|

Fisher

Body - Home

Fisher Body Craftsmanship Goes to War

Fisher Body - Craftsmanship

Fisher Body - Aircraft

Fisher Body - Aircraft

Instruments

Fisher Body - Guns

Fisher Body - Tanks

Fisher Body - Miscellaneous

The Plants

Fisher Body WWII Plant Database

Cleveland Plant #1, OH Plant

Cleveland Plant #2, OH Plant

Detroit Aircraft Unit,

Detroit, MI

Detroit Die and Machine Plant

Fleetwood, Detroit, MI Plant

Flint Plant #1, MI Plant

Grand Blanc, MI Tank Arsenal

Grand Rapids, MI Plant

Lansing, MI Plant

Memphis, TN Plant

Ternstedt Manufacturing Division,

Detroit, MI

Grand Blanc Tank Arsenal Built Tanks and Tank Destroyers

Grand Blanc

built M4A2 Sherman Tank Photos

Grand Blanc

Built M4A3 Tank Photos

Grand

Blanc M10 Tank Destroyer Photos

Lansing, Michigan Fisher

Body Plant - General Motors Corporation in World War Two

Recognizing a Company

from my Hometown that contributed to winning World War Two

Lansing, MI

1922-2007

Rest in Peace

Gone but not Forgotten!!!

This page updated 12-24-2021.

Other Lansing Companies that

contributed to winning World War Two

Lansing Fisher Body had an important place

in the first 23 years of my life. My parents met while working in

the plant after World War Two. My

father worked there six days a week on his particular job in the plant

while my sister and I were growing up, He worked not only Saturdays and Sundays, but holidays

as well. He spent a lot of time in "The Shop", as he

called it. It dominated our lives because he was gone so much.

My family's association with Lansing Fisher

Body started with my grandfather going to work there sometime after

1937, when he had been a participant in the Lansing Reo sit-down strike.

More than likely, he was hired into Fisher Body because he was a

musician. Fisher Body had a brass band in which he could play.

Reo was not at all in good financial standing, so moving to a GM plant

was more secure for him. Playing in the Reo Brass Band was the

reason he was hired into 'The Reo'. However, with the United

States entrance into World War Two in 1941, he lost his job when

automotive production stopped at Lansing Fisher Body. Most of the

workers were laid off until war work could be brought into the Lansing

plant. (There is more on this history of the plant below.)

Actually, for my grandfather, this probably worked out for the better,

as he got a job at the Nash-Kelvinator plant propeller plant as a

foreman in charge of blade balancing. As the new job was within a

short walk of his house, he was able to save on gasoline and tires which

were both rationed during the war. After the end of the conflict,

he returned to Lansing Fisher Body and retired from there.

On May 23, 1942, after traveling

400 miles from his hometown in Marquette, MI, my father walked into the Lansing

Fisher Body plant and was hired. How did this happen while

thousands of previous workers were laid off? This is a classic

case of "it's not what you know, but who you know!" My father was

looking for a better job, and there was not much opportunity in

Marquette. His high school football coach knew someone at Lansing

Fisher Body and was able to arrange the job for him. My father

therefore came down to Lansing and hired into Plant Protection, which

had a different union than the UAW that represented the majority of the

workers. Plant Protection was used by management to place persons

they wanted into the plant. In later years, plant management would

offer these positions to UAW Local 602 committeemen who were giving management headaches. That way it would not have

to deal with them anymore. Several of the committeemen took the

positions. I worked with two of them during several of my summers

in the plant. On October 6, 1942, my father was inducted into the

Army.

Sometime after my father left for the

service, my mother came to work in the plant as a salaried clerk in the

Materials Control Department. Her job responsibility was to keep

track of the B-29 components being made in the plant, including engine

nacelles and control surfaces. After having several depression-era low paying jobs after graduating

from Lansing Central High School, doing war work at Fisher Body was a

great opportunity for her.

My father returned to work after separating

from the Army on February 6, 1946. At some point, my parents met

while working in the plant, and were married. My mother did what

was the norm during that era. She became a stay-at-home-mother and

housewife. My father stayed at Lansing Fisher Body until he retired on

August 1, 1976.

