|

Fisher

Body - Home

Fisher Body Craftsmanship Goes to War

Fisher Body - Craftsmanship

Fisher Body - Aircraft

Fisher Body - Aircraft

Instruments

Fisher Body - Guns

Fisher Body - Tanks

Fisher Body - Miscellaneous

The Plants

Fisher Body WWII Plant Database

Cleveland Plant #1, OH Plant

Cleveland Plant #2, OH Plant

Detroit Aircraft Unit,

Detroit, MI

Detroit Die and Machine Plant Fleetwood, Detroit, MI Plant

Flint Plant #1, MI Plant

Grand Blanc, MI Tank Arsenal

Grand Rapids, MI Plant

Lansing, MI Plant

Memphis, TN Plant

Ternstedt Manufacturing Division,

Detroit, MI

Grand Blanc Tank Arsenal Built Tanks and Tank Destroyers

Grand Blanc

built M4A2 Sherman Tank Photos

Grand Blanc

Built M4A3 Tank Photos

Grand

Blanc M10 Tank Destroyer Photos

Surviving Fisher Body Plants

- General Motors Corporation in World War Two

Memphis, TN

1930?-Current

This

page updated 2-9-2021.

It was one of those rare twists of fate that allowed this former Fisher

Body Plant to continue to exist long after World War Two while most of

the other Fisher Body plants have been torn down. The plant

survived because Fisher Body no longer needed it and it

became a paper making plant, as it still is today.

Fisher Body originally owned the plant as far back as the early 1930s.

The purpose of the plant was to

provide hardwood, which was available in abundance in the area, for the

wooden bodies Fisher Body was building at the time. When the United States

entered the war in December of 1941, the plant was converted into

the war production of aircraft parts and expanded to 700,000 square

feet. The government, having paid for the expansion and the new

equipment of the plant, bought the facility. However, Fisher Body

continued to manage and operate the plant during the war, making B-25 and

B-29 parts and assemblies. When the war was over, the plant was

not needed by Fisher Body, as wood was no longer used in the manufacture

of automobile bodies. So, the War Assets Administration put the

plant up for

sale. It was purchased by Kimberly-Clark and converted into a paper

plant, which it still is today. The current owner is Kruger KTA USA,

manufacturing White Cloud products.

The Fisher Body Memphis Plant was awarded the

Army-Navy "E" for Excellence Award four times for its

excellent work during the war.

This is how the plant looked during World

War Two.

In the seventy years since the end of World

War Two, the plant has undergone numerous expansions and changes, making it

difficult to determine where the original structure was. This

shows what can be seen of the facility looking east from the north end

of Minnie Street. Author's photo taken in August 2015.

This is looking east again further south on Minnie Street and gives the

best view of the plant. Author's photo taken in August 2015.

This is the southwest corner of the building along Pear Avenue.

Author's photo taken in August 2015.

Looking down the side of the plant along Pear Avenue. Author's

photo taken in August 2015.

