|

Fisher

Body - Home

Fisher Body Craftsmanship Goes to War

Fisher Body - Craftsmanship

Fisher Body - Aircraft

Fisher Body - Aircraft

Instruments

Fisher Body - Guns

Fisher Body - Tanks

Fisher Body - Miscellaneous

The Plants

Fisher Body WWII Plant Database

Cleveland Plant #1, OH Plant

Cleveland Plant #2, OH Plant

Detroit Aircraft Unit,

Detroit, MI

Detroit Die and Machine Plant

Fleetwood, Detroit, MI Plant

Flint Plant #1, MI Plant

Grand Blanc, MI Tank Arsenal

Grand Rapids, MI Plant

Lansing, MI Plant

Memphis, TN Plant

Ternstedt Manufacturing Division,

Detroit, MI

Grand Blanc Tank Arsenal Built Tanks and Tank Destroyers

Grand Blanc

built M4A2 Sherman Tank Photos

Grand Blanc

Built M4A3 Tank Photos

Grand

Blanc M10 Tank Destroyer Photos

Surviving Fisher Body Plants - General Motors Corporation in World War

Two

Cleveland, OH

Plant No. 2

1942-1945

Rest in Peace

Gone but not Forgotten!!!

This page added 1-22-2020.

Fisher Body Cleveland Plant #2 received the

Army-Navy "E" Award one time.