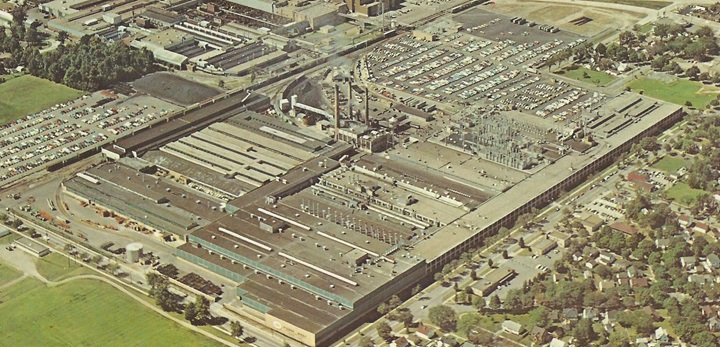

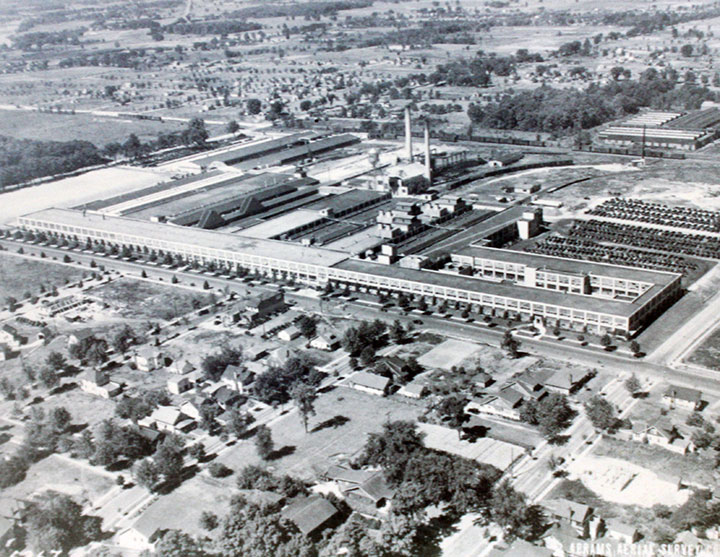

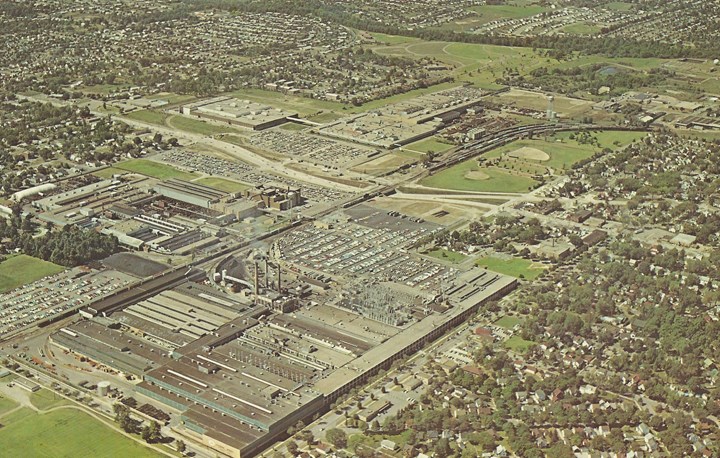

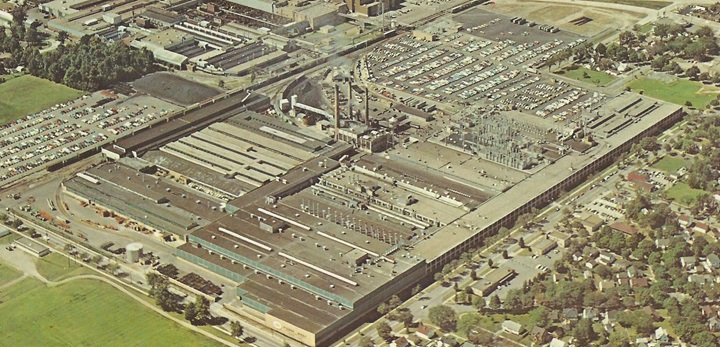

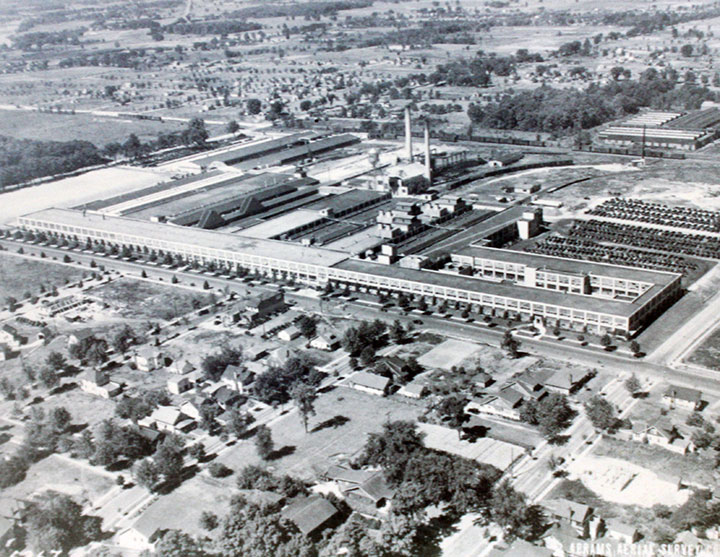

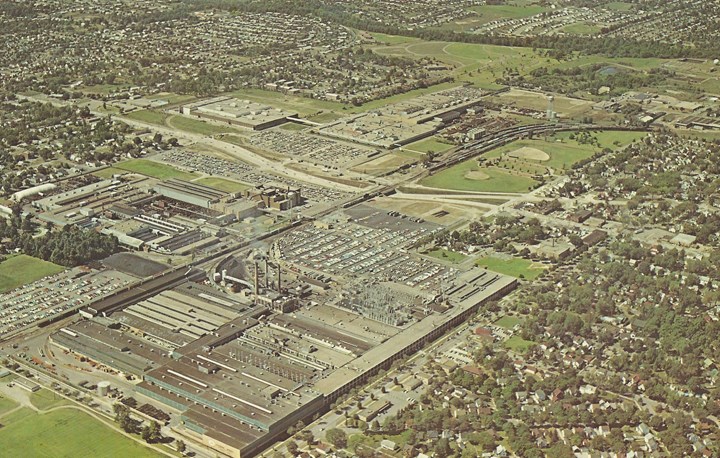

Lansing Fisher Body circa 1973. This

is how I remember the plant; and how it looked during the "Golden Years"

of General Motors during the 1950s, 60s and early 70s. It was

because of this plant that my sister and I always had food to eat and

clothes to wear. Because my father was on Plant Protection, he

worked through several GM strikes while I was growing up. While

going to college, both my sister and I had summer jobs in the plant. During the 1960s, if your mother or father worked in the

plant, you could count on a summer job while in college. Also,

Michigan State football players who needed summer jobs were

given special consideration. There were several such athletes in the plant during the summers I

worked there.

This is the Fisher Body Coach Emblem that was on the

south side of the Lansing Fisher Body Plant facing Michigan Ave and

Lansing Sexton High School. Now the emblem resides in the RE Olds

Museum in downtown Lansing. Author's Photo.

