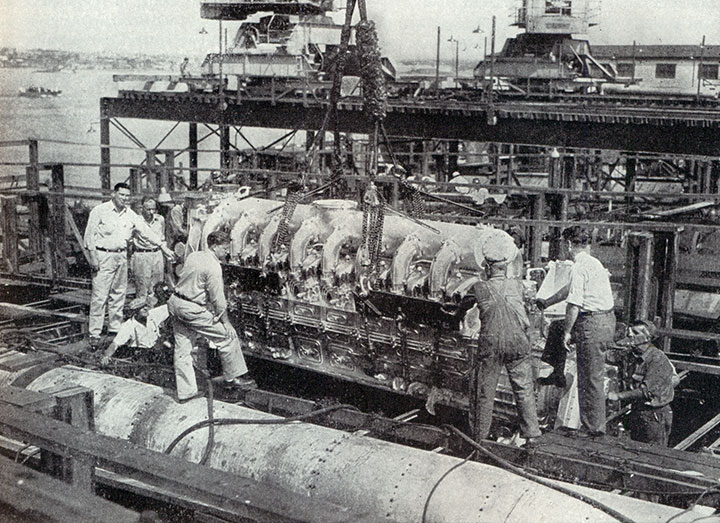

A Cleveland Diesel engine is being installed in a submarine during WWII.

|