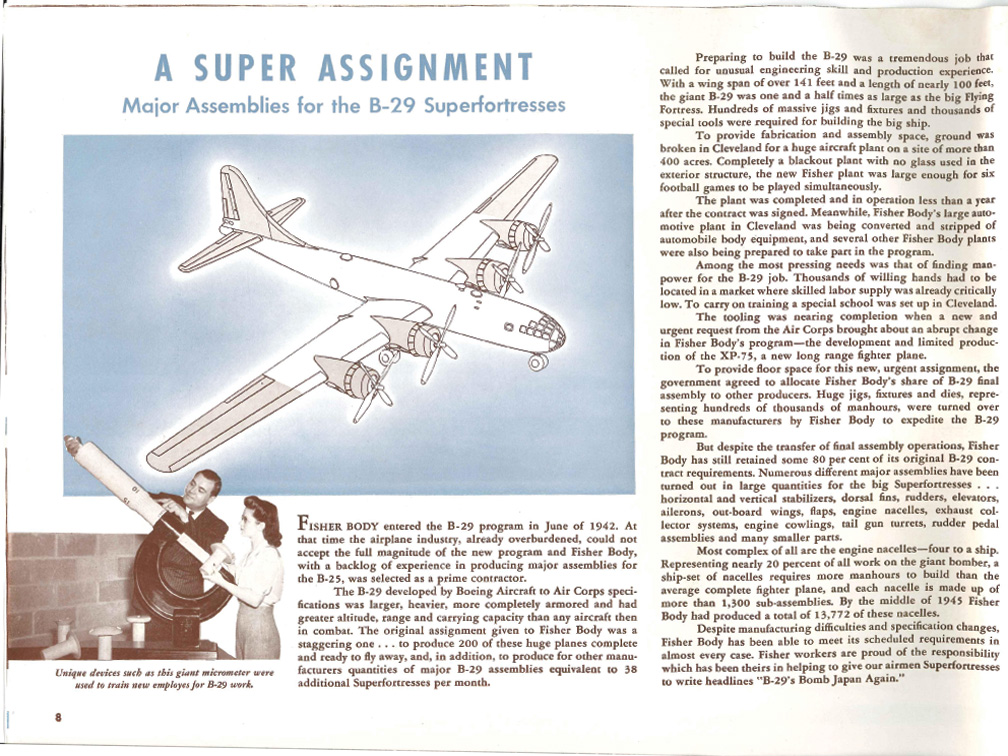

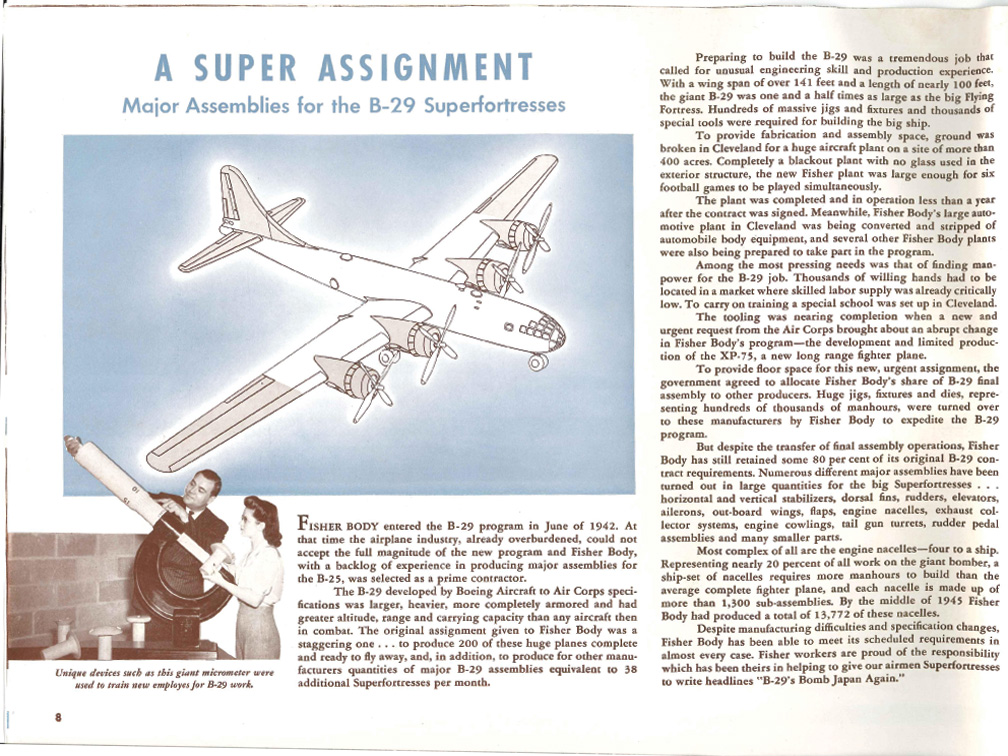

In June 1942, Fisher Body contracted with the

United States Army Air Forces to produce 200 B-29 bombers. Work on

a new plant at the Cleveland, OH airport was designated by Fisher Body

as Cleveland Plant #2, started a month earlier in May

1942 at . The plant, when finished, was 2.5 million square feet of manufacturing and final assembly space.

A year later, it was decided that the Martin Omaha, NB plant where the B-26 medium bomber

was being built, would be converted to B-29 production. So, the scheduled manufacture of

B-29s at Fisher Body Cleveland #2 was moved to Omaha. Fisher Body

Cleveland #2 would focus on the manufacture of B-29 airframe components

and became the largest plant in the country supplying parts for the B-29.

Components from Fisher Body #2 were sent to all four B-29 final assembly

plants

located in Renton, WA, Topeka, KS, Omaha, NE, and Marietta, GA.

Author's note: Several websites

indicate that Fisher Body Cleveland Plant #2 actually built the B-29

Superfortress. As noted above, the original plan was for it to

build 200 of the aircraft, but this never materialized. It appears

that one source erroneously published this information, and then others

copied the original without verifying whether the information was

true or false. Even the website for the International Exhibition

Center (I-X), which owns the facility now, states that the plant built

B-29s. This plant never built any B-29 bombers.

The page below is from "Fisher Body

Craftsmanship Goes to War." This shows that the B-29 was not built

at Fisher Body Cleveland #2.

At the end of World War Two, the plant was

declared excess and put up for sale by the War Assets Administration.

There were no takers at the time. So the plant was used as soybean

storage, the site of the 1946 National Aircraft show, and the location

of the post-World War Two National Air Races. Then the Korean

Conflict began, and the plant was converted into a tank arsenal.

For many of the persons in the Cleveland area, the plant is known as

"The Tank Plant."

In 1985 the plant was turned into the I-X

Center and is the world's largest single building exhibition center.