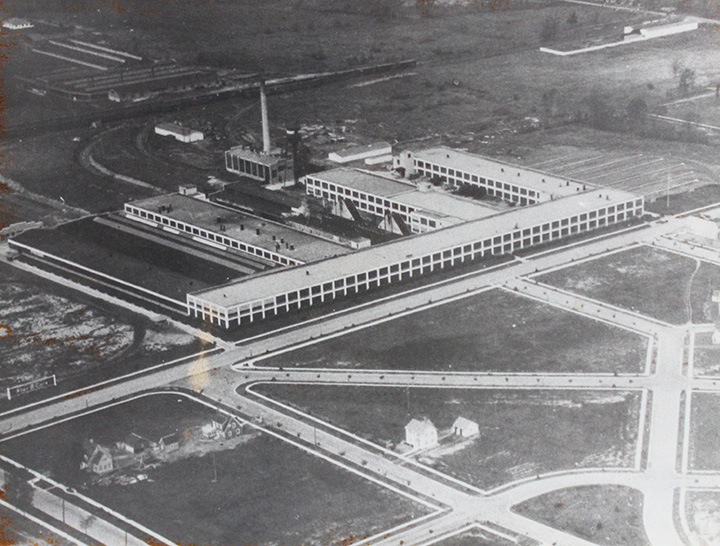

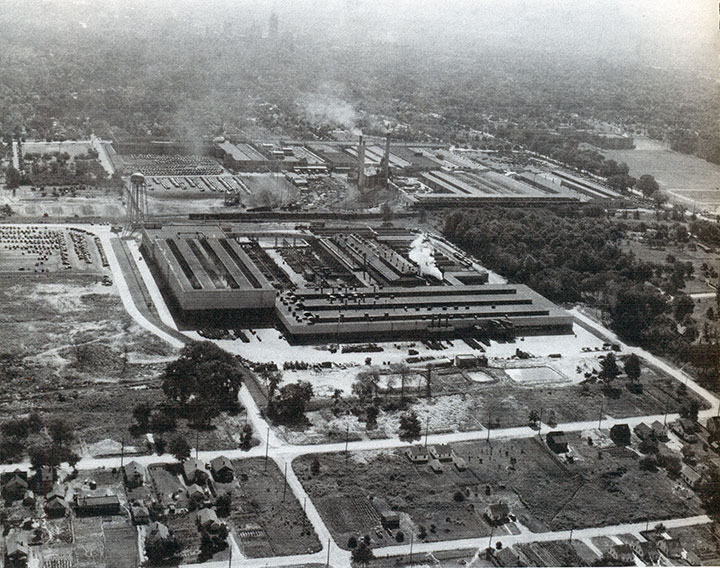

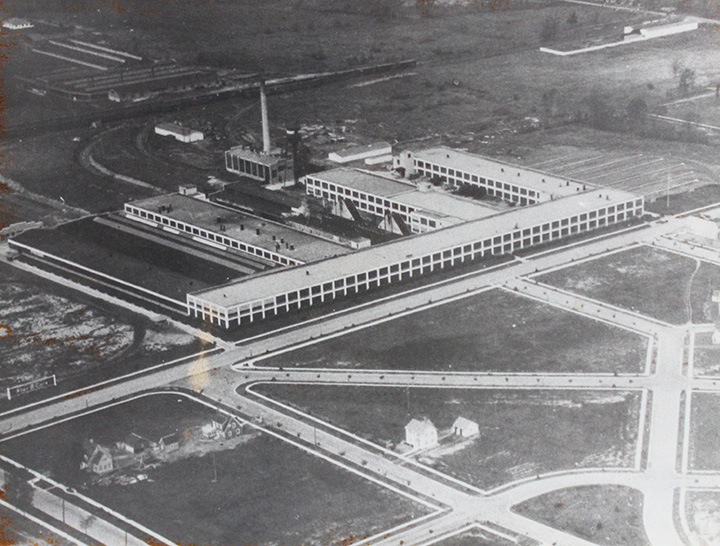

Early History: In the photos below, not only does the plant

grow over time, but the neighborhood to the east of the plant does as

well.

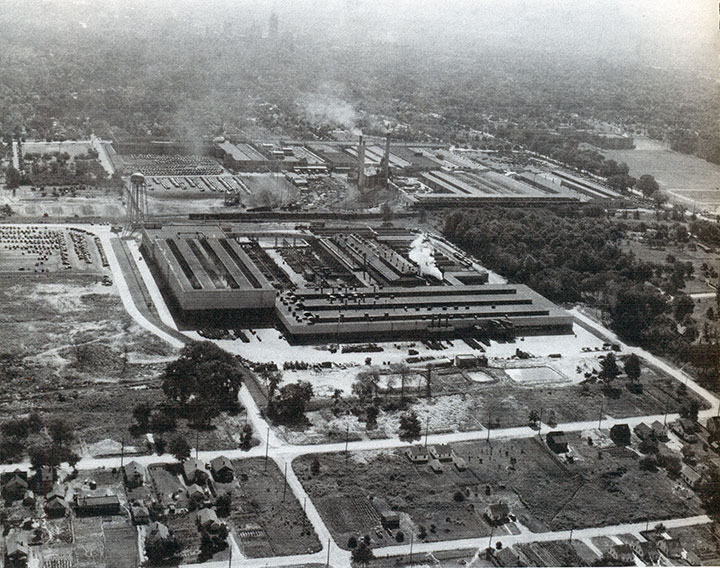

The building that later became the Lansing Fisher Body Plant was built

in 1922 as an automobile assembly plant for the Durant Motor Company.

The plant was built on 152 acres, and employed 3,000

workers when it opened. This aerial looking north-west shows what the plant looked like in 1922

after it was built. The plant was far smaller than it was when

razed in 2007, as there were many additions over the years.

Building One was the nomenclature for the long building facing Verlinden Avenue. The

empty area on the south or left end of the photo would be the location

of a post WWII two story addition known as Building 3X. It contained

the body shop on the first floor and final trim shop on the second.

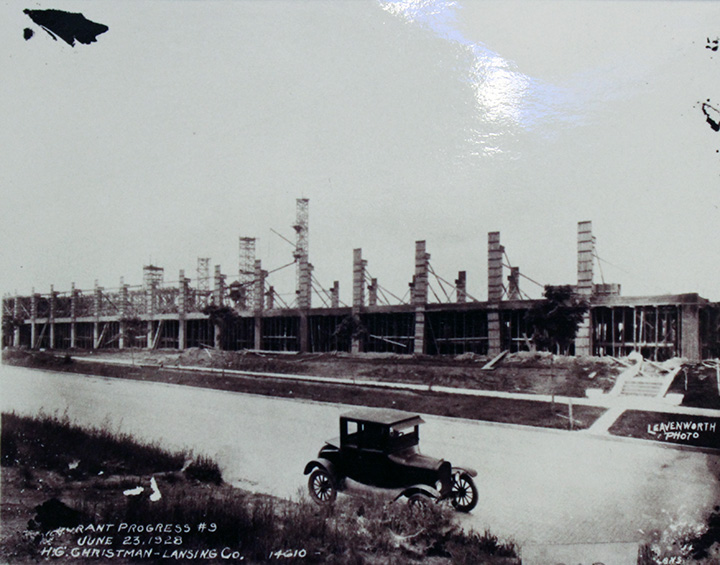

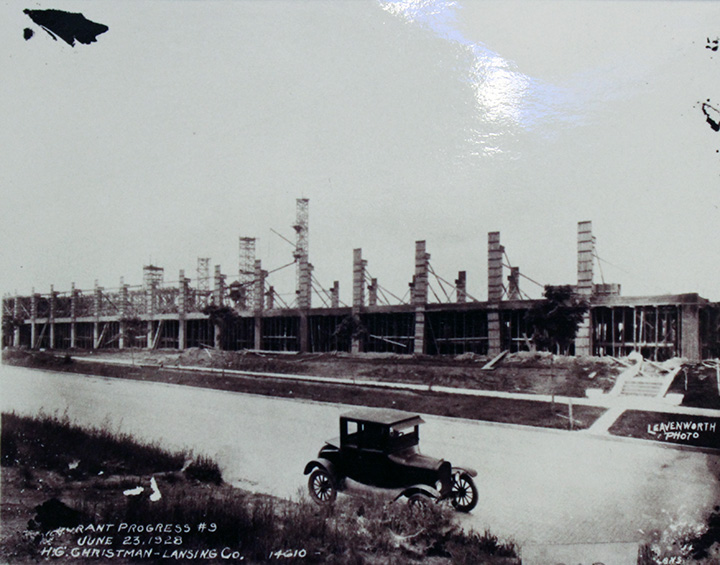

The 1928 photo below shows the addition going up on the north end of the

building that is a parking lot in this photo.

Verlinden Avenue is out in front,

and Michigan Avenue is the road along the bottom of the photo.

Three houses were built across the street from the

plant, and trees have been planted in the new

neighborhood. When I was a child. this area was all houses.

This photo, taken between 1922 and 1928, is

looking south down Verlinden Ave. while the plant was still part of

Durant Motors. The trees at the south end of Verlinden Ave. are

where my high school, J.W. Sexton, would be built during World War Two.

This 1926 Durant Star was built by the

Durant Motor Company in what later became the Lansing Fisher Body Plant.

The Star was the low priced line of vehicles produced by Durant, for

which production ran from 1922 to 1928 at Lansing. This particular

vehicle is on display and owned by the RE Olds Museum in Lansing, MI.

It

is an un-restored original. Author's photo.

How cool is this? For as far as can be

seen looking north up Verlinden Avenue, there is a double row of Durant

automobiles lined up in front of the plant. Each car had a driver

that drove it to its new owner. Photo added 12-24-2021.

The date was July 17, 1928. Photo added 12-24-2021.

A year earlier, on July 30, 1927, at

least nineteen Durant Star Sixes were lined up in front of the Durant

Motor Company on Verlinden Avenue in Lansing, MI. These vehicles

were all on their way to Chicago, IL. Photo added 12-24-2021.