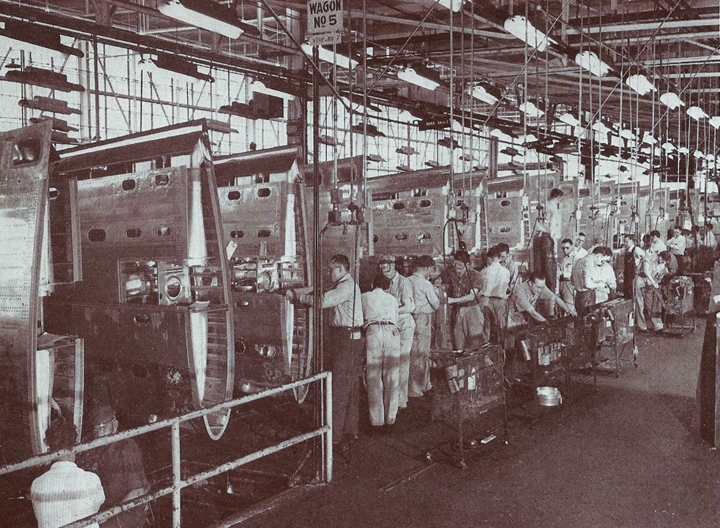

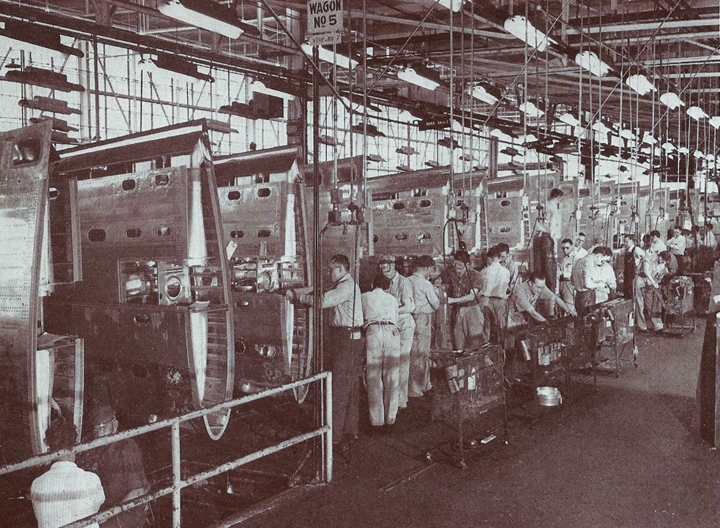

This photo of the Fisher Body Memphis plant during World War Two shows an automobile style production line making wing sections

for the B-25. The parts when complete and assembled in the wing

were sent to the North American B-25 assembly plant in Fairfax, KS.

The right vertical stabilizer for the B-25 is being riveted as it

comes down the assembly line. Photo added 12-25-2016.

Building a B-25 Mitchell bomber takes many

skills. Here, two young ladies are sewing the fabric onto the

right rudder for the B-25. During World War Two, many of the control surfaces on

the trainers, fighters, transports, and bombers were fabric covered.

All needed to be hand stitched onto the framework underneath. This

was tedious but important work. Making these components was

extremely time consuming. Photo added 12-25-2016.

This B-25 wing spar is being assembled in

the Fisher Body Memphis plant. The operators on the left are using

air tools to install rivets into the spar. The operators on the

right have bucking bars, which are used to flatten the end of the rivet.

This operation is called "bucking rivets." Photo added 2-8-2021.

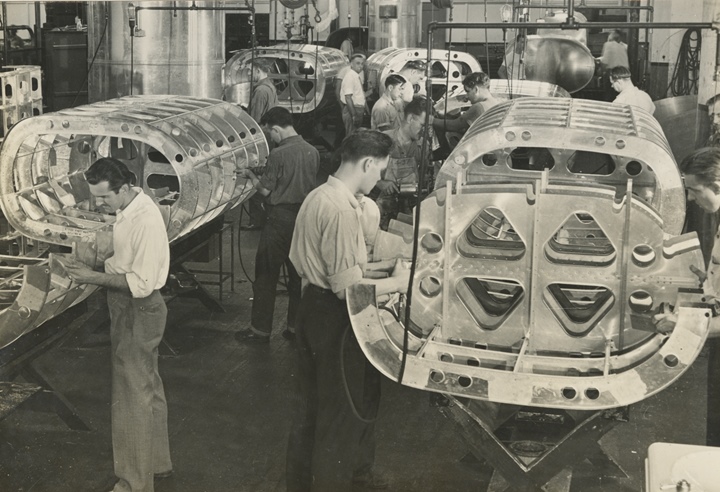

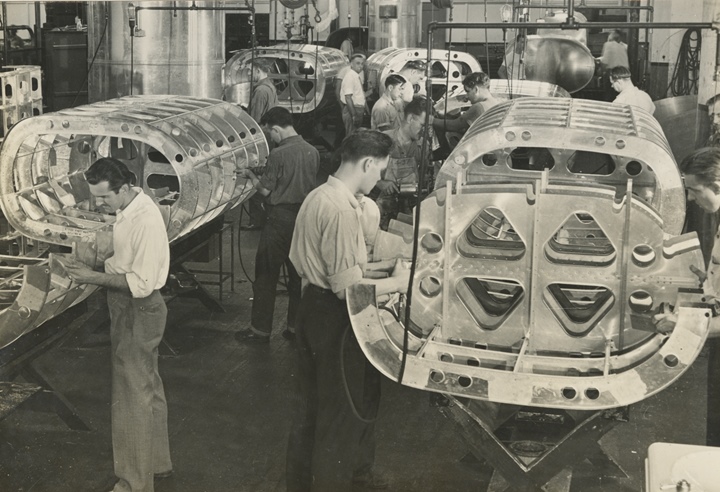

In this photo, B-25 fuel tanks are being

assembled. This is probably an early war photo, as several of the

men are young and subject to the draft. Photo added 2-8-2021.

|