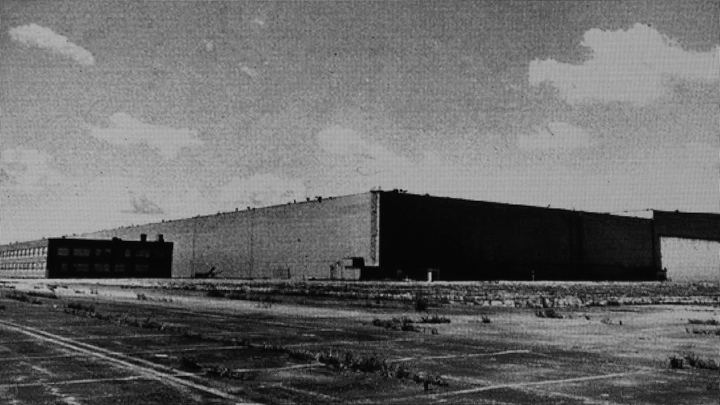

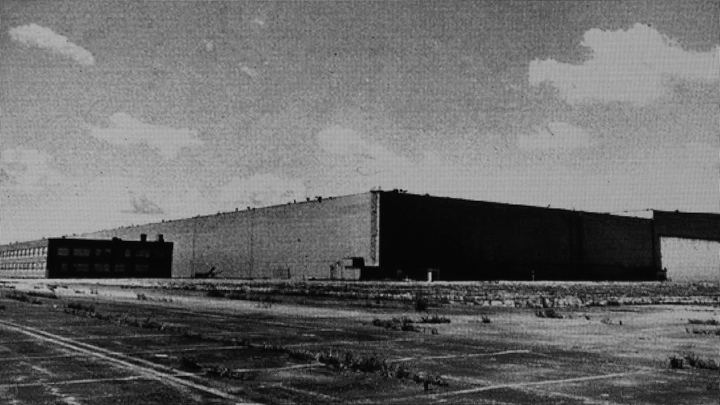

This photo is from the Tank Plant era.

The three story office building is on the east side of the plant.

This was removed when the building became the I-X Center. Today,

the west side of the building is the location of the main entrance and

there is a large parking lot next to it. There are two aircraft

hangars to the northwest of the main building. The runways for the

Cleveland Airport can be seen to the northwest of the complex.

The former Fisher Body Cleveland Plant #2 as the International

Exposition Center today. This is the west side of the building. Author's photo.

The construction of the two hangars was

wood. This was very common at the time, to save steel for weapons

manufacture.

Author's photo.

The hangars were large enough for a B-29. Author's photo.

This photo appears to be a post WWII photo,

as weeds are growing through the concrete of the abandoned parking lot.

Note that only two stories of the office building are viewable, compared

to the three in the aerial photo above. See the photo below for an

explanation. A small amount of the hangar door is painted white,

as visible in the right part of the photo. Fully assembled

aircraft came out the north side of the building.

This also appears to be another post-World

War Two

photo, this time from the plant's second life as a tank arsenal.

The automobiles look to be 1950's vintage. Note that a third floor

of office windows can be seen at ground level. The bottom floor

was built below ground level.

World War Two Products:

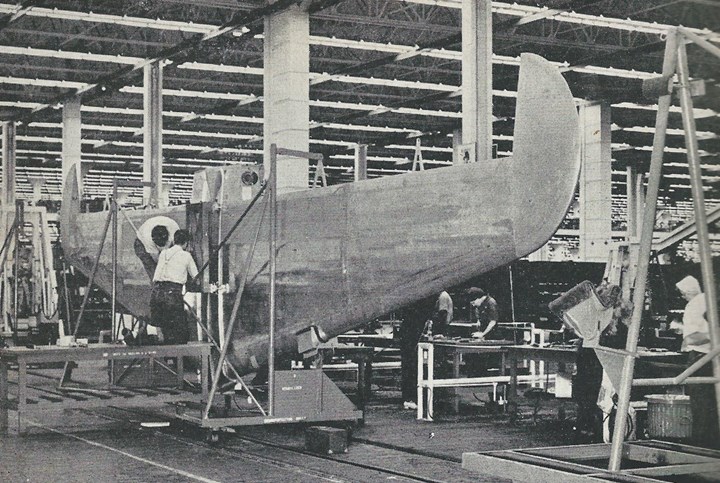

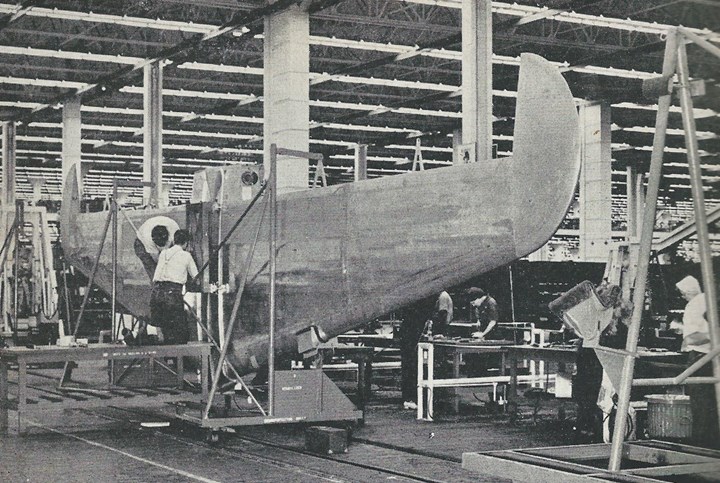

B-29: The main product of the Fisher Body Cleveland Plant #2 was major airframe and control surfaces for the B-29. This

included outer wing sections, flaps, horizontal stabilizers, and

vertical stabilizers.

B-29 horizontal stabilizer sections are

under construction in the vast main assembly hall of Cleveland Plant #2.

Note that most of the plant floor is occupied by all of the fixturing

needed to properly assemble the components into a final product.

In this photo the two halves of the B-29

horizontal stabilizers assembled into one piece.