This 1928 photo shows the addition on the north end of the plant and

Building One. The stairs lead up to what would become the "front offices"

for the rest of the plant's existence.

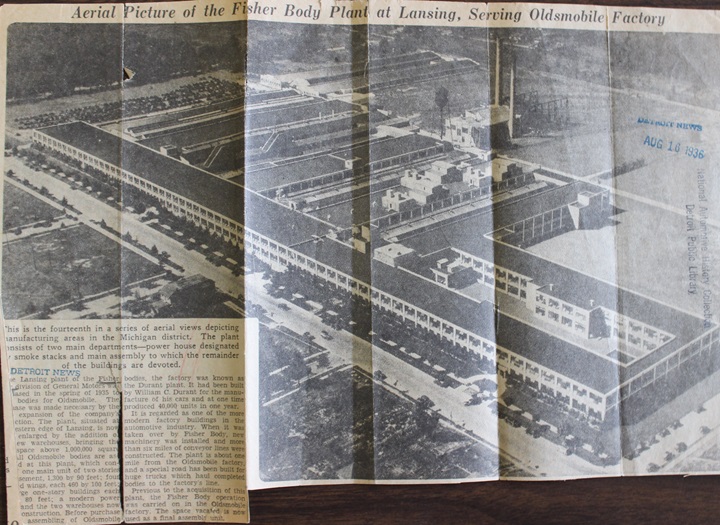

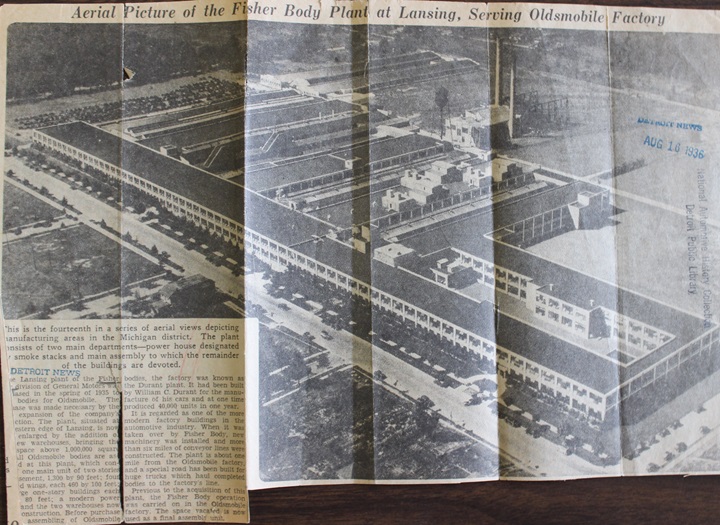

This newspaper photo shows the plant in

1936, one year after General Motors purchased it for Fisher Body.

Prior to the purchase of this plant, Fisher Body built its bodies for

Olds in leased space in the Oldsmobile plant. At this time, the

plant was 1,000,000 square feet, had six miles of conveyor, and

supplied all of the Oldsmobile bodies. There was not a direct road

between the two plants, so a road was built between them. This

would be Clare Street and Olds Avenue.

This is the Fisher Body Lansing Plant before World War Two. This

may have been taken at the same time as the photo above. The 1928

addition on the north or right end of the photo is easily visible along

with several other additions within the center of the plant complex.

During

summers while in college, I worked in this building. One of my jobs

was at the middle of the section at the right end (north) of the photo

on the second floor. There were two entrances along the front facing Verlinden Avenue.

One entrance towards the north (on the right) was

what we called "the front office" for the executives and some of the

office workers. The other entrance, in the middle of the plant at the intersection of

the two buildings facing the Verlinden Ave., was for the workers like my

father. The long buildings in the far upper left were known as

"cut and sew." Seat cushions and interior trim parts were made there until the late

1950's, when they became known as "the cushion room." "Cut and sew"

was moved to another plant and the seat cushions were then assembled

there.

On a related note, General Motors purchased the plant behind and across

the railroad tracks from RE Olds in 1940. It was originally built as a foundry in 1920 to hopefully provide

castings for General Motors. It went bankrupt several times and

was standing empty when GM

purchased it. It became Olds Plant 2 and was converted into a

forge plant to manufacture the 75mm and 155mm artillery shells

that Oldsmobile produced during World War Two. The Fisher Body Power House

supplied the steam for Olds Plant Two.

World War Two:

The March to the Michigan State Capital

building by 3,000 Fisher Body workers on January 20, 1942.

I had seen reference to this march of

Lansing Fisher Body workers in my early research on the plant but was

not able to obtain this photo until June of 2015. The date of this

photo is January 20, 1942. It was taken at the south end of the

Lansing Fisher Body Plant on Verlinden Avenue. It shows a small

portion of the 3,000 Fisher Body employees starting a march to the State

Capital a mile away to the east. The reason for the march was to

protest the impending job losses. Auto

production in the United States was coming to an end in February 1942. The workers were concerned for their jobs, because as of

this point in time there were no plans, or at least no plans that the

workers knew of, for war production in the plant. It was 44 days since the bombing of Pearl Harbor.

The

Arsenal of Democracy, for which the Lansing plant was later an important

part, was just starting to come to life.

The worker's concerns were not without merit.

In February 1942, 500 workers were laid off from this plant. No doubt some of

those laid off were in this photo. When the laid off workers applied

for work at The Reo in Lansing, only 95 were hired. Meanwhile, Reo

hired 400 women who had not previously worked in a factory.

Also, some of the men in this photo may not

have known it, but worrying about a job was not necessary. Uncle

Sam found jobs for them carrying M1 rifles after they were drafted into

the US Army. One of the big issues for all companies during World

War Two

was the constant drafting of experienced workers into

the Army.

My grandfather was employed at the plant in

January of 1942 and he is somewhere in this group of workers.

There are several interesting items to note in this photo. One worker is carrying a sign that states "C.V. dept

against the world". Before the advent of air conditioning along

with "flow through ventilation" being standard on vehicles, automobiles

and trucks had corner vents in the front side windows for ventilation.

The corner vents were known as C.V.s in the auto industry.

It is January in Michigan and there is no snow

on the ground.

Another worker has a sign that says "500

planes per day." This is a reference to the plan that UAW

president Walter Reuther proposed to keep auto plants running and

workers in jobs. Walter Reuther proposed this over a year

earlier when he felt that the unused capacity of the auto industry could

be harnessed to make 500 metal fighter aircraft and continue to produce

automobiles at the same time. Mr. Reuther, along with his

automobile company management contemporaries, totally

underestimated the complexity of building not only fighters, but any

aircraft during World War Two. Lansing Fisher Body would go on to produce

components for both the XP-75 fighter and B-29 bomber, while the Eastern

Aircraft Division of General Motors would produce 5,837 FM-1 and FM-2

Wildcat Fighters for the U.S. Navy over a two year period.

Note the pavement of Verlinden Avenue.

It is all hand-laid brick. Eighty years later, one may ask why was

it brick? Why was it hand laid? This was common practice

during the Great Depression, as many projects to put unemployed men to

work were to pave roads with brick, as this was labor

intensive. My

grandfather did not lay the brick on Verlinden Avenue, but he did lay the

brick on South Cedar Street in Lansing. That public works project put him back to work during

the Depression.

And speaking of the brick of Verlinden Avenue,

I can still remember driving down the street and hearing the roar of the

bricks under the tires, as I did my first of three road trips during

Driver's Training at Sexton High School in the summer of 1965. I was the first of the three students in

an Oldsmobile 88 to drive that day. Mr. James Bond (Imagine having this name in

the mid-1960s!) was the instructor, and he had to slow me down a bit, as I

was not paying any attention to my speed as I went down Verlinden.

Some years later the bricks were paved over

with asphalt.

Lansing Fisher Body received the Army-Navy

"E" Award in June 1945.

Lansing Fisher Body World War Two Products: The plant produced $43 million in war products between

1942 and 1945, divided into three different product groups. The

aircraft group consisted of B-29 control surfaces and engine nacelles,

aircraft tail sections, and XP-75 aircraft parts and assemblies.

The armor group was made up of M4, M18, M24, M26, and experimental tank

parts. The last group was carriages for (2,359) 90mm

anti-aircraft guns, and components for 5 inch naval guns mounts.

Very little information is available on what

the plant specifically built during World War Two. The following two

sources have provided what information I have been able to find.

From "Fisher Body Craftsmanship Goes to War": B-29, XP-75

aircraft parts

and assemblies. M4, M8, M24, and experimental tank parts.

90mm anti-aircraft gun parts and five-inch naval gun parts. On page 35, it states:

"In September (1943) Cadillac requested further assistance on the M24 in

welding a number of major hull assemblies. The work was assigned

to the Fisher Body plant in Lansing."

From "UAW Local 602 records": 90mm gun

carriages, tail sections for aircraft, gun mounts, hulls for tank

destroyers, small parts for Army aircraft. First Navy contract was

for five-inch naval gun mounts. Parts for XP-75 aircraft.

The Lansing Fisher Body Plant World War Two

Chronology: As determined from Local 602 records.

1942-1943:

Aircraft Tail sections, gun mounts (90mm), hulls

for tank destroyers, small parts for aircraft, parts for XP-75 "Eagle".

It is unknown for which aircraft types the tail sections or small parts were

built. They could have been one and the same for the

XP-75. The hulls for the tank destroyers were most likely for the

M10 "Wolverine" being built at Fisher Body Grand Blanc, MI.

Production of the M10 lasted from September 1942 to December1943.

Lansing could have also worked on the M-18 Hellcat built by Buick

from July 1943 to October 1944. Grand Blanc built many of the hulls and

turrets for the M-18, and could very well have sub-contracted some of

the work to Lansing.

1942-1945:

B-29 control surfaces and nacelles,

five inch naval gun mounts, assemblies for various type tanks.

The Flint Journal announced on

June 6, 1945 that work on the B-29 and the heavy tank project would

cease at the Lansing Fisher Body Plant at the end of July 1945, in order

to make way for the return of automotive production. Of interest

is that the heavy tank was

the M26 Pershing, which is not noted in either the Local 602 or Fisher

Body documentation. The Lansing M26 work would have been for

Fisher Body Grand Blanc, which was building the tank.

The first war contract for Lansing Fisher Body in 1942 was for 90mm

anti-aircraft gun carriages like the one seen here. Author's photo

added 11-26-2020.

The plant had 4,500 employees

before the war and only 600 to 1,700 during 1942. The plant was idle

for several months before the work for this project came in.

The parts made at Lansing Fisher Body then went to Fisher Body Pontiac.

There, 2,359 of the weapons were produced. Author's photo added

11-26-2020.

Lansing assembled the vertical stabilizer, horizontal stabilizer, tail

cone, rudder, elevator, trim tabs, ailerons, and flaps for the Fisher Body XP-75

and P-75A.

105,000 square feet, or 10% of the

plant's area, was allocated for this work. This photo shows the

only surviving P-75A at the National Museum of the United States Air

Force. This was taken when it was in the former annex hangar. Author's

photo.

Only (8) XP-75s and (6) P-75s were built

during World War Two. While

only fourteen total airframes were built, Lansing and other Fisher Body

plants were planning and producing for a high production run. Many

more than fourteen sets of components were built. In 2015 the

Fisher P-75A was moved to the main museum complex. Author's

photo added 2-15-2021.

This photo shows the horizontal and vertical

stabilizers along with the rudder. The small trim tab can be seen

at the bottom of the rudder. They and the elevators were all

assembled at Lansing Fisher Body. Author's photo added

2-15-2021.

The Lansing Fisher Body-built

ailerons and flaps can be seen In this photo. The ailerons are nearest the end

of the wing. Author's photo added 2-15-2021.

Lansing built parts for the M4 Sherman. It is unknown which parts

were made in the plant. It can be assumed that whatever was made

in the plant was sent to the Fisher Body Tank Arsenal in Grand Blanc, MI,

60 miles away. Of the 49,234 Sherman tanks built by ten different

manufacturers, this particular Grand Blanc-built M4A3 Sherman is on

display in downtown Bastogne, Belgium. Bastogne was the center of

the fighting during the famous Battle of the Bulge in December 1944.

The road intersection in the town where this M4A3 now resides

was an important road junction for the German battle plan to be

successful. The road junction never fell into enemy hands; and this

tank was one of many that helped the 82nd Airborne defend the town.

It was knocked out of action during the battle and then put on display

by the residents of Bastogne. Author's Photo.

This M4A2 is the oldest Fisher Body-built tank in North America, and is on display at Victoria Park in

London, Ontario. It came off the Grand Blanc assembly line in

September 1942. It landed with the Canadian Army at Normandy, and

then fought its way across Europe until the end of the war. It

survived the many battles it was in, and then came back to Canada.

Lansing Fisher Body may have built components for this tank in 1942.

Author's Photo.

Grand Blanc also built the M4A2 Sherman, as

seen here in downtown Vancouver, BC. Lansing could have also

helped build this late model Sherman tank. Photo courtesy of David

Jackson, Jr.

This Fisher Body-built M10 "Wolverine" tank

destroyer is on display at the Patton Museum at Fort Knox, KY. Author's

photo.

The Cadillac-built M24 Chaffee also had parts in it made by Lansing Fisher Body.

Work was assigned to Lansing in September 1943 for the welding of hull

assembly components. This particular Chaffee is actually a combat veteran from the Korean

War, where it served with the US Marines. It was captured by the Chinese,

and then recaptured by the US Marines. Author's photo from the

former Ropkey Armor Museum in Crawfordsville, IN.

This is a Fisher Body Grand Blanc-built M26 "Pershing"

heavy tank. At the end of the war, Lansing was involved with the

heavy tank program until the end of July 1945. Author's

photo added 11-10-2017.

Lansing's only Navy contract was to fabricate portions of the five inch

naval gun mount. The Fisher Body plant in Pontiac did the final assembly

on the mounts. This five inch gun can be seen at the USS Sullivans

at the Buffalo and Erie County Naval and Military Park in Buffalo, NY.

Author's photo added 11-10-2017.