The completed B-29 horizontal stabilizers

are ready for shipment to the aircraft assembly plants.

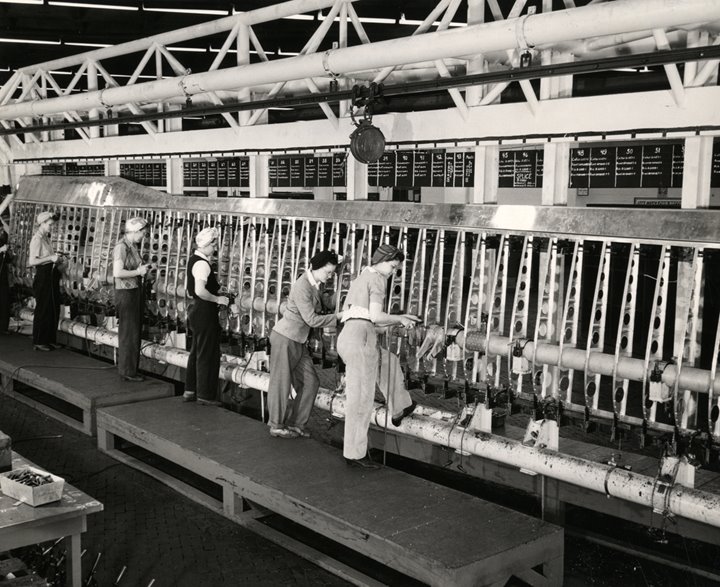

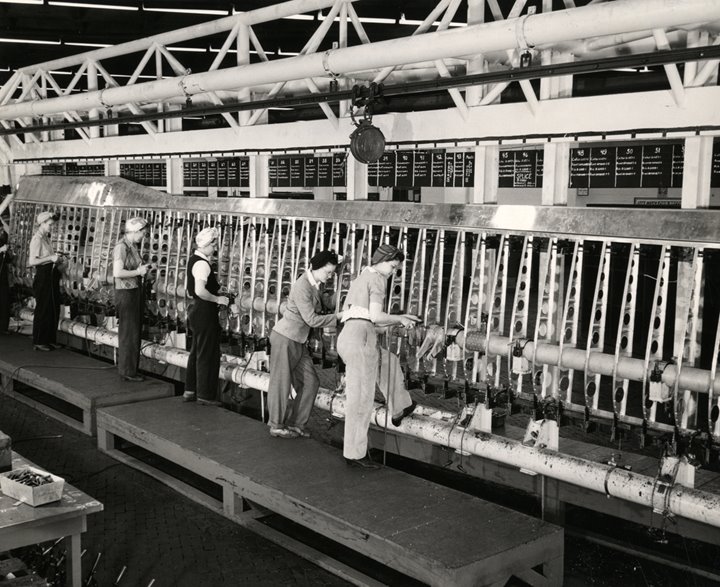

In this section of Cleveland Plant #2, these

women are working on a B-29 flap.

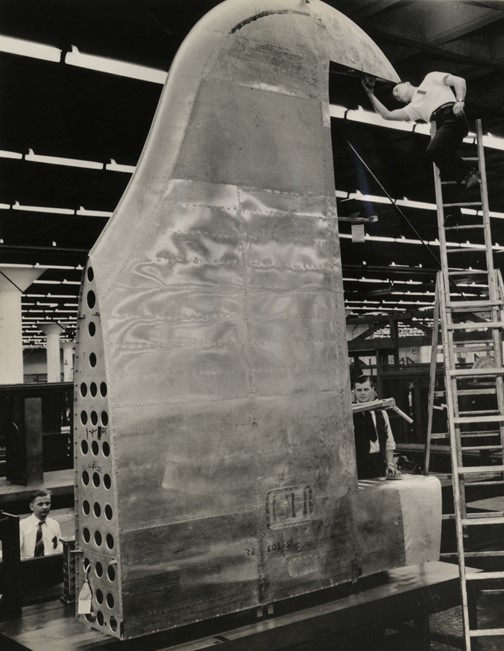

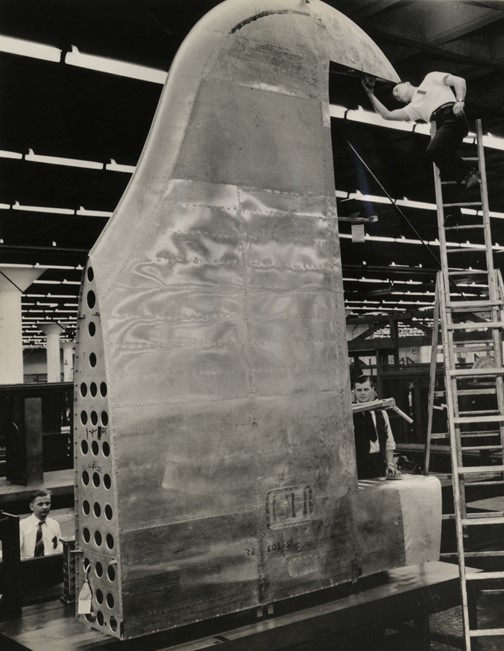

This fixture is for construction of a B-29

vertical stabilizers, or dorsal fin, as the sign on the fixture states.

B-29 vertical stabilizers further along in

the construction process are in the foreground. In the rear of the

photo work is being done on horizontal stabilizers.

Final inspection of the B-29 vertical

stabilizer.

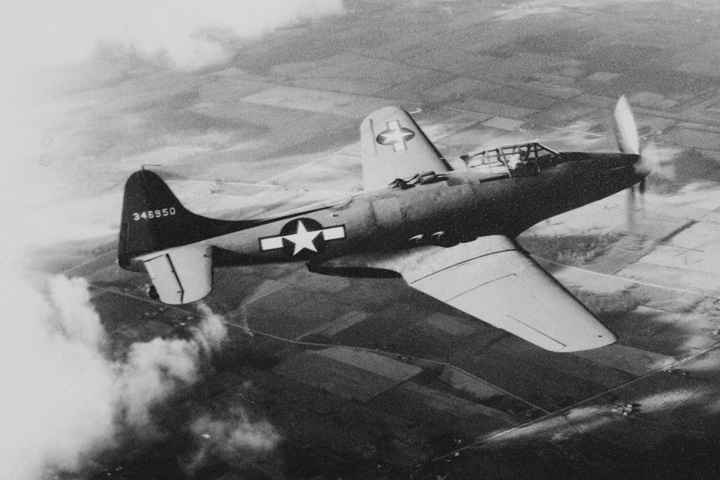

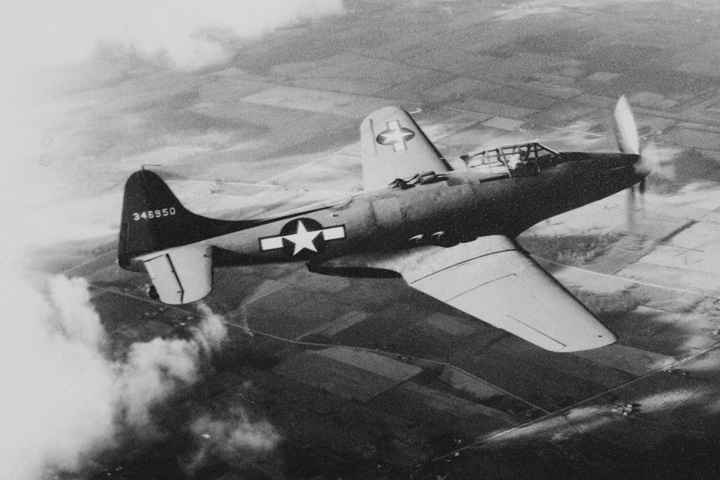

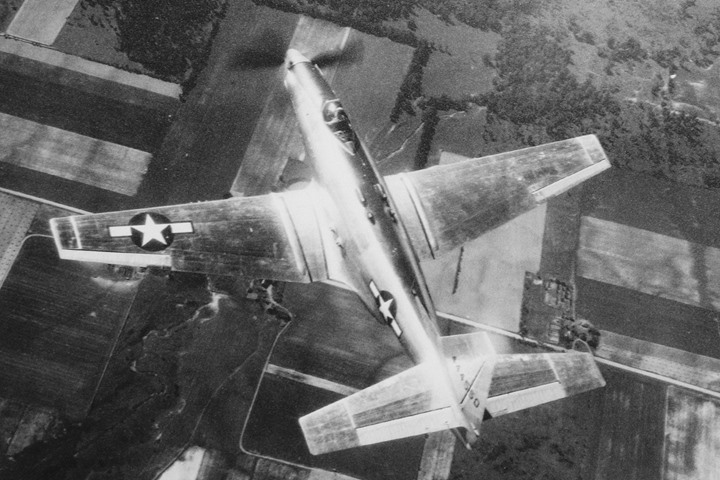

Cleveland Plant #2 XP-75 and P-75 "Eagle"

production: Cleveland Plant #2 actually built a handful of fighter

aircraft. In retrospect, it was one of those projects that fall

into the category of "it sounded like a good idea at the time."

Eight XP-75s and six P-75s were built, using components from several

other fighter aircraft already in production to save costs. By the

time design work and tooling were completed, there were enough of other

the

fighters being produced to meet the requirements of the Army Air Forces.