The B-29 Program at Lansing Fisher Body:

This is what my mother worked on. It was her responsibility in

Material Control to keep track of the assemblies being built, to assure they would be shipped to the aircraft assembly plants on time.

Originally, Lansing allocated 195,800 square

feet for the production of ailerons, rudders, and elevators. This

was 18% of the 1,066,667 square feet of the plant.

Lansing B-29 Project Scheduled Production

As of February 1944 |

|

B-29 Assembly Plant |

Boeing-Renton, WA |

Boeing-Wichita, KS |

Bell-Marietta, GA |

Martin-Omaha, NE |

Totals |

|

Nacelles (With Cleveland #1) |

2,700 |

1,464 |

400 |

200 |

4,764 |

|

Ailerons, Rudders, and Elevators |

300 |

|

900 |

|

1,200 |

Note that Lansing and Cleveland #1

supplied nacelles to all four B-29 assembly plants.

This is the B-29 Enola Gay which dropped the

first atomic bomb on Hiroshima, Japan. It is on display at the Udvar-Hazy Air and Space Museum in Virginia.

Of significance is that

Fisher Body supplied the engine nacelles to the Martin Omaha, NE plant

that built the Silverplate nuclear bombers. Both Fisher Body

Lansing and Cleveland Plant One built B-29 engine nacelles for the B-29s

built in Omaha. Therefore, there is the possibility that Lansing

built the engine nacelles on this aircraft.

Lansing built ailerons for the B-29, which is

the control surface at the bottom of the photo. Author's

photo.

This photo gives a better look at the Fisher

Body-built engine nacelles on the Enola Gay. They were the most

complex part of the B-29 after the forward fuselage section and contained

over 1,300 subassemblies and weighed over a ton. Author's photo.

Lansing built rudders and elevators for the

B-29 bomber. Author's photo added 11-26-2020.

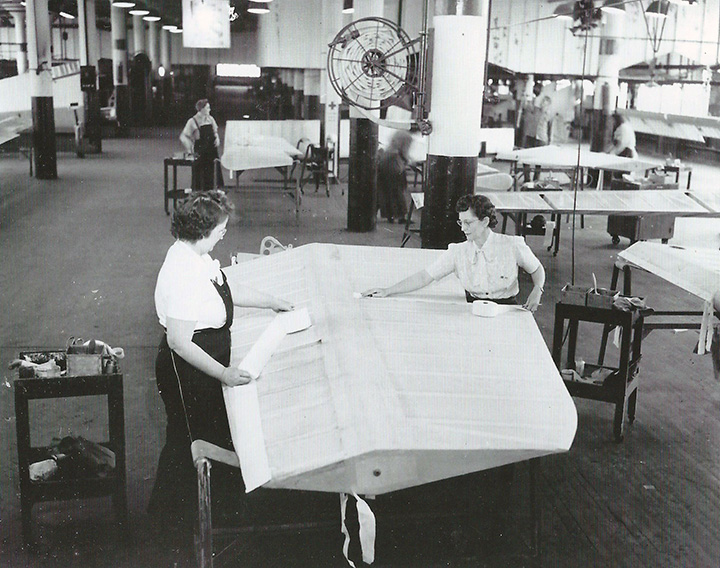

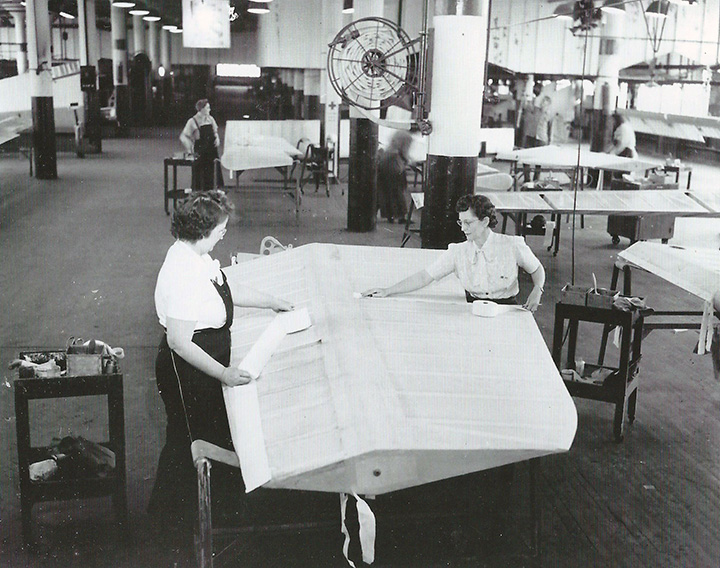

These women are working on a B-29 fabric covered rudder on the Lansing

Fisher Body plant floor. The woman on the left is applying tape

over the stitching that holds the fabric to the aluminum superstructure.

The stitching down the center has already been taped over. Once

this process is complete, a water-proof varnish is applied and then

cured.

While the B-29 was the most complex and advanced aircraft of the World

War Two

era, it still had fabric covered ailerons, elevators, and rudders.

In combat, the fabric actually had an advantage over aluminum covered

control surfaces. When enemy shells went through the fabric, it

did now leave any jagged edges like on the metal ones, which could then

jam the controls.

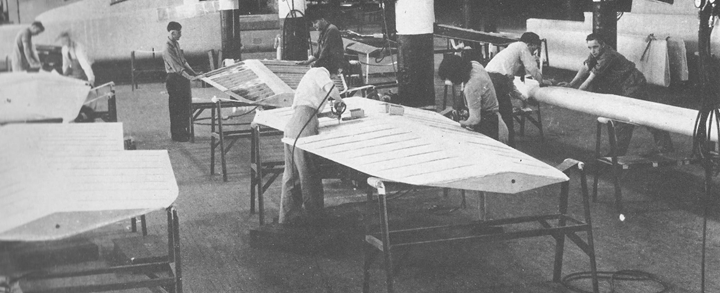

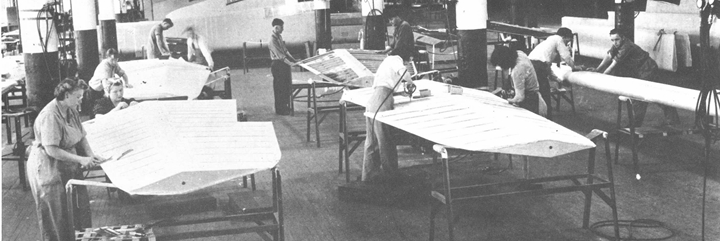

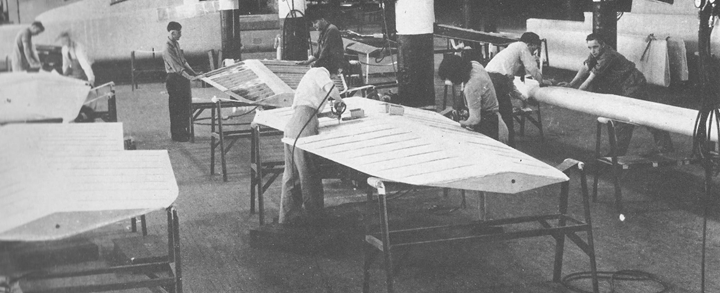

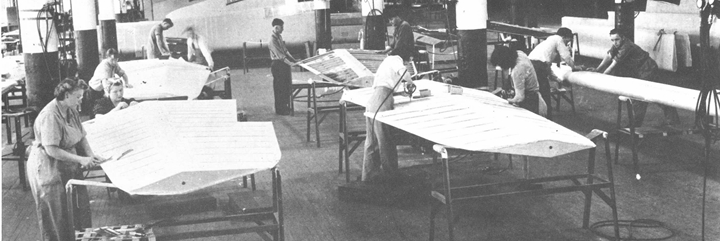

In this photo, both men and women are working

on the rudders in Lansing. They can be identified as rudders

due to the size of the cut-outs for the vertical trim tabs. The

completed rudders were then sent to the Fisher Body Plant #2 in

Cleveland, OH for assembly into the vertical stabilizer.

This shows a larger section of the plant

floor but is the same photo as above.

This photo of a B-29 rudder produced at

Lansing Fisher Body shows its size compared to the two workers. Photo added

11-26-2020.

The workers In this photo are working on a

B-29 elevator. Photo added 12-25-2016.

A completed B-29 aileron is in the bottom

half of the photo and a B-29 elevator is shown in the inset. Both

of these photos were taken at Lansing Fisher Body. Photo added

11-26-2020.

The tape covered areas where the fabric was

stitched to the ribs of the elevator can be seen on this B-29.

Author's photo.

The Lansing B-29 Nacelle Program:

Fisher Body committed to the United States Army Air Force for 290 B-29

ship-sets per month in 1945, which is 1,160 individual nacelles per

month. Fisher Body Cleveland Plant 1 had the capability of

producing 200 ship-sets and would reach that in January 1945.

Starting in December 1943, Lansing was also tooled up to

produce 90 ship-sets, or 360 individual nacelles per month. Production began

in May 1944 with full production being reached in July 1945. At

full production, Lansing produced 31% of the nacelles built by Fisher

Body.

60% of the Lansing plant was committed to

the production of the B-29 nacelles. This was 640,000 square feet.

The tooling for the B-29 nacelles in Lansing totaled 946 jigs, fixtures,

master gauges, and master plates which required 183,958 hours to build.

Lansing did not receive its Army-Navy "E"

Award until June 1945. It could very well be that it received the

award due to producing more B-29 nacelles ahead of the original

schedule.

This is the only known photo of B-29 engine nacelles coming down the

monorail assembly line at Lansing Fisher Body. It is unknown what

percentage of the 13,772 Fisher Body-built B-29 engine nacelles were

made in Lansing. My mother's responsibility was to come out to this

assembly line and then verify by job number that it was on schedule to

be shipped to Omaha or one of the three other B-29 final assembly

plants in operation during World War Two.

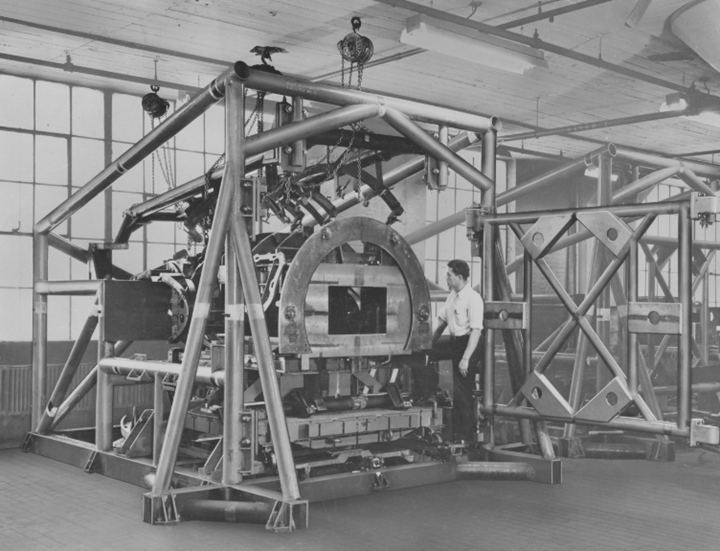

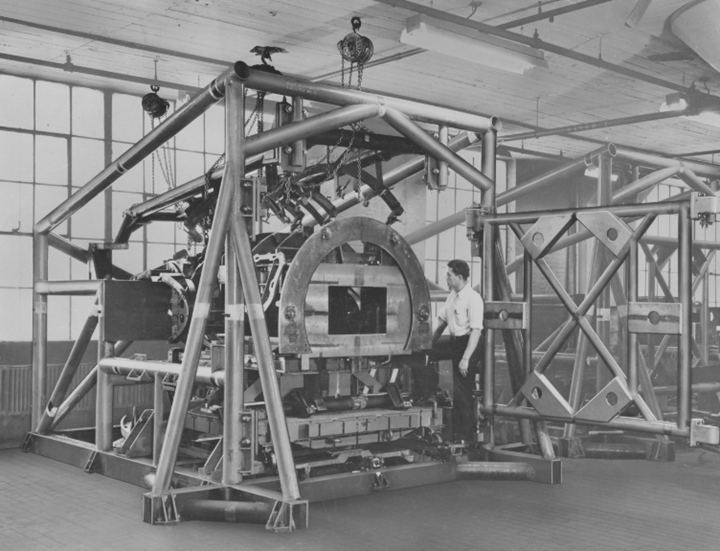

This master gauge is one of the 946 pieces

of equipment that needed to be built for Lansing to go into B-29 nacelle

production. Photo added 11-26-2020.

Post-World War Two:

Oldsmobile Plant Number Two in 1945.

The photo is looking

east with Lansing Fisher Body behind it. The newly completed J.W.

Sexton High School, that I would attend 20 years later, is located in

the right hand corner. The gymnasium is visible on the south end. The

Fisher Body plant's power house supplied steam to both plants.

Downtown Lansing is in

the distance through the smoky haze.

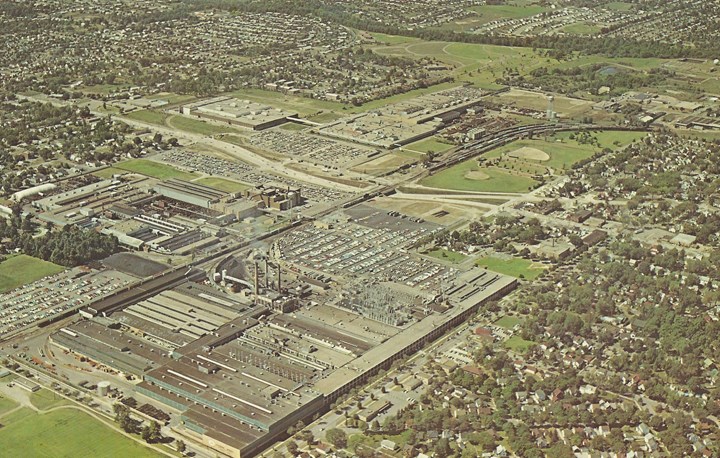

Fisher Body Lansing in 1973.

This is a post-1975 photo looking south. Verlinden Avenue is on

the left. J.W. Sexton Memorial Stadium can be seen to the south of

the plant along with the high school track. At this point, all of

the additions to the plant have been made.