So, the project was cancelled in late 1944. Besides that, it

wasn't that great of an aircraft. Hindsight is always 20-20!

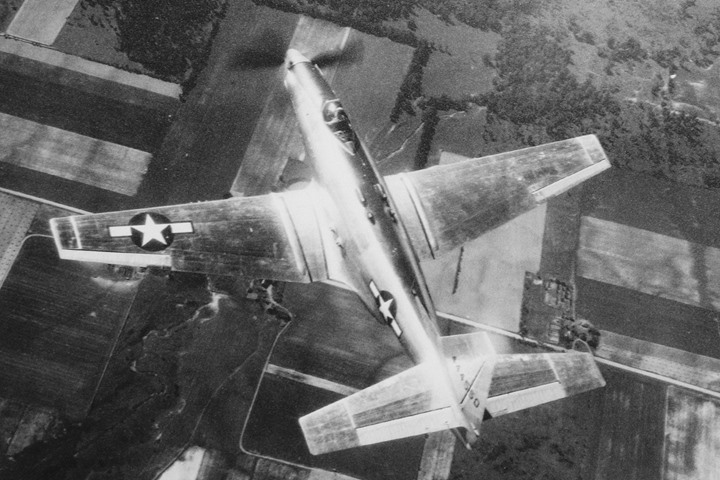

Photos of the XP-75/P-75 aircraft are rare.

Below is a collection showing the production line and several of the

completed aircraft.

Five aircraft are on the final assembly line

at Cleveland Plant #2. This was over one-third of the Eagles

built.

This is another photo of the Eagle assembly

line. Behind the left (port) wing of the first aircraft,

several workers are looking at one of the Allison V-3420 engines that

were installed in the aircraft.

A right quarter view of the XP-75/P-75

production. This gives a better view of the workstations they

were built on.

Five completed Eagles on the ramp to the

east of the main assembly building.

The original

XP-75 had a bird cage canopy and rounded vertical stabilizer.

The P-75 had a squared off vertical

stabilizer and a blown canopy.

One Fisher P-75 Eagle still exists today

and is part of the collection of aircraft at the National Museum of the

United States Air Force in Dayton, OH. Author's photo.

Other Aircraft: The plant also

was involved in XB-39 and XB-19 Aircraft Parts and assemblies. The

XB-39 was a B-29 with Allison V-3420 engines installed. The work

of making the engine nacelles, fitting and installing the engines was done at Cleveland

Plant #2. The final installation of the engines was completed in

one of the two hangars at the plant.

Post-World War Two:

In

1946, the National Aircraft Show was held in the plant. In the far

upper left, there appears to be a B-17 bomber on display.

The post-World War Two Cleveland Air Races were held at the Bomber

plant.

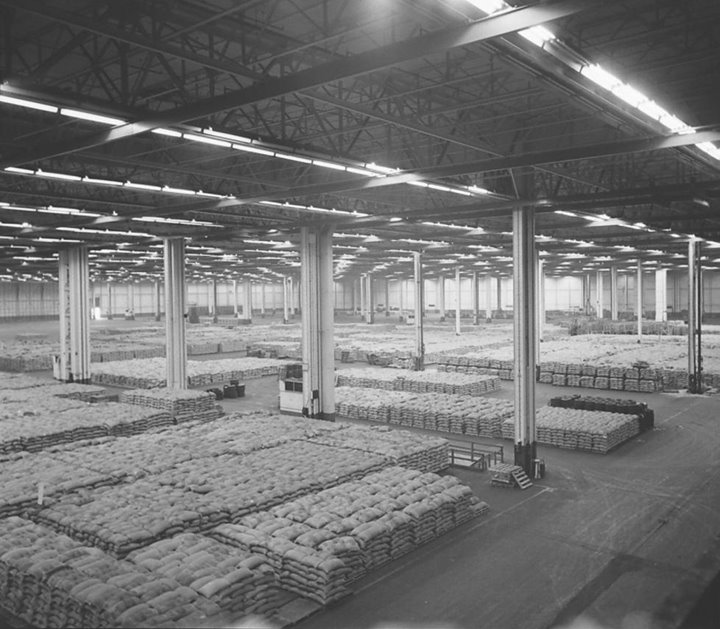

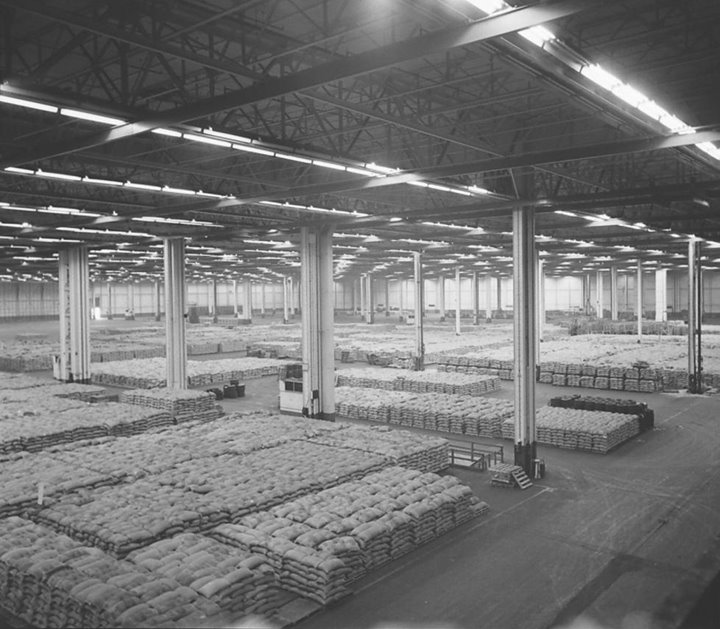

In the late 1940s, the Commodity Credit

Corporation stored 19.5 million pounds of soybeans in the plant.

This photo is one of the best to show how big the plant was inside.

The Cleveland Tank Plant: When

the Korean War began, the former bomber plant, still owned by the U.S.

Government, was re-opened as a tank plant. The Cadillac Motor Car

Division of General Motors was picked to build the M41 Bulldog light

tank and the M42 Duster Twin 40mm Gun Motor Carriage. These were

the first of several armored vehicles built in the plant by Cadillac,

Chrysler, and then the Allison Division of General Motors.

The following photos were taken at the MVPA

2017 National Convention in the former Cleveland Bomber and later Tank

Plant now the I-X Center. Included are several vehicles that were

built in the plant.

The five armored vehicles in the line from

left to right were all built in this facility. From left to right

there is the M114 Command and Reconnaissance Carrier, M56 Scorpion

Anti-Tank Gun, M109A3, M41 Bulldog and M42 Duster. Author's photo.

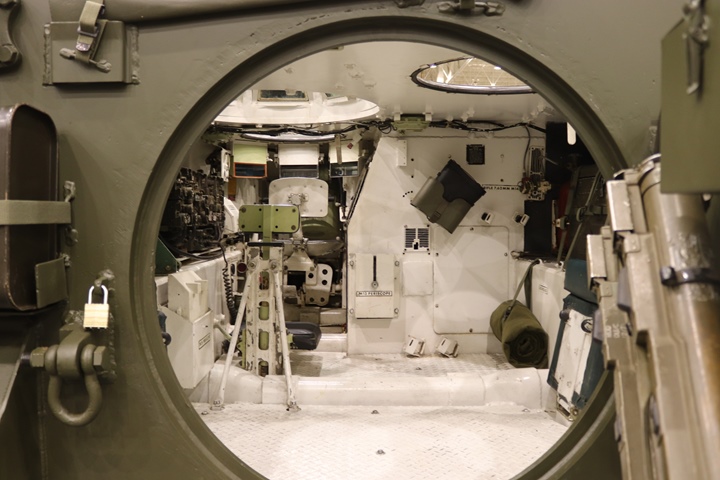

The Cleveland Tank Plant built 3,710 M114s

between 1962-64. The vehicle was amphibious and air-droppable.

Author's photo.

Author's photo.

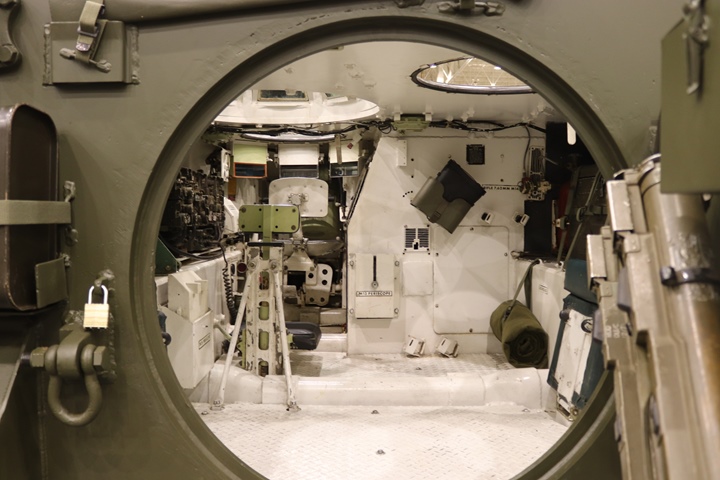

This is the interior of the M114 looking

through the rear hatch. Author's photo.

The M56 90mm Self-Propelled Anti-Tank Gun

was built in the plant. There were 150 of the Scorpions built.

Author's photo.