The Fisher Body Coach had been on the south side of building 3X since it

was added in 1960. Plant millwrights are removing both the sign and the name

"Fisher Body" on August 1, 1985. It then became the BOC Lansing Body

Assembly Plant.

How times have changed. The millwrights

do not have any safety harnesses on in case they were to fall.

Today's safety protocols require harnesses for this type of job.

Today the work would be done from a bucket truck.

The travesty of eliminating Fisher Body did not have to happen! In

1981 Roger Smith became Chairman of GM after being a bean counter for GM

in New York City. He wouldn't have known a body in white if one had

been shoved up his... ! Well you know what I mean. He was a

disaster for GM. He thought he was the smartest S.O.B on the face

of earth. While everyone could agree with the S.O.B part, only his

mother thought he was the smartest. And she only thought it true about half the

time! He was like a little banty rooster strutting around the GM

barnyard, making lots of noise, but not knowing how to run the world's

largest auto company. It was his harebrained idea to take Fisher

Body, the premier division in the company, destroy it, and combine it

into other divisions.

Instead of spending GM's money on new products

and technology, he went out and bought other companies to try

and fix the problems. One of the worst purchases was that of

computer software company EDS. This was the ultimate train wreck,

and caused dissention among the employees for years to come. Along

with EDS came its chairman, Ross Perot, who also thought he was the

smartest S.O.B. on the face of the earth. Because of this, he

forgot for whom he was working for, and thought he was the person running

General Motors. We ended up with two banty roosters strutting around the

GM barnyard, squabbling with each other, and screwing things up.

After the Fisher Body name was

gone, the plant was known as the Body Plant of Lansing Car Assembly.

The former Oldsmobile plant was final assembly. This is the

security gate after the modernization and expansion of the plant in

1975. The original security gate was formerly a stand-alone

building and was Gate 9. The area to the east of this location is

shown in the next photo.

This is what is left of the north end of the

plant in 2012. I used to have

a work station where the rubble stands today, working on Olds Vista

Cruiser station wagons on the second floor. Author's Photo.

The south entrance on Verlinden Ave. was

located where the slab of concrete protrudes into the grass. Everyone who worked at the plant used this entrance to

hire in, because the Personnel Department was located here.

One went down the steps, past security, and then up into Personnel.

Many of my family members, including both of my parents, my sister, and

my grandfather, and I passed through this gate to get to work. The plant was razed in 2007.

Author's Photo from 2012.

This photo shows strikers in front of the

above described entrance. Note that the bricks have not yet been

paved over on Verlinden Avenue. Photo courtesy of UAW 602.

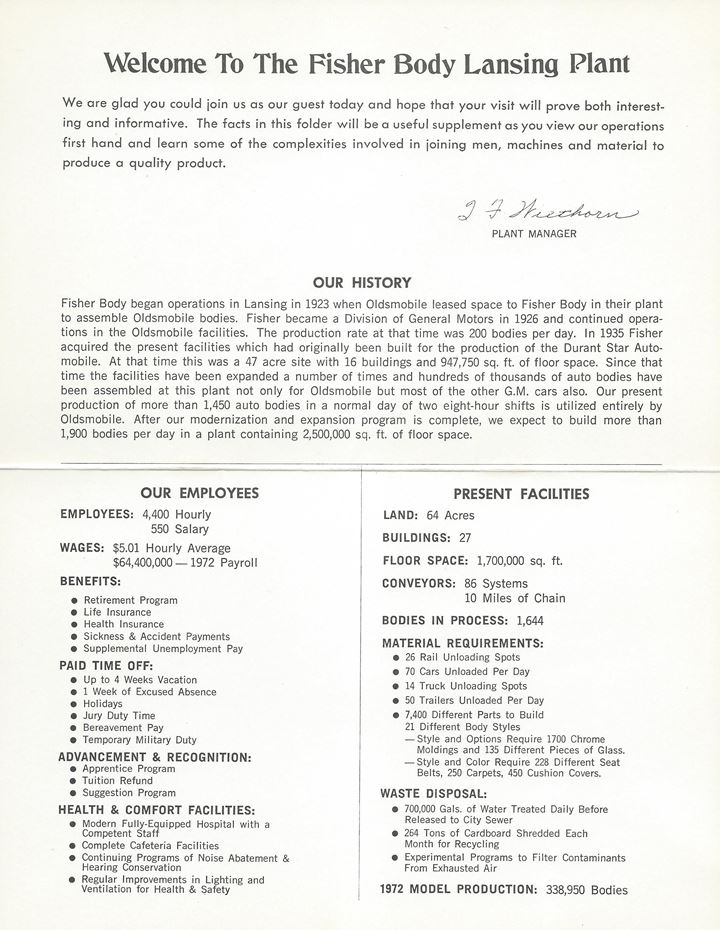

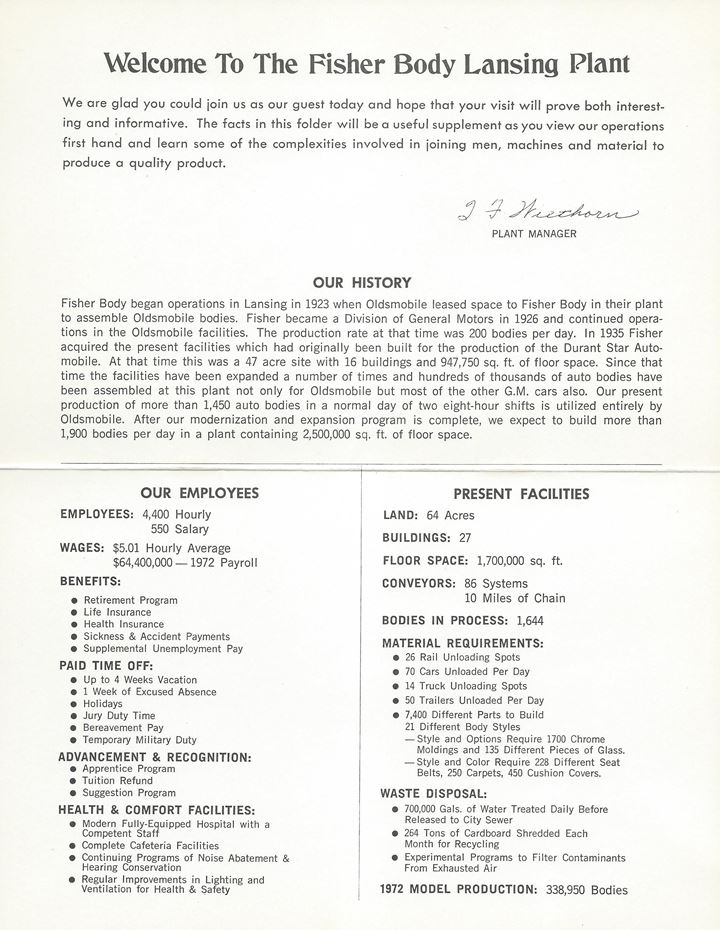

1973 Lansing Fisher Body Open House Brochure

May "The Shop" Rest in Peace!

Other Lansing Companies that

contributed to winning World War Two

|