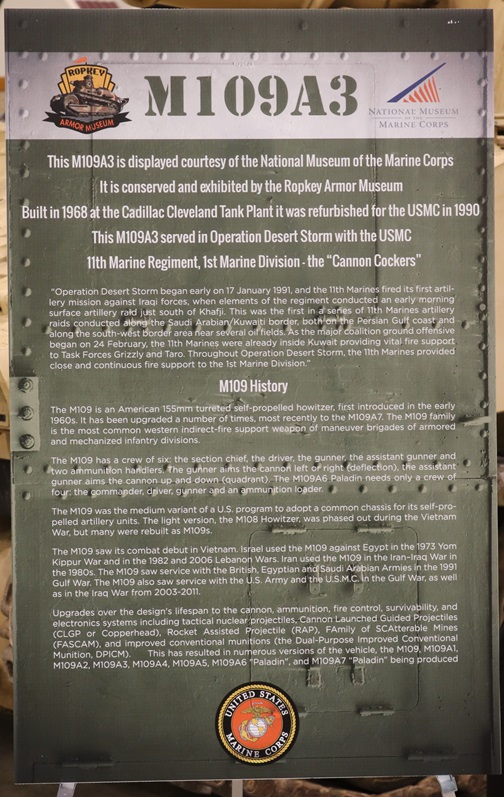

This M109A3 was brought to the Convention by

the Ropkey Armor Museum two months before the museum closed. The vehicle

is owned by the USMC Museum and the Ropkey Museum was its custodian at

the time. The M109A3 is now on display at the Indiana Military

Museum in Vincennes, IN. Author's photo.

This mural was once in the lobby of

the Cleveland Tank Plant. When the plant closed, Fred Ropkey of

the Ropkey Armor Museum in Indiana purchased it. With the closing

of the Ropkey Museum, the current owner is unknown.

Author's photo.

Author's photo.

The M41 Bulldog light tank was the original

armored vehicle built in the Cleveland Tank Plant. 5,467 were

built by Cadillac between 1952 and 1954. Author's photo.

Author's photo.

The plant built 3,700 M42 Dusters.

Author's photo.

Author's photo.

Next are a series of photos taken from the

deck of a Higgins-built LCVP at the 2017 MVPA National Convention. These give a panoramic

view of the final assembly portion of the building.

Author's photo.

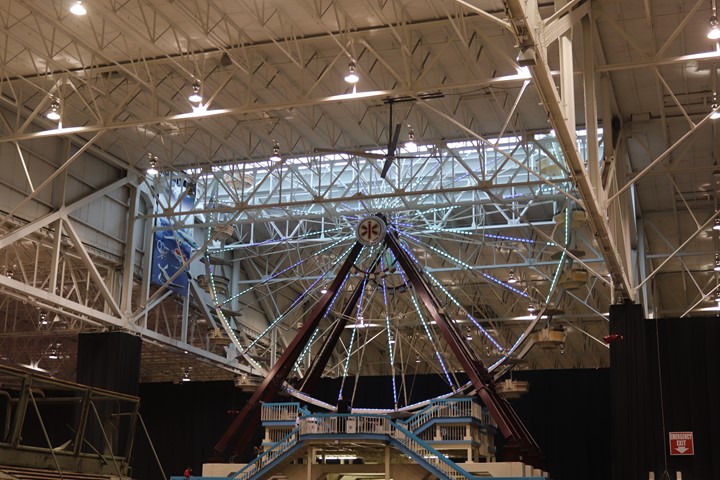

Needless to say, the Ferris wheel was not

part of the original plant, and was added as an attraction when it

became the I-X Center. Author's photo.

Author's photo.

Author's photo.

Author's photo. The black curtains in

the background have divided off a portion of the huge final assembly

section of the building not needed for the show. Author's photo.

Author's photo.

Author's photo.

The plant was built with a basement.

This is the former cafeteria for both the former Bomber and Tank plant.

Author's photo.

The former cafeteria can be used for small

conventions and exhibits. Author's photo.

There are corridors that run underneath the

building. Author's photo.

Author's photo.

Author's photo.

This is one of two areas in the building

that were used for parts manufacturing before they were taken out to the

main assembly hall to be built into aircraft or tanks. Many of the

B-29 components were manufactured in this area. Author's photo.

During the Korean War, the plant also had a contract

to build 81mm mortar shell bodies, nose cones and tail fins. It

built a total of 100,000 at 700 per

shift. A separate assembly line was set up in an area like this to

manufacture them.

For those interested in learning more about

this plant and its very interesting history, I highly recommend

"Cleveland Tank Plant" by military historian and author David Doyle.

He gained access to the General Motors archives, so that his book has

many rare photos of the plant, both in its Bomber days and as Tank

Plant.

|